* NOTE TO THE READER *: Due to a text size limitation of the Hackaday. io site a few chapters have been moved to "Log files". In this case you have just to click on the link of the chapter's title to open a new tab and read it.

* * PROJECT STATUS (18/04/2023) * *

HW:

- Released all the HW related files (see the FILES section);

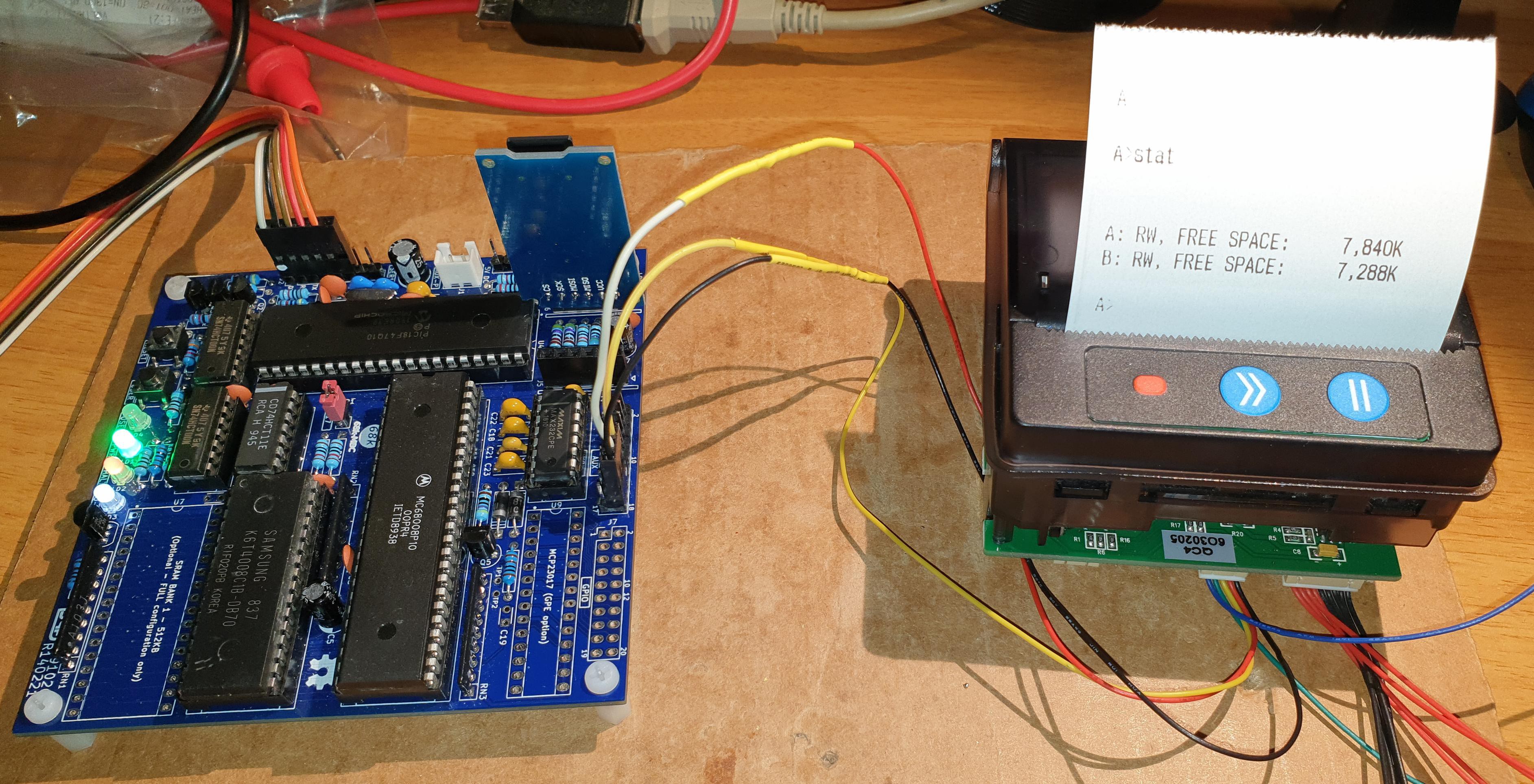

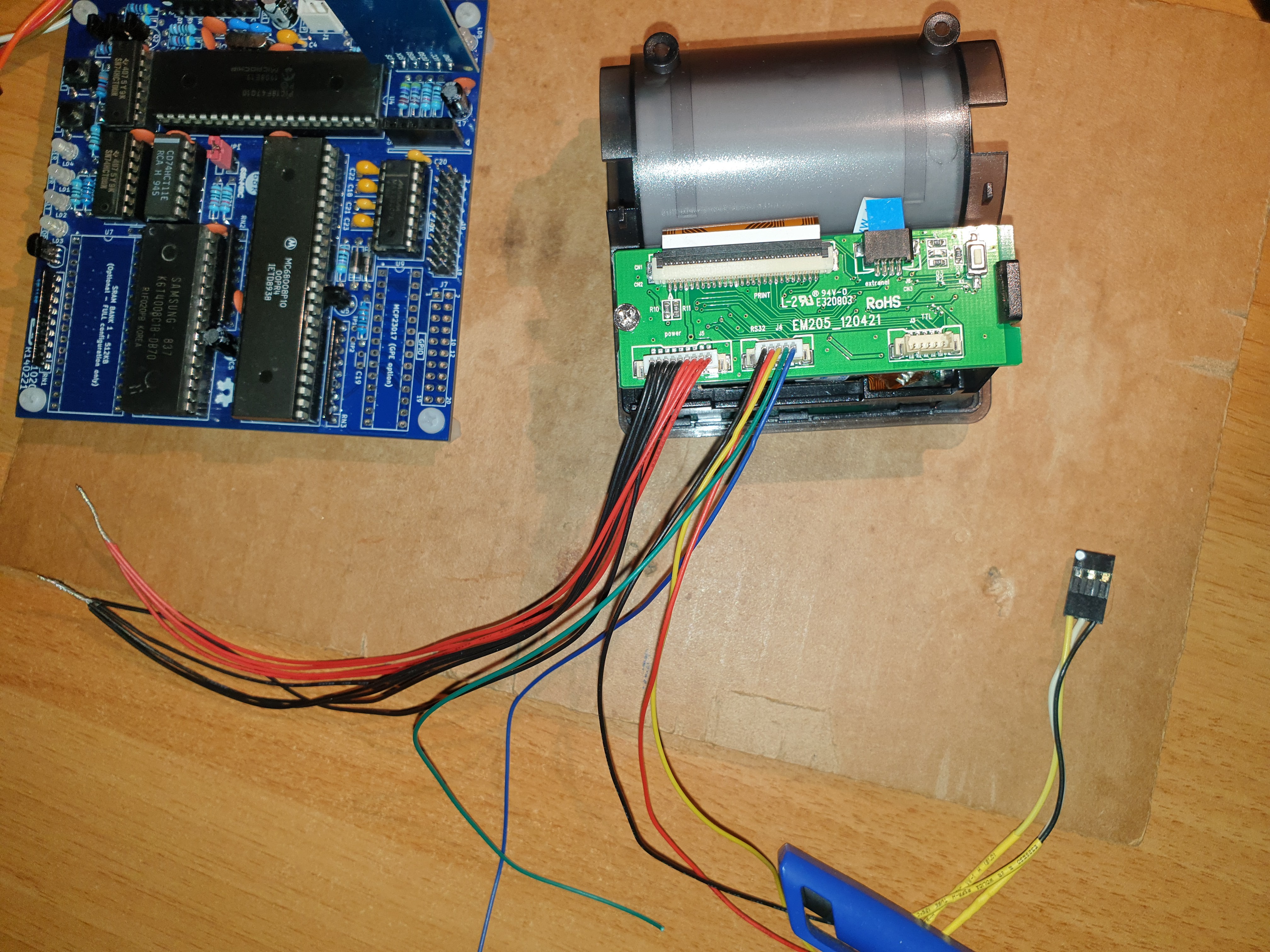

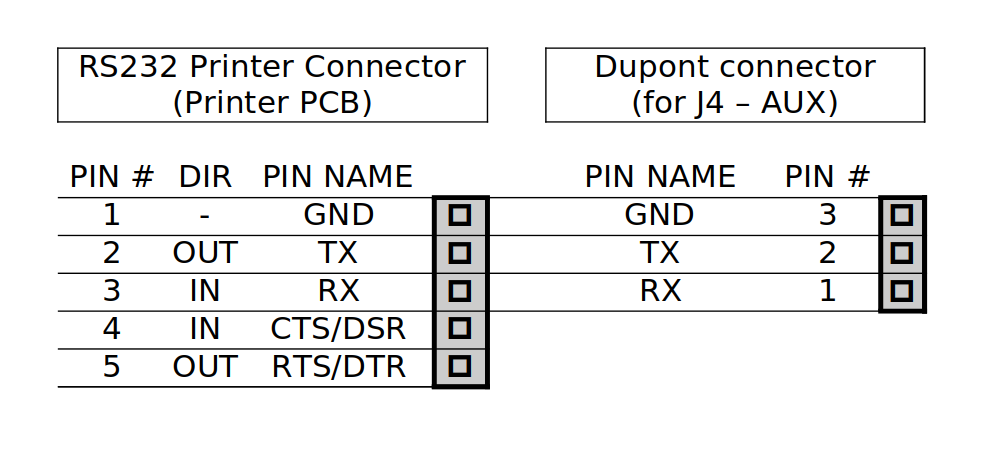

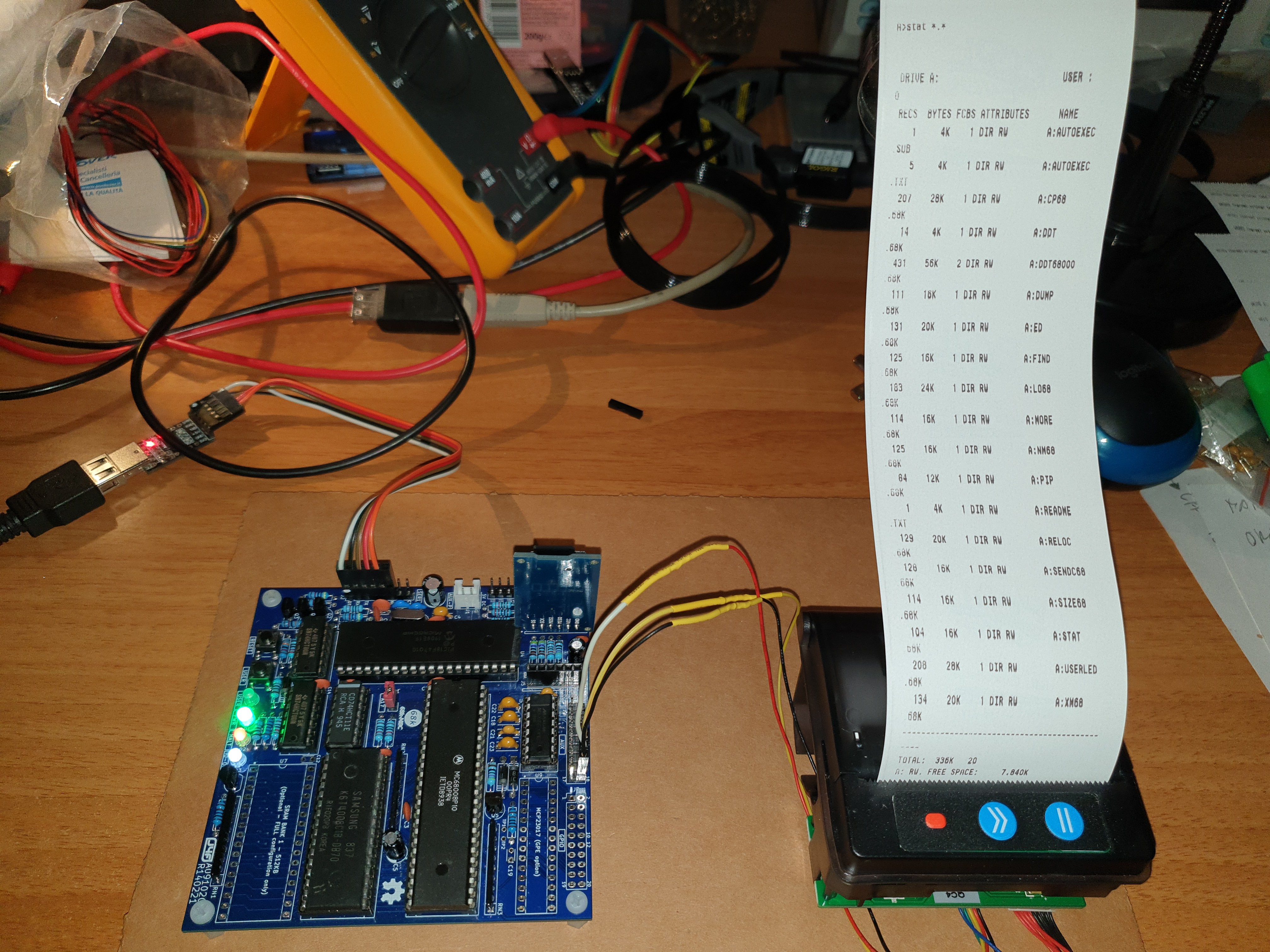

- Added the USING A SMALL THERMAL PRINTER chapter;

