The mane problems encountered during the 1st 74 miles were the paw controller's ergonomics, the tires being noisy & too hard, the battery cover coming off, motor encoders slipping out of alignment, lack of torque.

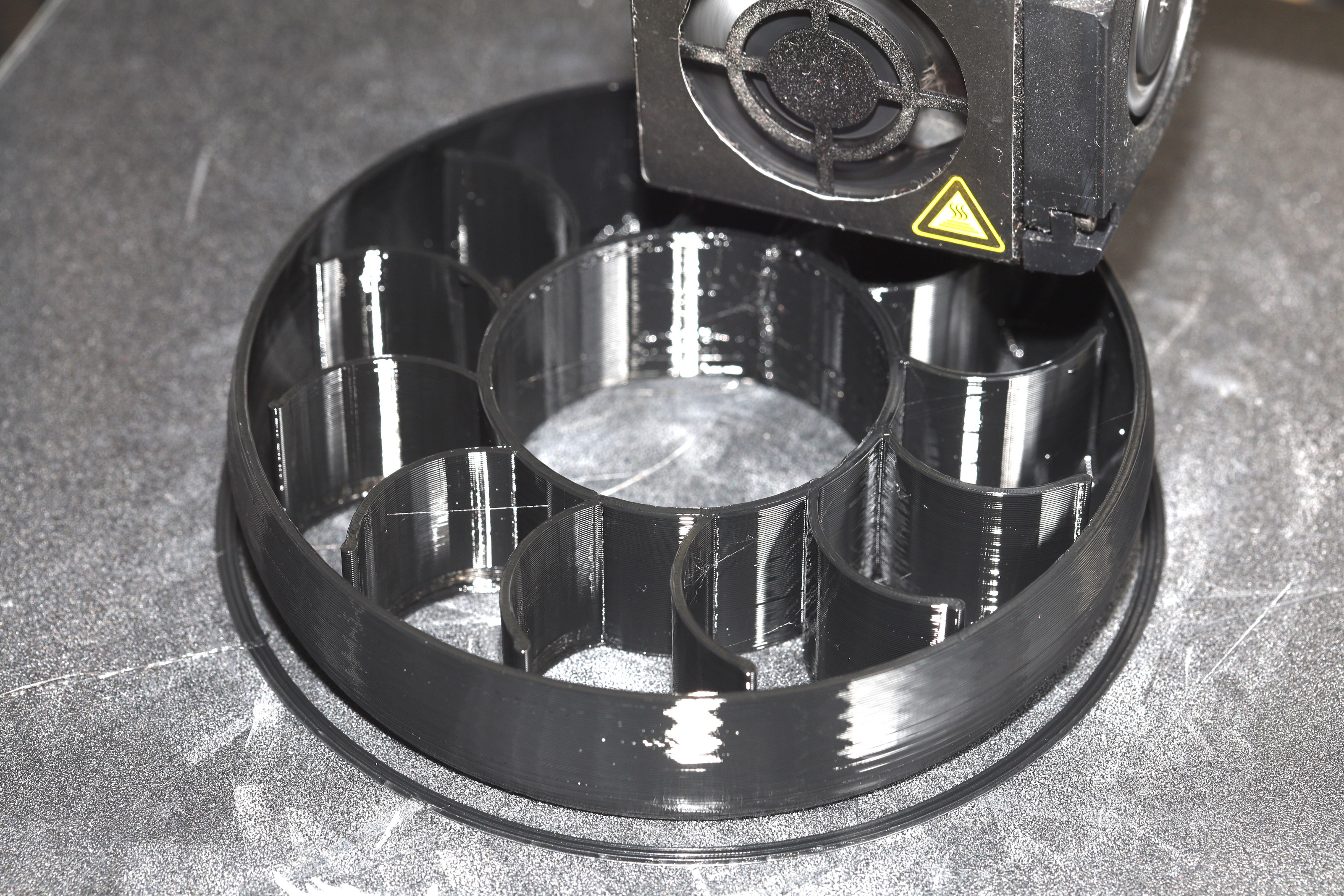

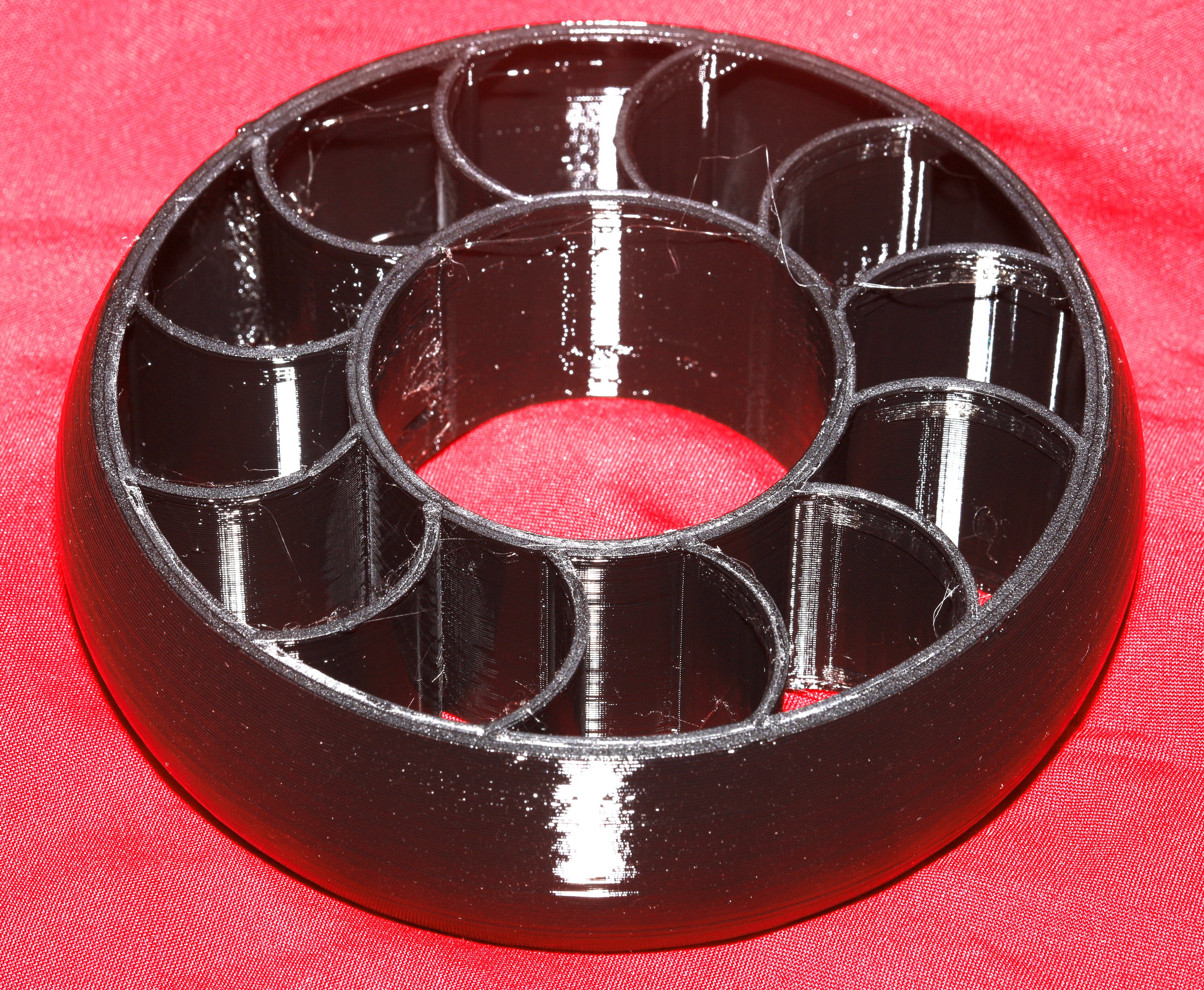

A pile of 3D printing yielded improved tires & a new paw controller.

The new tires were about as compliant as TPU could get. The mane variables are whether to have a tread, how curved they should be, how wide they should be. They got down to $1.50 of material. They were slightly quieter than the 1st tires.

