HEAT CIRCULATION vs LIGHT

Case: Imagine a part of your living space, where you can grow greens all year round, and at the same time use the heat-output to warm up your space. This could not only provide food all year, but also expand the outdoor season by starting sprouts indoor, in a controlled environment, before they are ready to be planted out. Why not just sow the seeds, you may ask. The reason for planting out the sprout, is to give it a competitive advantage, compared to unwanted plants.

Another mayor benefit by utilizing the radiated heat, is the possibility to fully heat your living space with green energy. This means less foresting for wood to burn. Less Co2 emissions from NOT BURNING WOOD or other carbon-based energy sources. Naturally all this requires a solid environmentally friendly energy infrastructure.

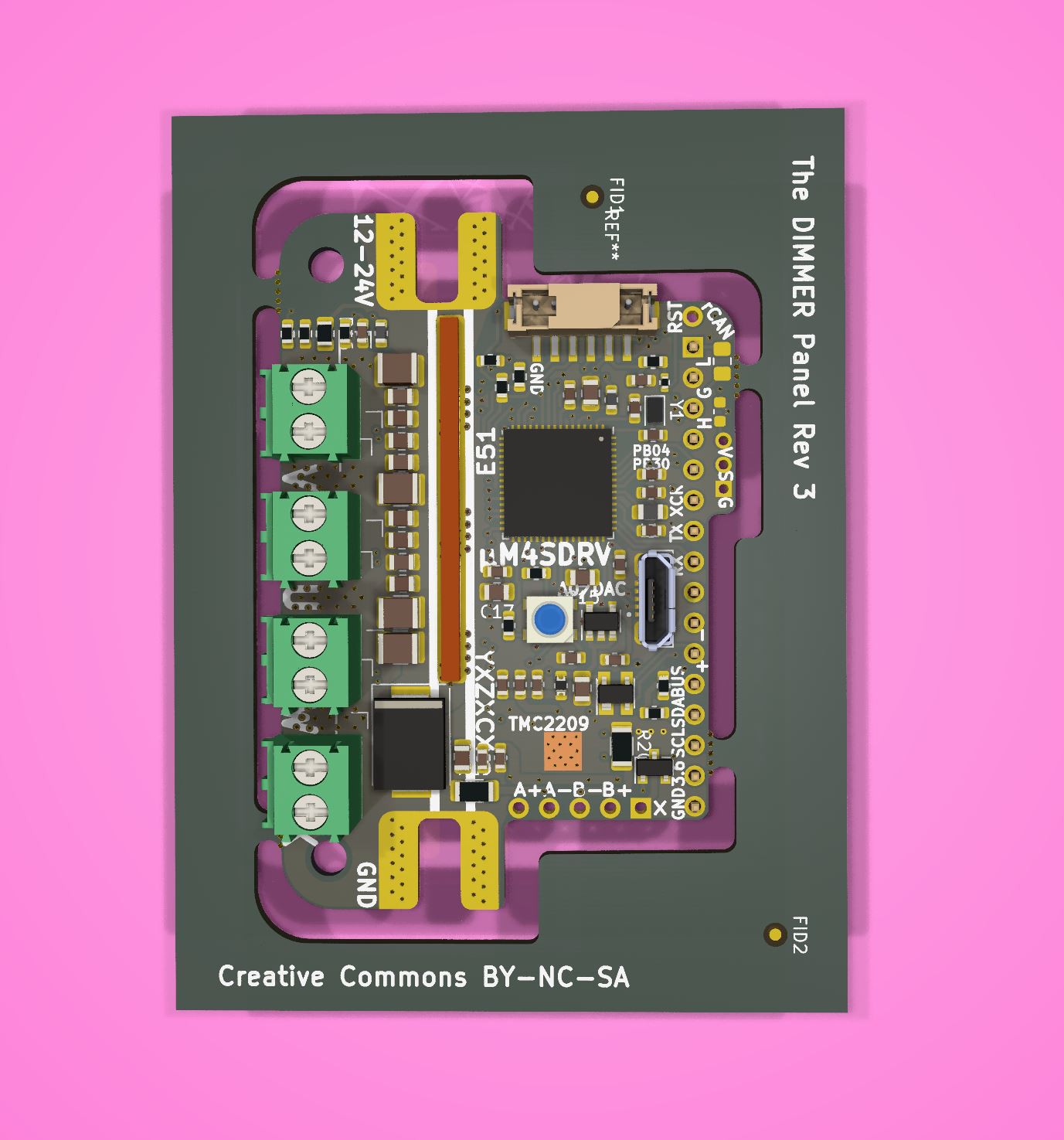

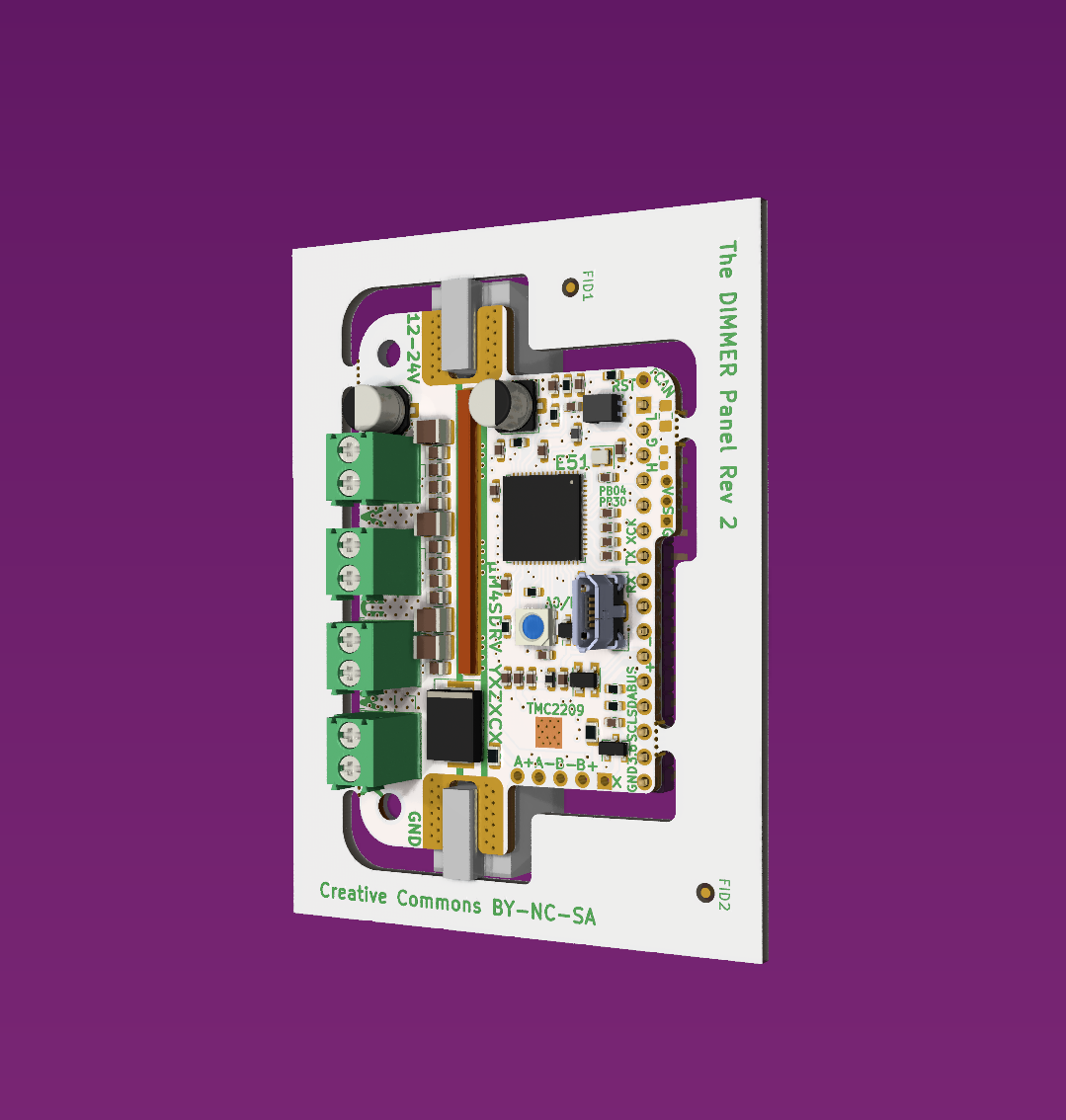

By introducing CAN (Controller Area Network) to the "intelligent" GEM/lamps, if several lamps are connected only a "Master" CAN node will need a connection through either USB or wireless. This means a great deal in a greenhouse scenario, where many lamps all need to be monitored and controlled from a central hub. Likewise only one wireless module in the network is necessary, depending on the case.