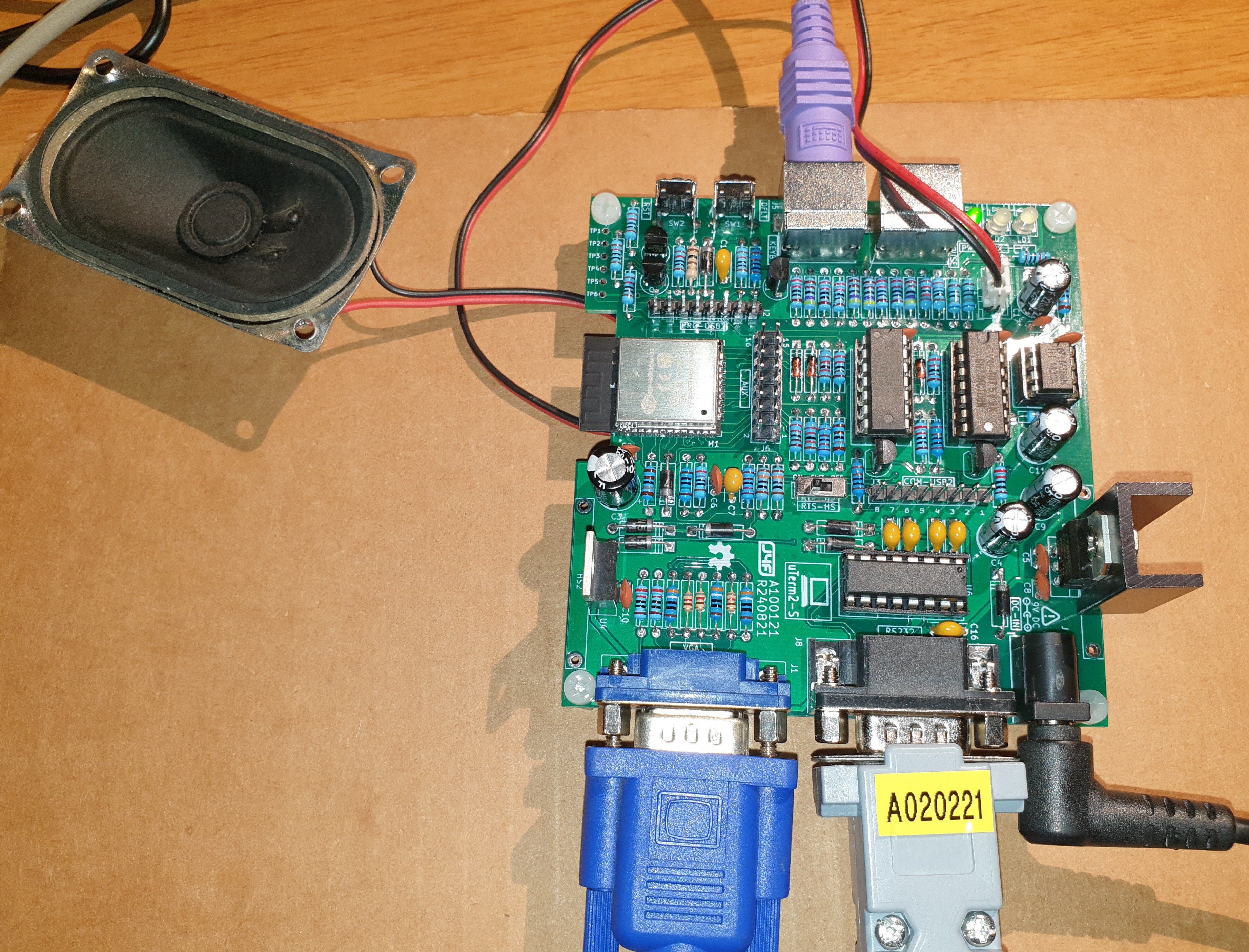

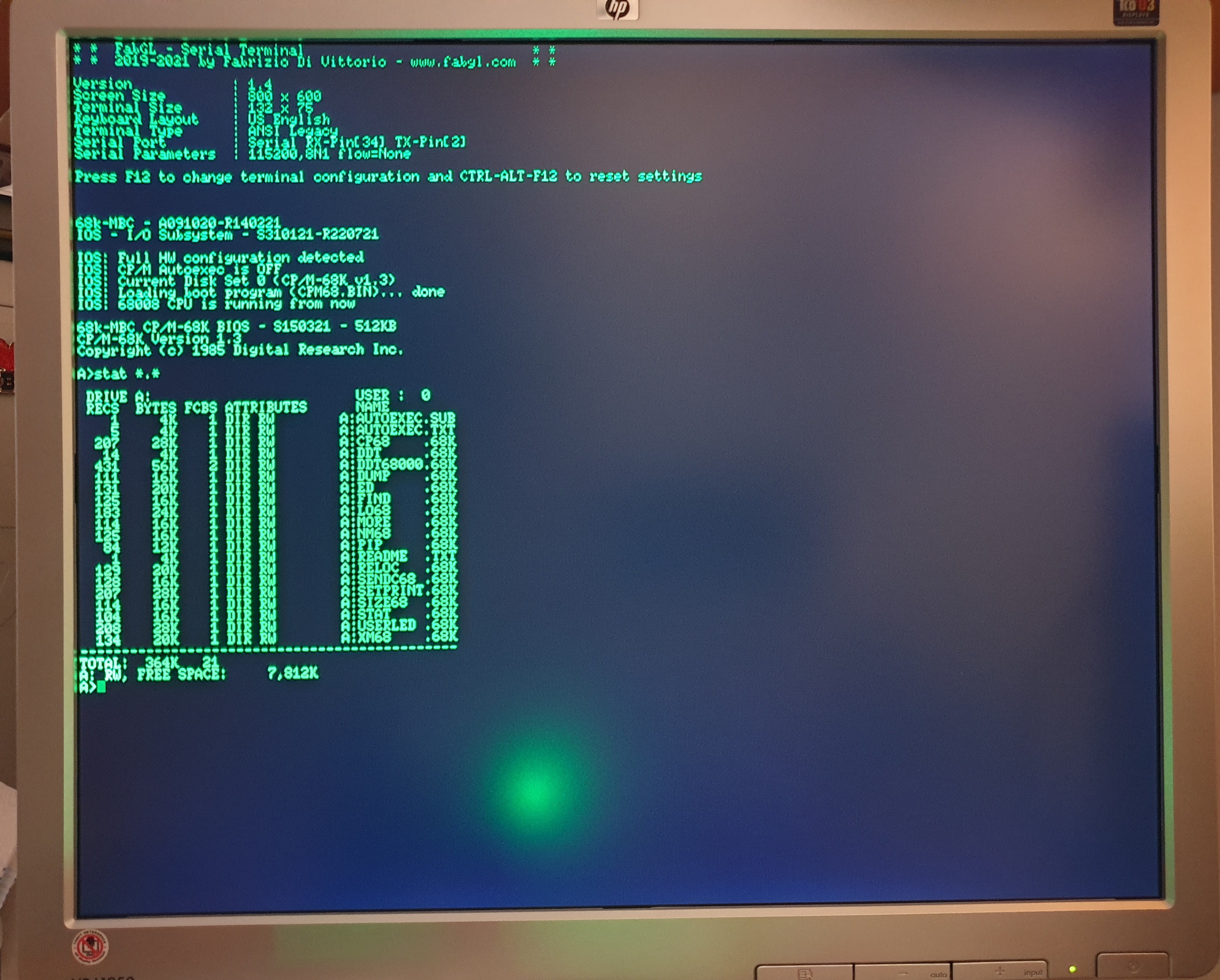

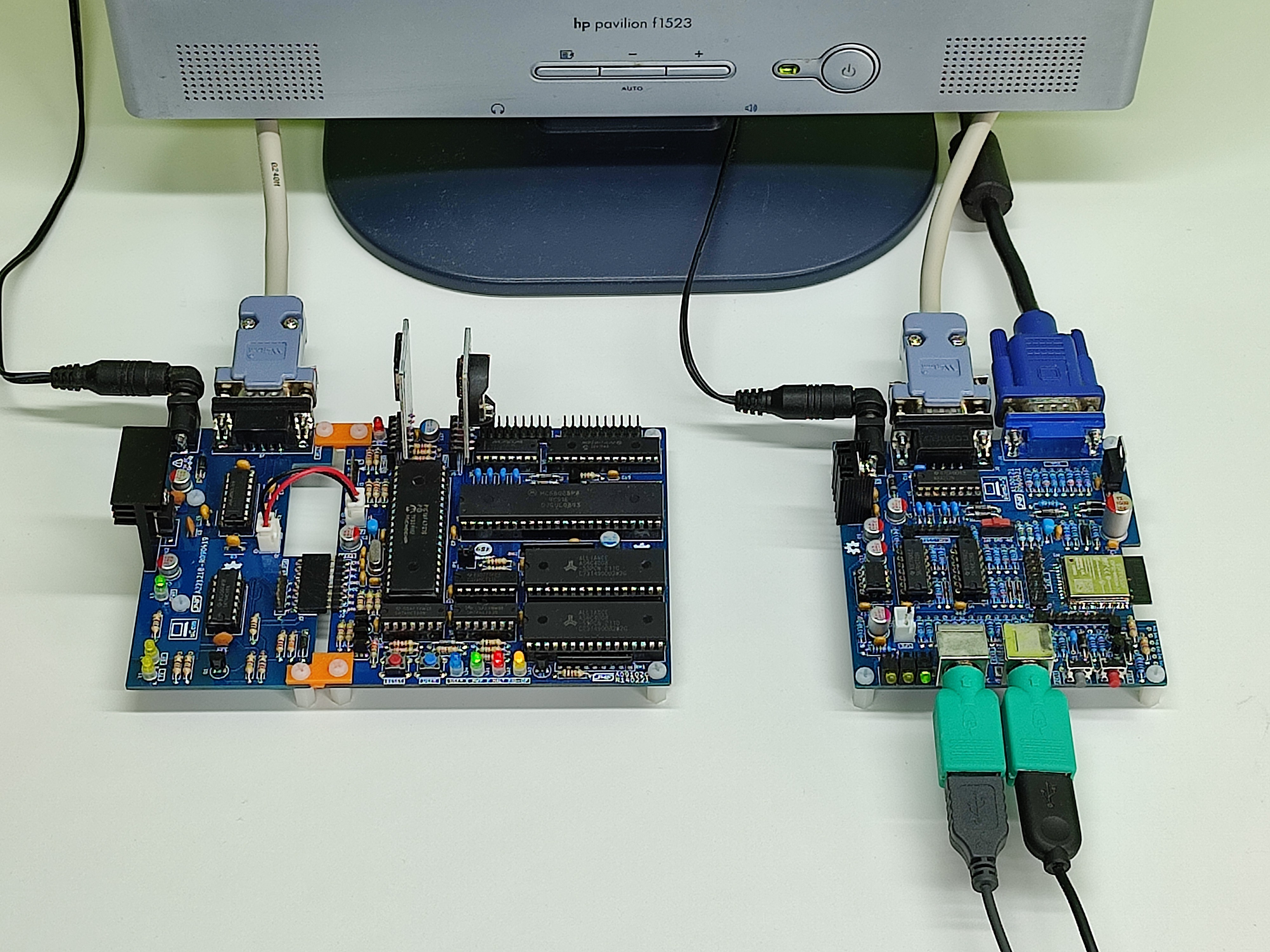

