I Built A Prototype!

Below is a video where I built a small section of the treadmill to test what it would be like.

If I can think of solutions to the issues I described I may make a new version.

A Concept for a Cheaper Active Omni-Directional Treadmill

Many Omni-directional treadmills exist today and I see most if not all of them falling into one of two categories.

- Passive - omni-directional treadmills that rely on a smooth, low-friction surface that the user slides his feet on. Also commonly known as slidemills. Examples of these are Omni One by Virtuix and the Kat Walk C.

- Active - omni-directional treadmills that use motors to actively move the platform the user is on. Examples of these are the Infinadeck, ACTVR, OmniDeck, and Strider VR.

Each category has its own set of advantages and disadvantages. Slidemills have less moving parts so are cheaper and easier to maintain, but some users may find that sliding instead of actually walking feels uncomfortable. Active treadmills can actually move the floor below you so that it feels very close to actual walking. But active treadmills tend to be more expensive, with the Infinadeck going for $40,000 to $60,000 each for example, have more moving parts so is more likely to break down, and can suffer from inertia problems.

Here I will explain my own concept for an active omni-directional treadmill. My concept should be cheaper or as cheap to make as other active omni-directional treadmills, not suffer from inertia problems, is scalable to any size, and easy enough to build that anyone with a 3D printer, saw, drill, and basic tools could build one for himself.

When I first started thinking about my own active omni-directional treadmill concept, my first priority was to try to make it as cheap as possible. You could make an omni-directional treadmill out of omni-wheels using a design similar to the Celluveyor.

But omni-wheels are not exactly a cheap option when you consider that you would need many of them to make a treadmill out of. I also considered if ball-transfer units could be used, but they are noisy, can't be motorized, and aren't cheap enough either.

