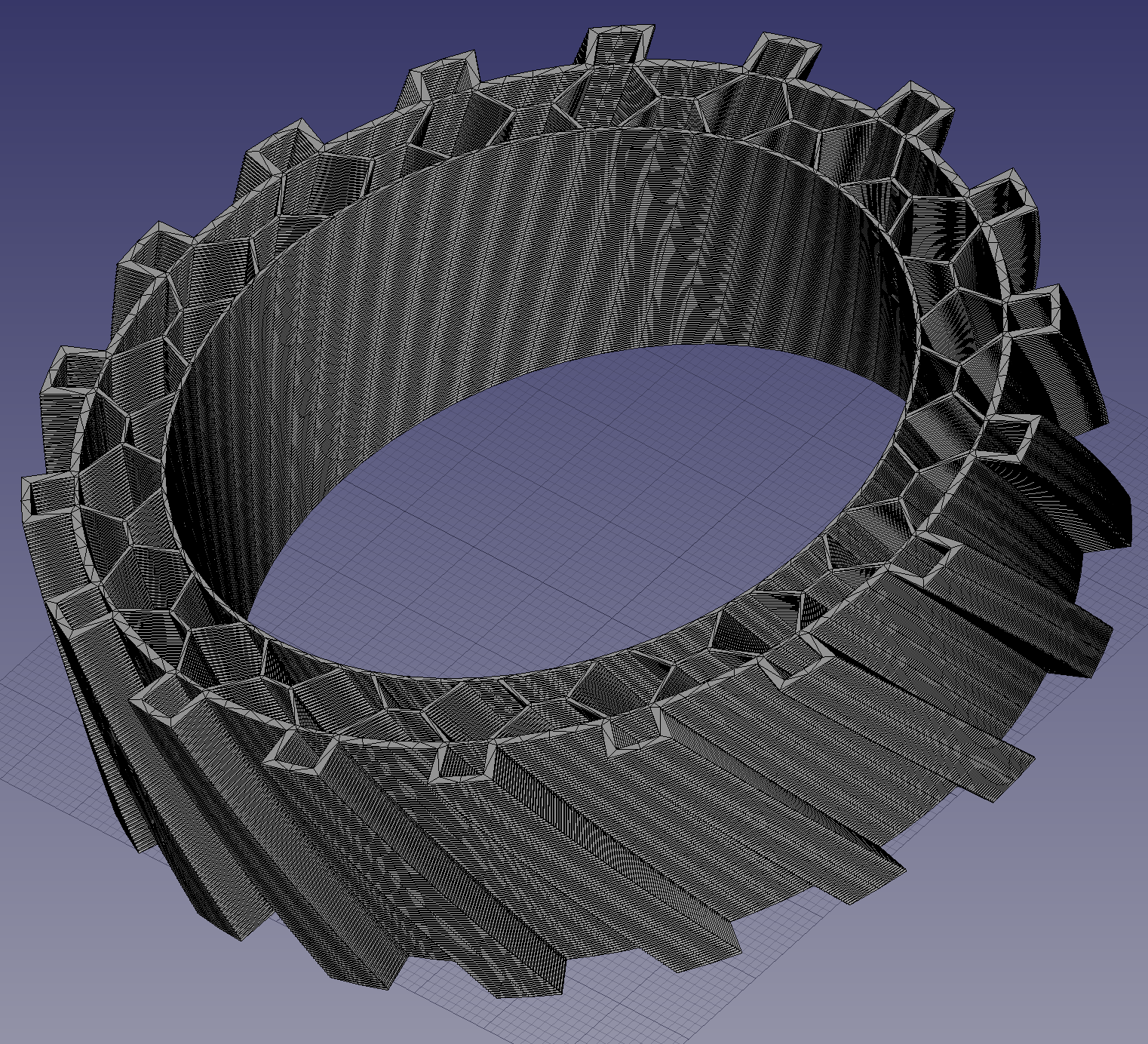

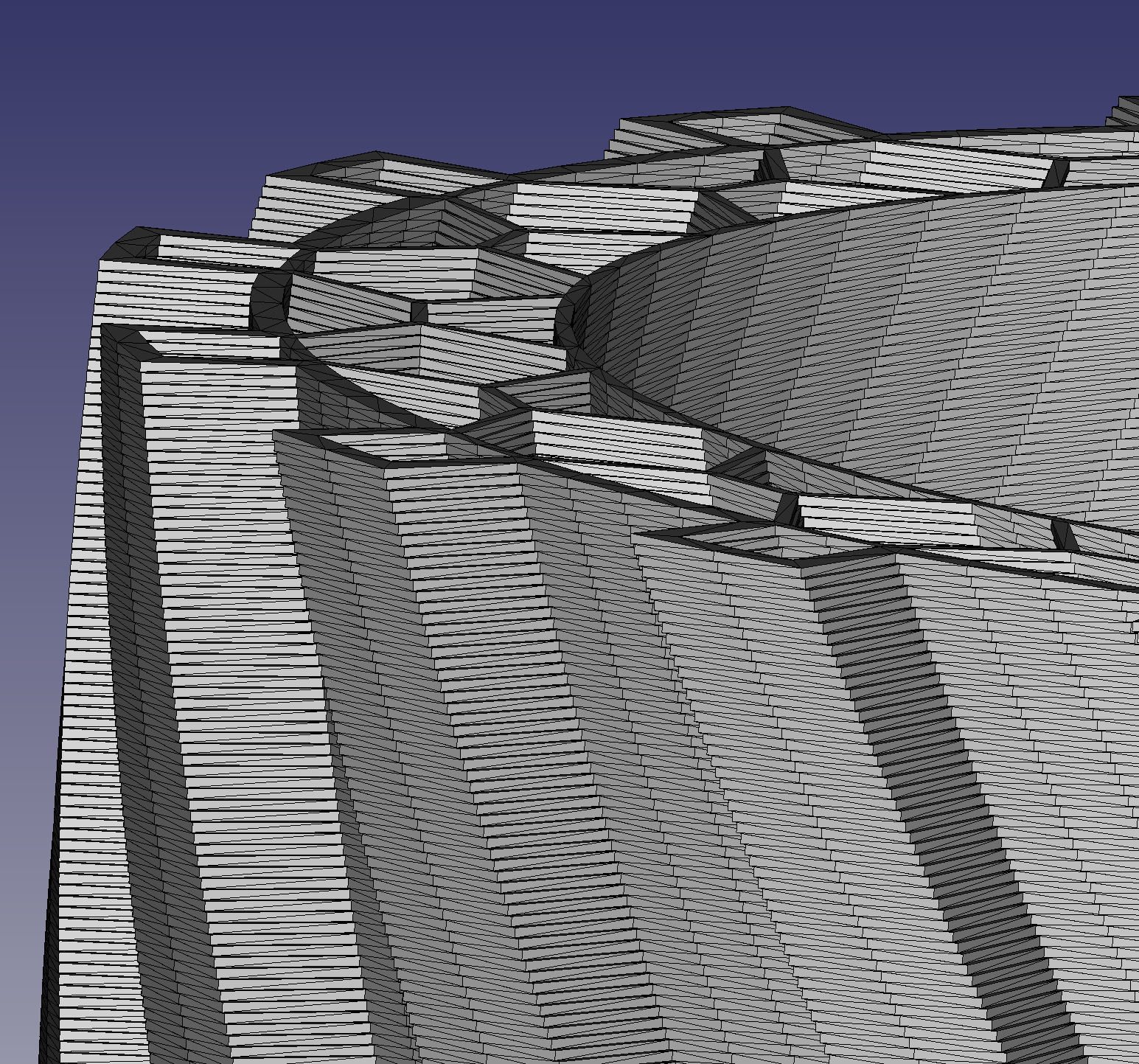

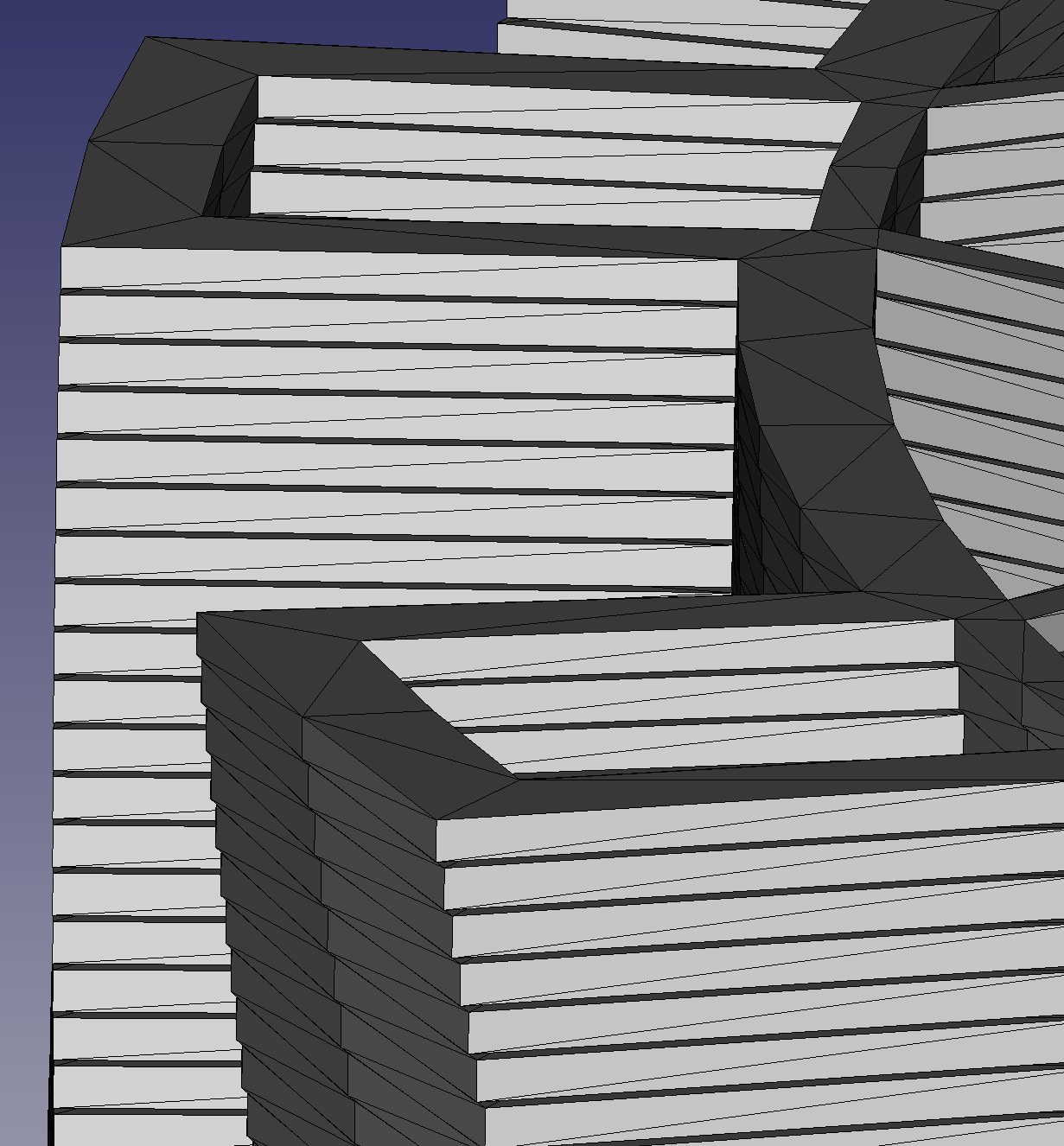

The problem with lofting between 2 models to get a helix is it constricts the center like twisting a sheet of paper. After much fighting with Freecad's lofting tools, a better way emerged. Extrude a single layer, then make a copy for every layer, with a slight rotation. The 96 discrete models require manipulating an STL file in C. To retain some layer adhesion, it had to use parallel treads instead of V's. Getting a V tread would require moving the treads much closer together.

Wider tires would be another win for offroading but cost more.

These got new hubs so they could be swapped in easily. They were adhered with elmer's school glue since Calif* outlawed rubber cement.

