The current stage of the project:

Done:

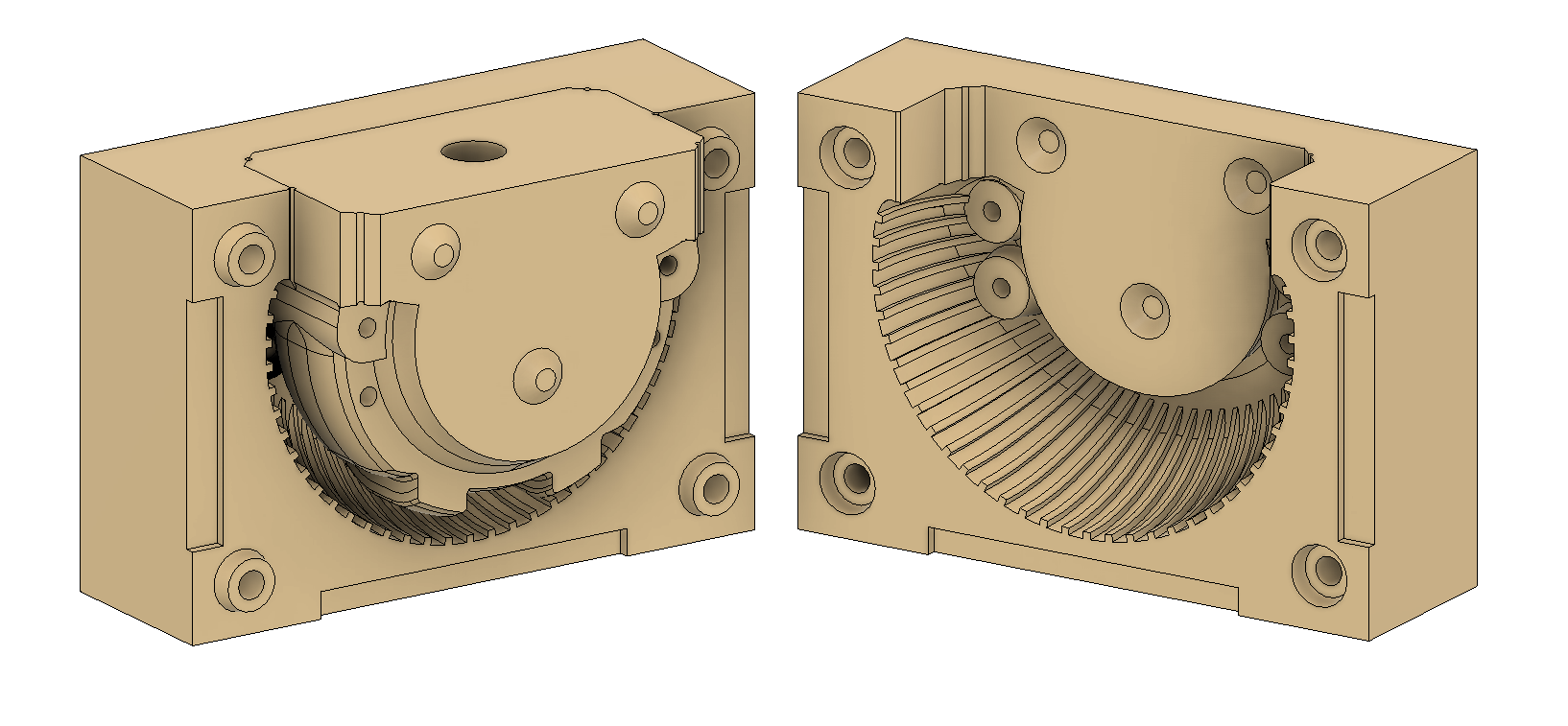

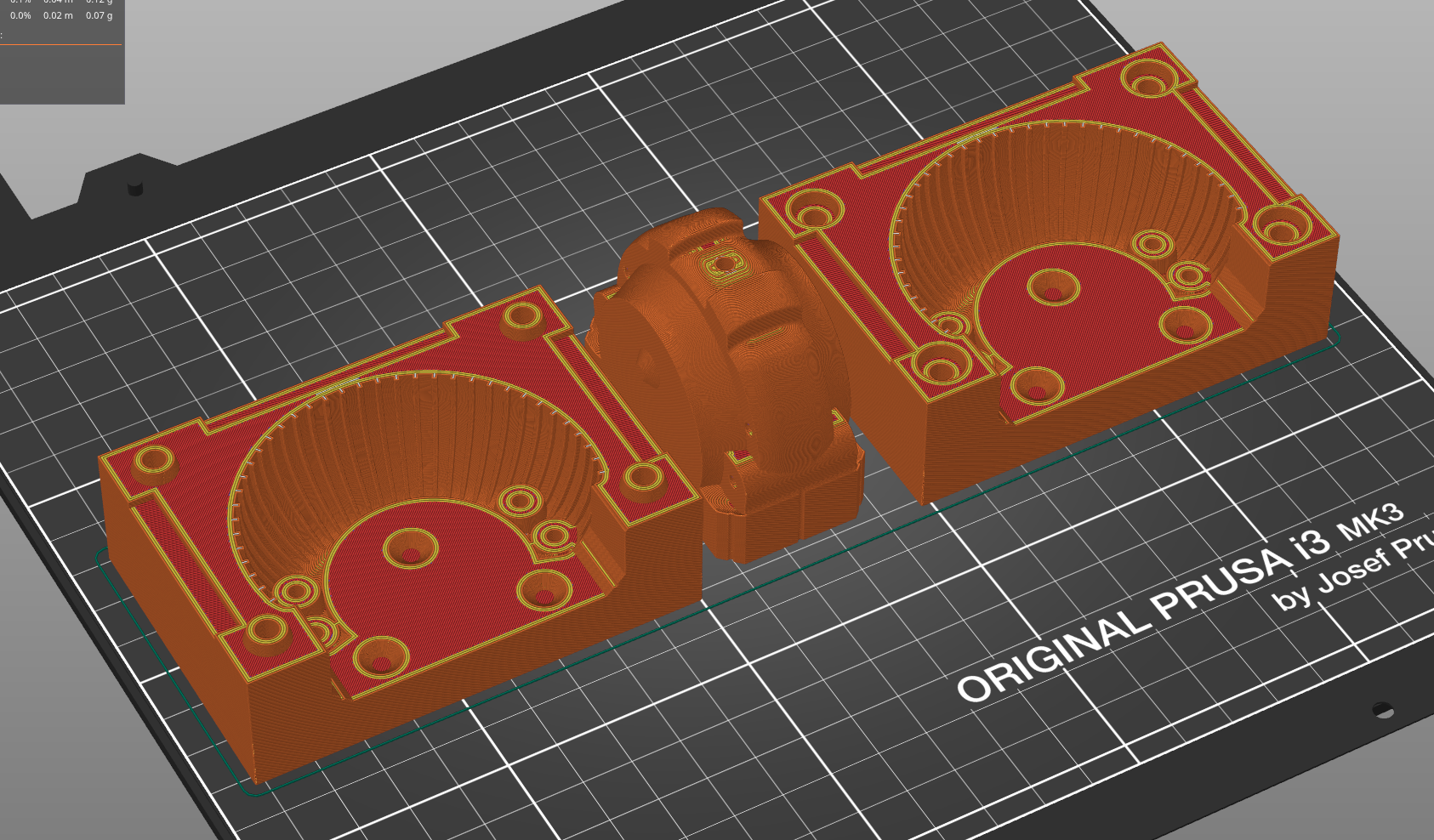

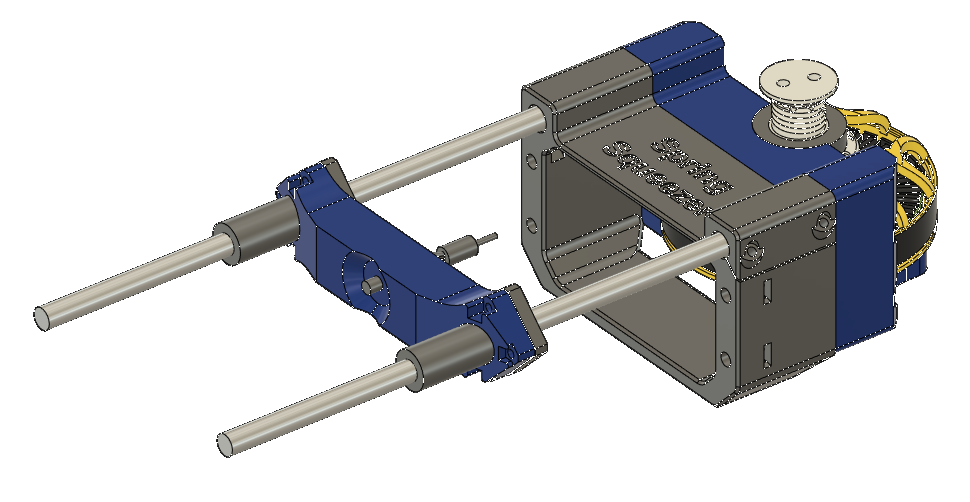

- Design a single capstan reducer and build a test stand for it - perform tests and improvements.

- Design and build a 2Dof leg - with the knee and hip joint.

- Write a python script for communication with the moteus r4.5 controllers over the USB-CAN_FD adapter

- Solve inverse kinematics and scripts for jumping and various other demonstrations.

