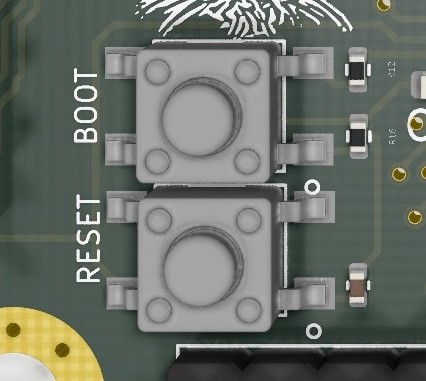

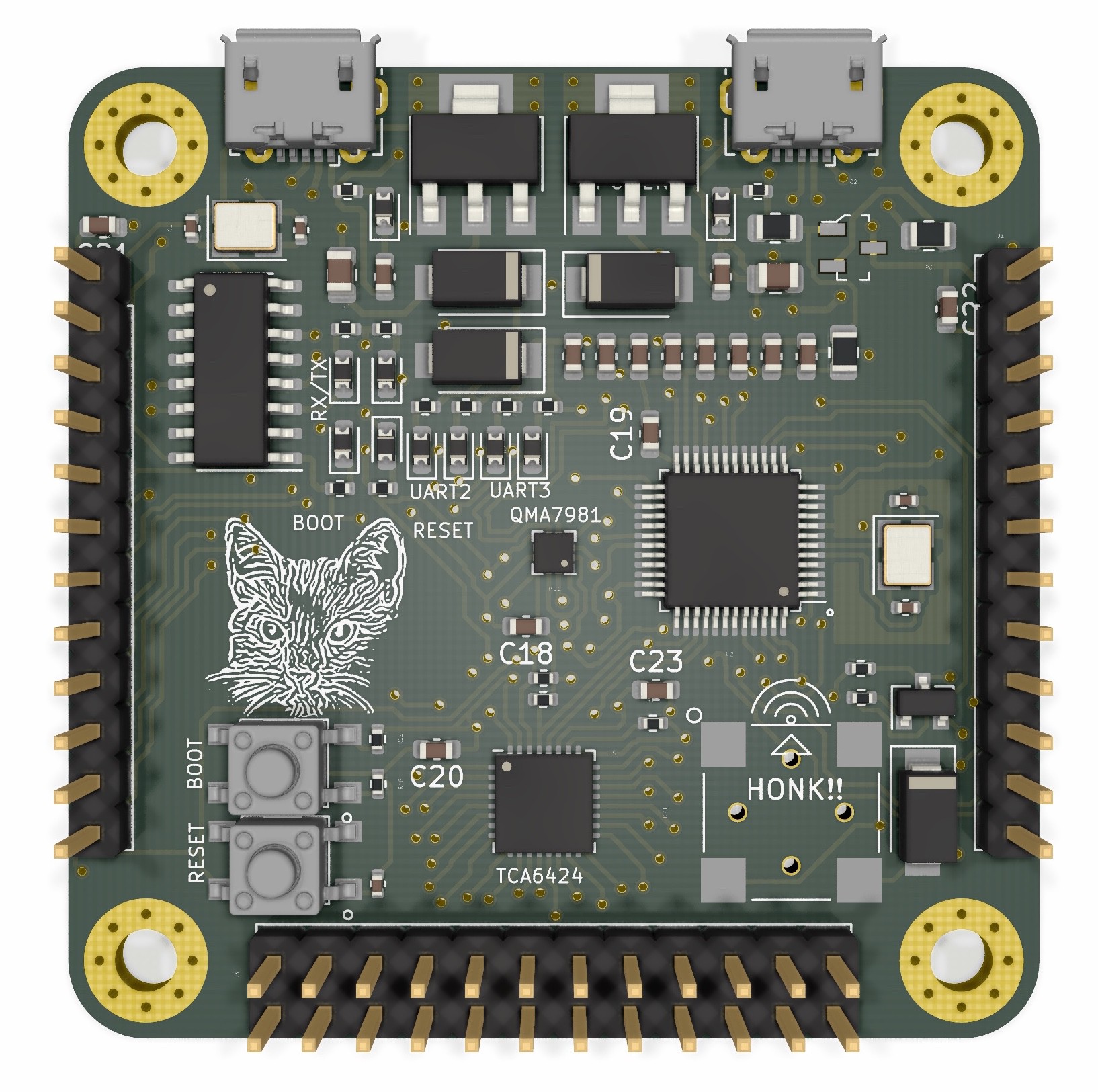