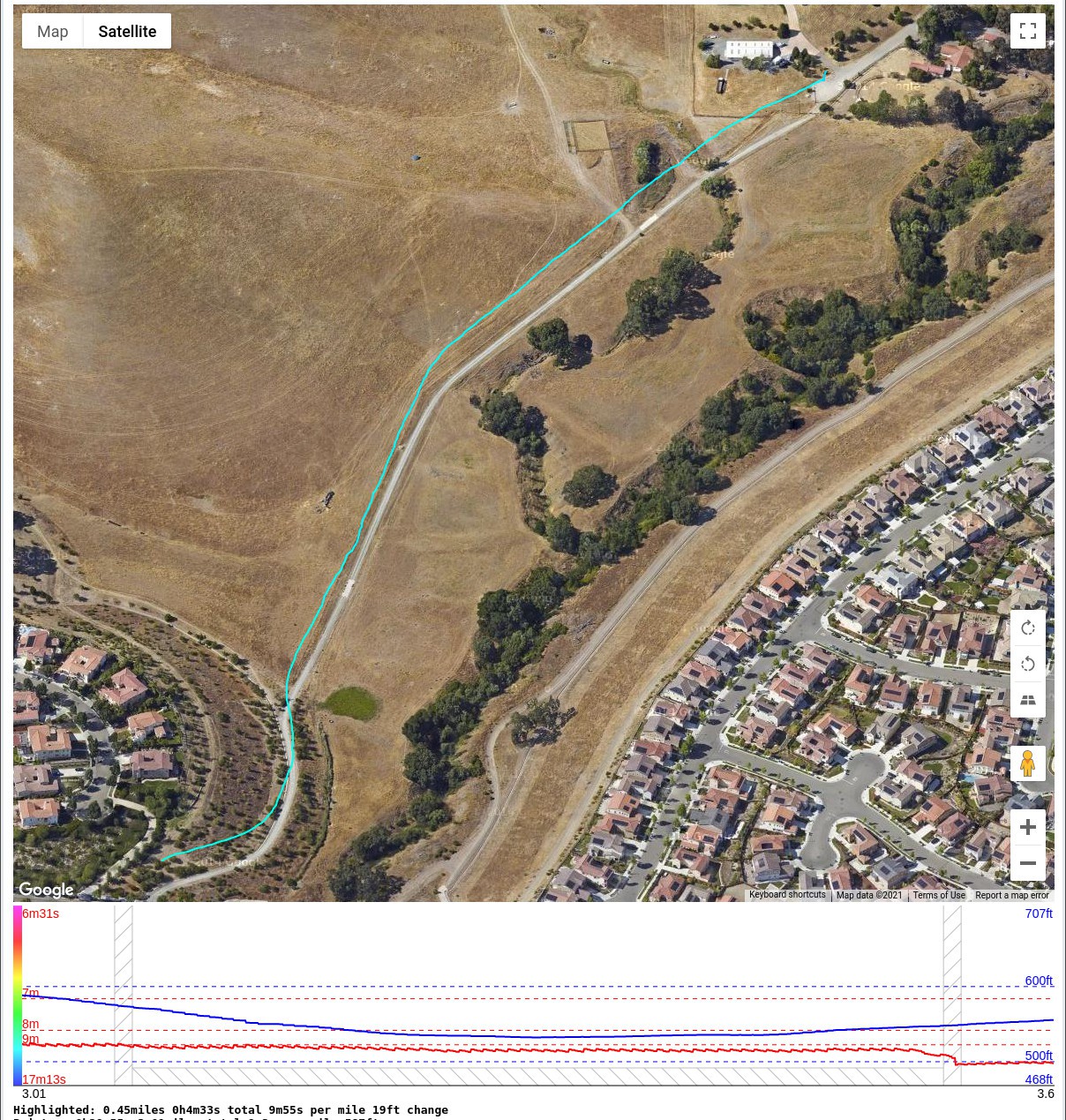

It went up the test trail in 4m33s. The smooth tires went uphill in 5m11s. The smooth tires went downhill in 4m9s. In exchange for this slight improvement, they were much noisier on pavement, despite the helical treads. They actually handled bumps & hit the programmed speed about as good as the smooth tires. The 5mm treads acted just like another 5mm of tire radius.

They dug a lot more into the gravel. There's a plan to widen the tires, but it requires finalizing on the 15mm thickness & amount of cushioning. Lions can't afford to iterate on the wide tires.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.