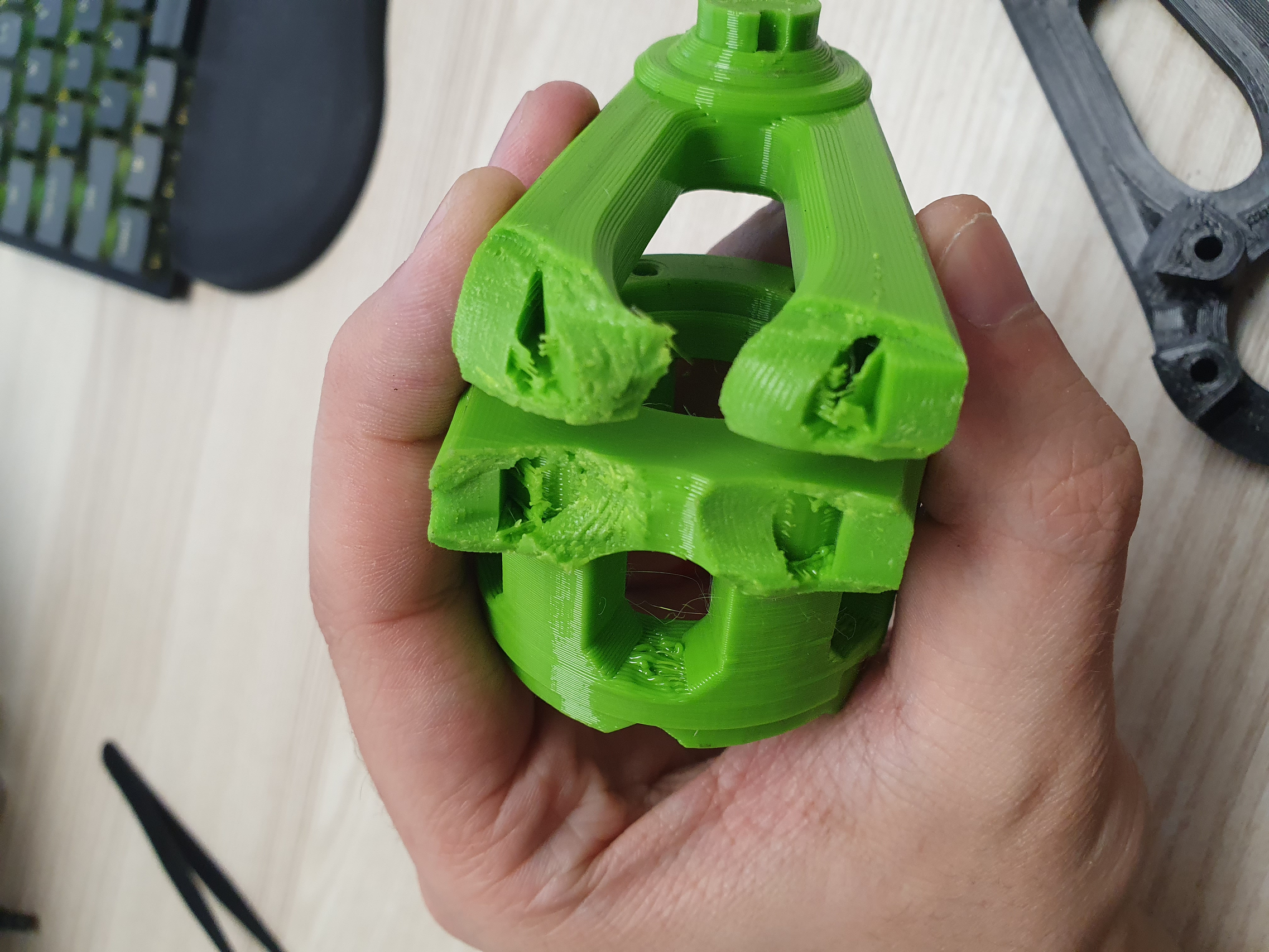

- Perform testing on the 2Dof leg - continuous jumping for 1h - inspect, iterate.

- Design and build a 3Dof leg - adding the ab/ad joint.

- Perform testing on the 3 Dof leg - continuous jumping for 1h between randomly chosen points.