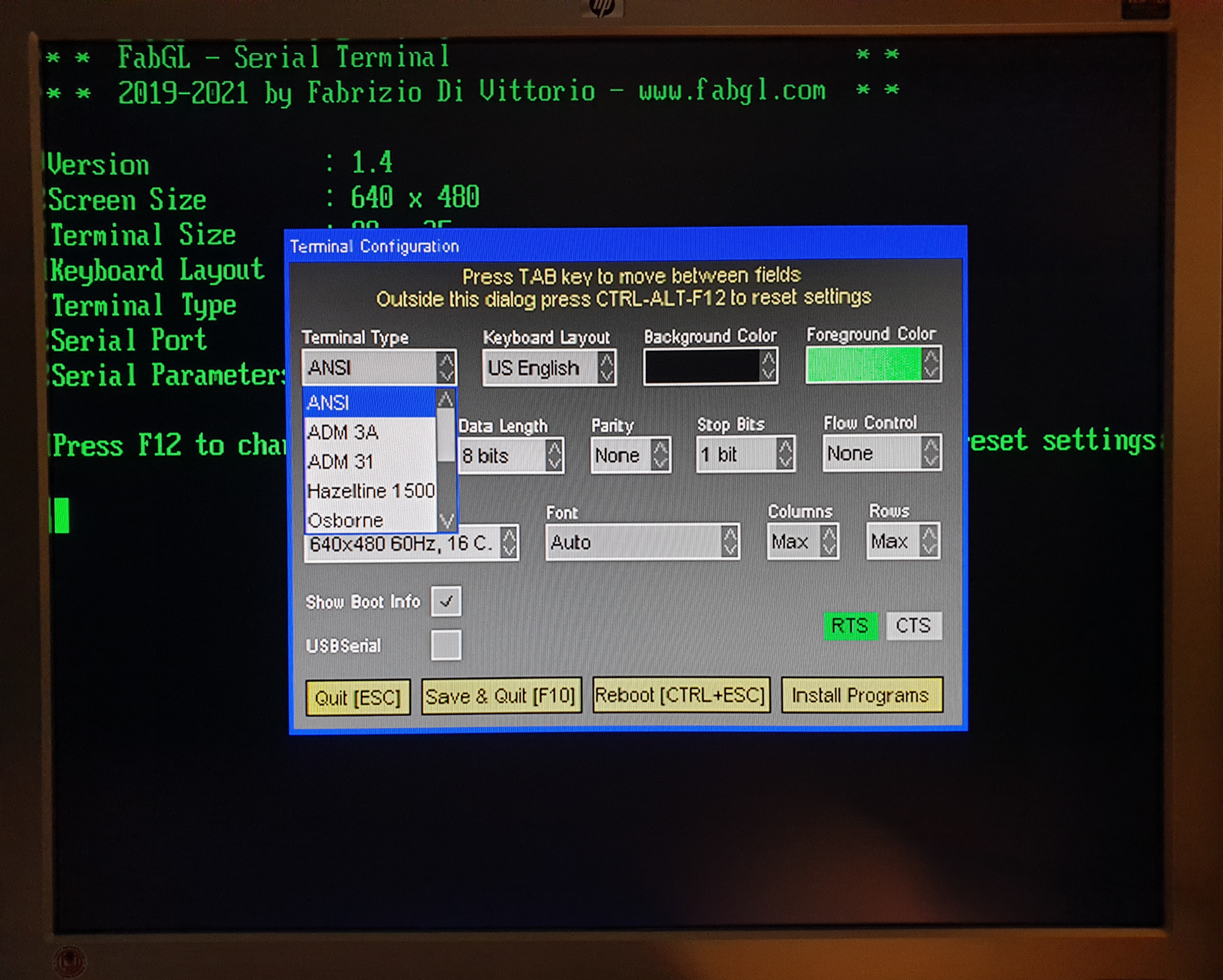

- Added the USING A uTERM2-S RS232 TERMINAL chapter;