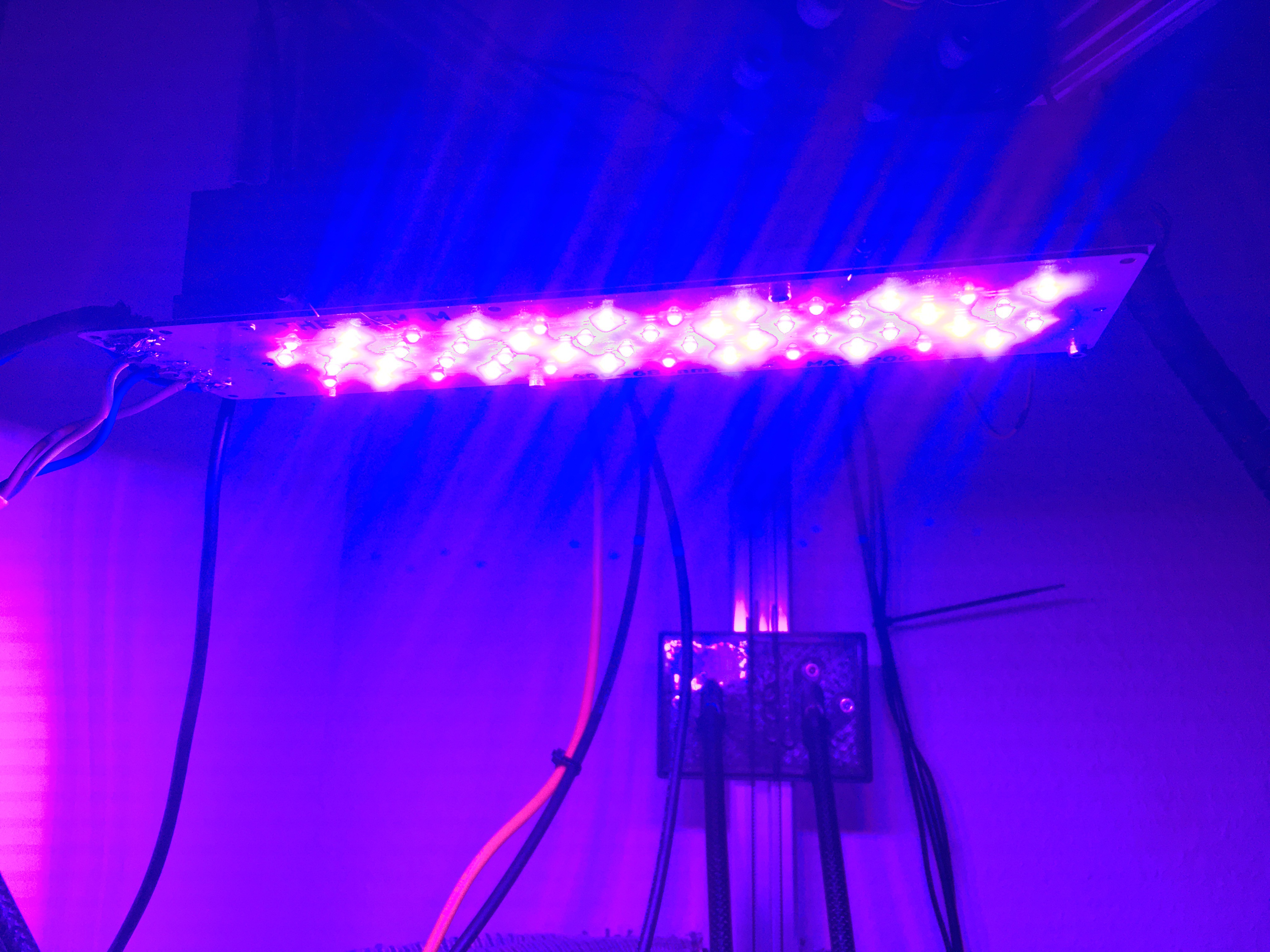

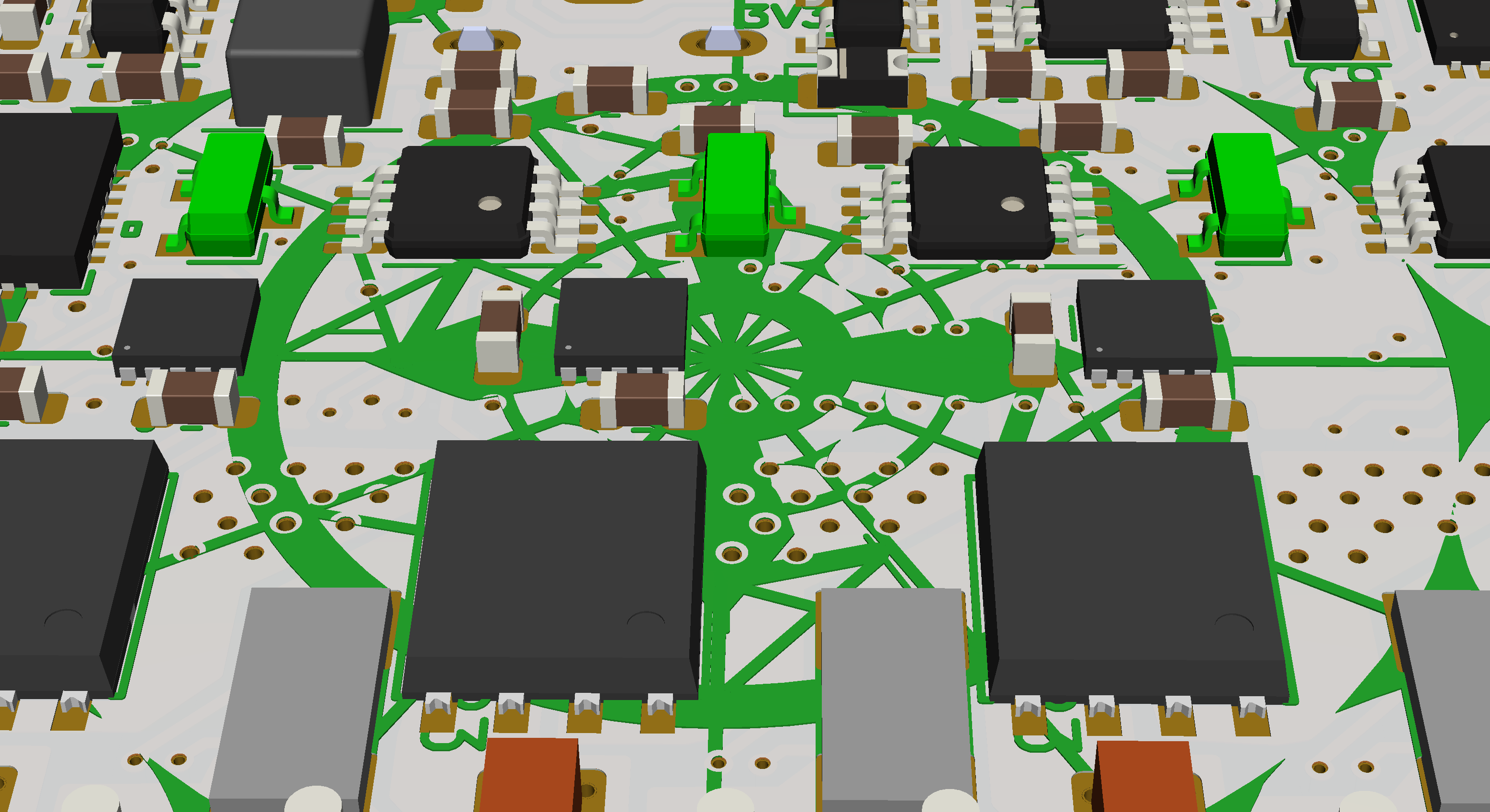

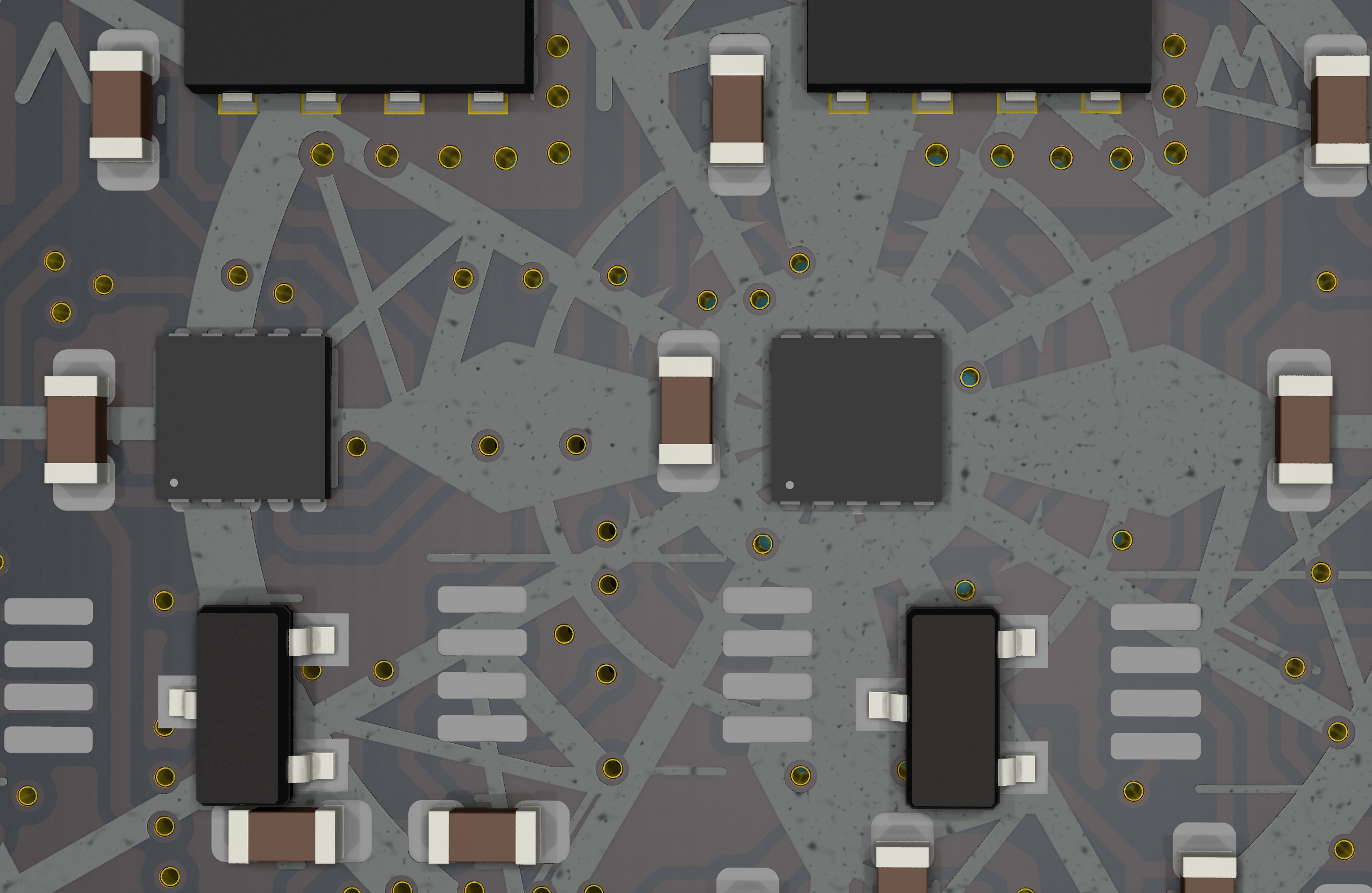

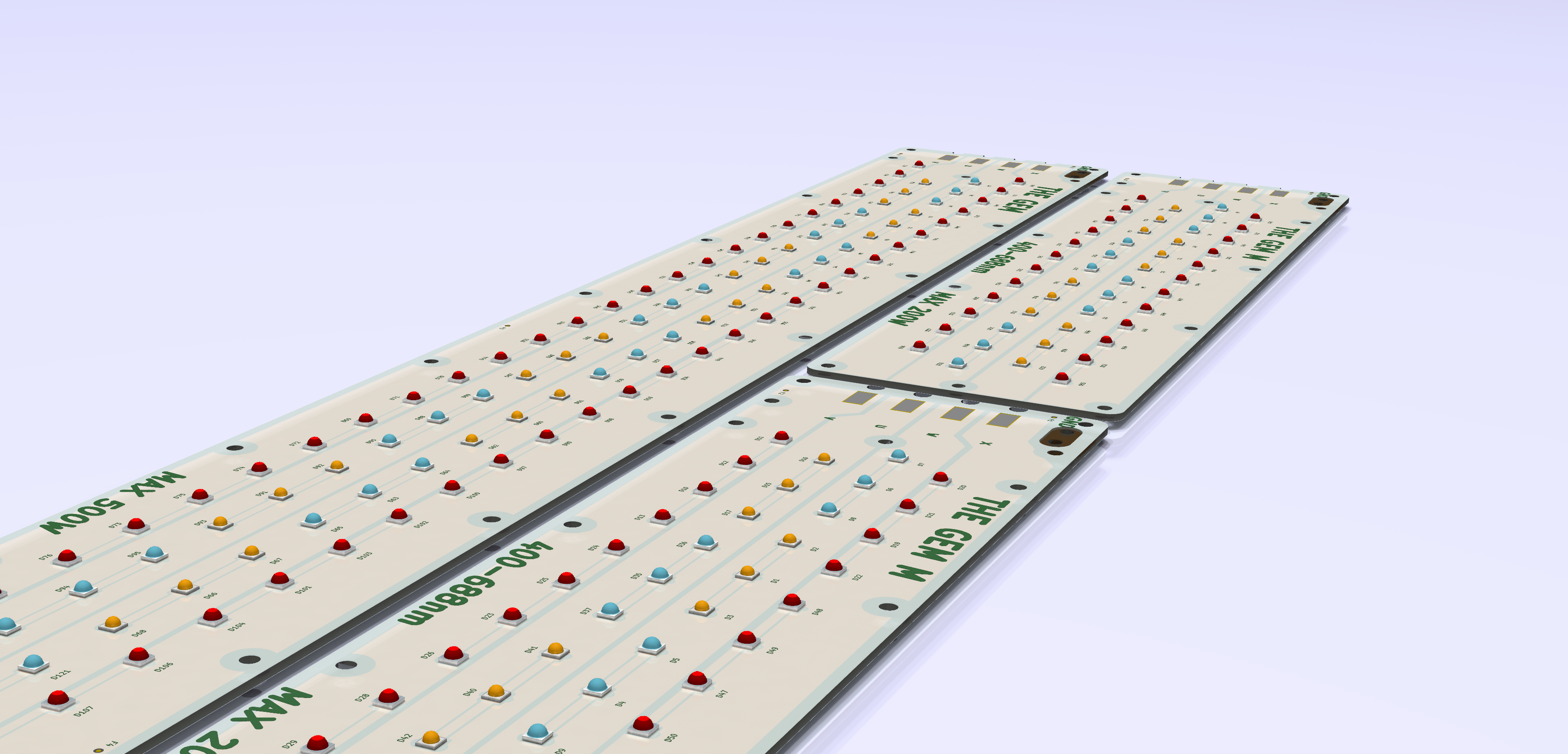

UPDATE: The process of finding the best pcb for high current LED´s led me to Metal Core PCB with sinkpad´s. Sinkpad connects the cooling surface of the MCPCB and heat pad on the LED. This gives a x100 performance in heat transfer and thereby optimizing cooling. Literally the LED´s will be mounted more or less directly on the heatsink. The PCB´s has been ordered and I am making the final adjustments to the heatsink.

CREE LED´s

https://www.cree.com/led-components/media/documents/CreeXLampHorticultureFeatureSheet.pdf

Design

The design is starting to manifest.

