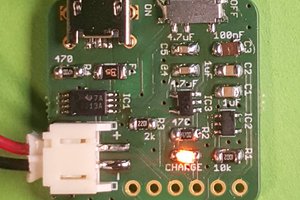

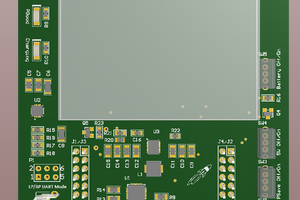

Solar panels connected to power managers with little to no soldering, to a fault.

The purpose of this project is to simply brainstorm a variety of configurations, even ones that aren't even designed to produce power.

Why would I do this?

Soldering is a relatively permanent action to these boards, and I have never even soldered something, let alone de-soldered anything. [Edit: 2/19: I have soldered my first electronic board yesterday- two solar panel leads for a 2V DFRobot Solar Power Manager Manager. While I will do more soldering, this project will continue for prototyping purposes (the discarded or temporary combinations will be posted here]I am more interested in prototyping at this time to test the minimum conductivity of panels without needing to solder anything. Once I determine a useful system, I will look into developing more around a particular set of solar power managers, panels, and batteries, etc. And soldering.

It's not a fear of soldering, but perhaps a fear of having to spend more time de-soldering or buying a new one if some contacts are irreparable.

Another reason is I was able to allow conductivity on 500mA boost converter pass to a Raspberry Pi (connected to a Lipo battery charger and/or a Solar Power Lipo charger) without soldering any USB pins but briefly pressing the contacts against the board on an angle. Prototyping is so brief, the desired results can be achieved in the time it takes to test something. Also the USB contacts could be used on a different board if needed, saving the materials in the process.

Giovanni

Giovanni

davedarko

davedarko

Maso

Maso

Just to throw one more in...

https://youtu.be/ycFTxCoNAQk

Also, while I've known Big Clive to be a bit dismissive of the 'joule thief' concepts suitability in applications beyond that of momentary hobbyist flashlight fascinations, I think there may be merit in using a particularly beefy one with a massive smoothing-cap setup and a regulator of some basic sort, to power something like this. It would not be hard to cobble together a sort of 'doomsday supply' with such, along with a few scavenged solar panels, an old motorcycle battery or two, and a 'vibrator' regulator, to get a crude but effective power supply for a portable PC if the power demands were kept reasonable.