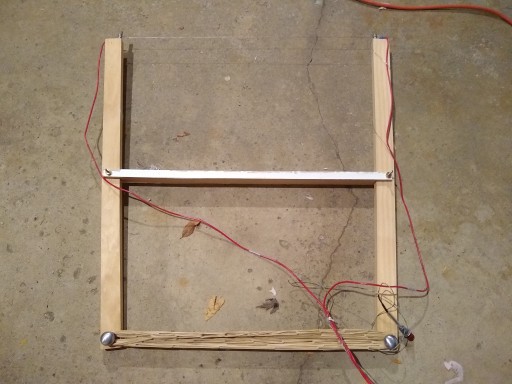

The bow is a simple affair, just a frame which can mount and keep under tension the cutting wire. It will have a switch that can remotely turn the supply output on and off.

I used some 1x2 scrap lumber, cutting slots in the ends of the central piece to make hinges and an H frame. Some long machine screws with knobs make for easy adjustment.

Tension is provided by an elastic cord on the back side, pulling the outer pieces together. I used a couple old drawer knobs as hooks. I didn't have long enough/strong enough elastic cord, so for first tests I folded what I had into 4 parallel strands, and used twine with loops tied into it to make up the distance. The loops, about 1 every 2 inches, allow for easy tension adjust.

After some testing, I found that while it worked, more tension was desired. Thicker elastic cord would be good, though using what I had on hand, I made a rubber band rope, and tensioned it around several times. This resulted in about 20-30 pounds of tension on the wire, which worked great.

To easily attach the cutting wire, I used a pair of old ground binding posts. These are all metal, so generally only useful in electronics for a ground point. But here, mounted in wood, and not concerned about shielding, they can easily be put to use.

One note about using binding posts is how you attach the cutting wire. While I did line up the wire holes in the posts, I'm not going to use these. Using that and tightening the post creates a somewhat sharp edge the wire is pressed against. This makes that point weak and more prone to snapping the wire. Instead, I wrap the wire around must under one turn and tighten. This prevents the possible breaking point. However, if doing this, you need to attach the wire in the correct direction. From the main length to the tail, it needs to go counter clockwise. This way, tension on the wire will tend to tighten the post, not loosen.

For wire, I had some old heating coils from a scrapped thermal chamber. I estimate this to be about 21 gauge nichrome wire. It measures 0.81ohm/ft. It was wound into coils, and mounted in a frame on ceramic bushings. To mostly straighten it, it was a simple matter of sliding a rod through the center of the coil, then pulling perpendicularly at an end. This unwound the coil as I went, and now have an easy bundle to work with. Alternatively, nichrome wire can be easily ordered online for not too much.

For the power leads, I terminated then with round crimp connectors that the binding posts mounted through. Then simple drew then together and did a natural twist to keep them paired. For convenience, I put a dual banana plug on the end.

The remote control is a simple round pushbutton, with a pair of wires attached and protected with heat shrink. This also got twisted around the power and a banana plug on the end. I might mount the switch on the bow once I determine the best way to hold it while cutting.

I made two central poles. One with a nominal 24" span, and one with 42". You can use the larger one for smaller cuts, but it is much easier to manipulate the smaller one. The above picture shows the smaller one.

Quinn

Quinn

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.