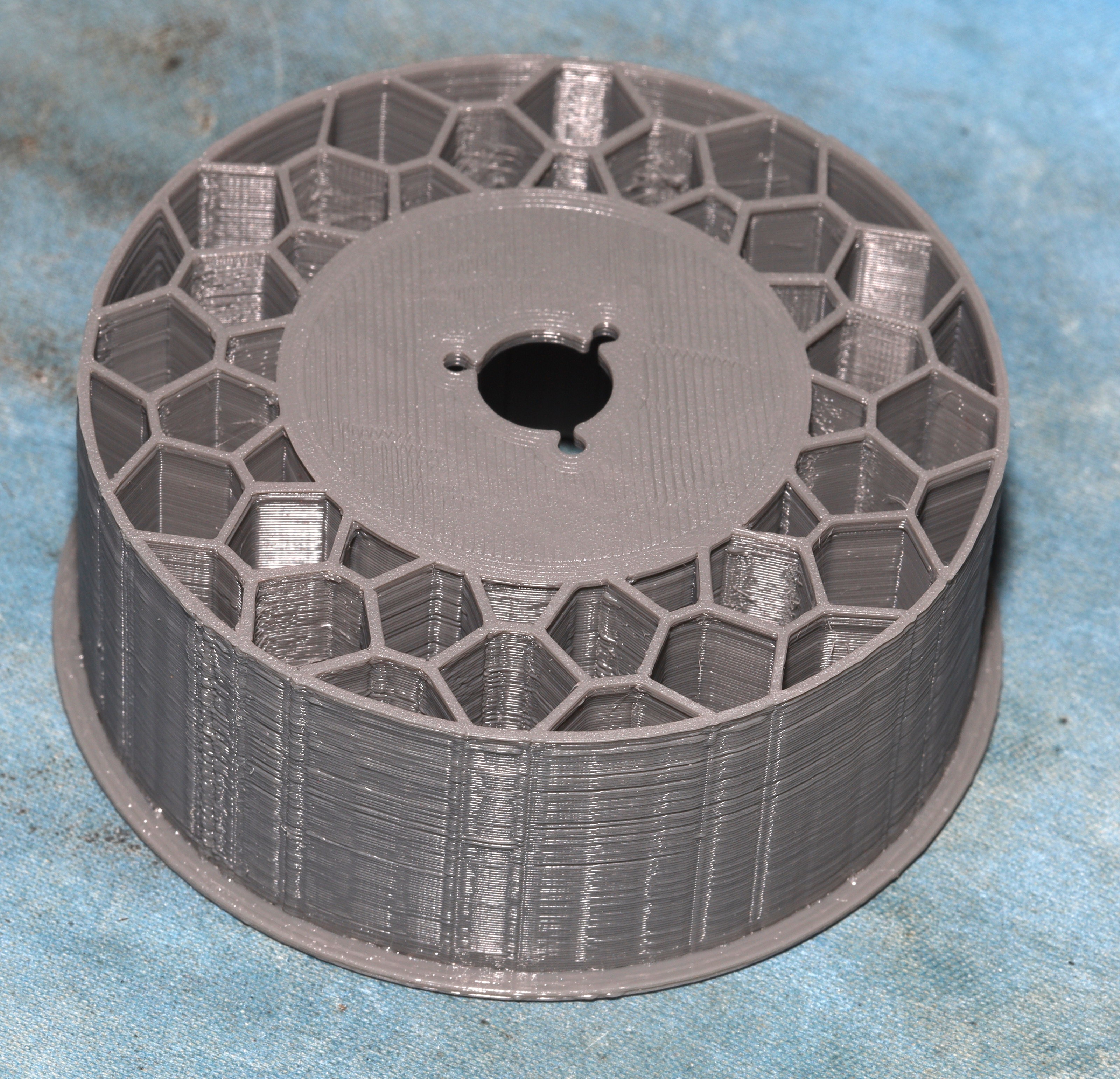

The last tires got very high efficiency but couldn't handle bumps. They also got noisier & noisier at slow speeds because the interior structure was perpendicular to the motion. Eventually it was almost as bad as a gearbox, so the next step was a helical tire. They also got slightly thicker to try to handle bumps better. The material is still under $2 per tire.