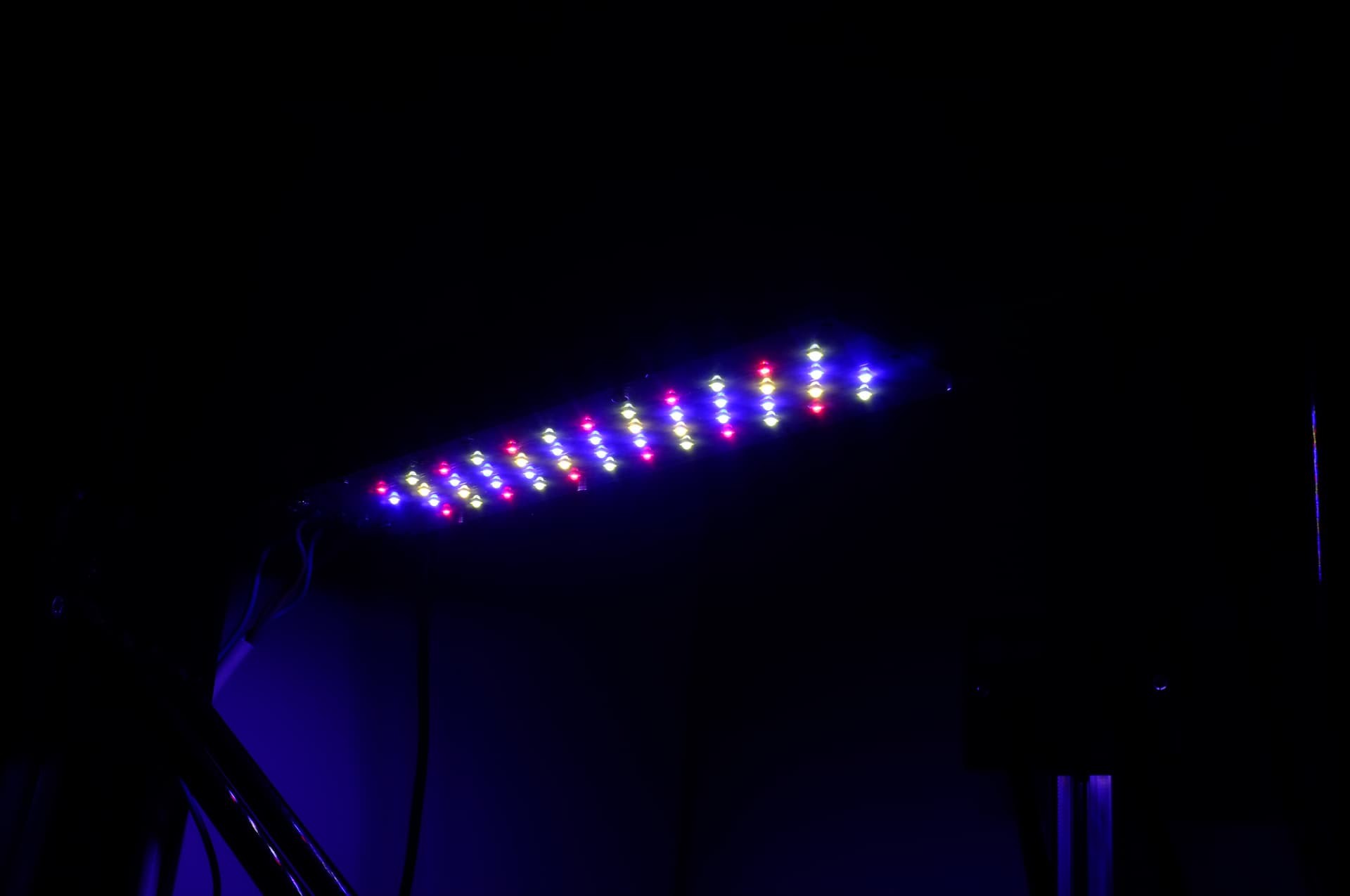

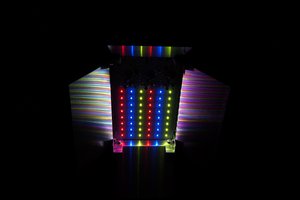

White LED´s use energy to lite up the full visible spectrum. The Red and Blue only one wavelength(area) and is therefore cooler in use. The difference between the red and blue wavelength is another matter.

For a office environment, the fully white GEM will be more pleasant for the human eye. In a school scenario the lamps will be part of photon to plant growth experiment.

Juan-Antonio Søren E.P.

Juan-Antonio Søren E.P.

t.oster92

t.oster92

Moritz Walter

Moritz Walter

Yann Guidon / YGDES

Yann Guidon / YGDES