Stanley’s feet design needed an update.

So far we had been using Fiberlogy Fiberflex 30D to print Stanley’s feet in two parts.

Although we like this filament a lot, there are inherent limitations to how soft and sticky a 3D printing filament can be.

These limitations are caused by the construction of FDM extruders. Even an extruder that is well optimised for flexibles, like the E3D Hermera - still needs to grab onto the filament, push it through a metal tube and fight the backpressure created by the small nozzle hole on the other side.

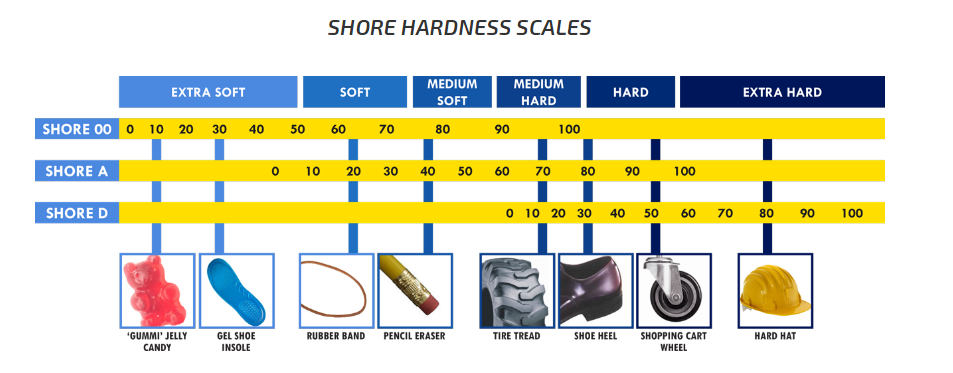

This means that the softer this filament is, the easier it will be for it to buckle and press against the wall of the tube, and the higher its coefficient of friction the more resistance this pressure will cause. That is why the softest filaments on the market are in the Shore 75~85A (20~30D) range.

This limitation does not apply to castable silicone rubbers. These come in hardness levels all across the Shore hardness scale. We made an educated guess and picked a silicone rubber at the Shore Hardness of 25A for Stanley’s feet.

The silicone rubber is so soft that it needed scaffolding in order not to move around too much. We designed a scaffolding that includes two ridges that prevent the rubber from sliding along the scaffolding during forwards acceleration.