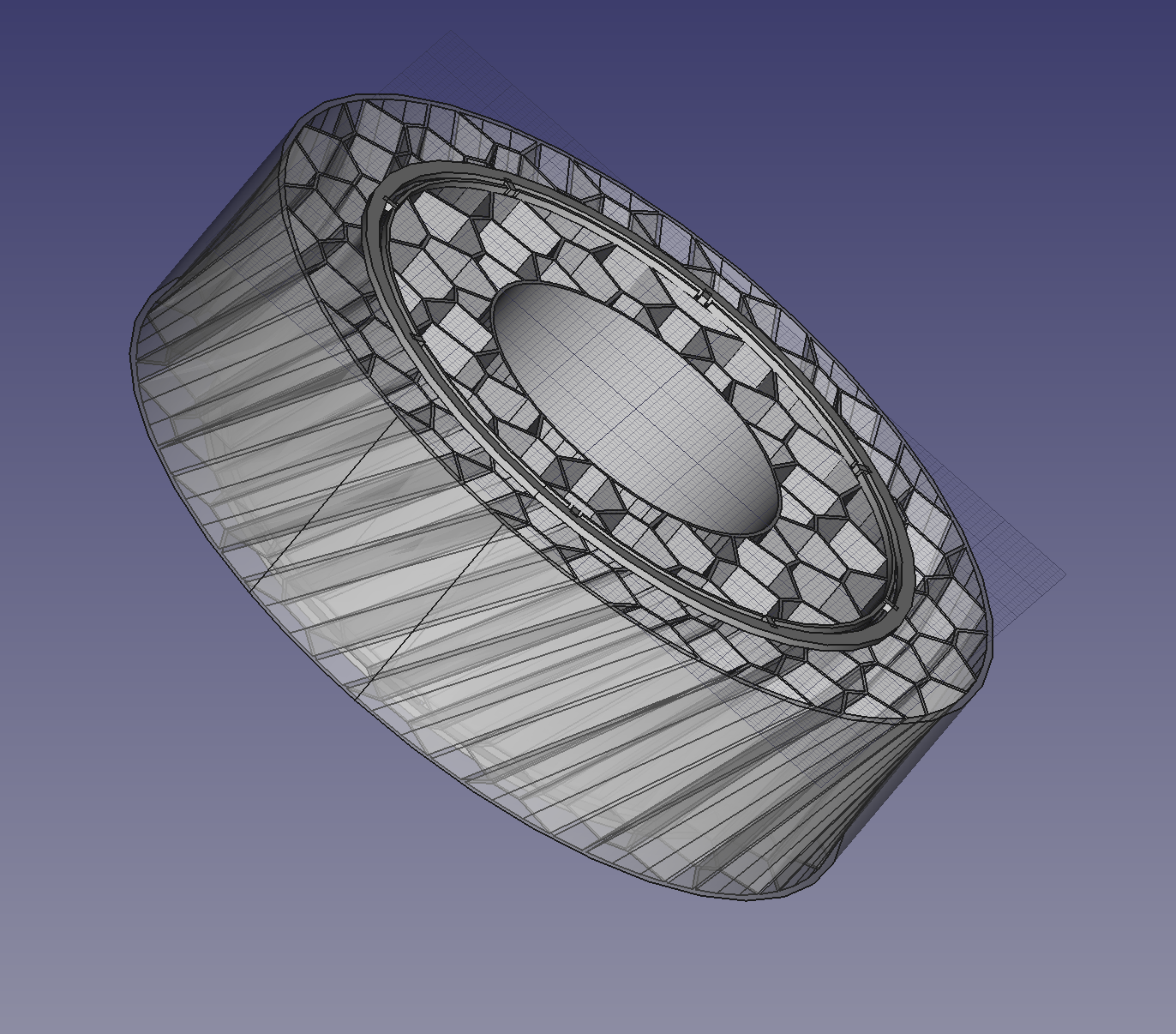

The trick with Freecad is lofting a perpendicular tire 1st, then rotating the 2nd outline. It also requires lofting in the part designer. Lions have no idea how the part designer tools became the standard in Freecad when every other CAD program is happy to rely on the simple part tools.

