This project is modular, meaning some of the modules may be of interest for other projects.

The 100v DC booster can be modified for use with a Nixie clock.

The main amp board is the only thing needed and a 12v supply for listening to music, all the other things are optional.

There was a lot of info that I already wrote on my blog and info is availble on YouTube, see the links on the left for more info.

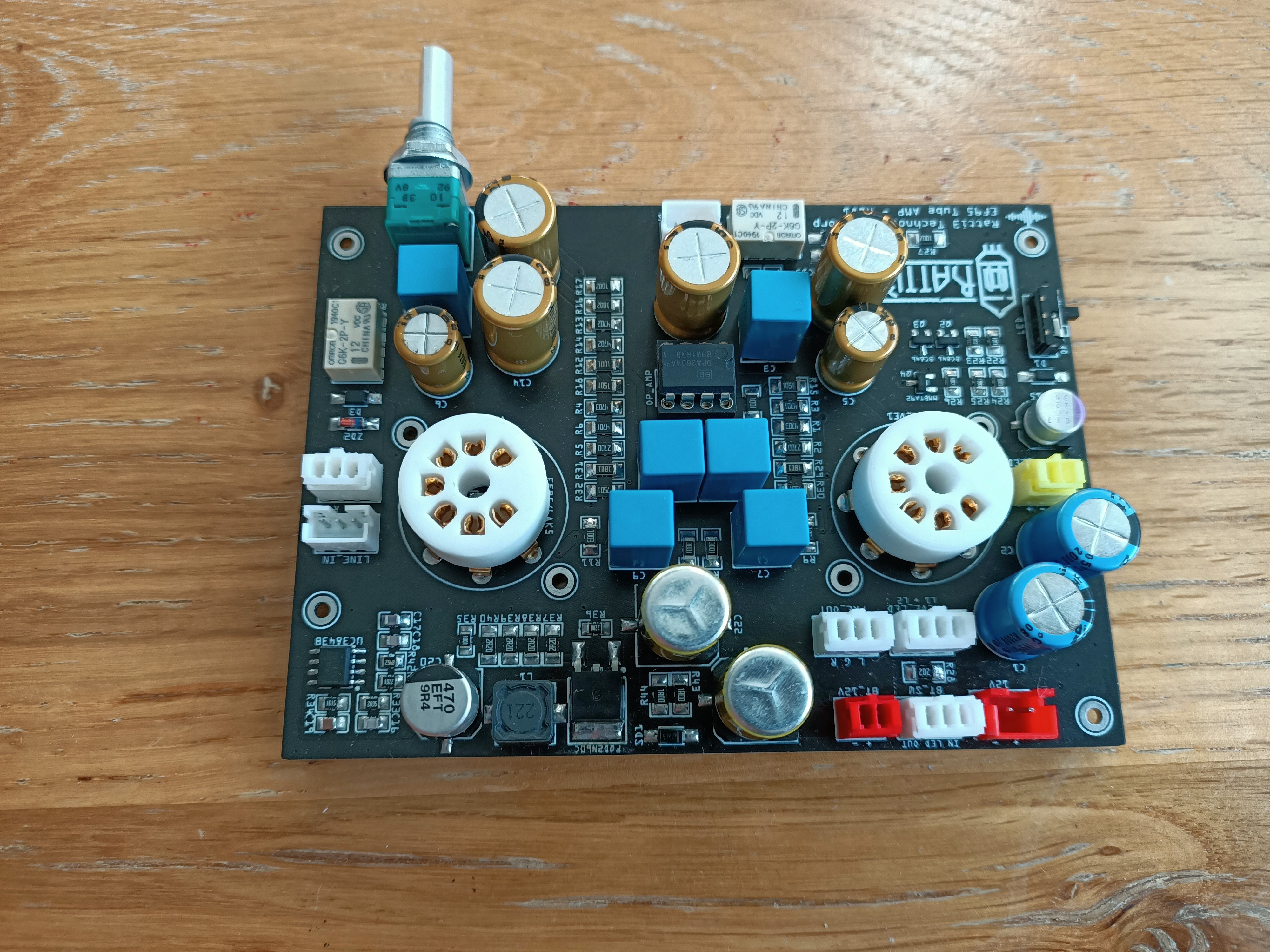

The valves are EF95/6AK5, so you can use GE JAN 5654W or similar, the valves do the initial amplication before an opamp is used for the headphone amplication.

