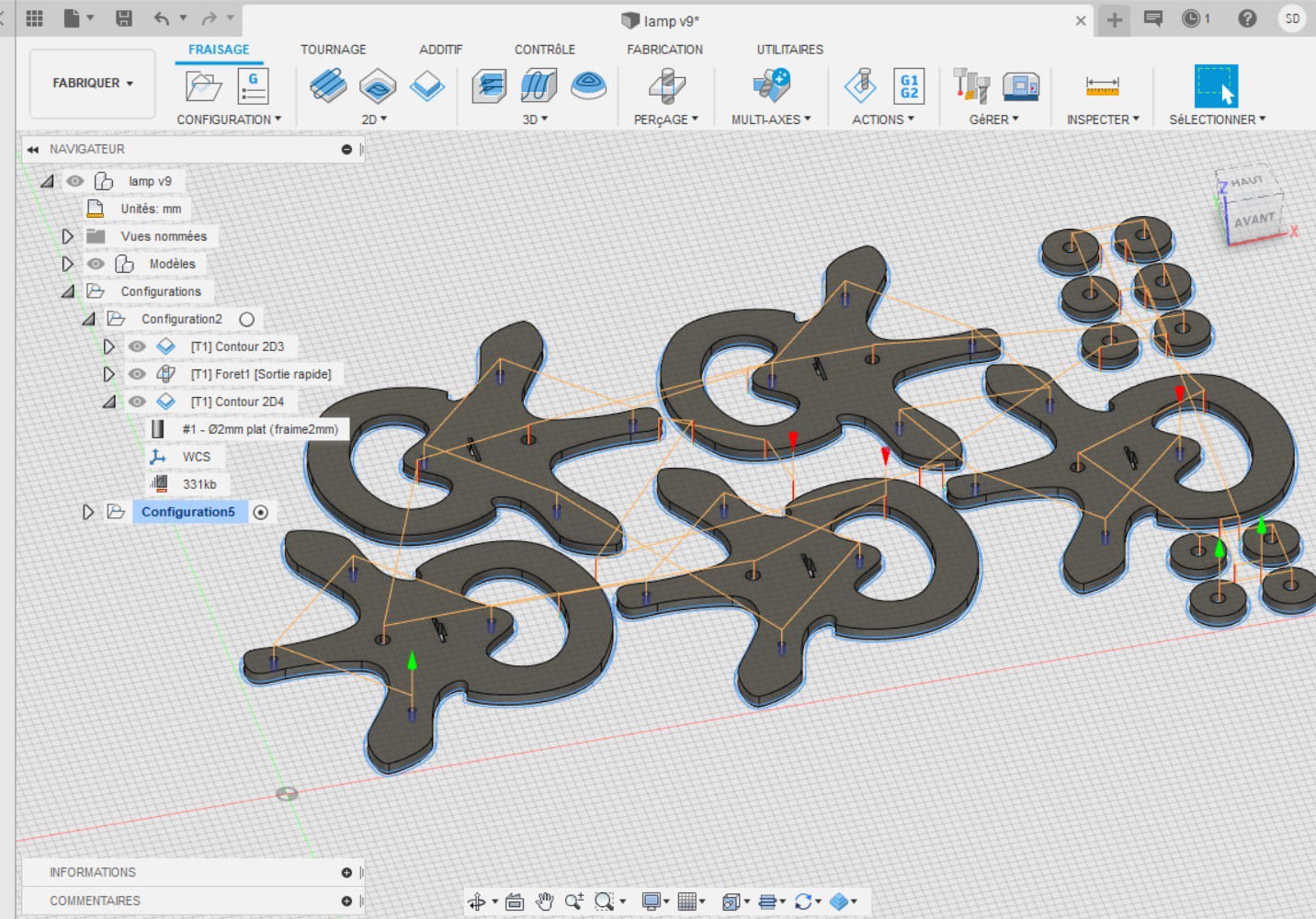

Back to Fusion360...