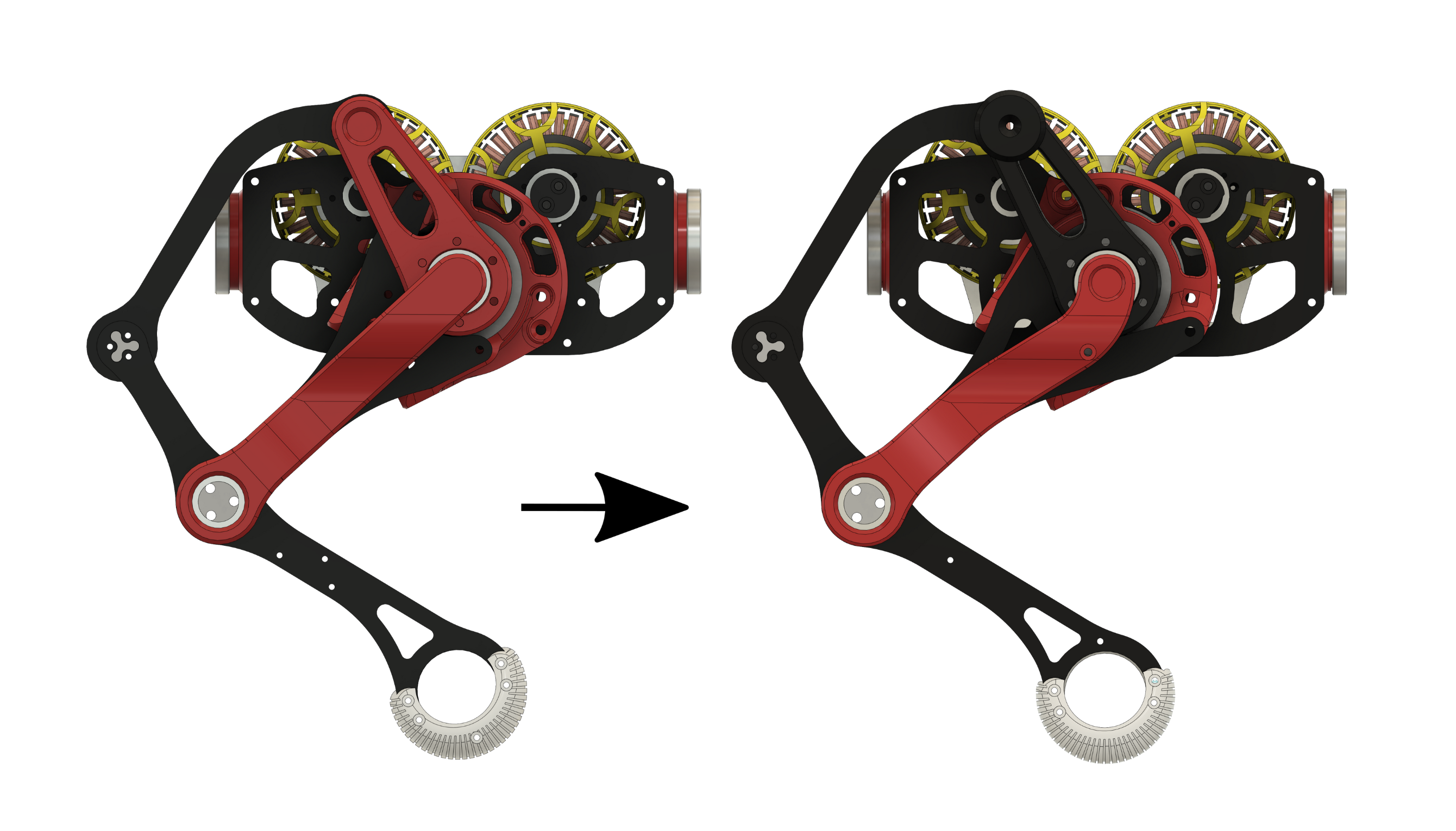

- Make design corrections based on the test and retest. Also perform mass reduction improvements.

- Design the chassis.

- Print a mock-up of the chassis before ordering the "real thing" in FR4 to verify the design .