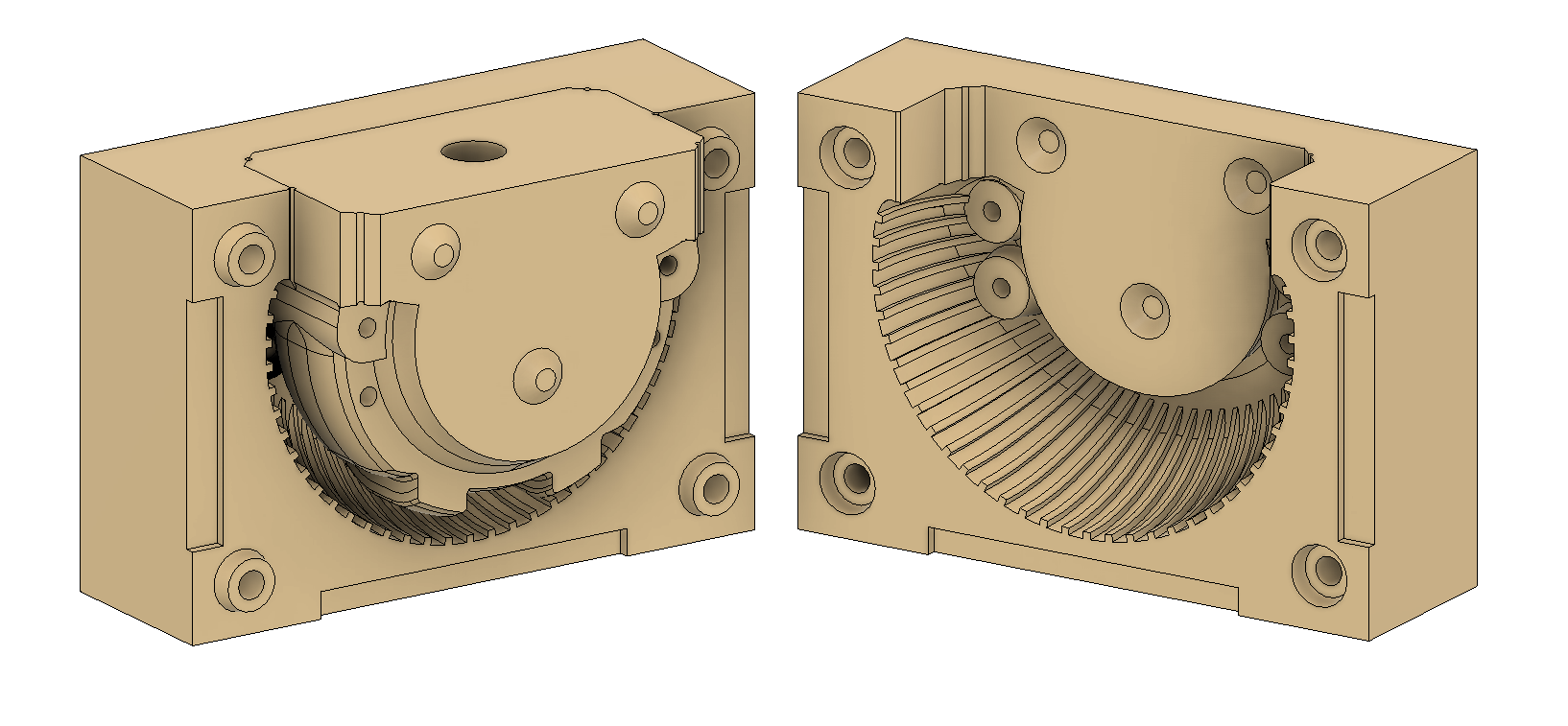

Now when this was ready we needed a mold! We designed it in 3 parts:

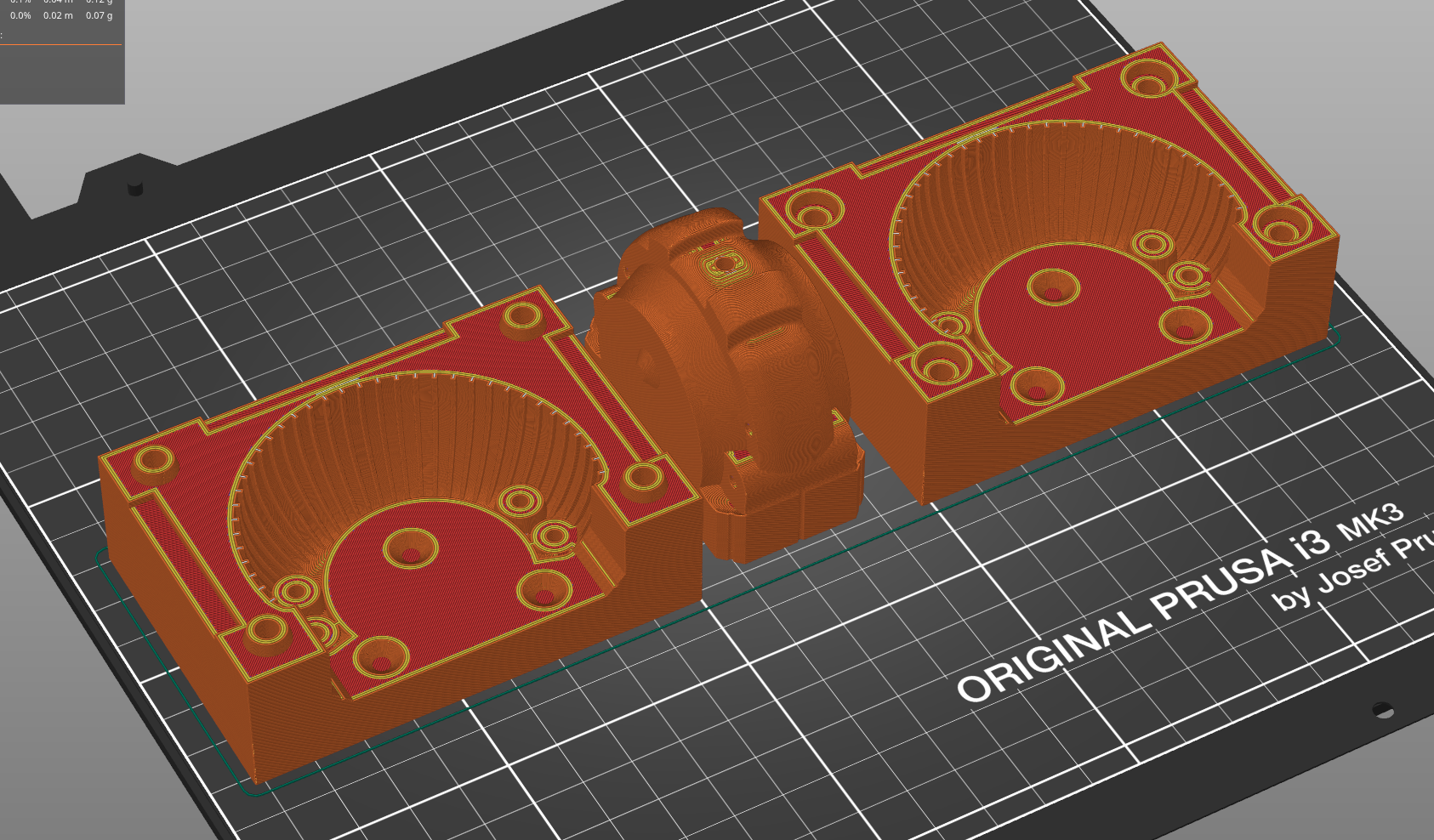

That print like this:

We use 4x M4 screws to assemble the mold and we also push 4x steel rods into it, which act as the negative for screw holes in the feet.

We use a big syringe to inject the silicone into the mold through the top hole.

The 3 conical features on the central part of the mold act as locating features, improving assembly precision. The cones around M4 screw holes serve the same purpose. The recessed tabs around the edges make opening the mold easier.

Have a look at the very satisfying process of demolding Stanley's rubber feet in this short video:

Gaelle

Gaelle

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.