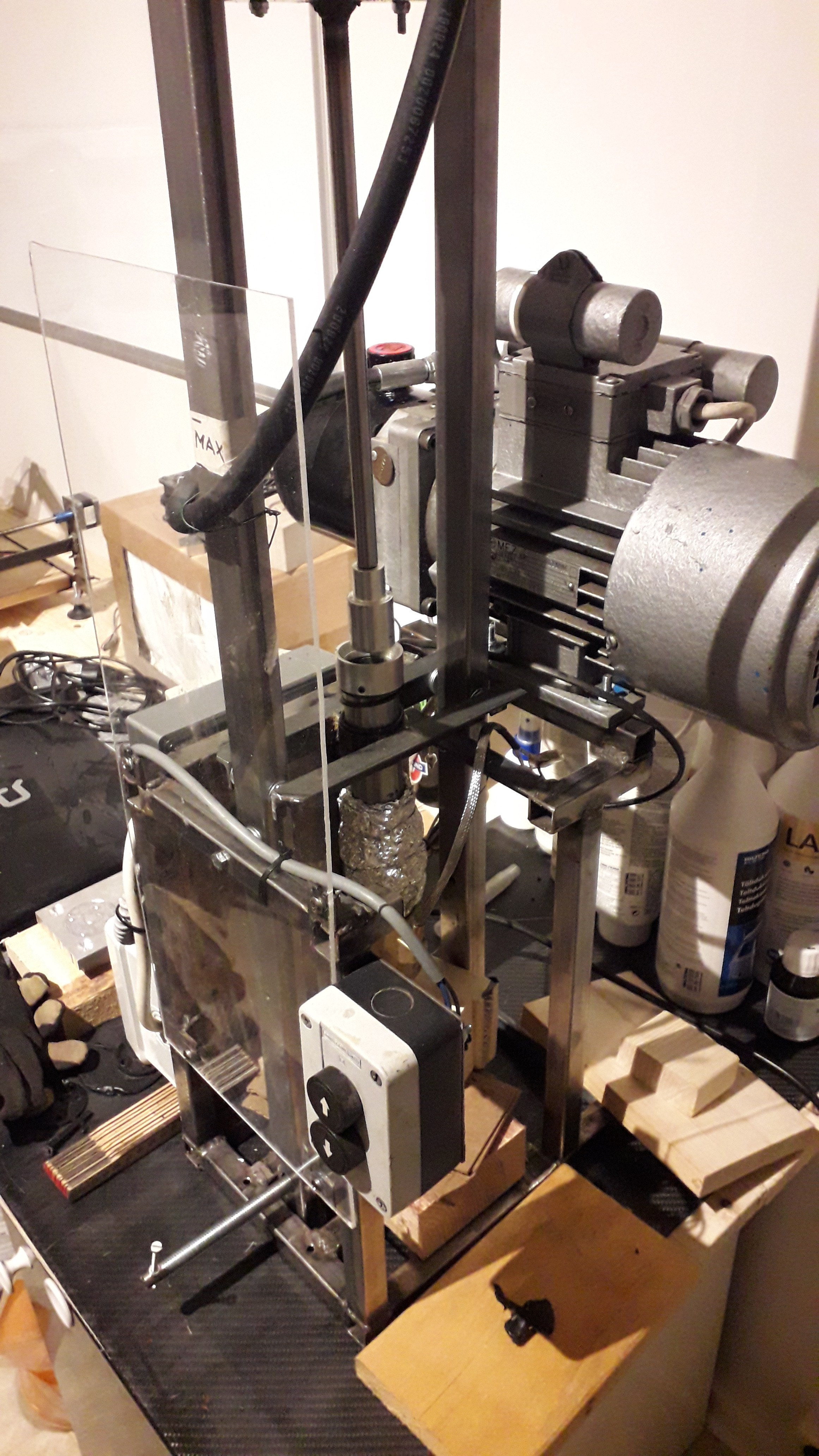

After propably ten rebuilds I finally got the injection molding machine working properly. It's a lot harder than it might look. Temperatures, dimensions, nozzle design etc etc.

There are still some improvements to be made to make it even more reliable, but it works as supposed. What I really would want is a hydraulic flow regulator. Because the pressure is immense! Smaller molds will fill upp in less than a second and the overflow has such high pressure that it can easily break or bend the mold if you're not careful.

