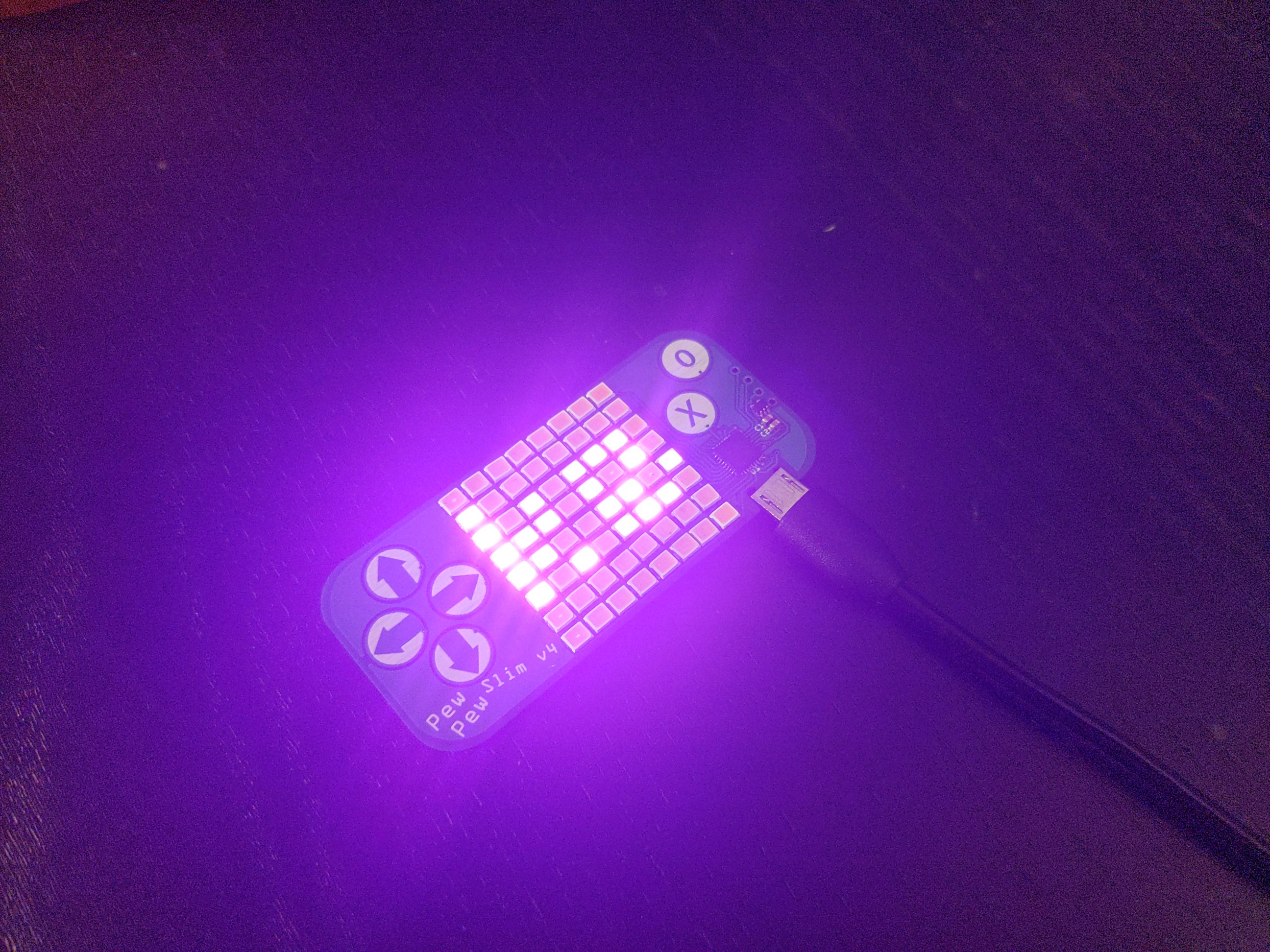

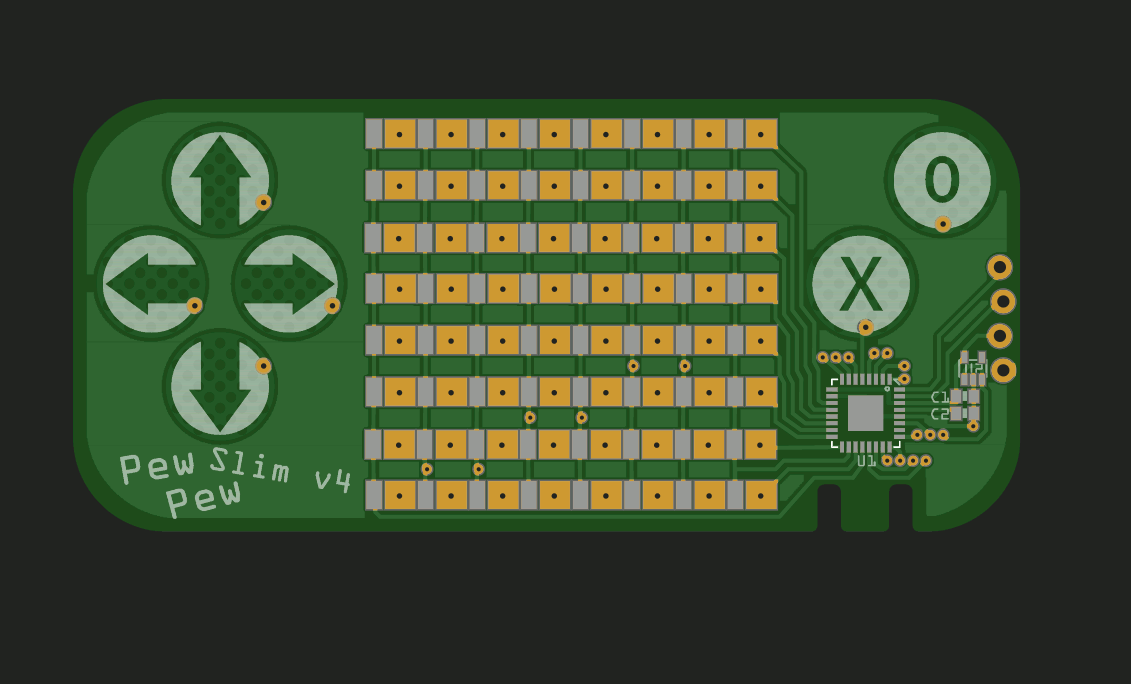

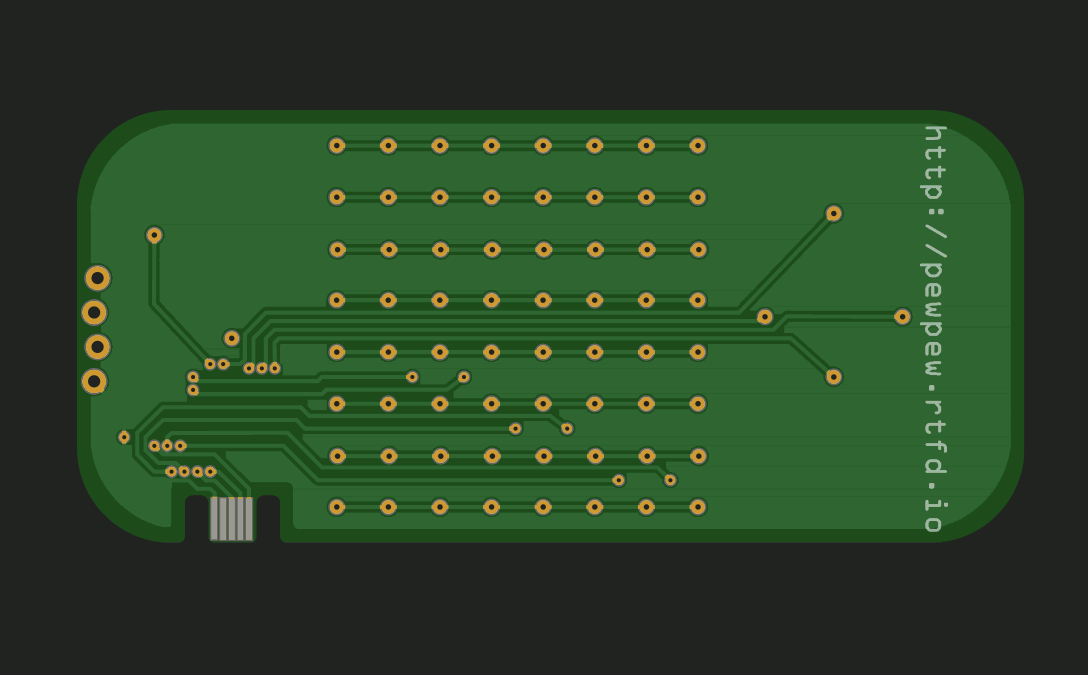

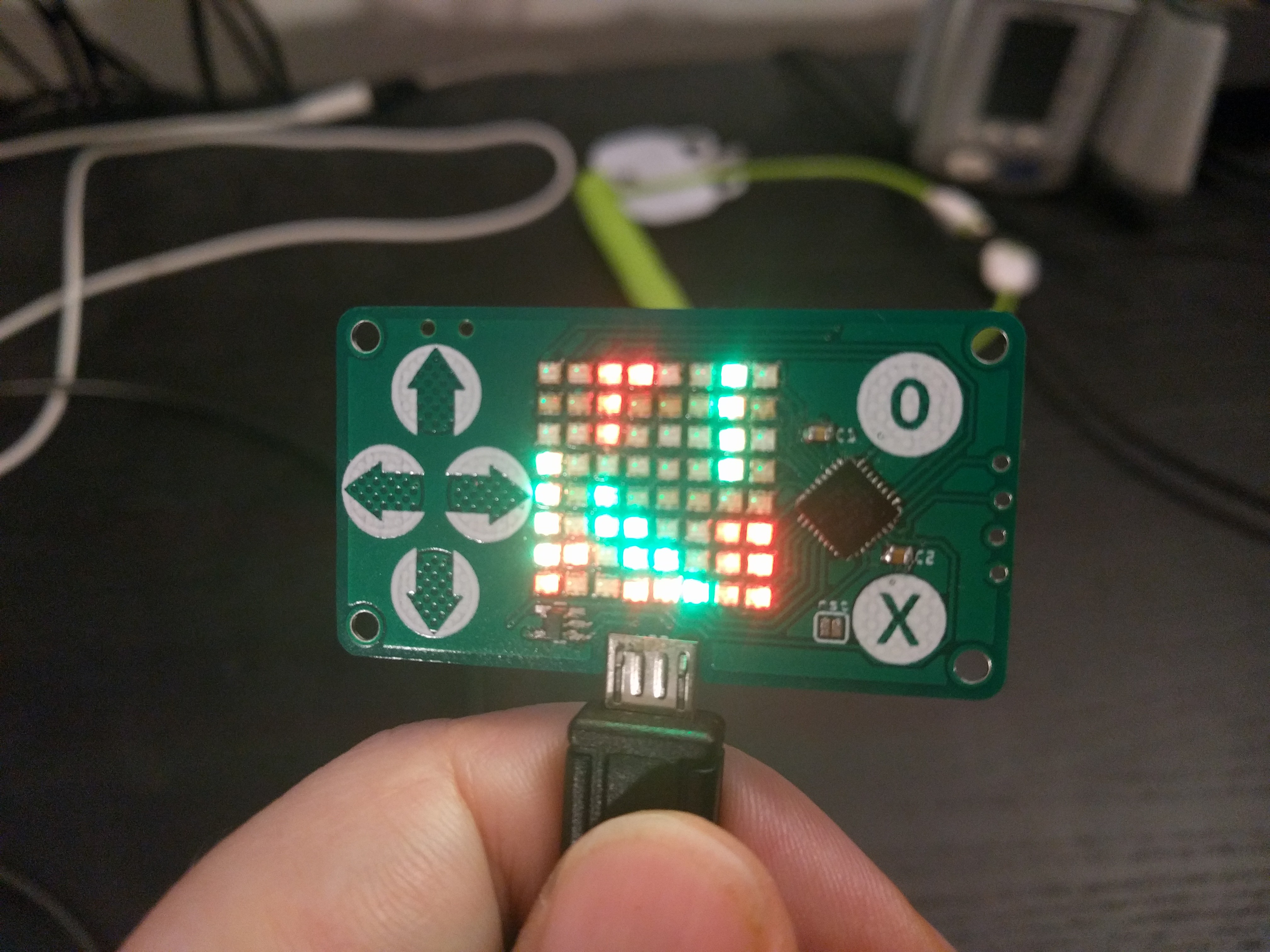

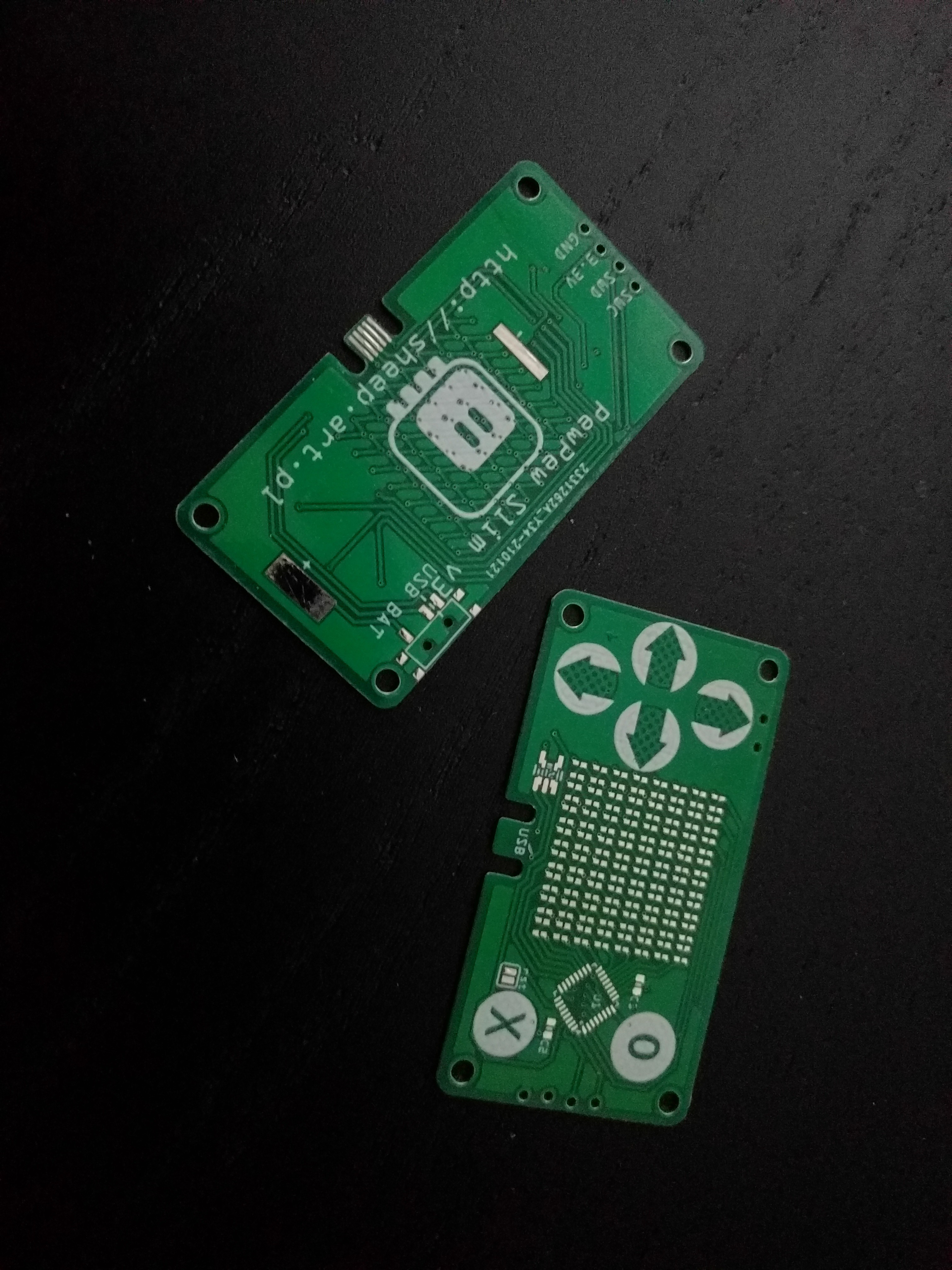