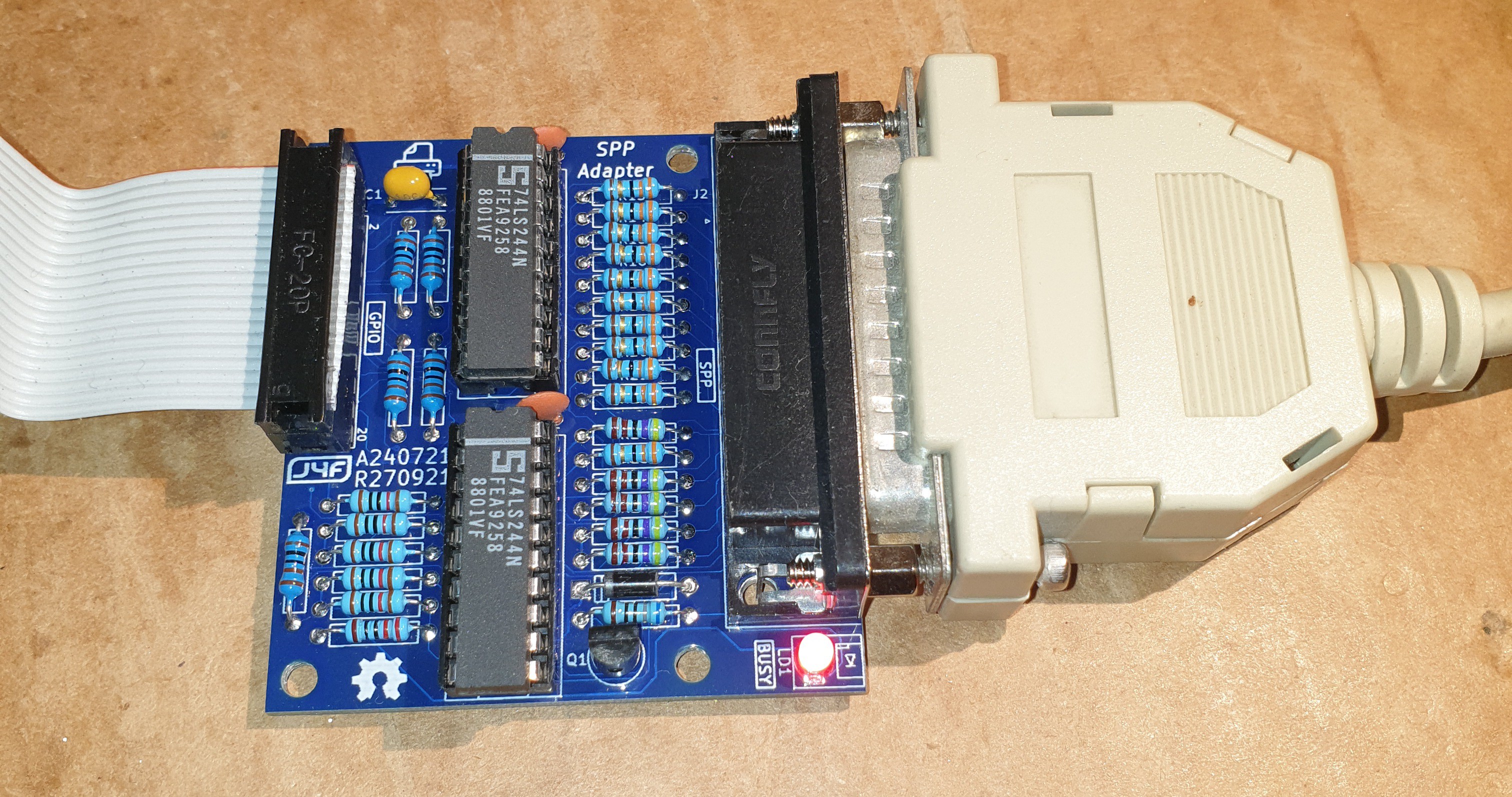

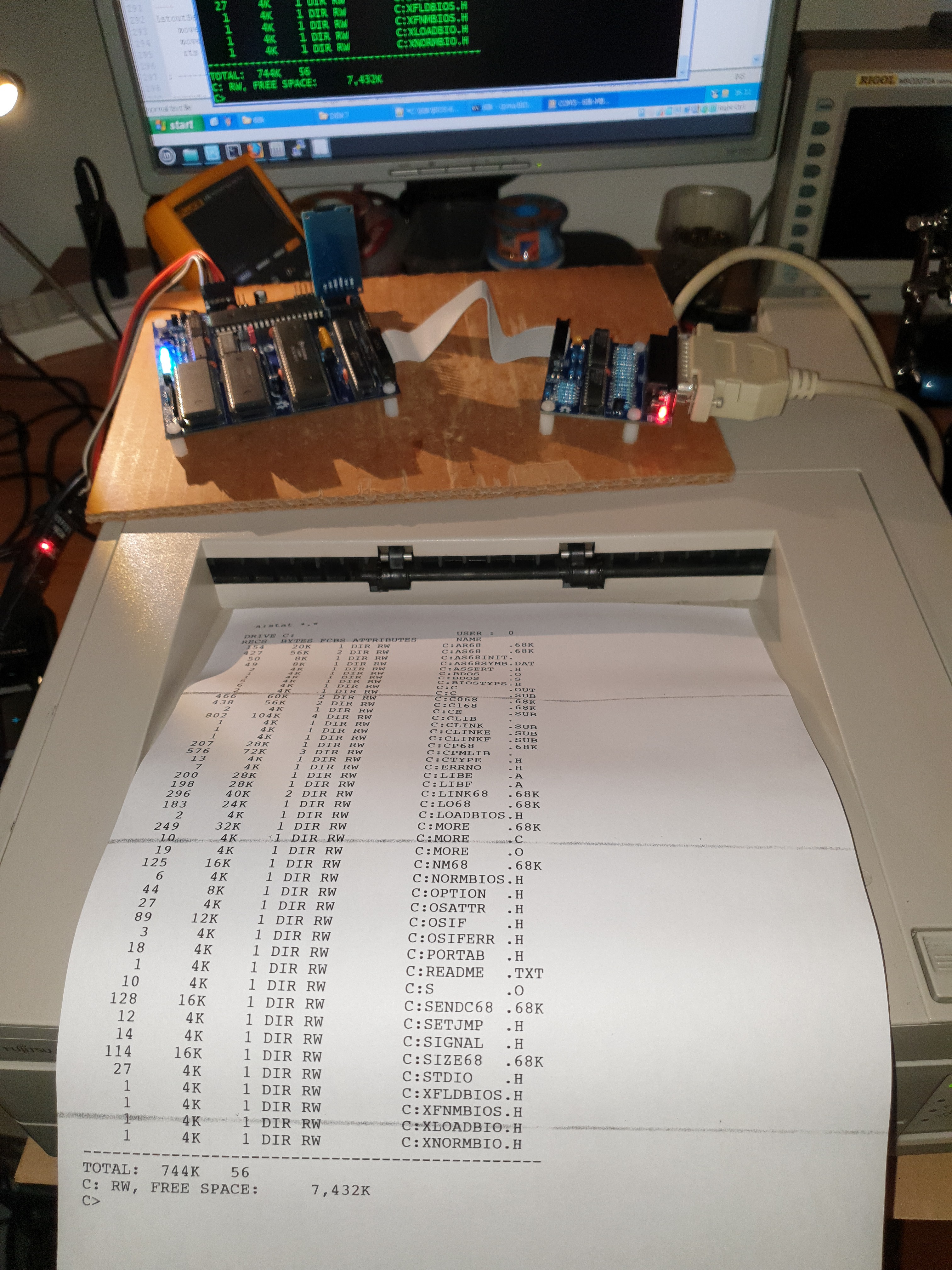

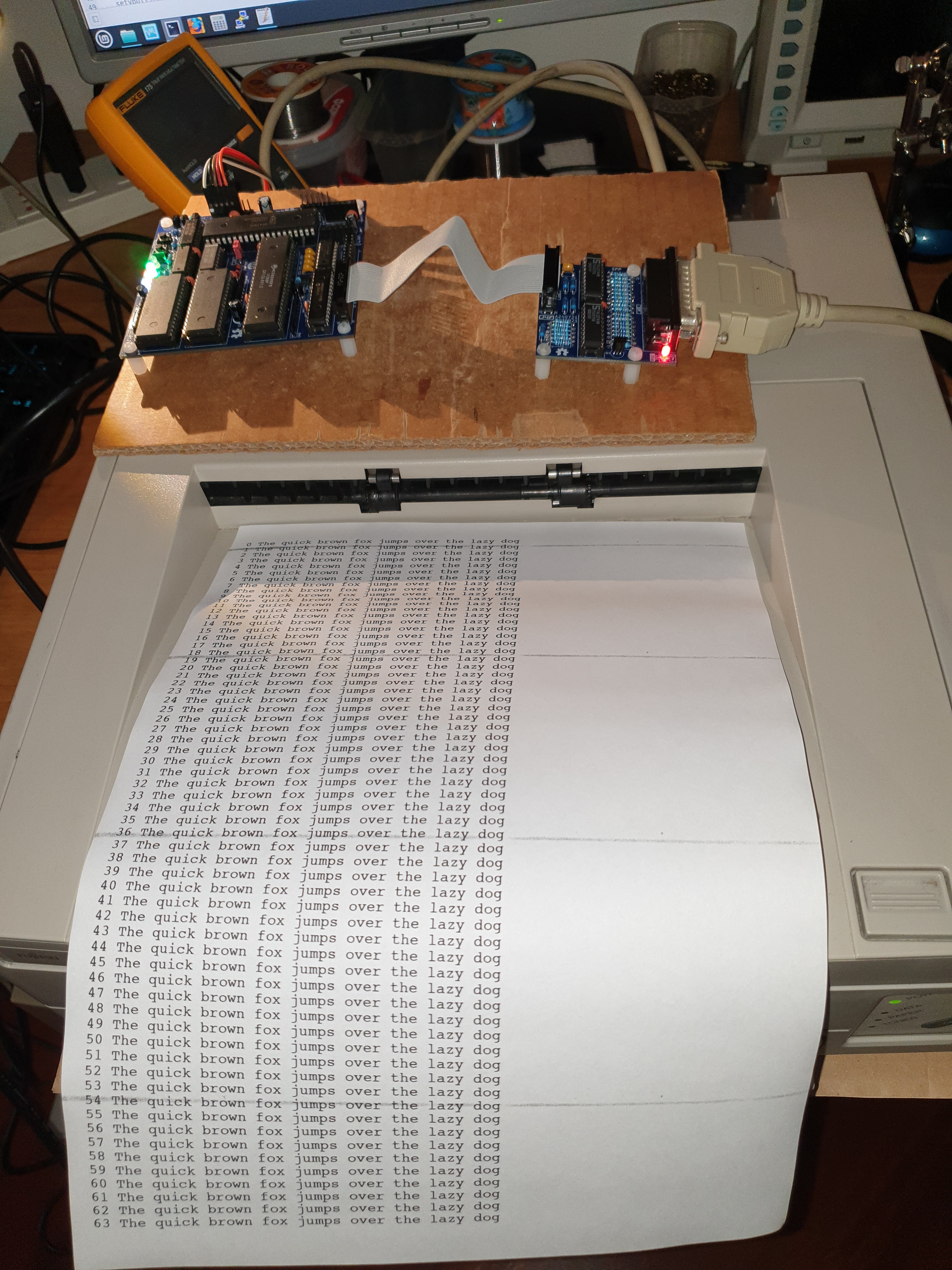

- Added the SPP (STANDARD PARALLEL PORT) ADAPTER BOARD chapter;

- Added documentation to build the SPP Adapter board (A240721-R270921). See the FILES section.

SW:

- Released all the SW related files (see the FILES section);

- Updated IOS S310121-R130421 and SD-S310121-R130421-v1.zip (see the FILES section);

- Added the complete collection of the 4 Manuals of CP/M-68K (see the FILES section);

- Updated IOS S310121-R150421 and SD-S310121-R150421-v1.zip (see the FILES section);

- Added the SW/FW for the Arduino Uno PIC programmer, including the "ICSP Shield" board (see the paragraph: FLASHING THE FIRMWARE WITH AN ARDUINO UNO AS PROGRAMMER);

- Updated SD-S310121-R150421-v2.zip (see the FILES section);