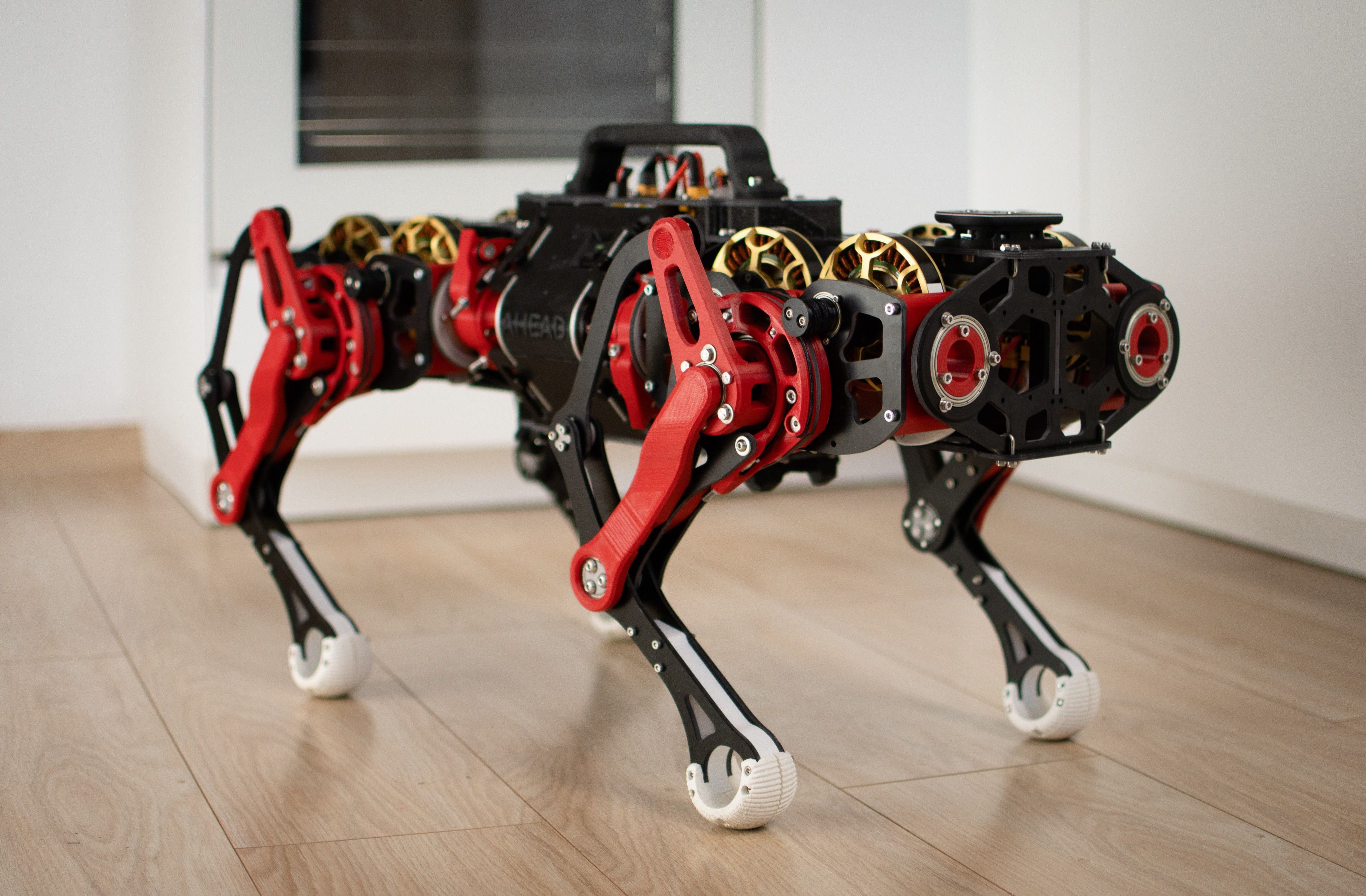

- Get all FR4 Parts and assemble The First Stanley.

- Lay down cables.

- Get the internal CAN communication working.

- Get the Xbox360 Controller working with RPi4B.

- Solve inverse body kinematics, make a demo.