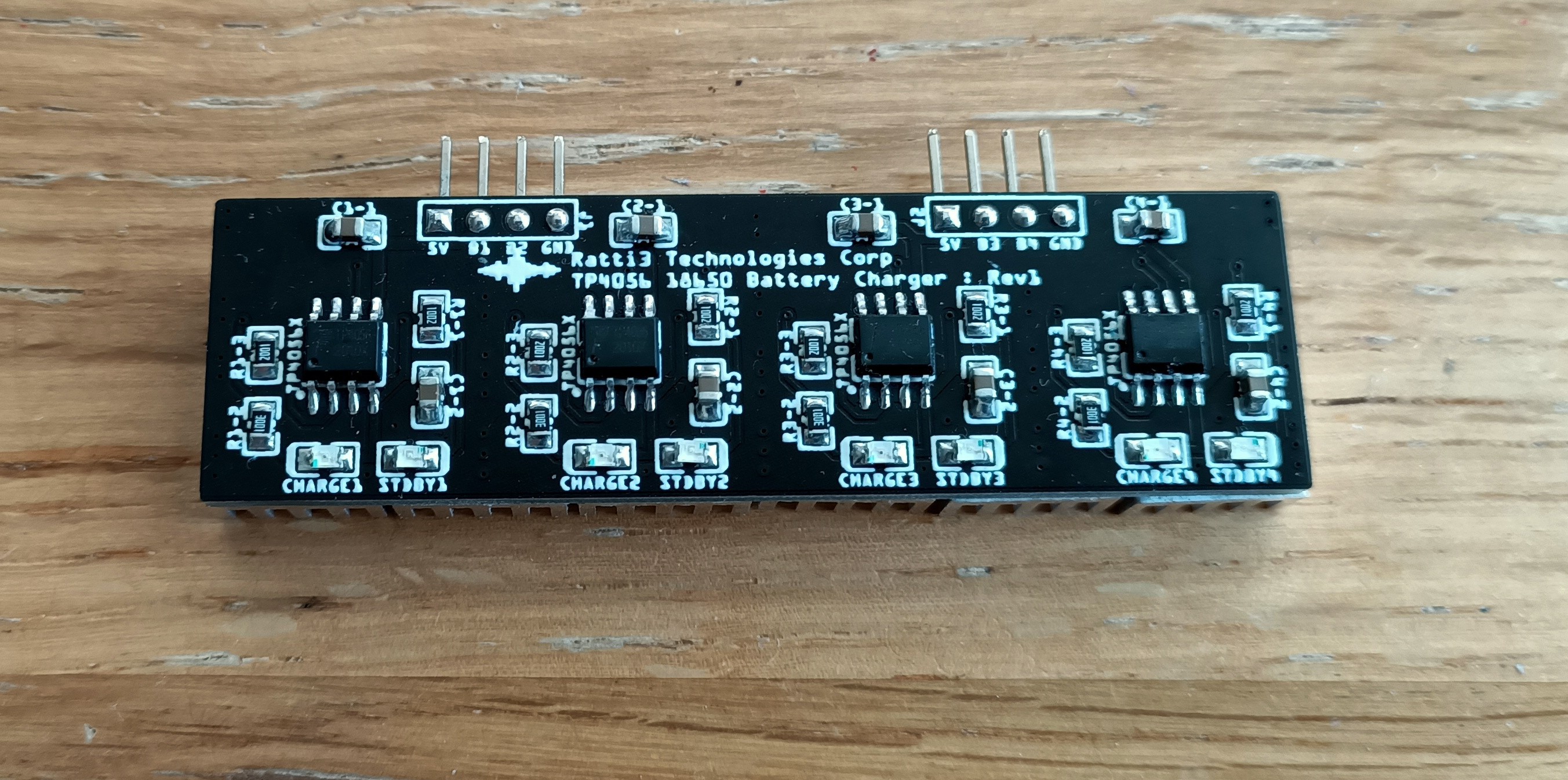

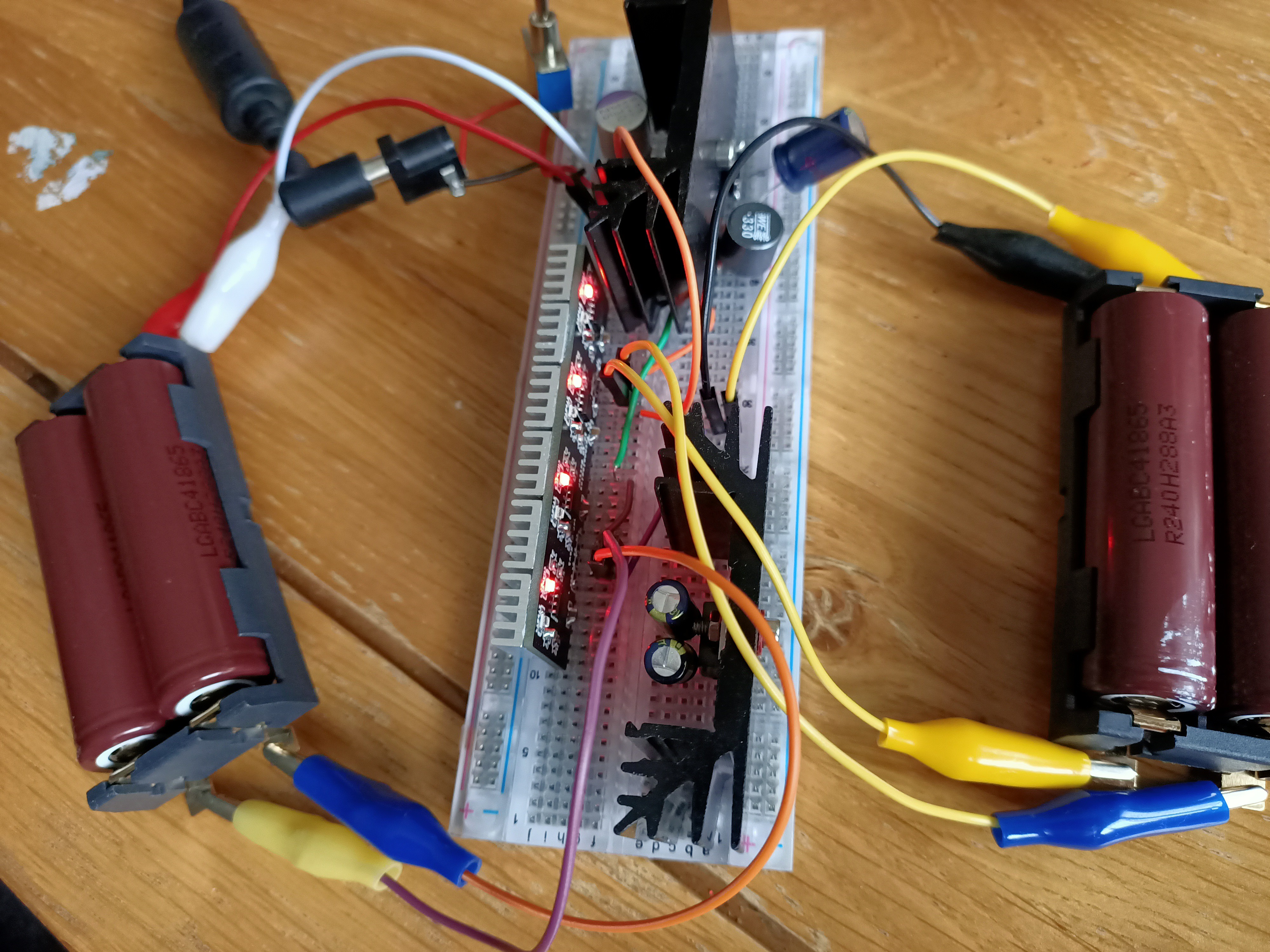

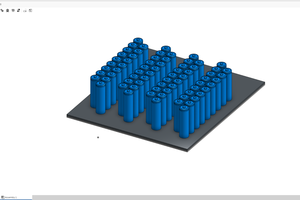

The battery charging is done via four TP4056X modules, I decided to make this board myself as I believe the modules on ebay are fake or cheap clones, the TP4056X is the latter revision of TP4056. The IC cuts off at 4.2v and can charge at a maximum of 1Amp, I've limited this to 580mA.

To keep the heat low as all four ICs are on the same board I supply an input voltage of about 4.6v and have several heatsinks on the board. The temperature of the board reaches between 50-60 degrees which is acceptable.