With all due respect for open-source projects, i had a hard time using Freecad v0.18 to do what i wanted... But it helped me a lot to grip the basics notions of CAD and CNCs. So back to fusion 360:

This time, it was much easier to scale things up :

- import svg (had to rescale it even if it was defined in mm ,weird)

- extrude the shape by clicking on them to match my plywood thickness

- create a job

- create a 2mm tool

- select the edges i wanted to cut in the first pass : all the >2mm holes and create a 2d contour

- configure the number of passes ( 2 of 1.8mm each in my case )

- run a simulation to see everything running fine

- added a drill pass to cut the 2mm cable holes

- repeat all the steps 3-7 to add the outside contour cut

- post process my gcode file and voila !

Know your limits

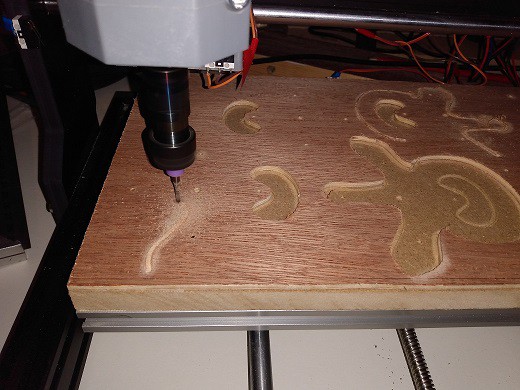

So let's fire GRBL candle and plug the cnc : after the origin setup , i send the gcode and start to see the magic :

Unfortunately , things started to go wrong in the last step : the outlines cuts. For some reason , the bit started to go down wayyyy deeper than what i expected: 6mm instead of 1.8 ! After a second of hesitation, i see that the machine still want to cut at this depth, so be it ! I'm so close to having my first part, lets see... yes ! first part finished! it goes to the second one ...Oh no! the upper Y axis limit is hit ! ABORT !

I was way too greedy on the size of my work area : they said 3018 so 30cm x 18cm workspace right? Not quite on my machine :)

Lets do a rescue Gcode to save the remaining profiles :

what? it also hit the X axis limit !?! what a noob !

In the end i managed to get 2 profile out of my first cut, not that bad...

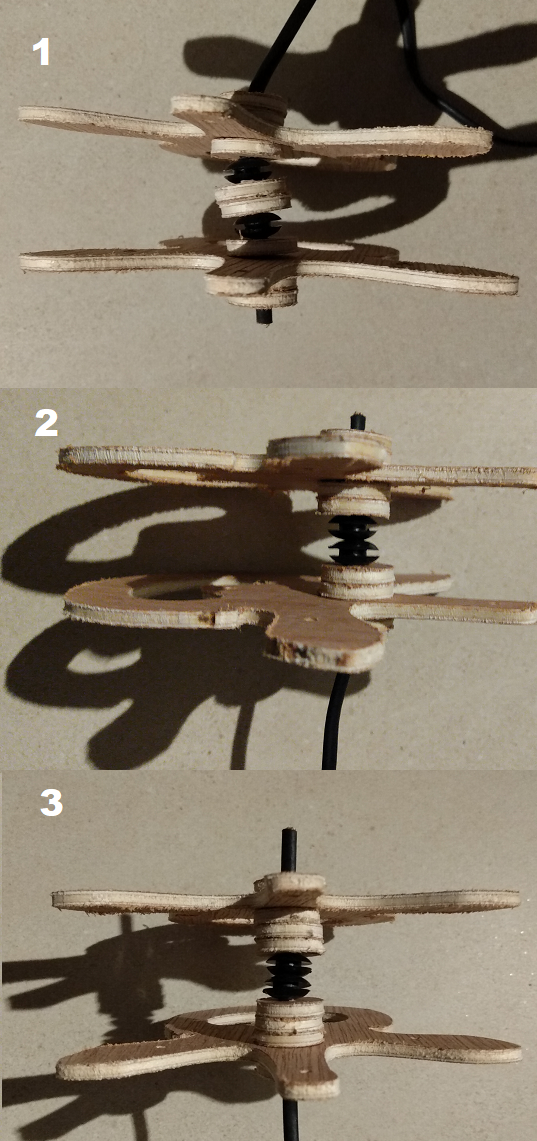

At least it's enough to start testing some assembly schemes :

Number one seems to be too twisty to be usable, number two is okay but with a 27mm spacing, i'd need 37 of them to complete my meter long arm! Maybe i'll go number three with 800mm-ish length /36mm spacing and 22 of them. We'll see...

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.