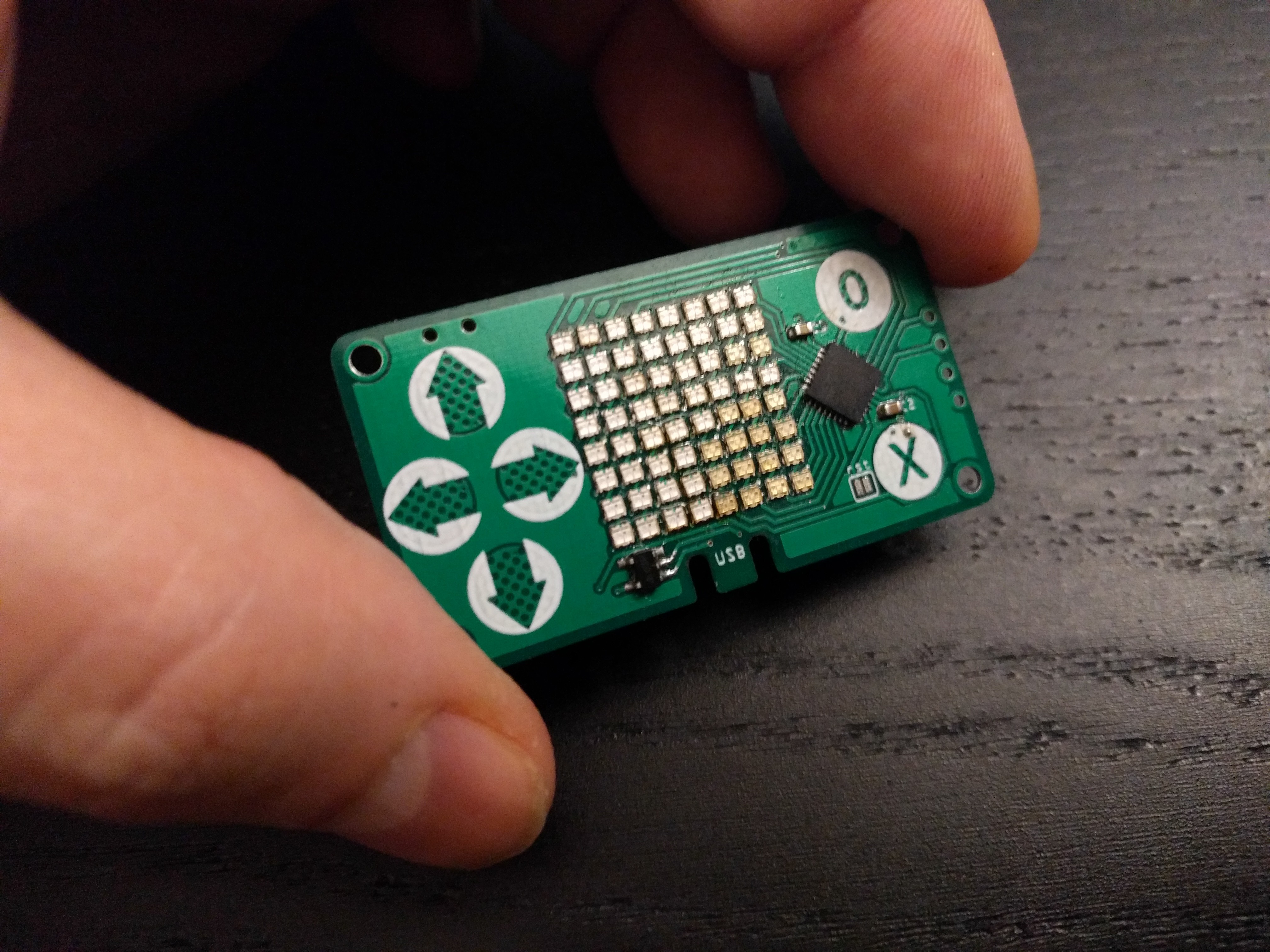

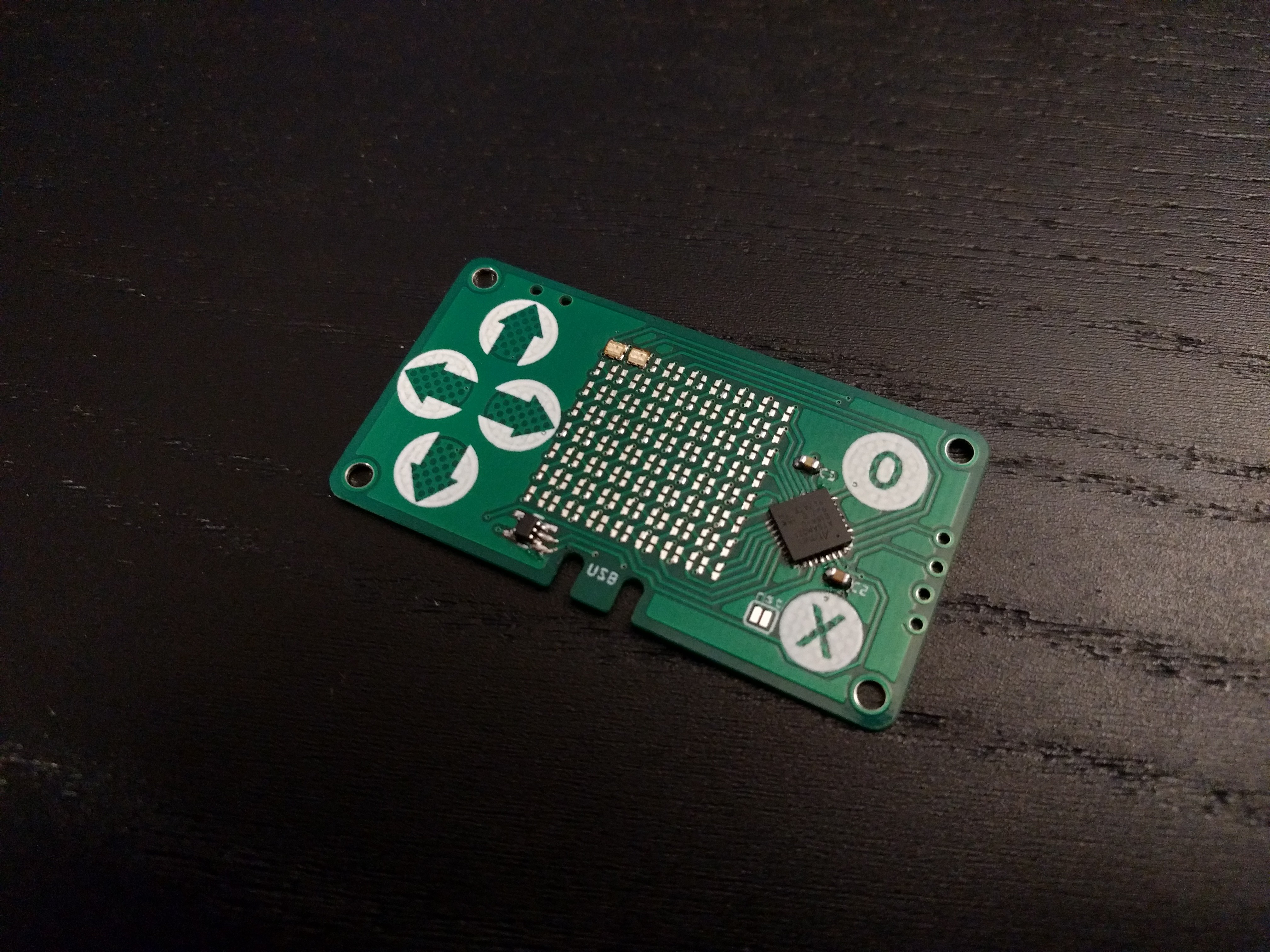

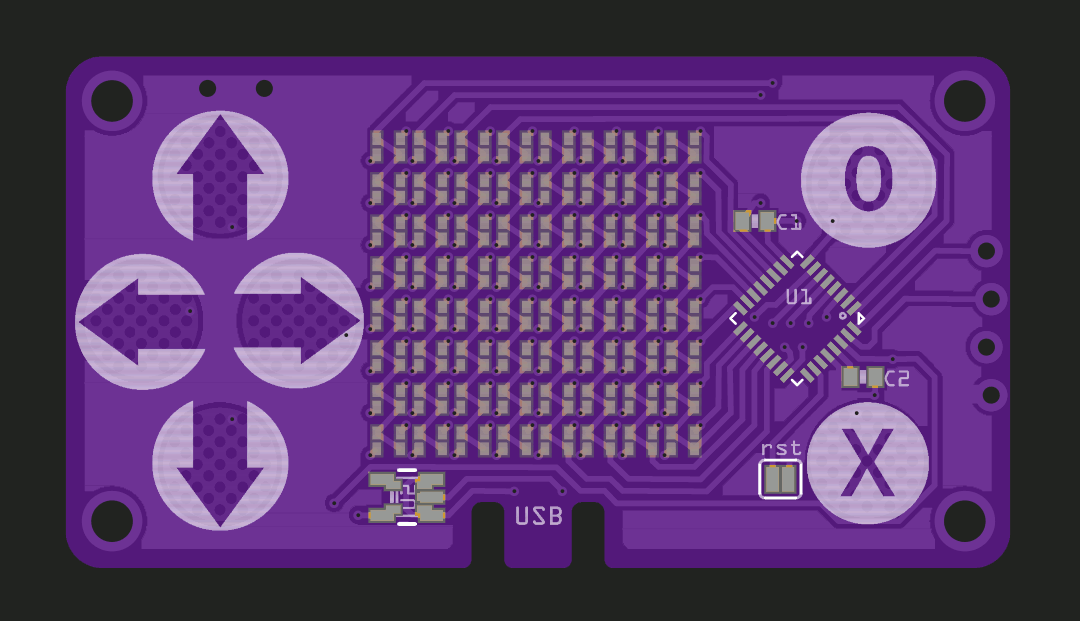

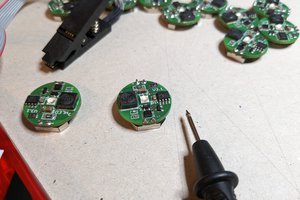

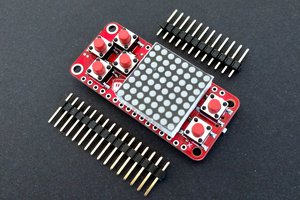

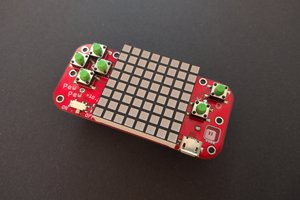

The #PewPew Standalone is optimized for cost, and since that means that you want to do as little soldering as possible, it uses a ready LED matrix as a single component. However, if you instead use discrete LEDs, replace the buttons with touch pads, the USB socket with a 0.6mm thick PCB cutout and drop the battery and power switch, you can get something really thin — below 2mm total. Something that could possibly be used as a business card.

deʃhipu

deʃhipu

schlion

schlion

rrace001

rrace001

Awesome stuff my man. I am BiggestGuy and I approve this project.

I reckon if you could maintain this form factor and find a way of implementing user interaction you could create a sort of business-card-sized remote control. With something like a membrane top with metal underneath (in the same sense as a membrane keyboard) it could make for a pretty interesting and ergonomic system that could be paired to other projects.

either way its super cool!