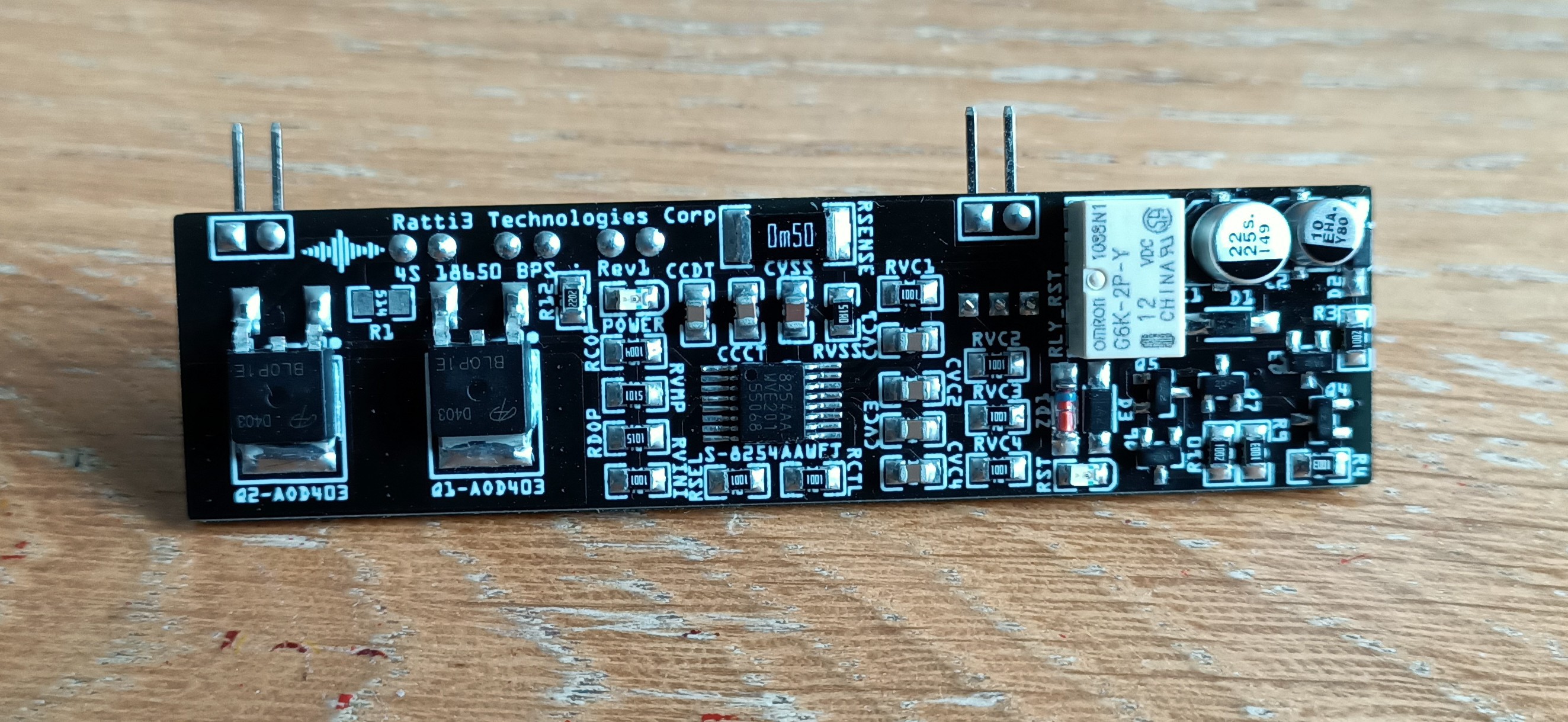

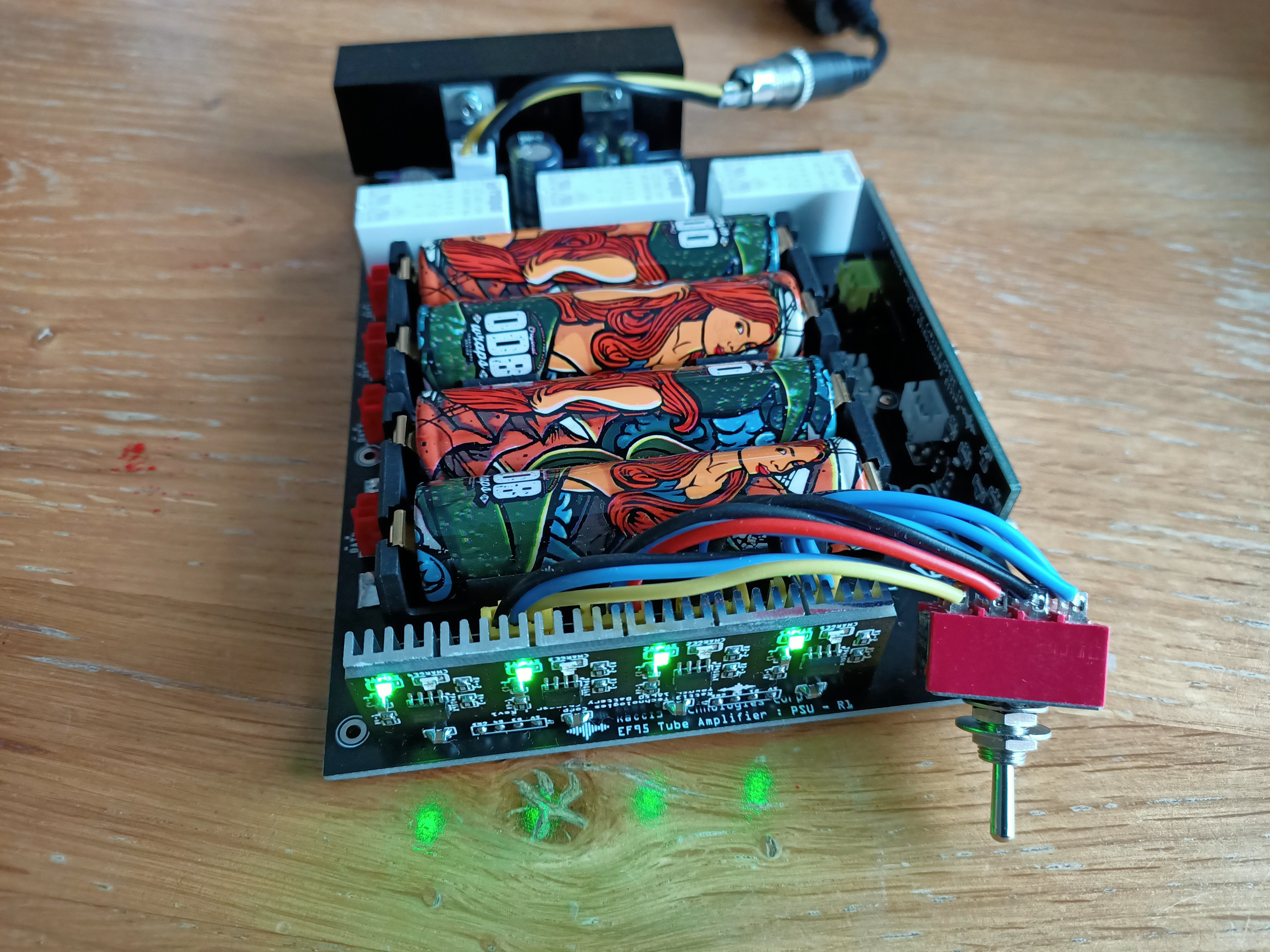

Battery protection is done via the ABLIC S-8254 IC, is cuts off if the battery voltage drops below 3V, I designed the protection board so it auto activates/enables when the batteries are connected.