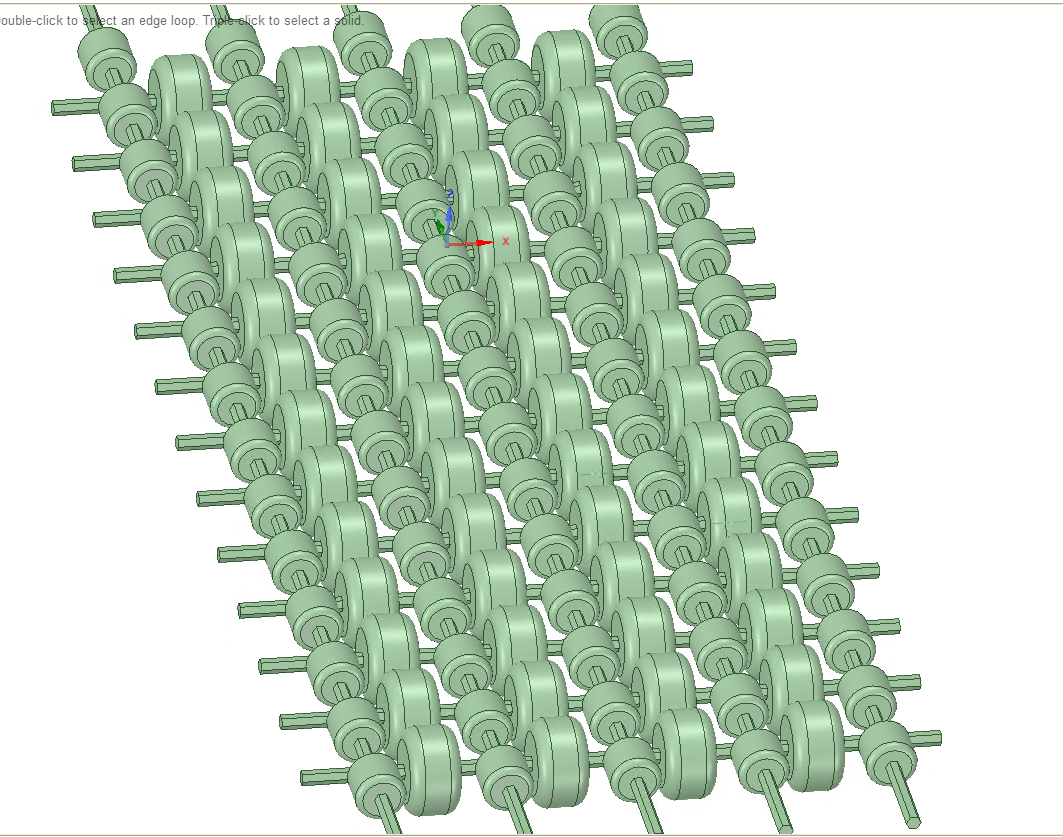

So my first idea was to use simple rollers instead of omni-wheels or ball transfers. A simple roller would be very cheap to make and it wouldn't be too expensive if you needed hundreds of them. The next challenge came with deciding how the rollers should be arranged to achieve have omni-directional capabilities. A the rollers going one way would just produce the motion a regular treadmill produces, so you'd need half of the rollers rotated 90 degrees so you could also have sideways motion. But, each roller has an axle going through it. If you have a set of rollers for forward/back and another set for sideways, won't the axles collide? This stumped me for a while, but then I thought of a solution. Yes, if the rollers are all the same diameter they will, but they don't have to be the same diameter. That led me to make this quick 3D-model.

This treadmill consists of two sets of rollers. The rollers are of different diameters, so the axles do not intersect as you can see more clearly here.

This treadmill consists of two sets of rollers. The rollers are of different diameters, so the axles do not intersect as you can see more clearly here. Of course, the obvious problem with this idea is that it will produce a lot of friction. If you're walking forward, the sideways rollers will just create sliding friction. This could possibly be reduced by having groves on the rollers or adding a low friction material on the rollers, but then you're going to have to try to balance low-friction with also having enough traction for the rollers to actually move you.

Of course, the obvious problem with this idea is that it will produce a lot of friction. If you're walking forward, the sideways rollers will just create sliding friction. This could possibly be reduced by having groves on the rollers or adding a low friction material on the rollers, but then you're going to have to try to balance low-friction with also having enough traction for the rollers to actually move you.After this I was again stumped for a while. I decided that the roller had to be a little more complicated, but still be cheap to produce. I recalled the omni-sphere design that I developed for a previous version of my VR shoes.

These were partially omni-directional, meaning they could produce powered forward, backward, left, and right motion, but nothing in-between. There are other omni-sphere designs, such as this Omni-Crawler.

I couldn't think of a way to make an omni-sphere capable of full omni-directional motion, but I realized I probably don't need to. You can have the omni-spheres rotated at different angles. Essentially one omni-sphere cannot be fully omni-directional, but several together can.