- Released a working experimental doker image for a gcc cross-compiler toolchain (See the paragraph: SLOAD: HOW SETUP A "DOCKERIZED" GCC + NEWLIB CROSS-COMPILING AUTOMATED TOOLCHAIN (LINUX));

- Updated IOS S310121-R250521 and SD-S310121-R250521-v1.zip (see the FILES section);

- Added the 68000 IDE installation files and the custom cstart.asm file for the 68k-MBC (128/512/1024KB versions. See the FILES section);

- Updated SD-S310121-R250521-v2.zip (see the FILES section);

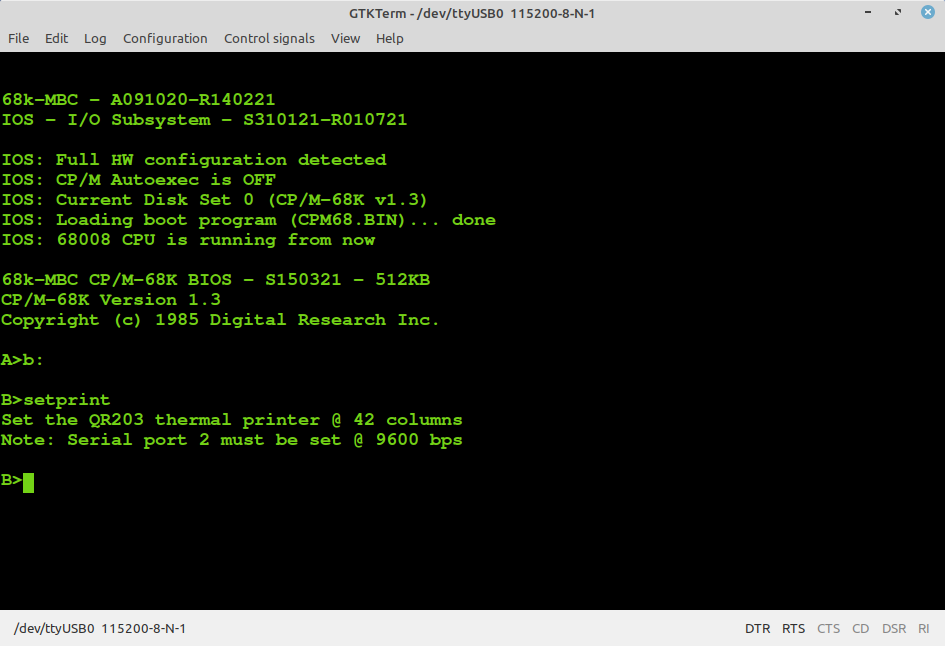

- Updated IOS S310121-R010721 and SD-S310121-R010721-v1.zip (see the FILES section);

- Updated IOS S310121-R220721 and SD-S310121-R220721-v1.zip (see the FILES section);

- Updated IOS S310121-R231021 and SD-S310121-R231021-v1.zip (see the FILES section);

- Updated SD-S310121-R231021-v2.zip (see the FILES section);

- Updated SD-S310121-R231021-v3.zip (see the FILES section).