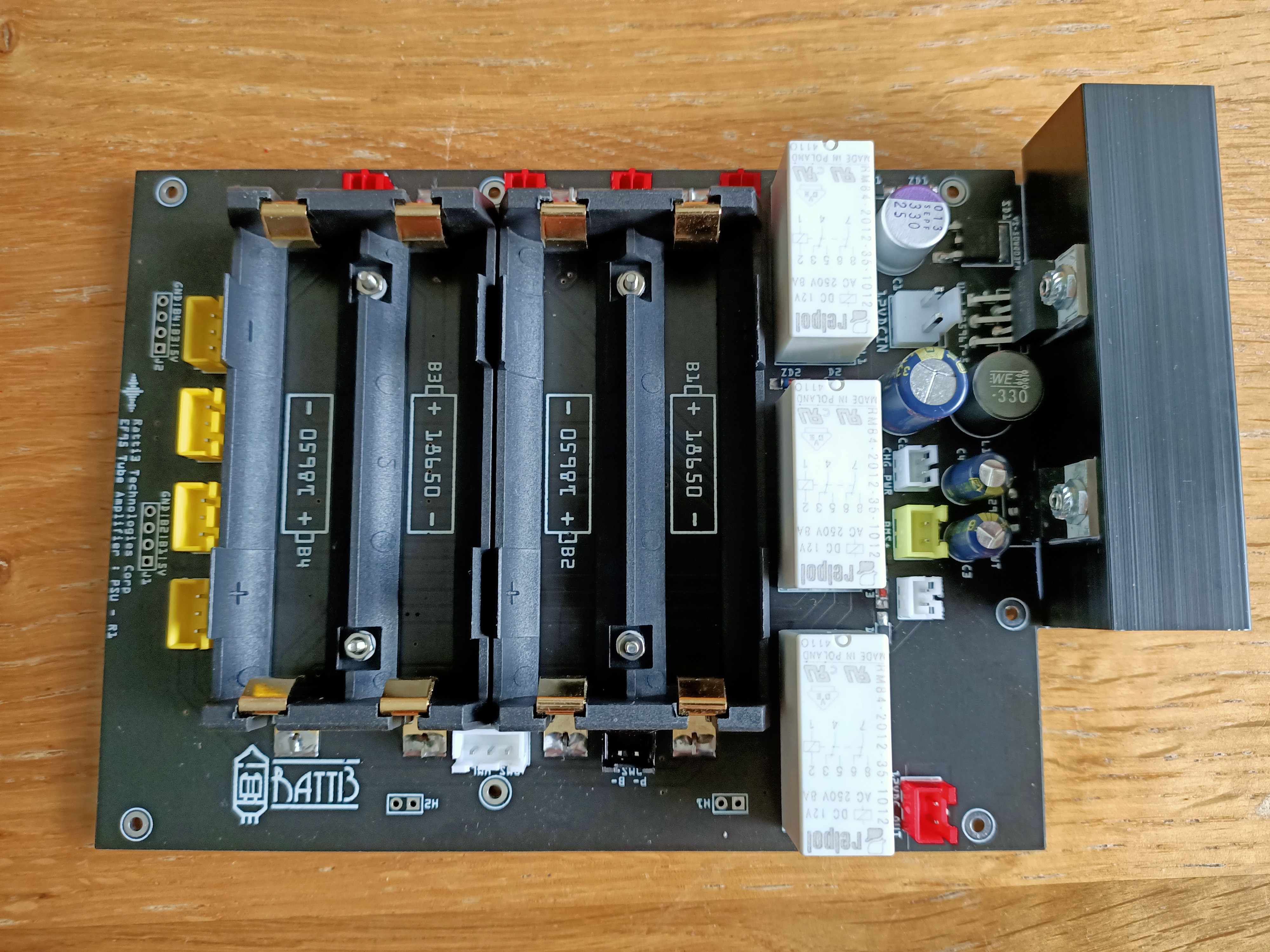

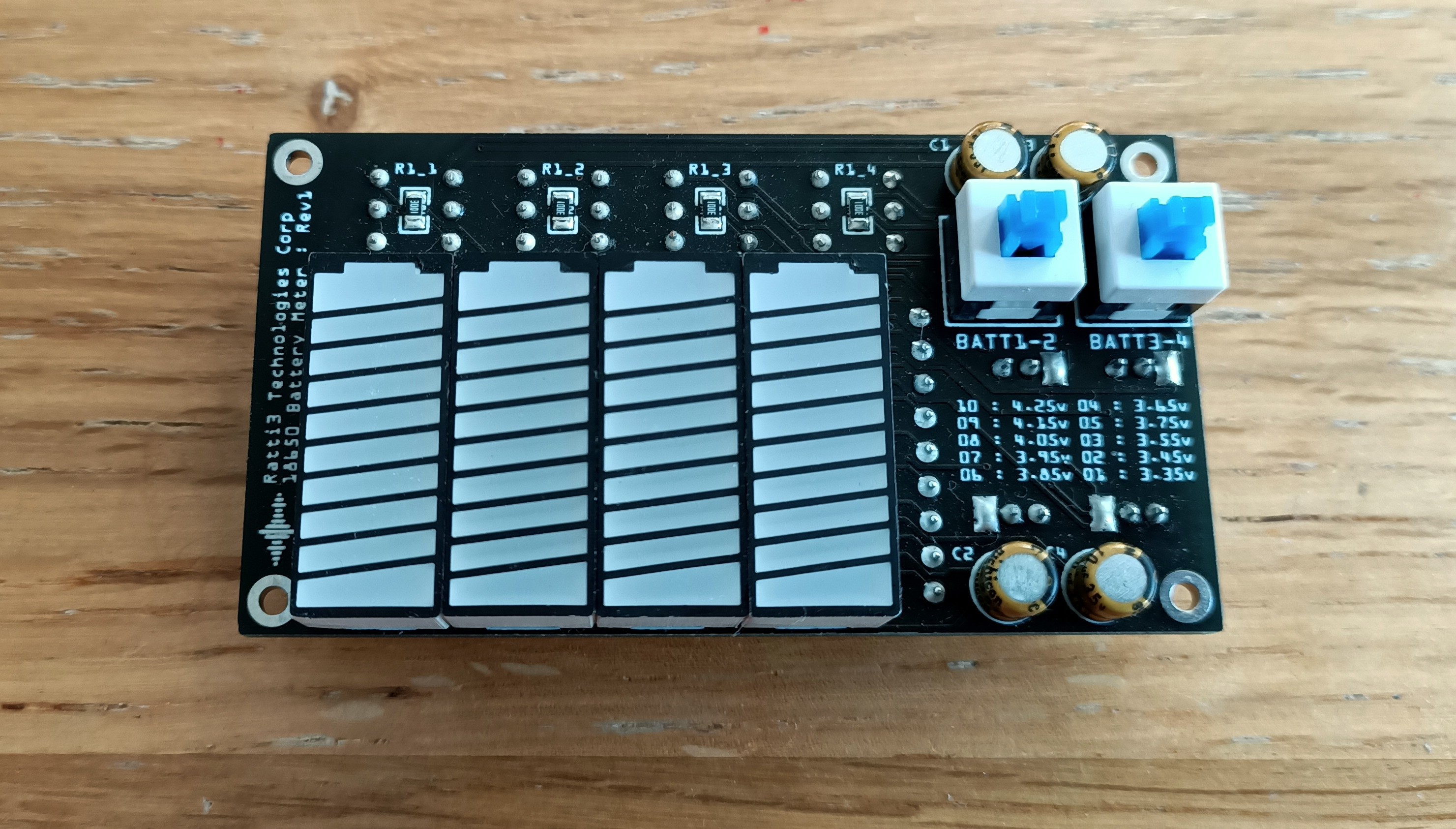

Battery monitoring is done using four LM3914 modules, battery levels are visually shown for each battery on four LED bargraphs. This module can be calibrated to set the low and high battery voltage.

The high voltage DC boost is done using the UC3843B IC, the circuit takes 12v and boosts to 100v, this can be adjusted at the time of soldering components by changing the feedback voltage divider resistors. In hindsight I could have designed this better with better HV to LV seperation, better choice of mosfet and inductor and getting rid of the extra output filters.