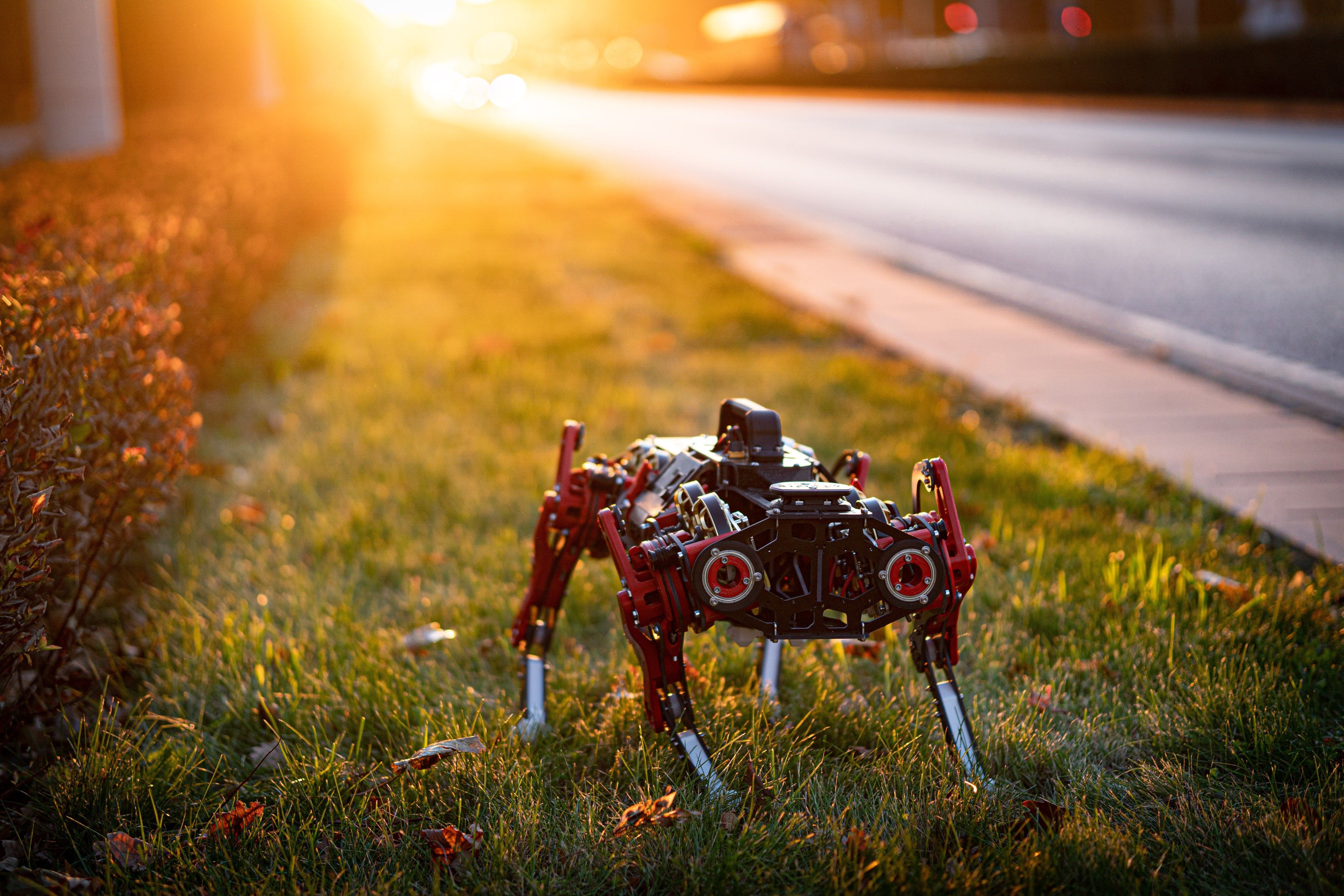

- Create a parametric step trajectory generator, make Stanley walk for the first time.

- Tune the walking algorithm.

- Add jumping functionality.

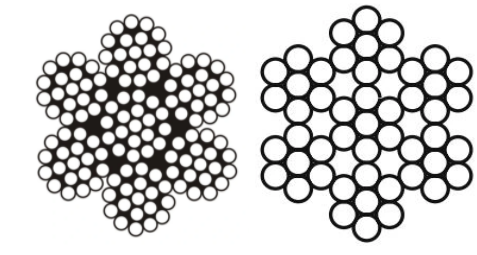

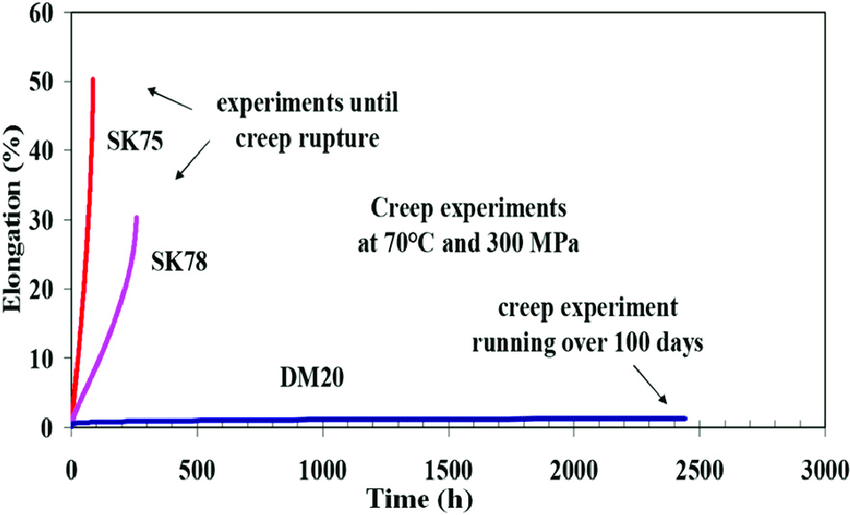

- Test different types of cables, choose the best one.

- Make assembly improvements.

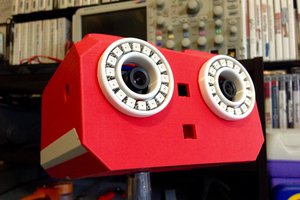

- Create prototype payloads for JetsonNX and Intel cameras.

- Create side covers that better protect the insides of Stanley

- Redesign cable tension system for easier assembly.

- Create assembly tools.

To do:

- Increase reduction ratio to 1:8.

- Make Stanley’s legs longer.

- Make the AbAd actuator more compact.

- Introduce new, lighter motors (probably).

- Make more space inside Stanley for compute and batteries.

- Further assembly improvements.

- Reduce the number of types of screws used in the design

- Develop Mobile Application to control .Stanley missions.

- Create SDF for simulations.

- ...

Ahead

Ahead

zapwizard

zapwizard

Maximiliano Palay

Maximiliano Palay

ThunderSqueak

ThunderSqueak

Martin Pålsson

Martin Pålsson

are you still planning to release the STL and CAD files?