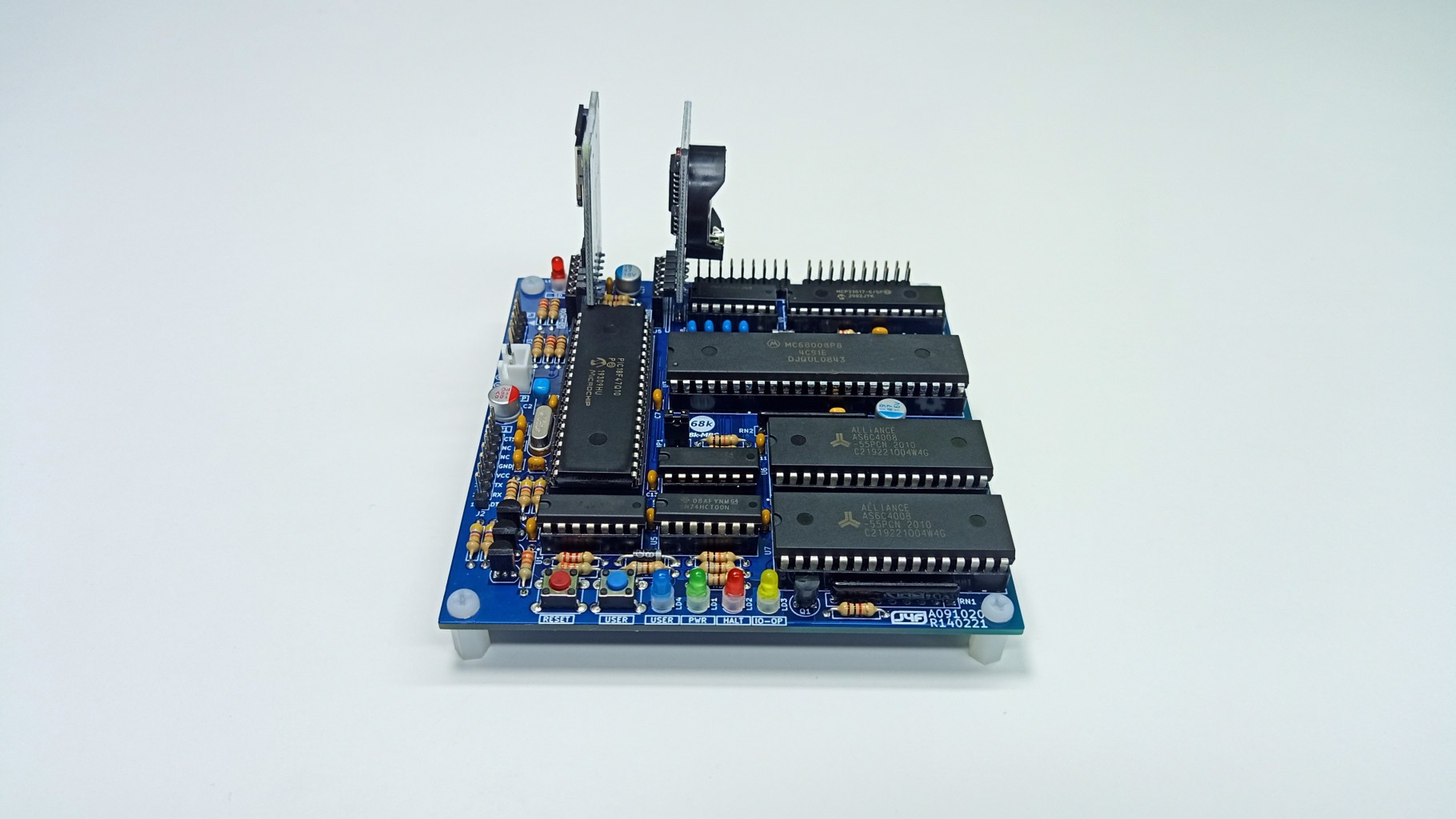

* * THE PROTOTYPE * *

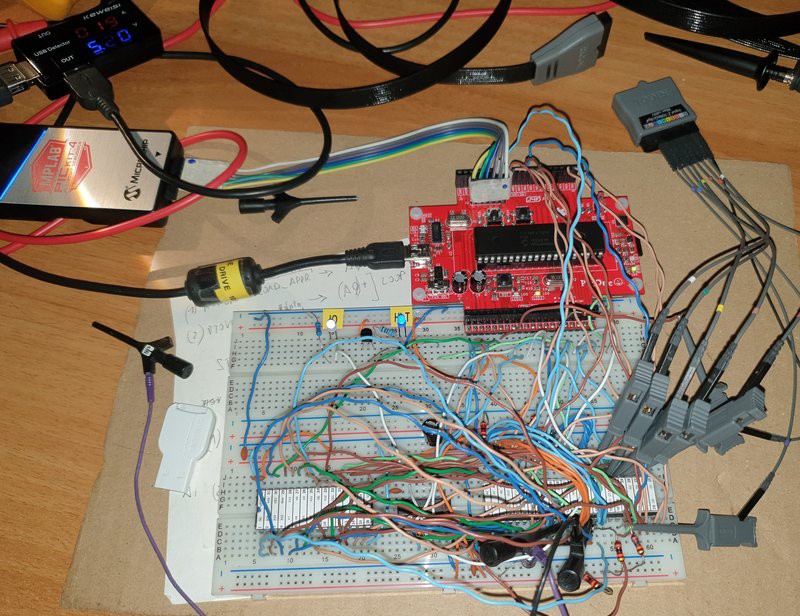

In the first phase of the design I've used a prototype on a breadboard to check the basic "concepts".