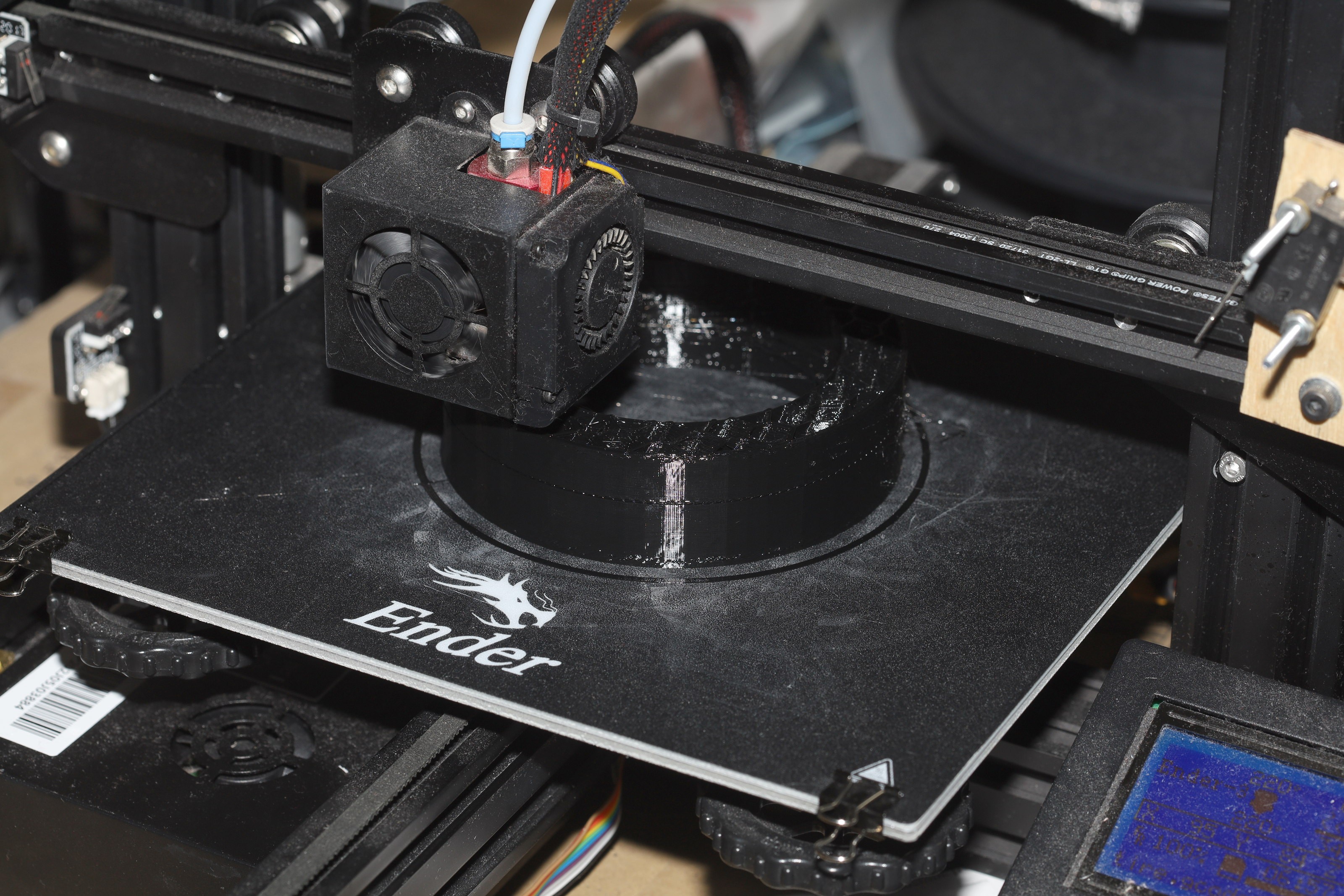

Some really bad .32mm layers. Not sure why the PLA looked much worse than the TPU.