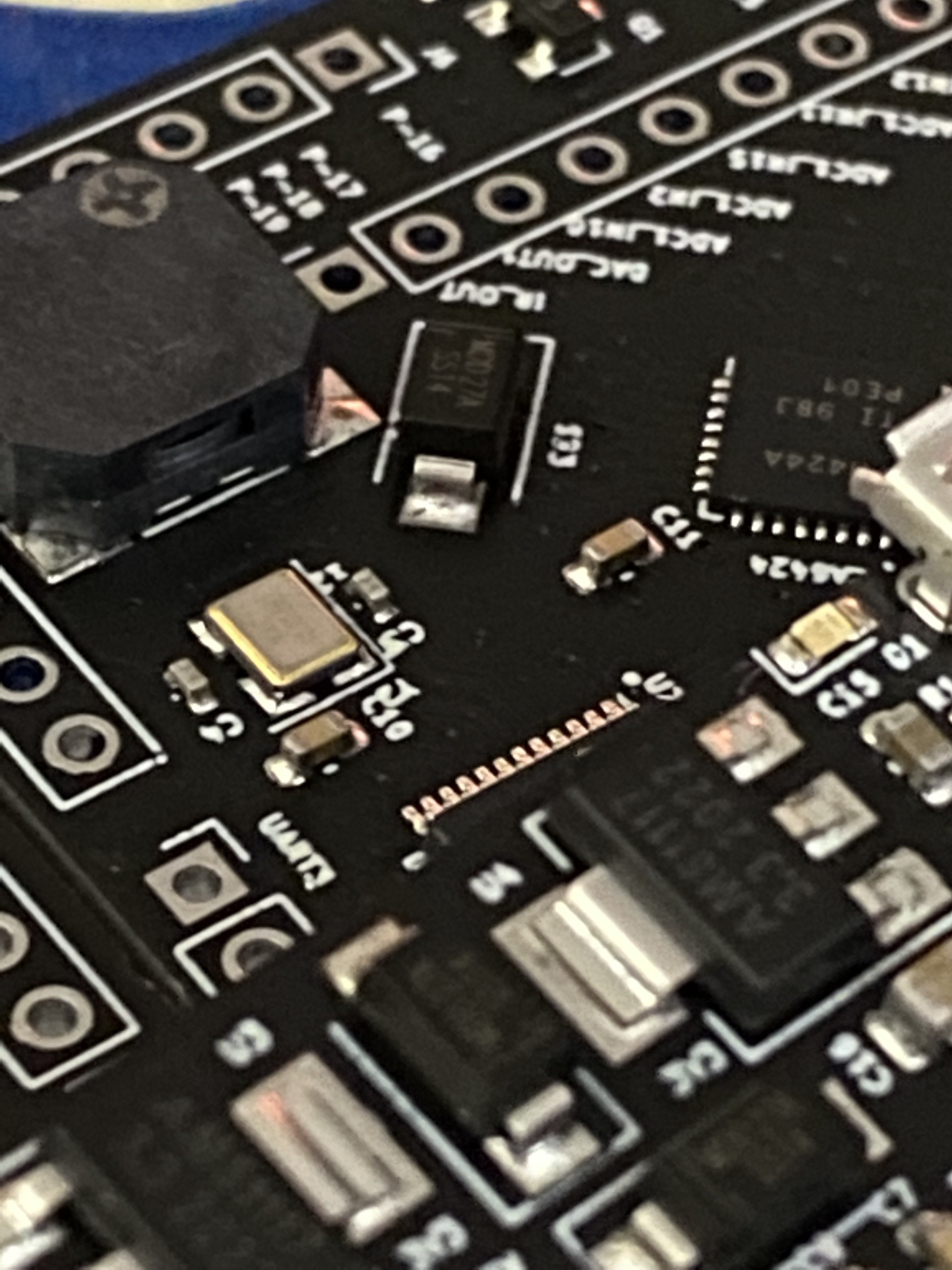

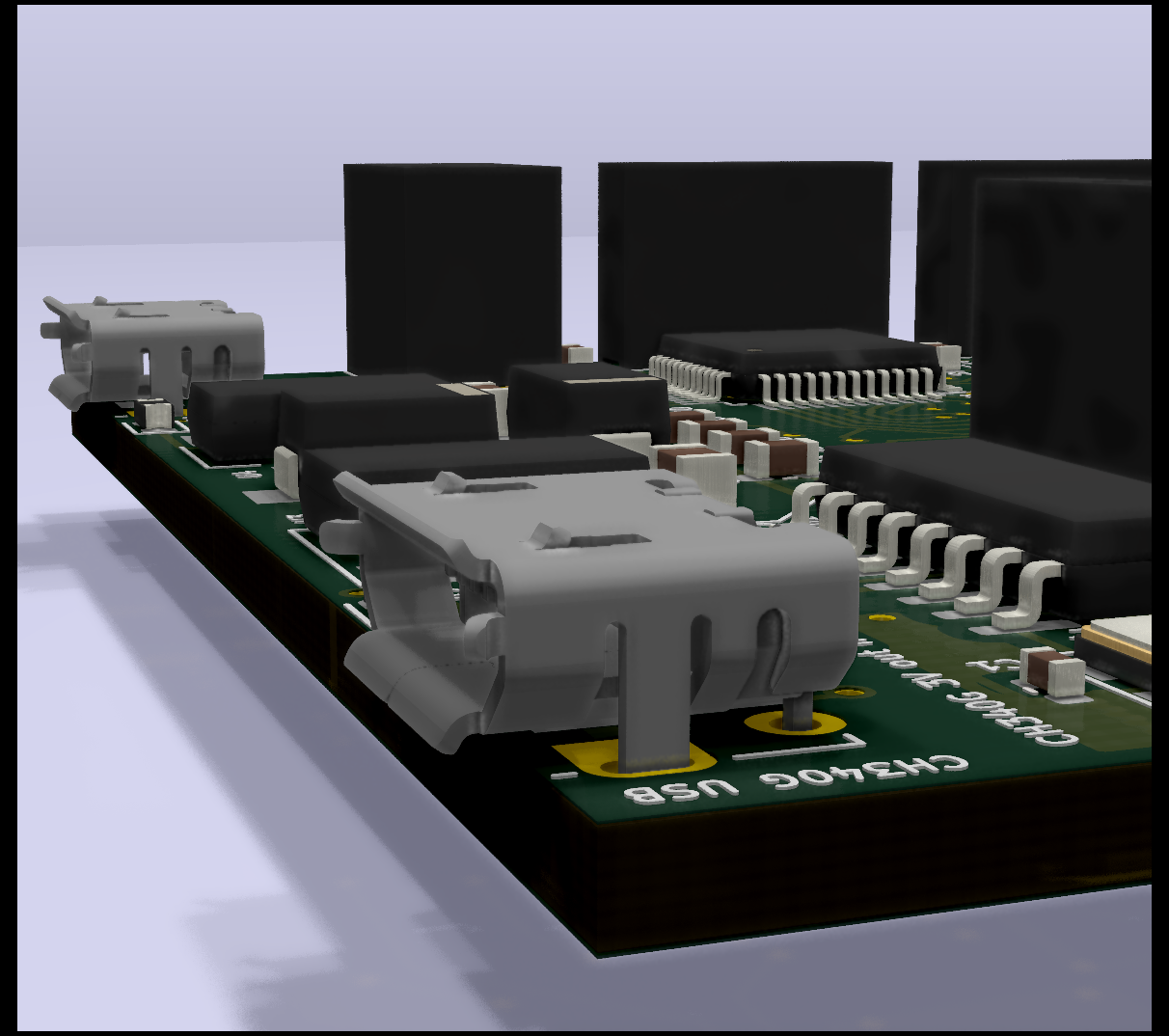

