This shift in concept of application accidentally slid in while working on the motivating application for this project.

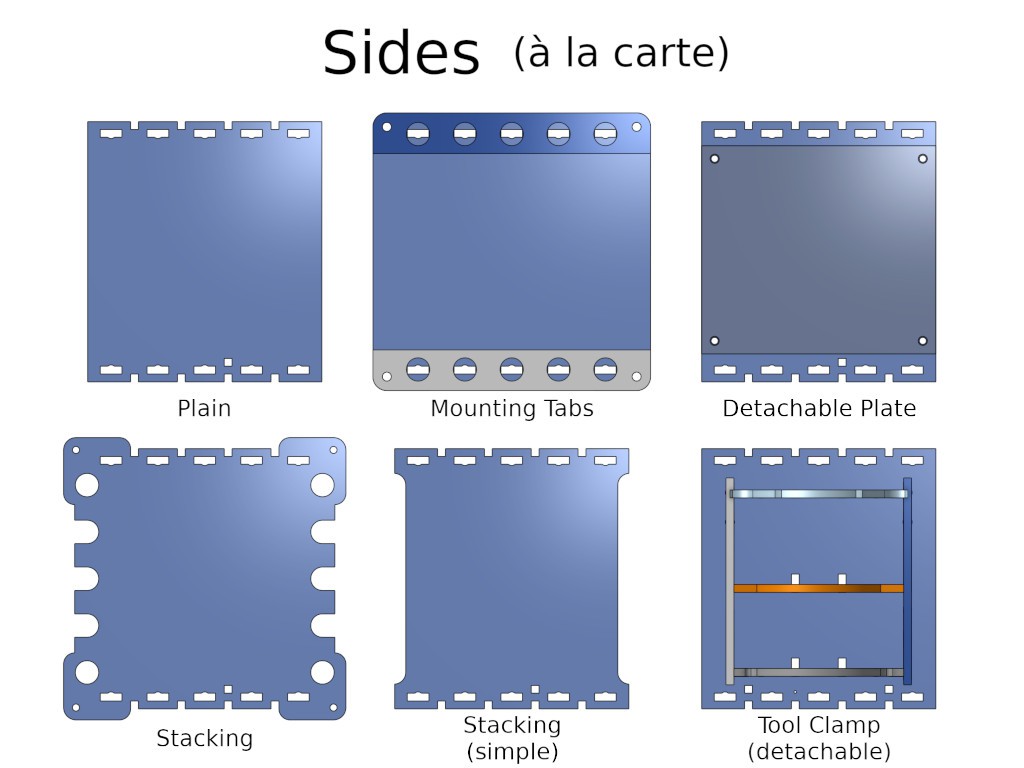

The concept in my head from the start had been to model an internally configurable, externally featureless slide as a generic reusable component. For use by carving up the side plates, either literally with tools or in CAD or vector drawing to adapt the part for an application before before making it in the first place.

While working the application side of this idea -- the proverbial eating my own dogfood -- I eventually got the clue that a useless default defaults to useless when the universe of applications grows beyond contemplating how it might be applied. Derp. ("Plain" is close to useless because there's nearly no clearance on the inside of the plate for anything like a screwhead -- and I disparage hot glue/epoxy/etc enough to not want to eat that crow)

So it makes sense to provide at least one way to do something.

The "Stacking (simple)" side-cuts were half a nod at that after I stopped trying to keep the slide narrower than the length between the rows of screws at each end. The side cuts allow units to fit together across each other but left attaching them as a problem for later. They also take material away from where bendiness is already a compromise.

So that's the set-up for the Slow Dawn of the Obvious:

- attach slide side to something else

- attach slide side to side of another slide

- attach something else to slide side

are a small option space that cover a big fat most of what there is to do. (where "spoil board" is the degenerate case of attaching something to the slide)

And picking from a short list once for each side evades thinking about how many combinations are actually plausible.

The clamp for a specific rotary tool breaks from the idea of general utility, but a uniform clamp/slide interface teases the possibility of a more general/adaptable clamp or general way to roll your own specific clamp. (update: like this!)

CAD & 'ible updated (the 'ible still needs some finishing up re rigging and using the clamp - as of writing this)

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.