I made some 3D printed parts to mount my rotary tool - available on Thingiverse. Time to test out milling / routing!

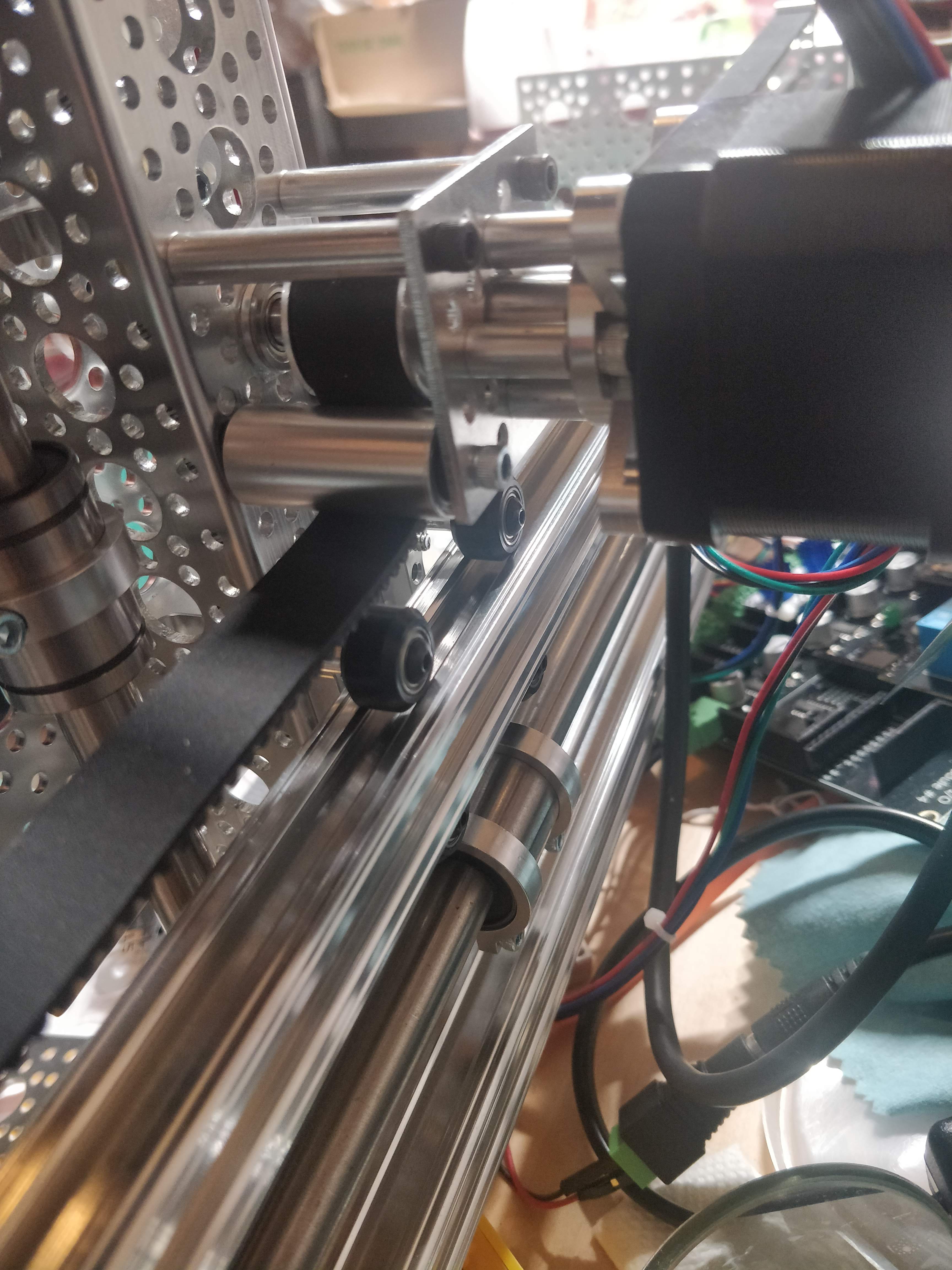

I had planned to use MGN12 linear rails for the X-axis, but shipping from China, they took awhile. I had some spare parts and used a V-groove slider and a 12mm linear shaft bearing:

This worked surprisingly well. I suppose I should expect that since X-Carve and many others use V-wheels. The biggest problems were not any issue to slack, but rather pitch wobble (around X axis) due to the flex of the shaft and the proximity of the shaft and extrusion. Also there was significant roll (rotation around Y axis) due to only using one linear bearing on each side of the Z slider shafts. The two linear bearings in use on the X axis were meant for the Z axis - I really needed them back there.

With the rails installed and all 4 linear bearings in use for the Z axis, it is dramatically more rigid. There is still some pitch wobble. In part due to the small size of the extrusion. But also the supports on each side flex a bit.

I've experimenting with a lot of CAM. bCNC (used for the spiral), JSCut, F-Engrave (for the face) and Fusion 360.

One goal is carving up insulation foam for prop making. Since it works fine on pine, I expect it to work just as well / better on foam.

It's quite noisy though, so I probably won't be experimenting much on the router/mill side of things until I have a real project for it ready. (Despite no Loctite, no screws have wiggled loose yet due the noise/vibration.)

Ted

Ted

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.