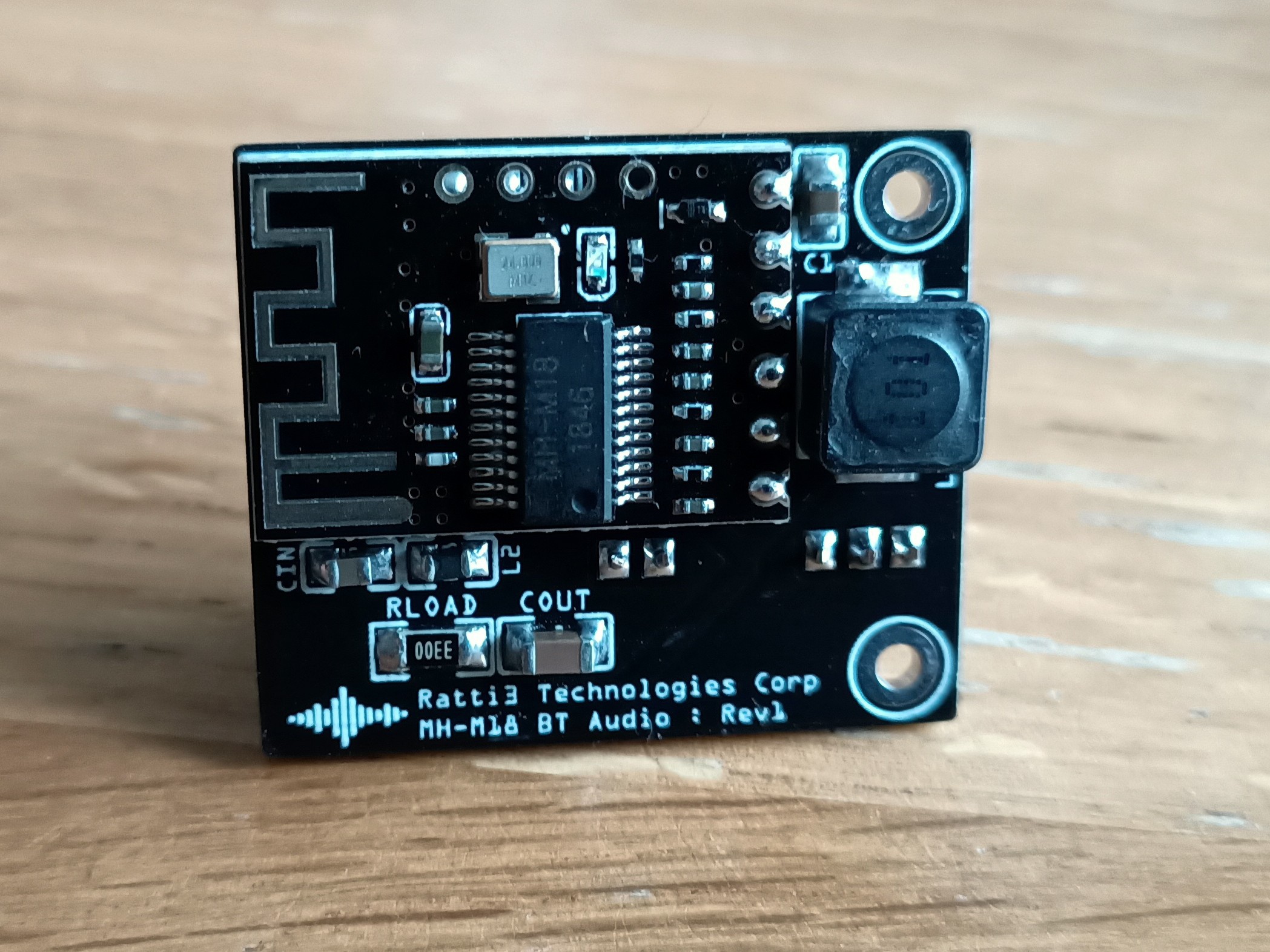

The bluetooth module is the only thing I did not make, I did make a breakout board for it, as I had to use an DC-DC islolator to get rid of the ground loop.

There are two voltage regulators on board, one for charging the battery which is a switching buck convertor and the other is a linear convertor for converting the 4S 16.8v to 12v.

I noticed this was featured on the Hackaday.com site, for some reason I was unable to post my replies.

I'll try and answer some queries here:

No this is not a hifi amp, I've seen many pointless discussions about solid state vs tubes.

I made this for nostalgic reasons, however I was surprised by the quality I use it frequently now. Tubes are meant to add distortion.

I only have Sony MDR-1R and a Master & Dynamic MW60 headphones, both are 32ohms, they play very loud at about halfway up, too loud to listen but I noticed no distortion.

I believe based on other op amp amplifiers this will probably struggle to output to headphones that are >150ohms.

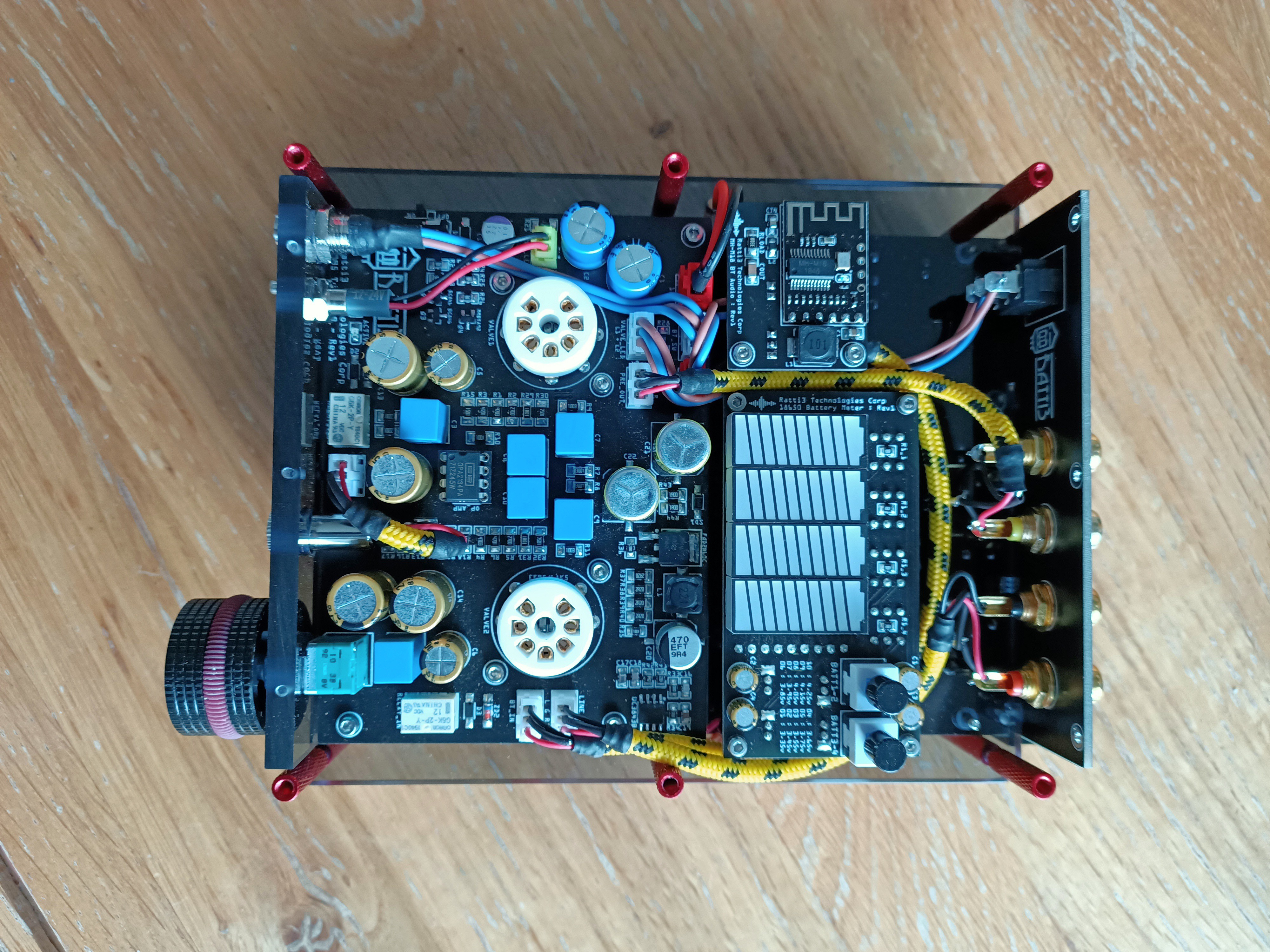

The amplifier is made from the following components:

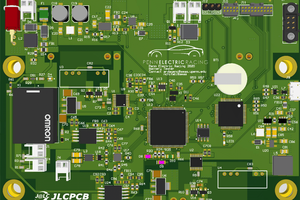

The main amplifier board, this can be used as a standalone ampliflier, you just need 12DC, line in and headphone out:

Next we have the 4S Battery board with the voltage regulators and battery monitoring/switching connections:

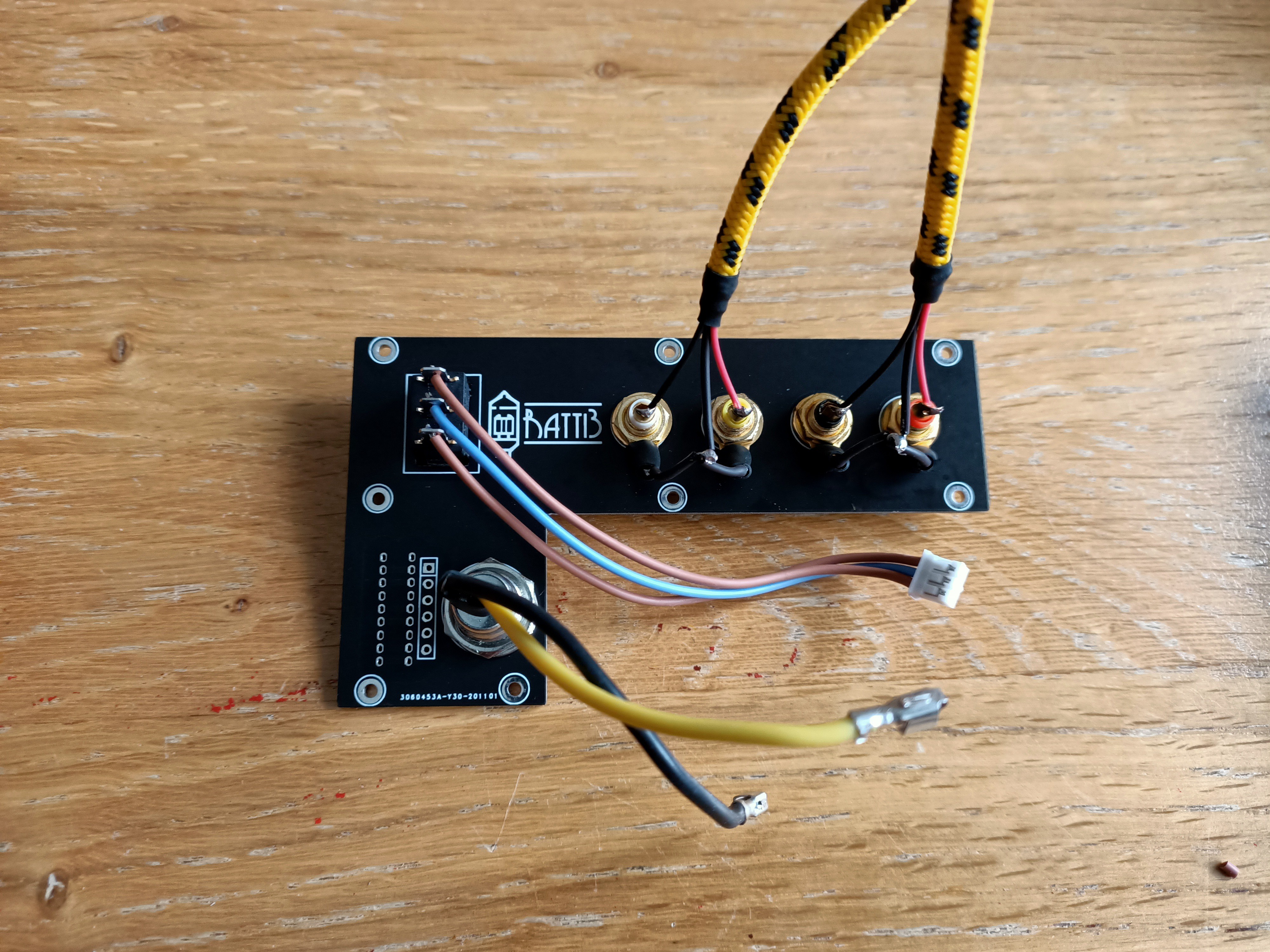

This is the 4S Protection Board:

This is the TP4056X Charging Module:

LM3914N Battery Level Indicator:

MH-M18 Bluetooth Module:

Ratti3

Ratti3

Hulk

Hulk

AVR

AVR

AirCruiser

AirCruiser

Looks fantastic, I'll check out the videos to hear how it sounds. Nice work, thanks for posting!