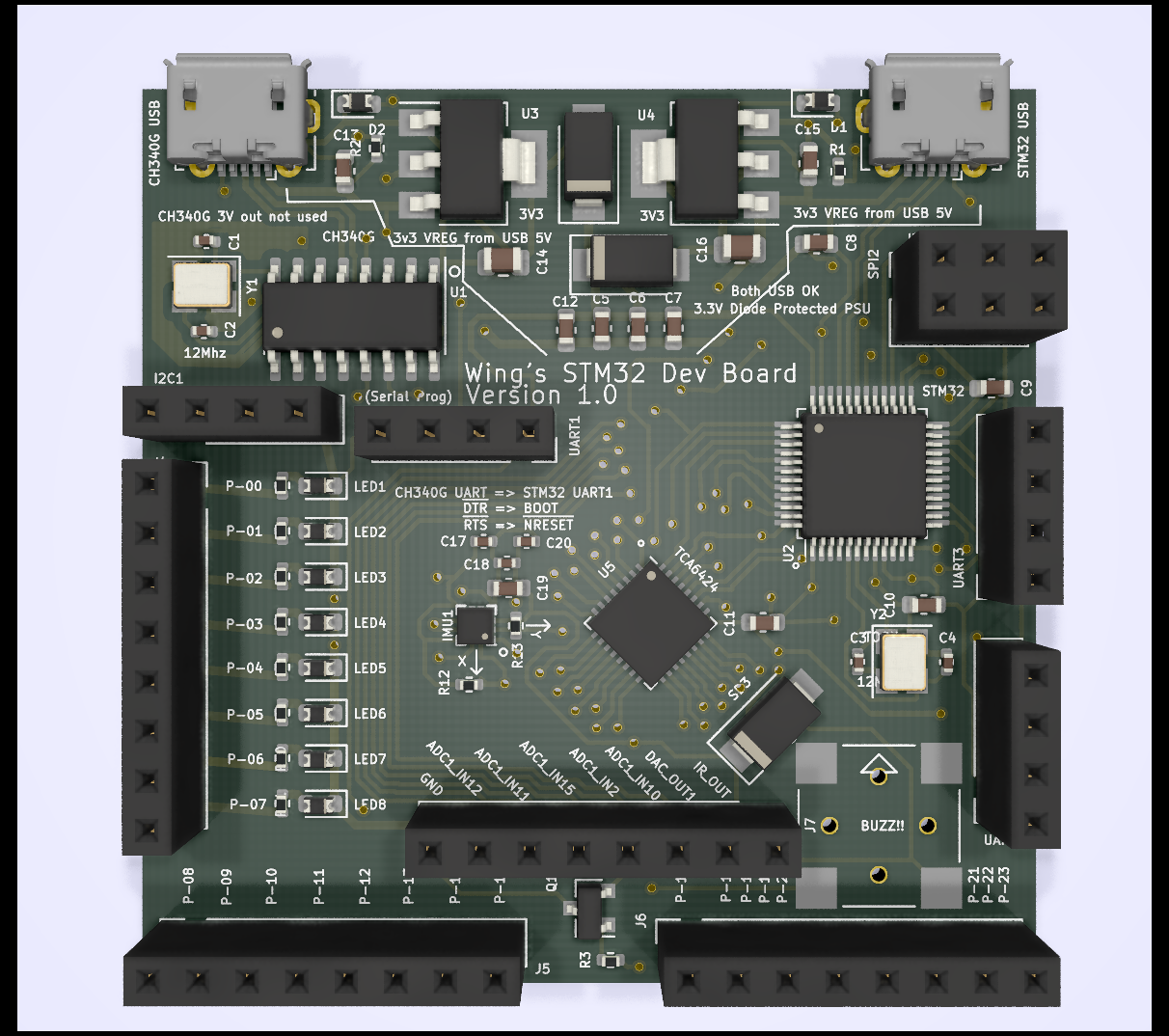

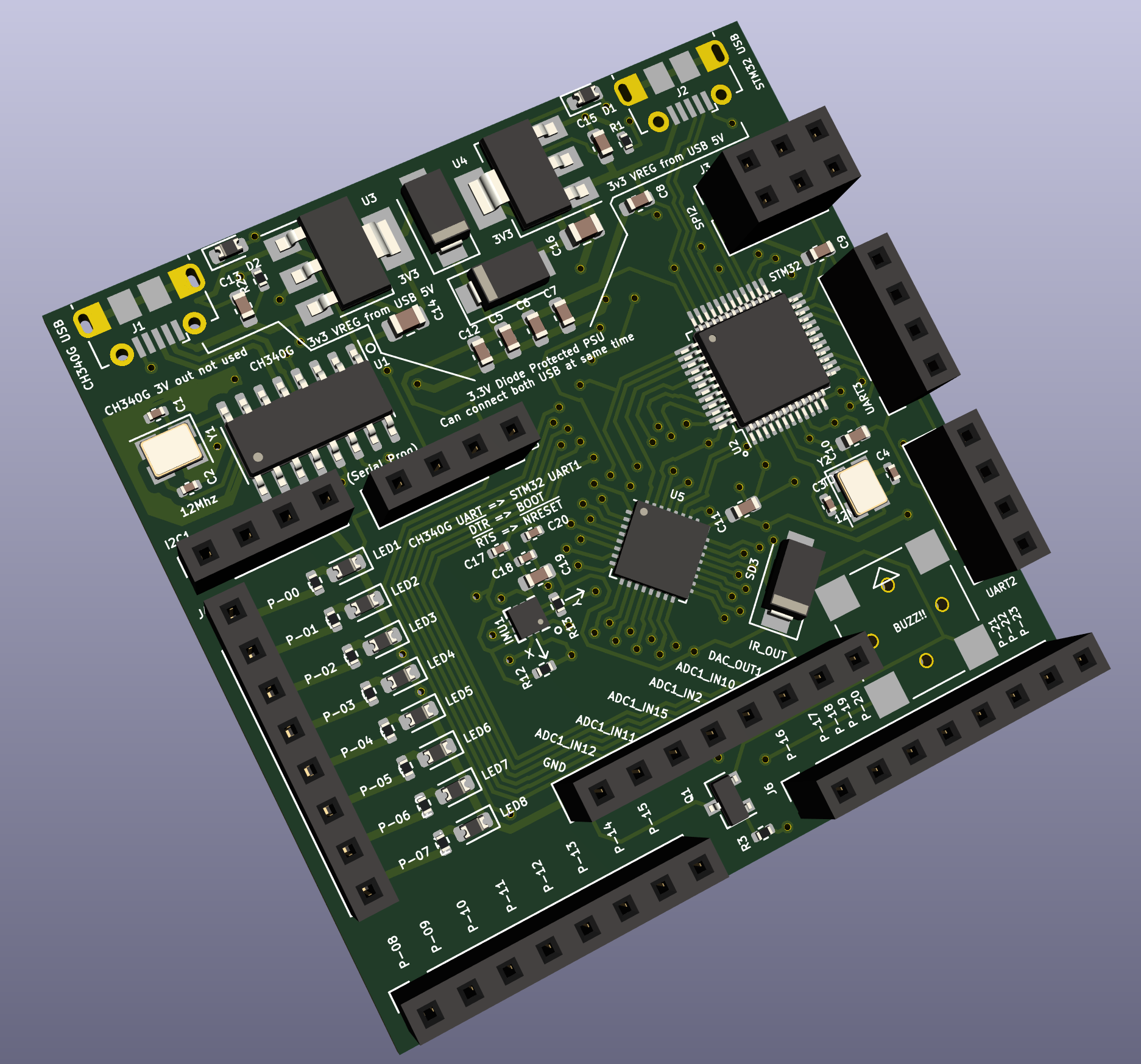

- Reproduce the typical USB => USB/UART IC => STM32 programming flow.

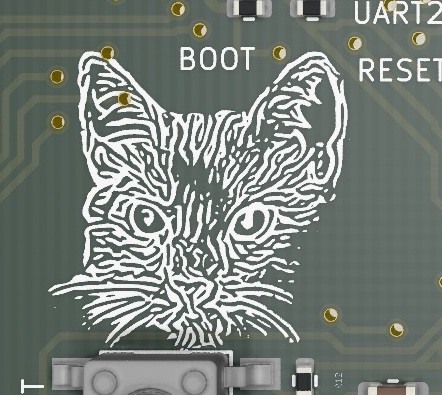

- This involves the control of the BOOT and nRESET pins. This is normally facilitated via DTR/RTS.

