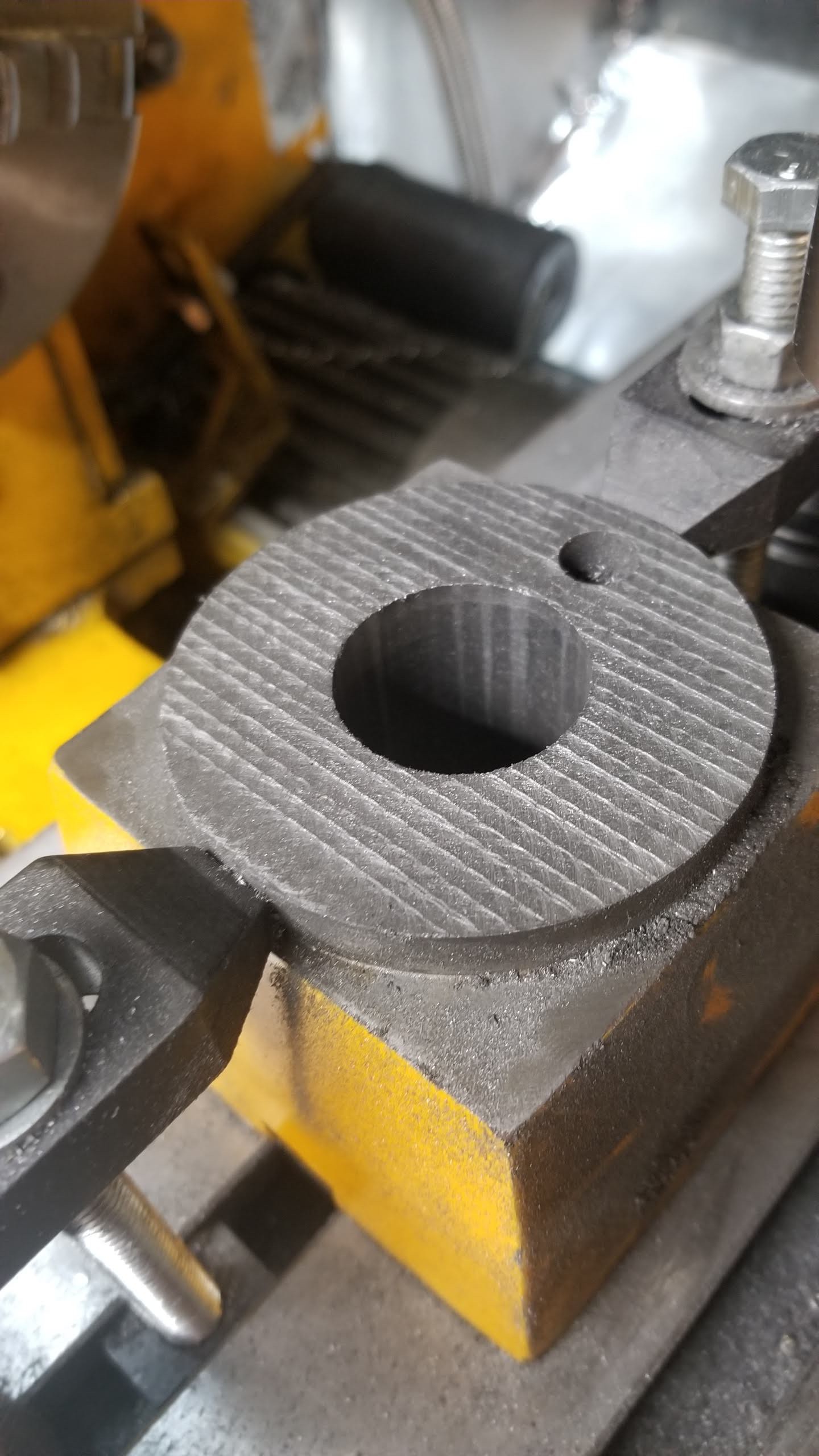

The original toolpost is a turret type, 75mm on a side with a fixed height set to bring a 12mm lathe tool to the spindle center which is 100mm above the table. The turret sits on a roughly 75mm cubic chunk of cast iron which has a 30mm hole through it and close fitting t-slot keys. A 30mm rod with an integrated T-nut holds it to the table when tightened by a 12mm threaded rod with a handle on the top. As far as turret toolposts go, it works pretty well.

A while after purchasing the machine I bought the Shoptask QCTP, which turned out to be proprietary - and poor - design. This toolpost was only offered for a short period and later vanished from the Shoptask website - presumably from embarrassment. While the toolpost itself is effectively junk, it sits on an almost identical cast iron block, complete with t-slot keys. The plan is to recycle this item to support the Multifix. Initial calculations show it to be pretty near the ideal size and height. This will leave the original post intact to keep the machine functional should I upgrade to a dedicated lathe in future and move the Multifix to that.