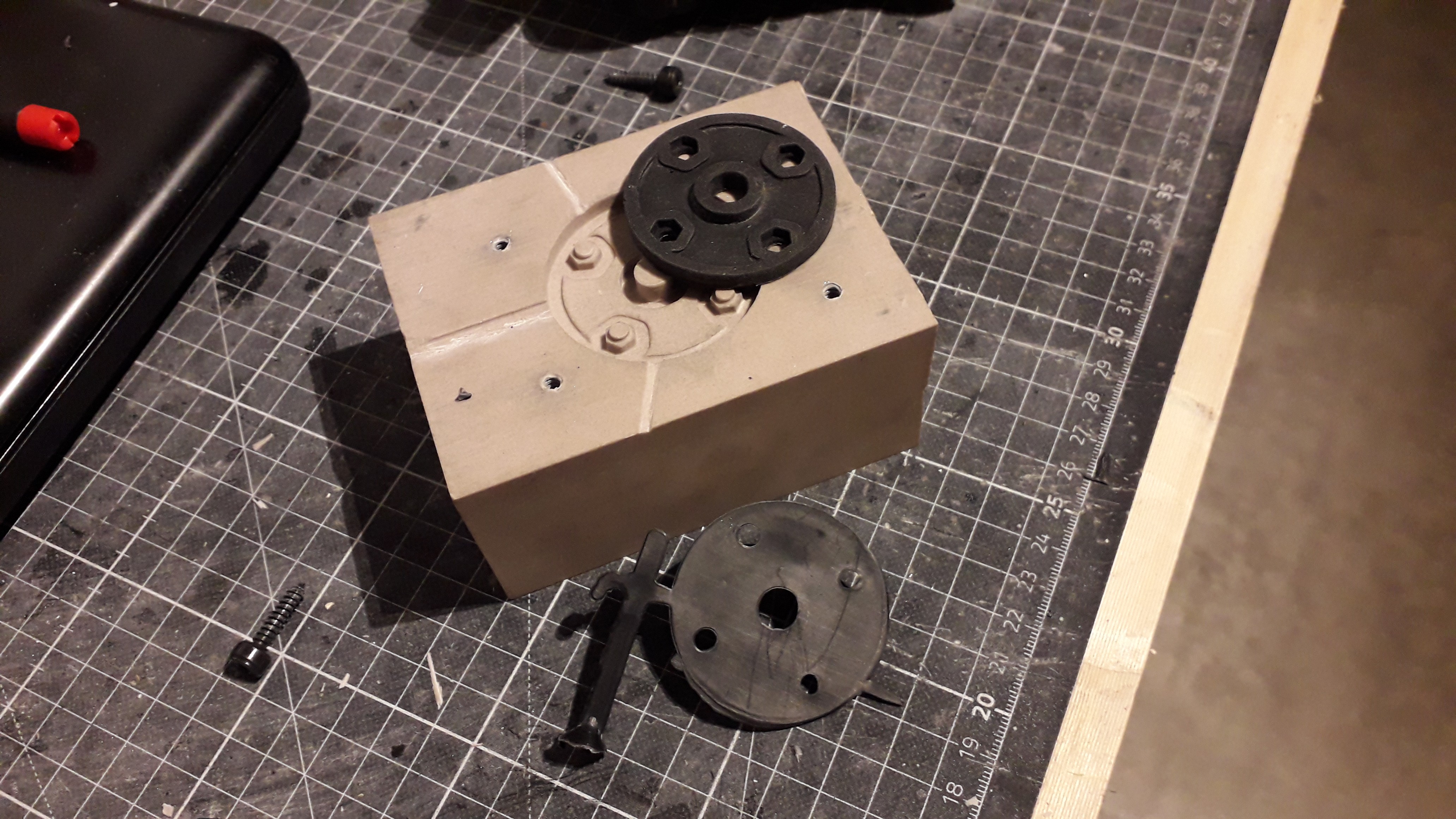

The next hurdle towards the MK2 is making the injection molds. Aluminum works by far the best, but is too hard on my old CNC router. I have two options; either strengthen my CNC or perfect my mold making skills with tooling board (you can see my first attempt in the photo below). I could let someone else make the aluminum molds for me, but the quotes I have gotten would be a total of approx $4000 for the three different molds I need to make the Satran MK2 rotator. Waaay above my budget. One mold out of tooling board ("renshape") would cost less than $100, but would only last perhaps 50 cycles. Good enough to get me started at least.

Daniel Nikolajsen

Daniel Nikolajsen

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.