There was a new castillated mechanism for attaching retaining rings. It made most aspects much easier but gluing was more tedious.

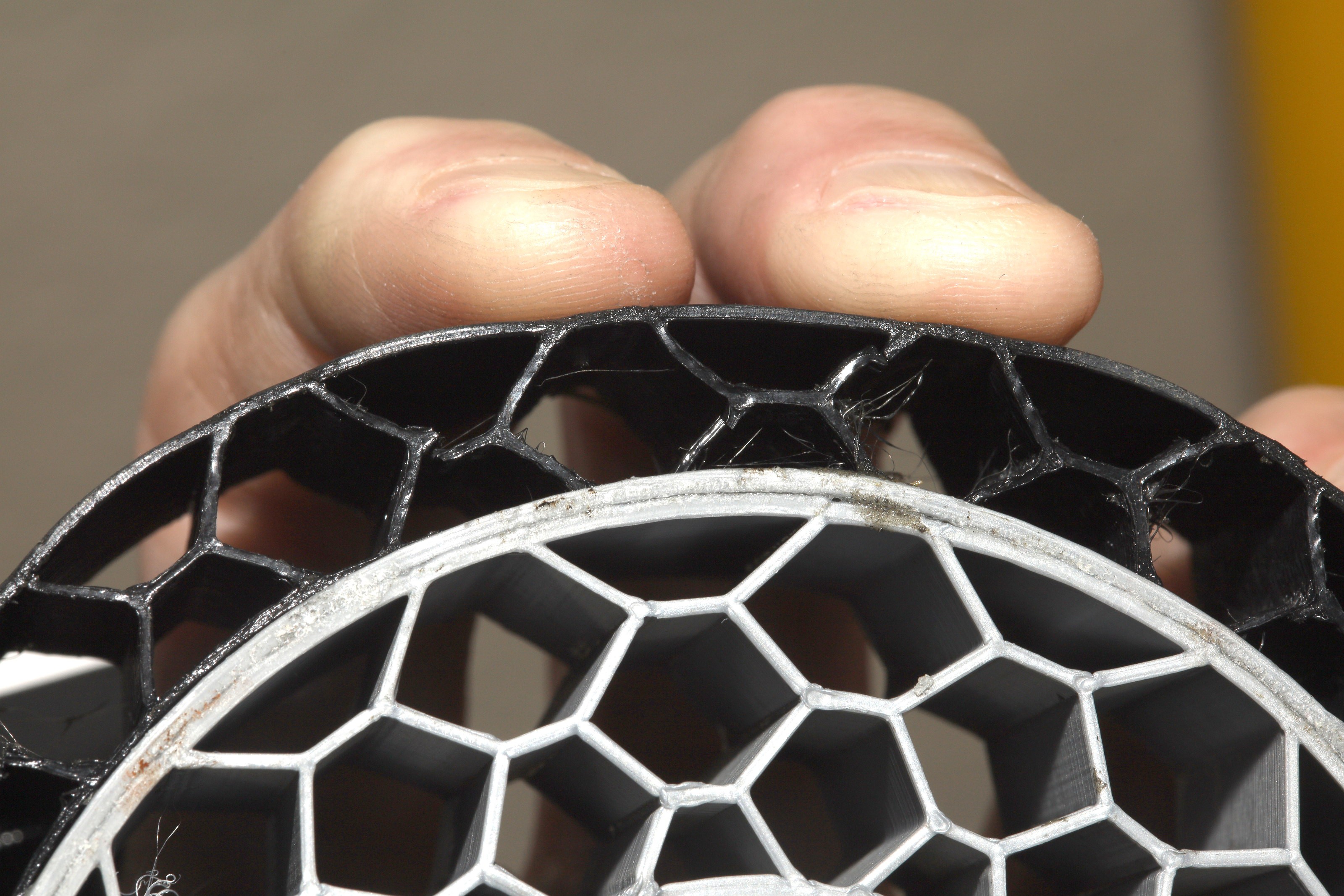

The castillations make the hub look cracked ahead of its time.