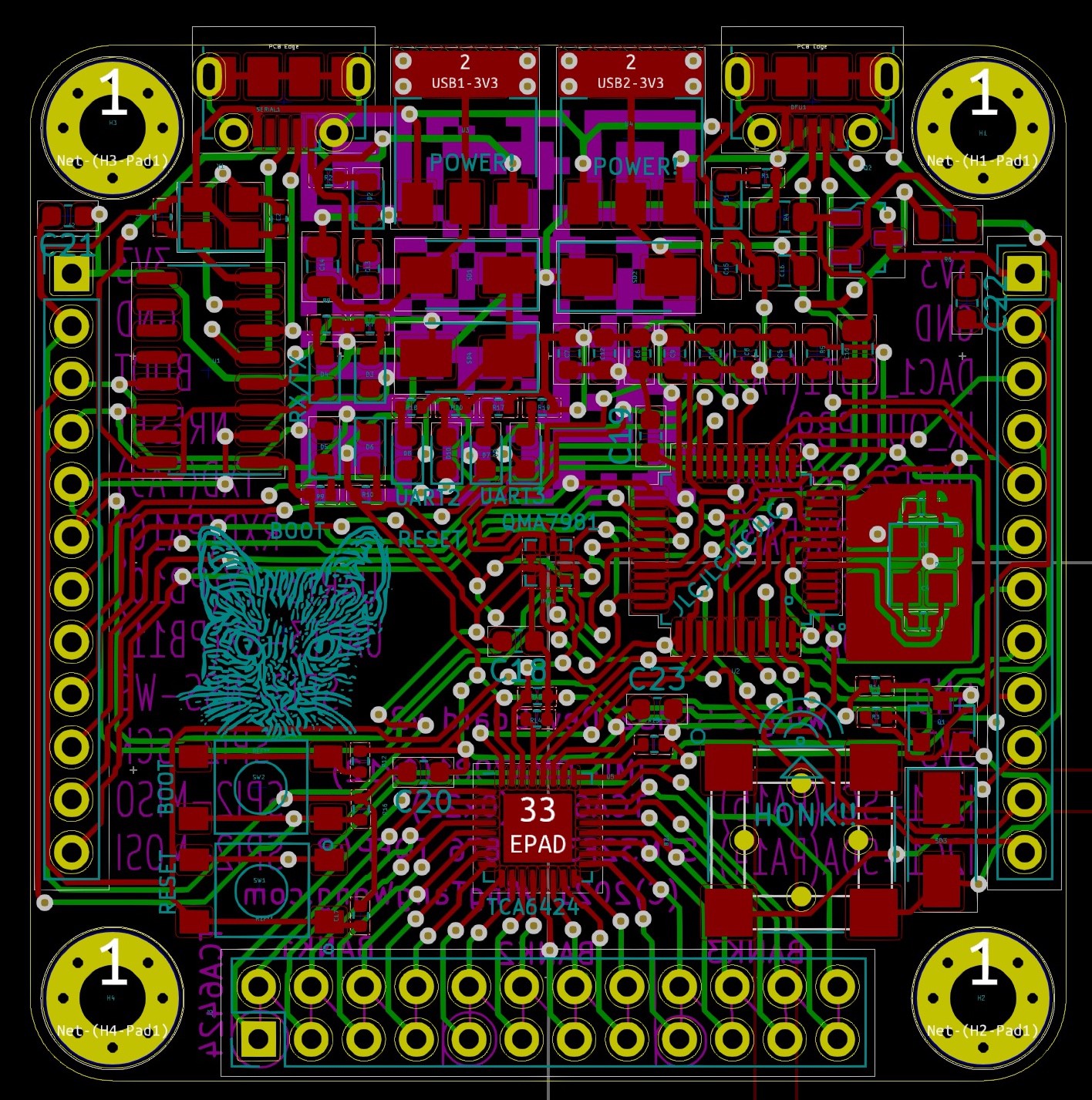

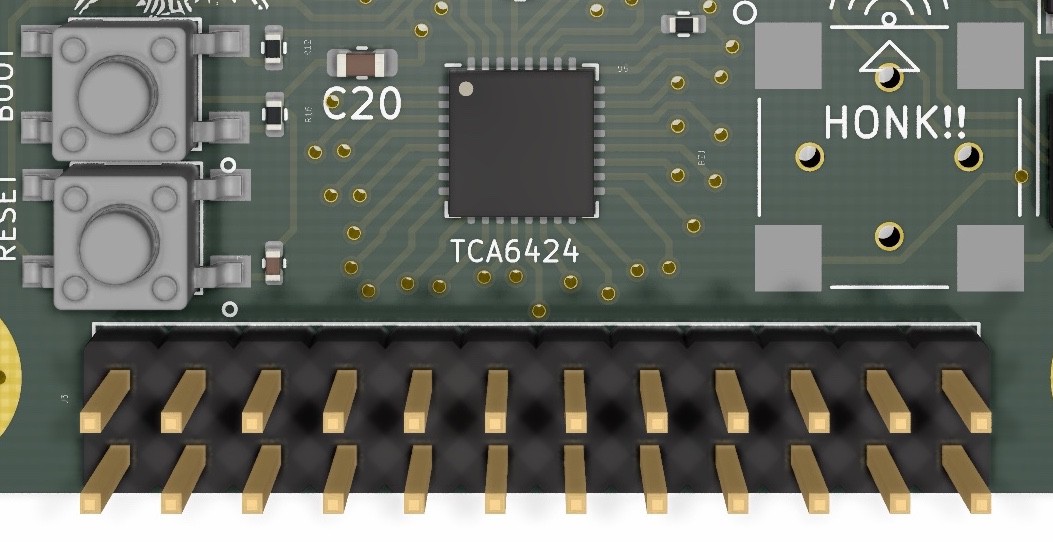

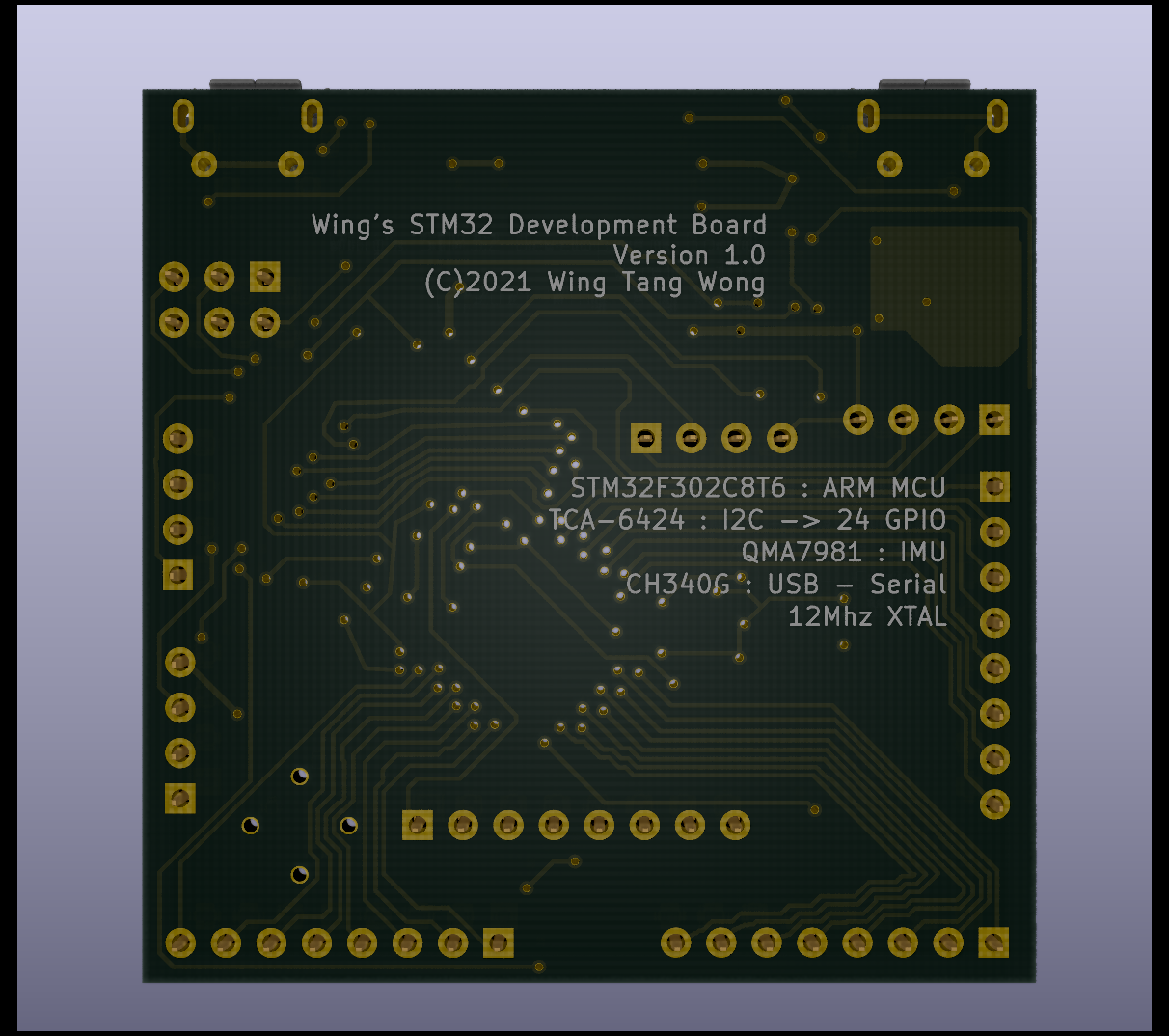

- Provide LOTS of GPIO for the STM32 IC in the form of an expander. TCA6424 in this case.