The toolpost is on order from pewetools.de and will hopefully be here by Christmas. I have some 12L14 for a new hold-down in the mail from hobbymetalkits.com which may get here by the weekend.

Alastair Young

Alastair Young All present and correct.

All present and correct.

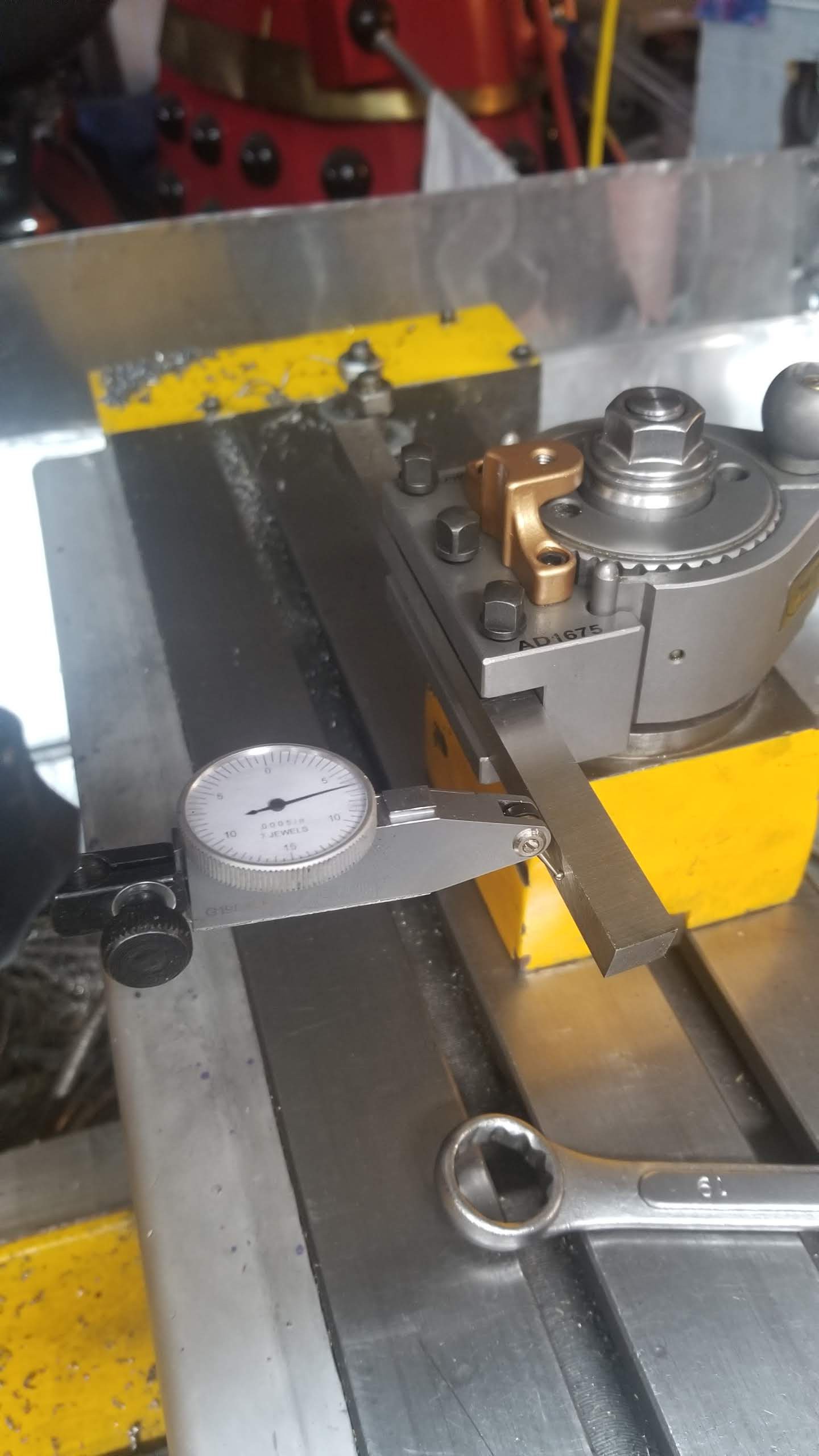

Squaring it up before installing the dowel pin hole.

Squaring it up before installing the dowel pin hole.

Crum3le

Crum3le

Josh

Josh

Andy Lee

Andy Lee

How's it working for you? I installed a bxa on mine and it's so much better.