Introduction

Water condensation on surfaces is a phenomenon that, depending on circumstances and applications, can be a desired or unwanted effect. While psychrometric devices can provide information about the thermodynamic properties of the water vapour-air mixture, few devices are available to detect and quantify the actual build-up of dew droplets on surfaces. Even less are capable to quantify the concentration of liquid water in an aerosol, that is when relative humidity goes beyond 100%.

This sensor addresses this problem providing a way to detect and quantify the amount of liquid water particles in air at proximity of the sensor's sensitive surface, or detect and quantify the amount of fine water droplets deposited on its sensitive surface.

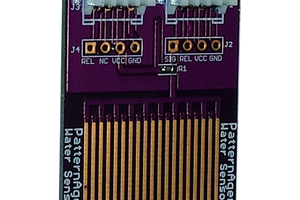

This project has undergo throughly experimentation to test the capabilities of the sensor and particularly of various design and configuration of the electrodes that form the sensitive area of the sensor.

How it works

It works exploiting the well known capacitive effect (self capacitance) when a body is influenced by an electric field. Ultimately it can be seen as a peculiar version of a capacitive sensor. Electric fields are generated providing charges to the electrodes through a current source, and a comparator detects a specific level of voltage calibrated on the limit of the circuit, and removes the charges to start a new measurement cycle.

TL;DR

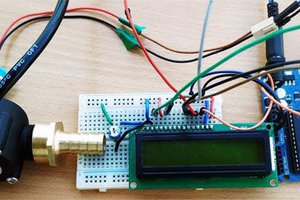

Basically it is a constant current source that charges a capacitor created on the PCB and designed in a way to magnify the projection of the electric fields, converting the measured capacitance into a variable pulse width signal that is carried through the same line that powers the sensor itself, to an external processor that reads the signal and controls the power cycle of the sensor to limit the risk of self-heating.

It is a pretty simple circuit, you know, often the challange is making things simple and efficient.

Projected fields

Unlike in a typical capacitor, the generated electric fields are projected toward the space above (and below) the sensitive area thanks to the design of the network/grid of electrodes. These projected fields expand the sensitivity to the air above the sensor's sensitive area.

When exposed to air (or any other gas for the matter) the sensitive area projects the electric fields through the air (or gas) and if any solid particle is floating in proximity of the electrodes, it interacts with the electric fields causing a variation in the mutual capacitance composed by the electrodes, the air/gas gap, and the particle. This variation is related to the dielectric permittivity specific of the material of which the particle is made of. Thus in the case of water (liquid, at 25°C) the difference between the relative dielectric permittivity of air and water is about 80 times larger for the latter.

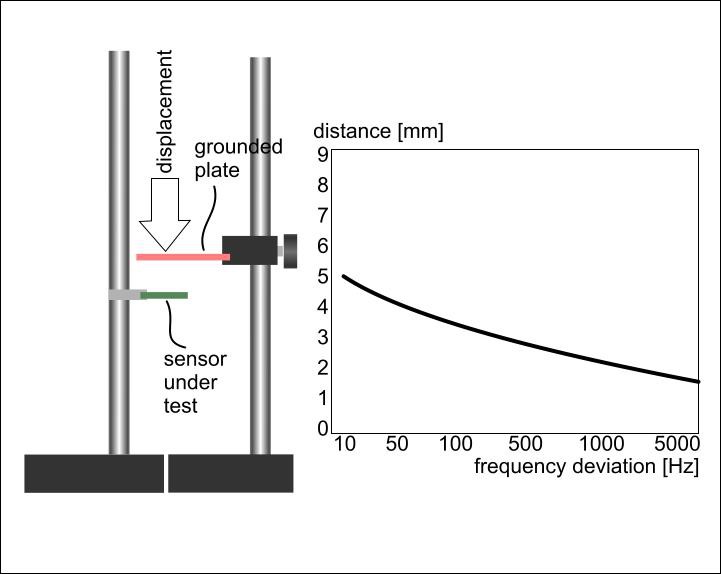

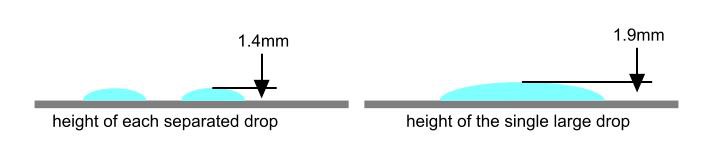

An experiment was made to test how far the fields are projected. As expected, there is no linearity and a cut off distance has been set to discard non significative variations. It was assessed that the sensitivity significantly starts from about 5 mm above the sensitive area.

Effect of droplets build-up

Even the build up of droplets show a limited linearity. In an other experiment aimed to demonstrate this, resulted that a single drop with smaller surface area, but thicker, produces a larger increase in deviation than the thinner drops that in sum cover a larger surface area.

Comparison with other similar technologies

Capacitive sensing is a well known technology in the state of the art. Proximity and touch sensing have been developed using open plate capacitors[1], with circuits that are based upon frequency deviation[2] or upon frequency excitation such as the one integrated in the FDC1004 produced by Texas Instruments[3].

Even though the sensor...

Read more » Claudio G. Hutte

Claudio G. Hutte

Pattern Agents

Pattern Agents

electronicsworkshops

electronicsworkshops

Cedric

Cedric

I was not aware that describing something in a way that should be comprehensible even to people that is not so familiar with certain specificities, although yes a little bit formally, it is now deemed to be as "faux patent legalese", LOL. But yes, it comes from a paper that has been written with the intention to hamper any possible patent filing, so yes maybe some formalities have leaked into this description. Sorry for that. I think it should not detract from the fact that the main intention was to let understand quite well what is going on, though. I did some research last winter and noticed that exploiting capacitive effects on projected electric fields is not so largely well documented. I didn't find much except proximity sensors, touch screens, and rain detectors (rain, not invisible particles of water!)

However thank you for this comment, it hints me to add a TL;DR paragraph.

I already mentioned in the description that we are in a well known field, many other sensors based upon the capacitance over projected fields has been made in the past (so why you repeated what I've already said?) but almost all use an other method.

So I think you have mistaken some points, as the exact way the capacitance is measured *is* material part to the idea, almost partially.

Good luck to sense micro particles with those 1950 droplets in steam sensors. Also to my knowledge those old sensors do not exploit projected fields, but the main field created through plates.

Sensing micro droplets is still a field of great interest as documented, for example, by this paper: https://www.mdpi.com/1424-8220/19/20/4500 (which however uses the galvanic principle).

Also the project is not just the capacitance measurement but how the information is transferred back to the processor, the parasite powering allowing the use of just two wires that gives the processor the ability to control the power cycle to reduce self-heating, and thanks to this arrangement the possibility to control an array of sensors through a single processor even through relatively large distances.

Again, those are not "inventions", but it is just to say that the project is not merely about capacitive measurements.

Have a nice year.