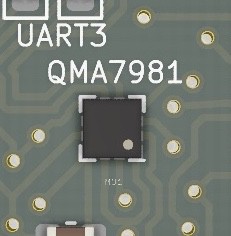

- Provide a sensor. An IMUU in this case.

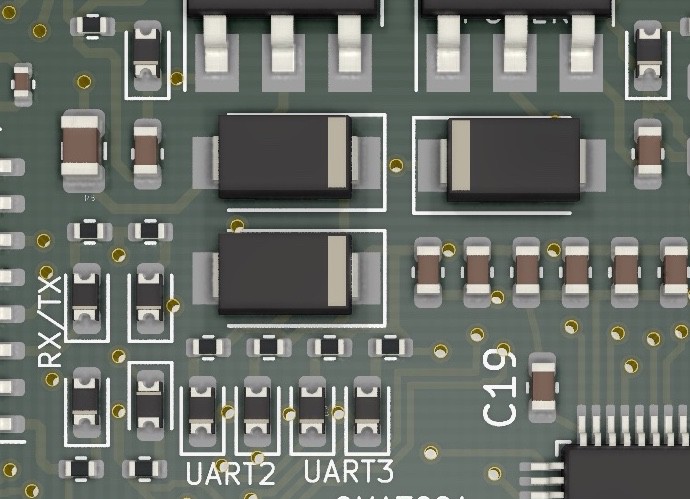

- Provide a breakout for the communication channels on the STM32.