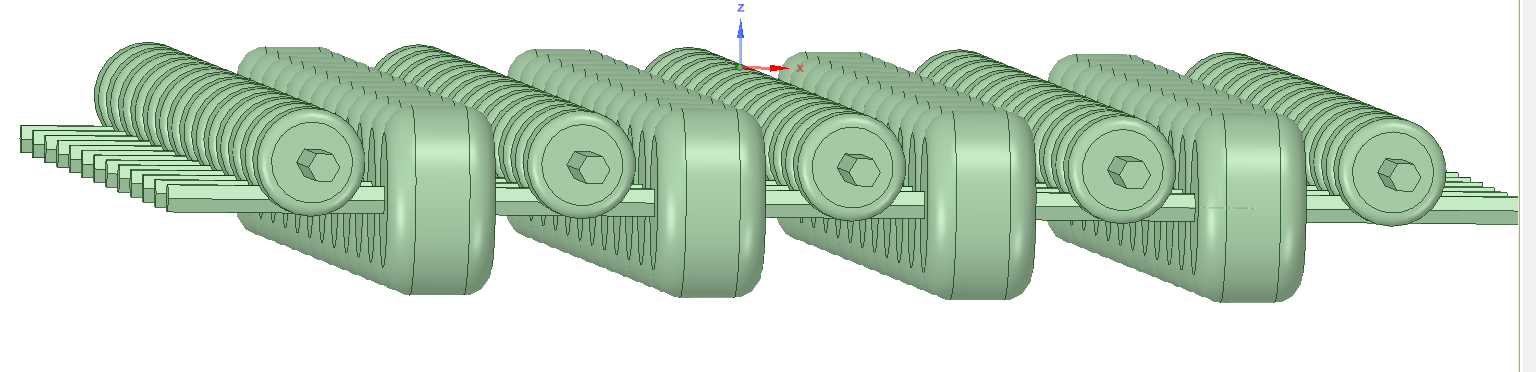

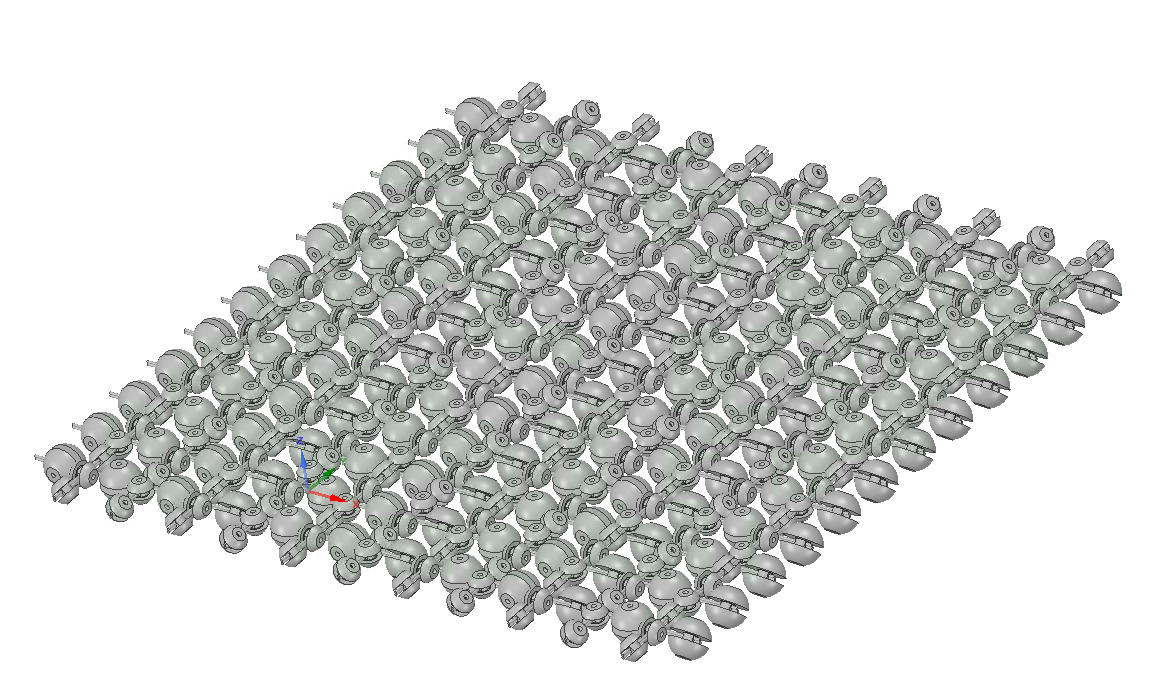

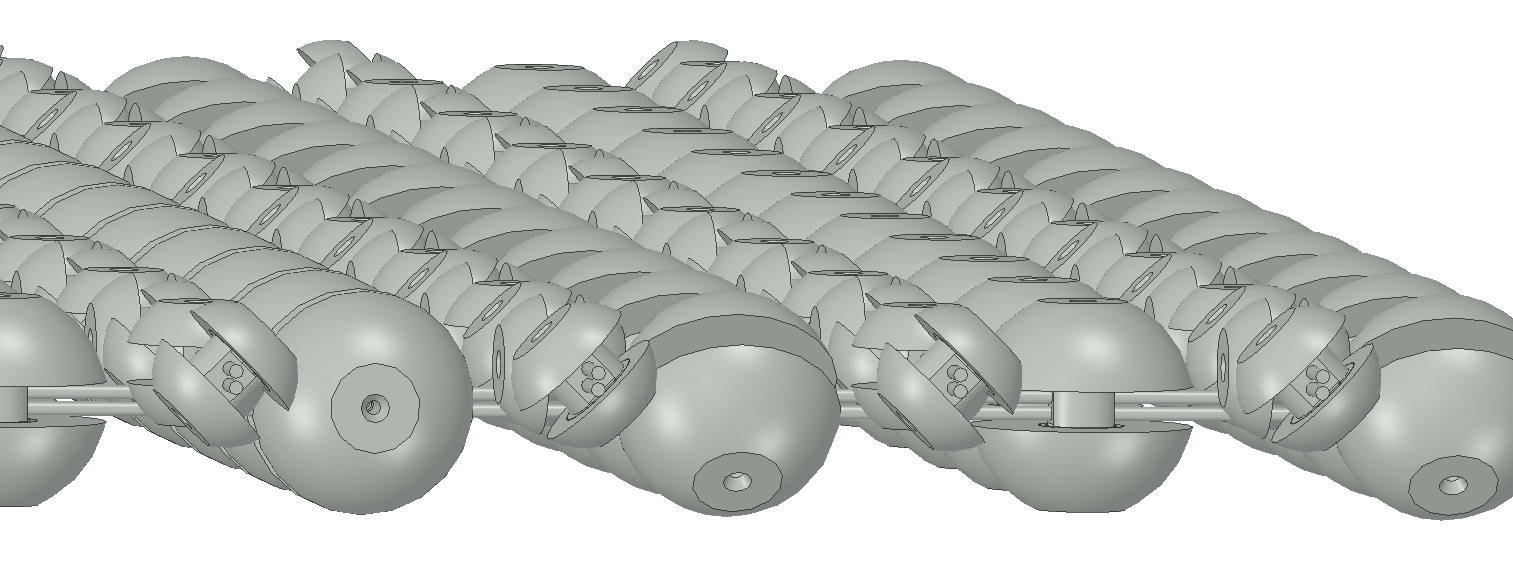

Here is the omni-sphere I designed for the active treadmill. It's a 3ft by 3ft square.