The old wheels were truly bashed.

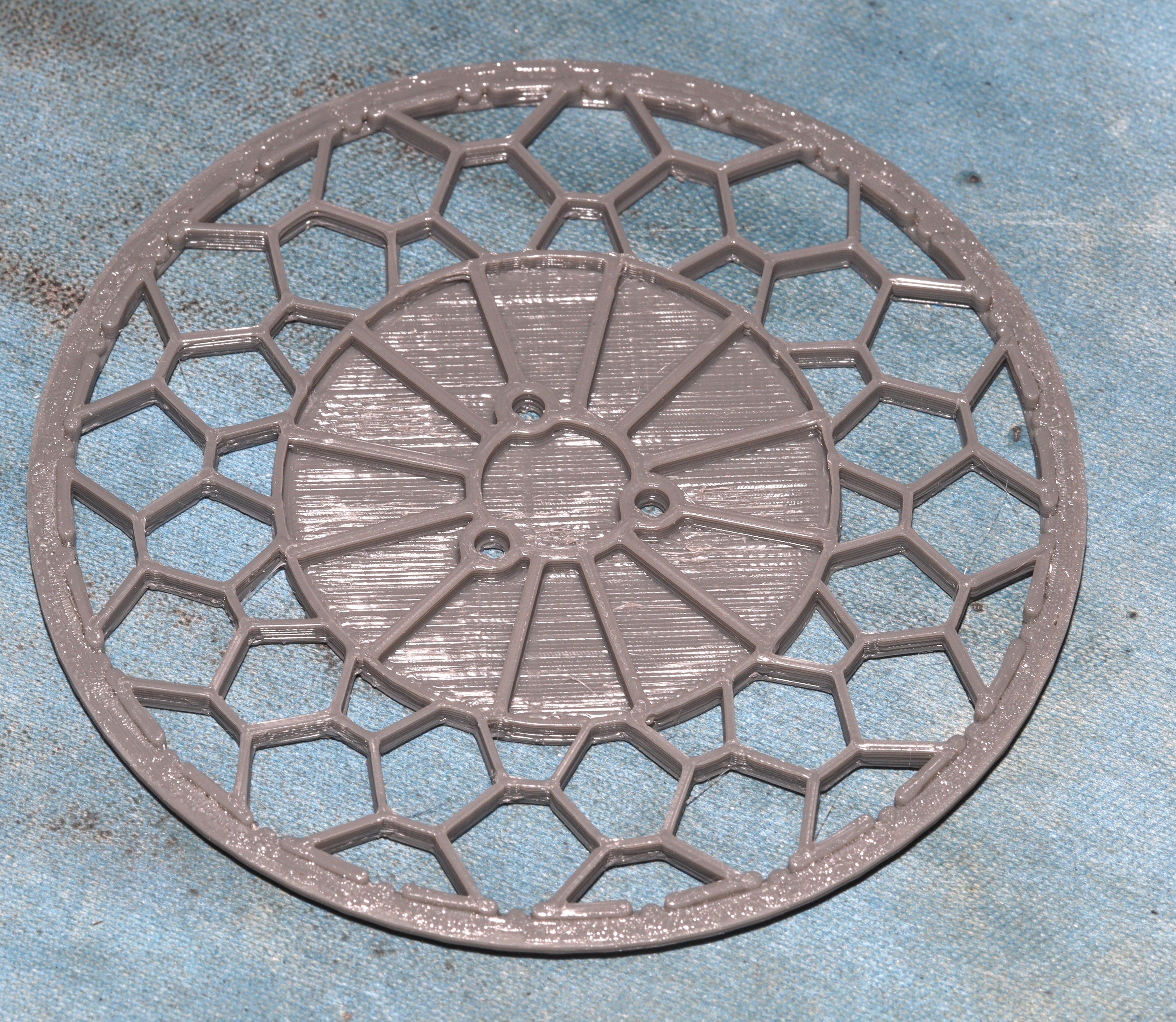

The 1mm tread & .5mm TPU honeycomb cracked in many places.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.