- Provide a means of having multiple concurrent USB/power sources plugged in without things going _boom_.

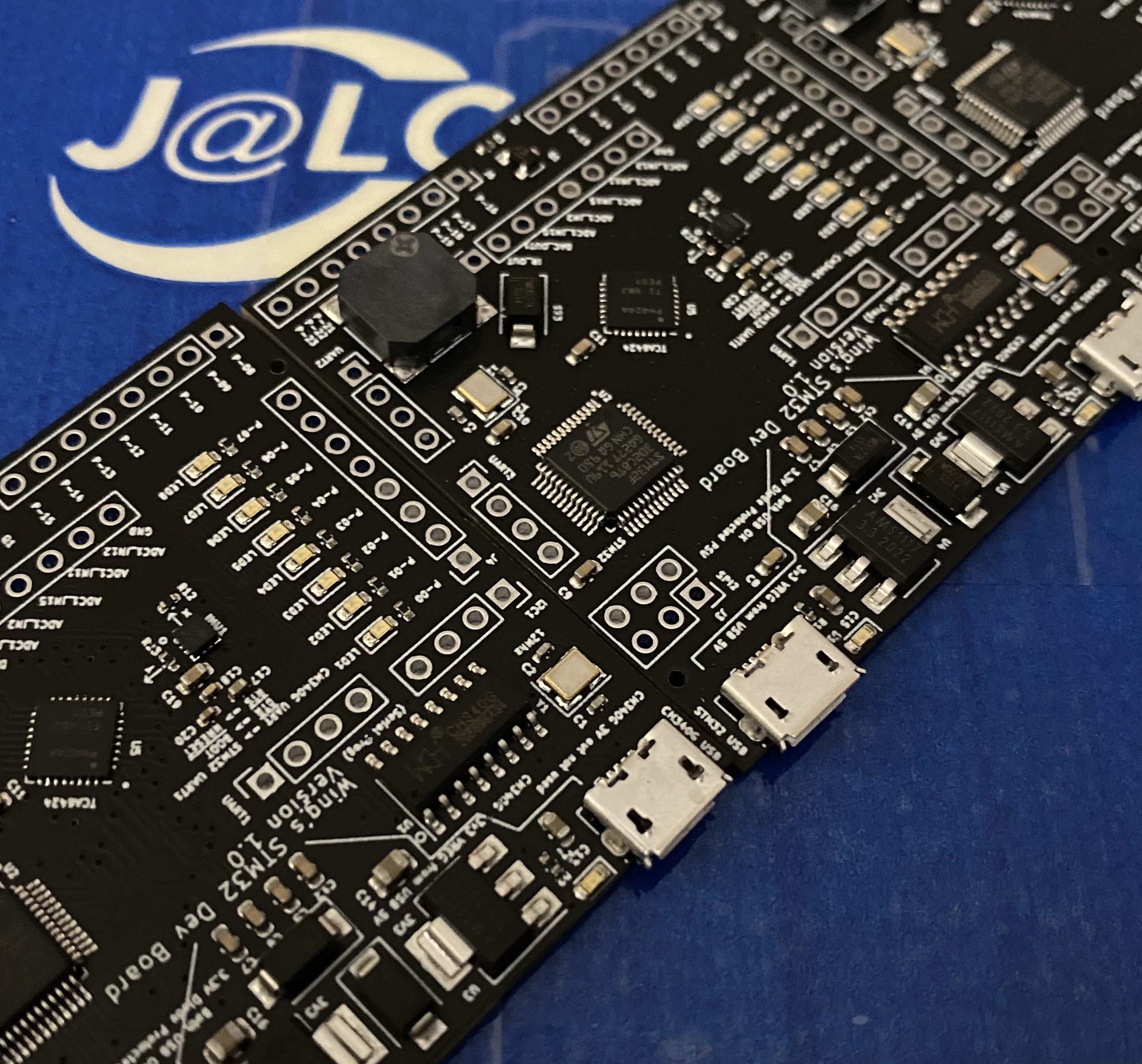

Wing's STM32 Dev Board

A small project to build a STM32 development board using KiCad

WingTechCorner

WingTechCorner

Alexander Mandera

Alexander Mandera

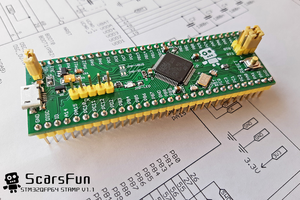

ScarsFun

ScarsFun

Jakub Piasecki

Jakub Piasecki

Great Design !

One Question though, how do you connect the CH340G to the STM32?