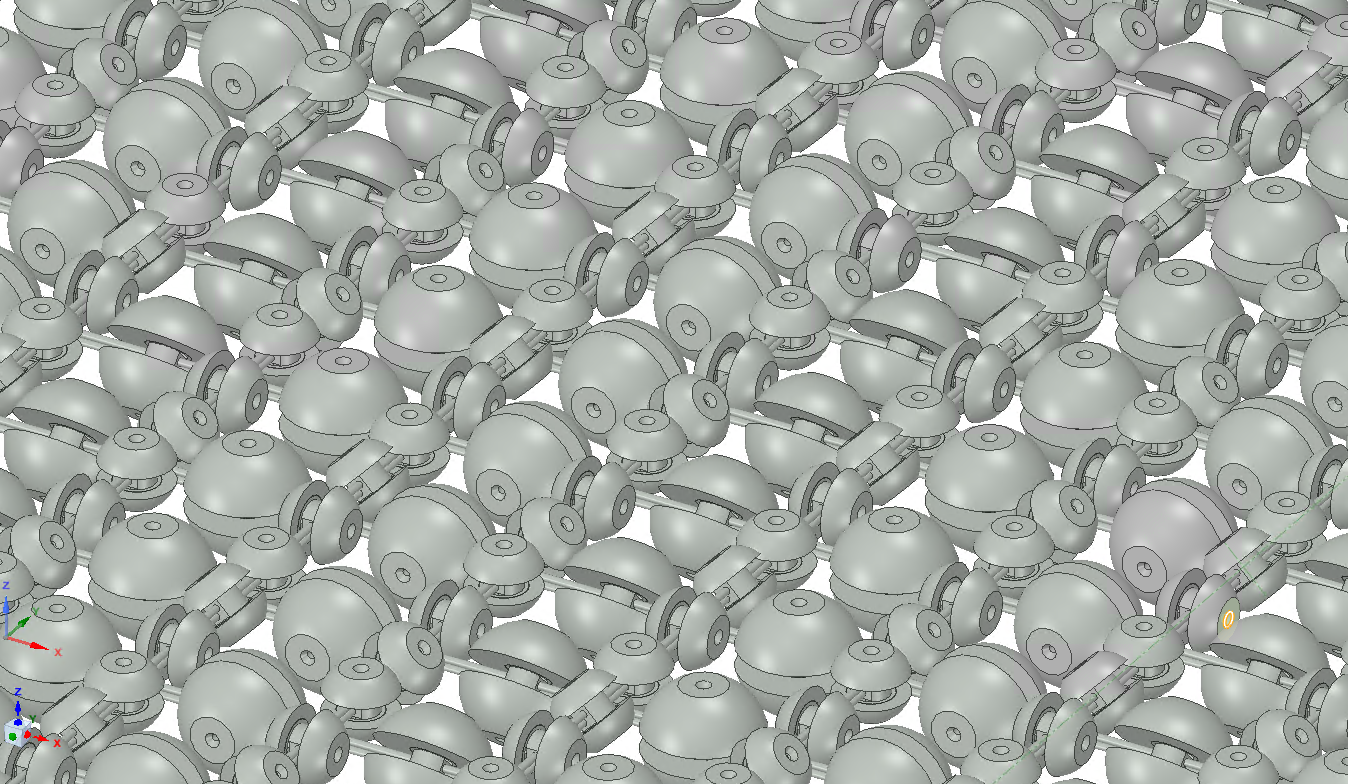

It consists of two hemispheres and a cylindrical coupler that holds them together. The hemispheres rotate on the coupler for idle movement in one direction while an axle can be put through the middle of the coupler to active powered movement in the direction 90 degrees from the idler direction. In this design I actually have two smaller axles going through the coupler to eliminate the need for a set screw or a square or hex rod. Round rods are generally cheaper and more widely available so I wanted to use them, but didn't want to deal with a set screw.

Additionally I added a tube that fits around the cylinder that the hemisphere can slide on. This tube can be made of a low-friction material such as PTFE (Teflon) or maybe even a the widely available 3D printable material TPU. Of course, if you wanted an even better low friction solution you could design the omni-sphere to use bearings instead, but I wanted to make them as low-cost as possible so I left bearings out.

The spheres are of different diameters like before so that the axles don't collide. You can see that the omni-spheres are rotated at different angles so that true omni-directional motion can be achieved. The idea is that adjacent pairs of spheres are arranged so that one of them supports the foot during the angular interval when the other sphere is close to its pole where it can't easily rotate. There is also the flat part on each hemisphere so that when the ball is at the point where it can't rotate at all, it will be below the platform's plane.

After creating the design I calculated how much the components would cost. I created an excel spreadsheet, which you can find linked to this project, and came to a cost of around $350, assuming the cheapest 3D printer filament would be used (the cheapest I could find was $16 per 1kg). Keep in mind that the $350 cost is only for the components for the basic concept. It does not include the cost for the motors, electronics, frame and supports, safety harness, etc. Still, I'm guessing that if you'd include the cost of all those things, and also even include the cost to have bearings in each omni-sphere, you'd get a cost that is still under $1000.

$1000 or under is a lot cheaper than the $40,000 needed to buy an Infinadeck. The $40,000 is the selling price, so maybe the BOM cost is, lets say half of that, $20,000. Still significantly cheaper. My concept would also most likely not suffer from inertia problems since the components are light and you can add as many motors as you want to combat inertia. My concept is also something your average maker with a 3D printer could easily build.

In conclusion, I believe my concept has many advantages over other active omni-directional treadmills that exist today. It's not exactly cheap by consumer standards, but it's much cheaper than existing solutions, except for maybe Strider VR, but I don't know how much it costs to make. It's also something any maker with a 3D printer can easily build. It uses light components that should eliminate inertia issues. Lastly, it can be scaled to any size and additional motors can easily be added for more power.

I am currently working on my VR shoes, but I may come back to this concept and build it myself in the future. If anyone builds this or expands on it I'd love to see what you come up with!

Design files are available on my Github.

finallyfunctional

finallyfunctional