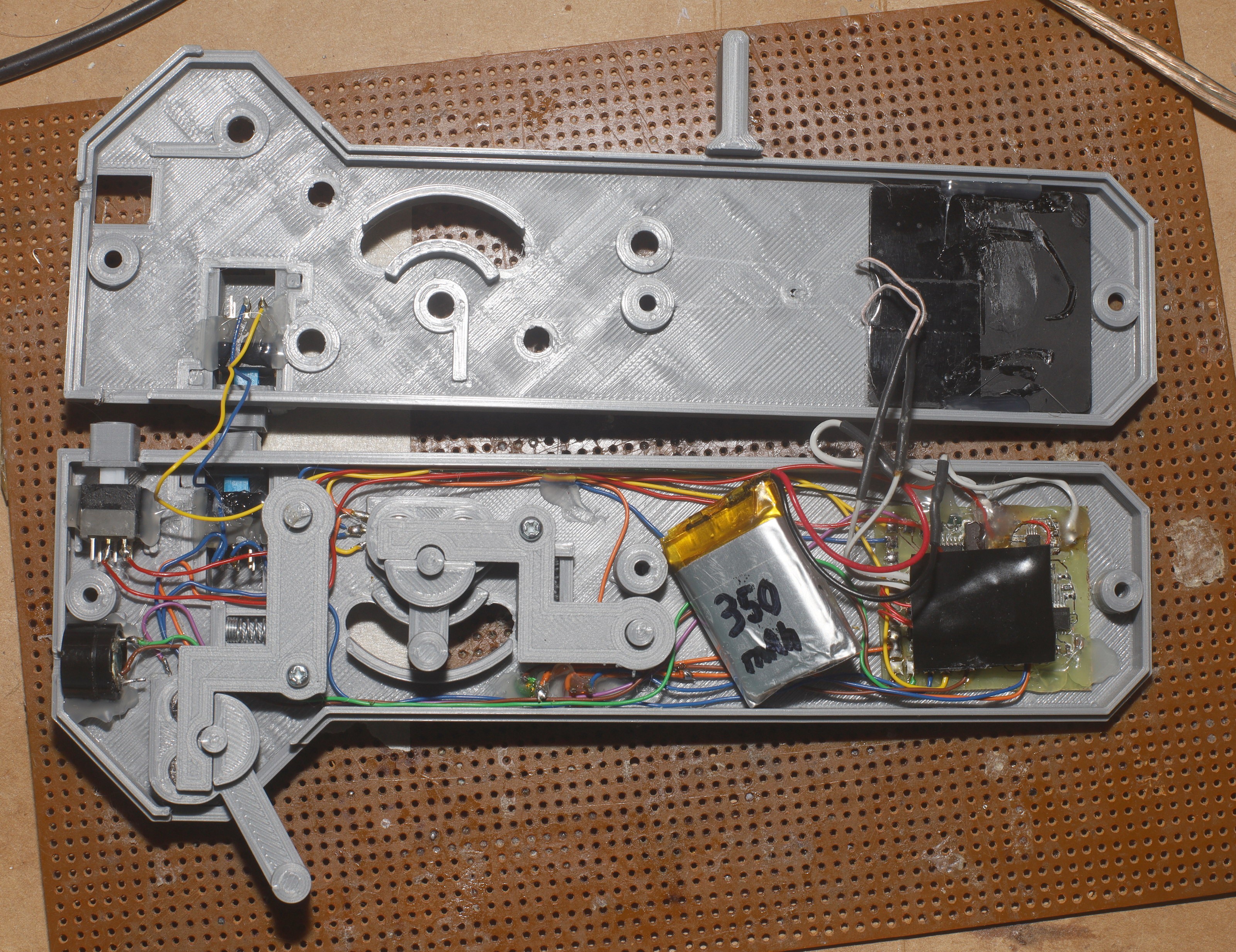

The paw controller was more of a manufacturability upgrade than an ergonomic upgrade. The enclosure was made a single thickness. The new controller is thinner & lighter than the old one. There wasn't enough room to keep the isogrid or any of the markings. The steering lever was shrunk to make it easier to steer while going in reverse. The problem is lions stretch more in their right paws than their left paw so it's never going to be a perfect fit in both paws.

The speed buttons were enabled, opening a new world. Never before was it this easy to adjust the speed. Lions immediately began stepping up the speed for every downhill, taking a lot of time off their runs. Unfortunately, the clamshell tends to separate, creating a lot of variability in the analog readings.

All manual steering or throttle ended up useless. The confuser does a much better job than the lion, so binary steering & binary throttle were put back, using the analog readings to have 2 steps for steering.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.