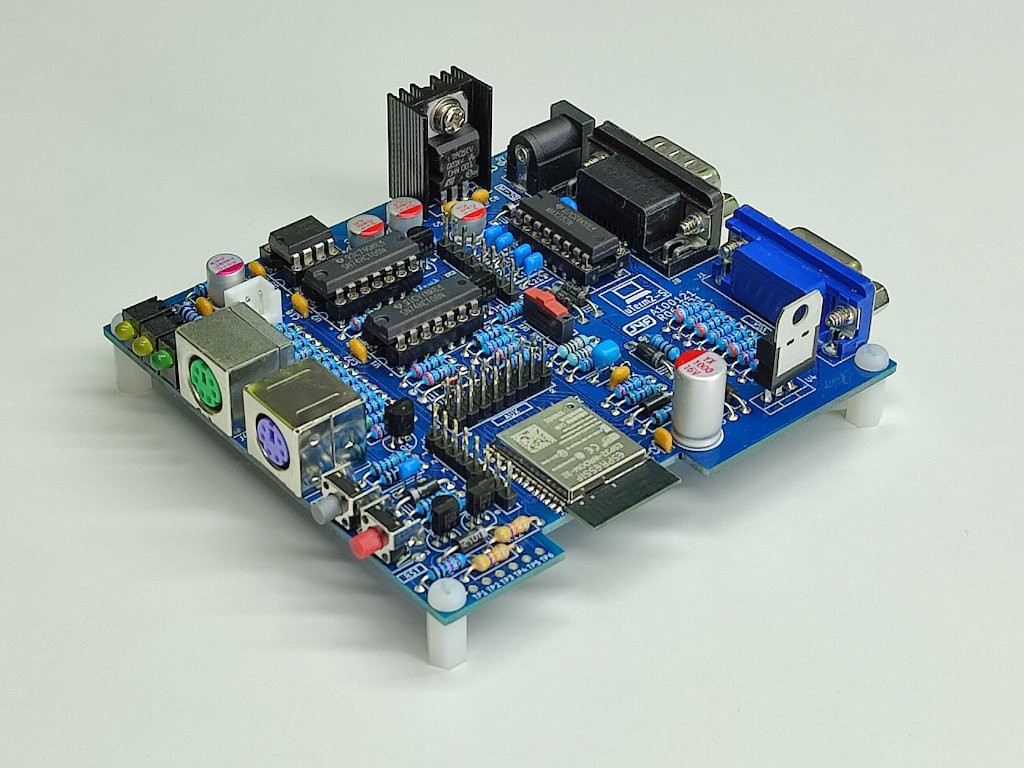

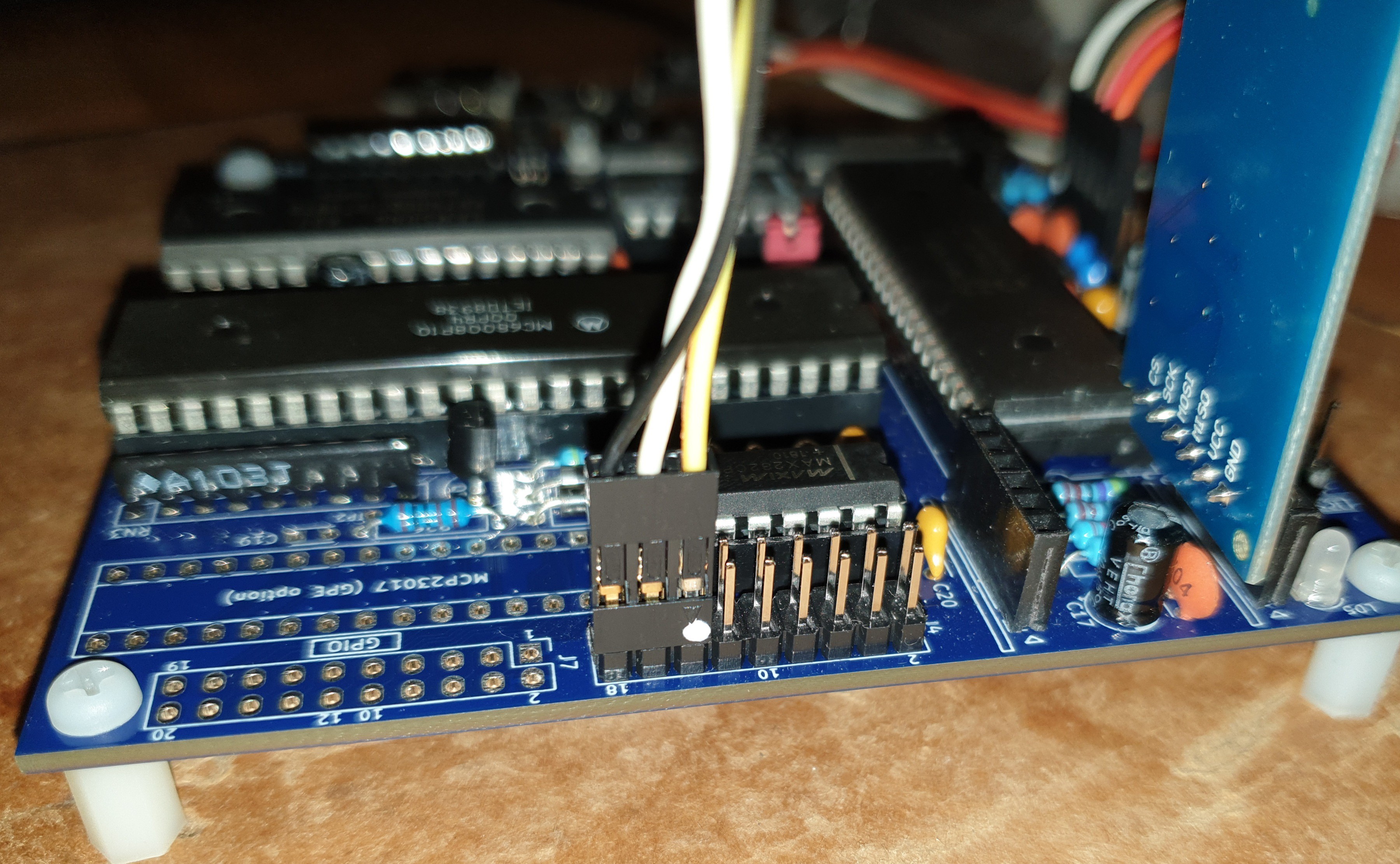

I've used as "companion" MCU a PIC18F47Q10 on a custom board (PicOne) I previously made and that it is directly pluggable on breadboards, and with onboard microSD card and USB-serial adapter.:

To make the firmware for the PIC18F47Q10 I've used MPLAB X IDE with the MCC plugin.

Here a short video with an automated assembler toolchain using Easy68K as assembler and sLoad, a custom SW utility to load from the serial port and execute a Motorola S-record formatted executable:

To allow a real automated toolchain an auto-reset circuit on the breadboard takes the DTR signal from the serial-USB adapter and uses it to reset the MCU (like in the Arduino Uno board), so it is possible reset the breadboard from a batch file running in the PC using a macro of Tera Term.

* * WHY A PIC? * *

Those have followed the previous Z80-MBC2 and V20-MBC boards will note that I haven’t used here an Atmega MCU. Using an Atmega MCU allows to use the friendly Arduino IDE and many ways to flash the MCU, so this is an enabling factor.

Unfortunately Atmega MCU GPIO ports are not TTL compatible, and this limitation was solved in the previous boards using a CMOS CPU that under given conditions can accomplish the digital levels of the Atmega MCU.

But here the 68008 CPU isn’t available in CMOS technology at all, so an Atmega MCU cannot be used.

So I’ve done some searches to find an alternative MCU having three main constraints: must have TTL compatible GPIOs (I mean strictly "guaranteed" TTL compatible), must be a TH part and cheap too.

The only part I’ve found was a PIC18F47Q10 MCU, and I must say that it accomplish the previous constrains very well. More, it is a modern MCU with lot of interesting features and more flash and RAM memory than the previous Atmega32 MCU.

Of course nothing comes free, and the choice of a PIC18F47Q10 brings some complexities. The first is the need...

Read more » Just4Fun

Just4Fun

Fuzix.org can run on this device?