Problem

Sargassum is a natural, even essential, part of the Caribbean's ecosystems but theserecent blooms are having a devastating impact on the region, both ecologically andeconomically. Many tourist areas and islands were inundated this year. It piles up onbeaches, sometimes many feet thick covering large area of shore waters and begins to decay. In the process of decay, the hydrogen sulphide that gets released smells like rotting eggs and many resorts had to close their doors. Hydrogen sulphide is dangerous to humans in large quantities, causing headaches, dizziness, nausea and even asthma has been reported in some local communities. Since the species are Sargassum natans and Sargassum fluitans float they block sunlight creating dead zone beneath them because plants under need sunlight to survive. The cleanup and removal of sargassum is an expensive task because they come in large quantities at fast rate which makes the traditional and modern clean up method very high cost dependent.

Solution

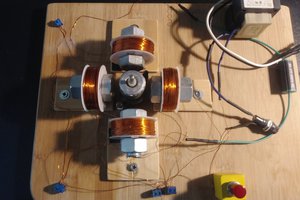

This project is about building a semi automation cleanup mechanism that can clean and collect the piled up Sargassum in shore land without ground accessibility interference. This is done by building a small scale locomotive Sargassum gathering device that is powered by a battery which can be pushed and pulled by human being to collect the piled up Sargassum easily from one place to another. This device consists of a battery, electric motor, three rotating blades, two pulley systems, one conveyor, holding tank, handle and four wheels. The three rotating blades collect the piled up Sargassum on the ground by picking them up and hold the Sargassum on their holding structure. As they rotate on the axis of the electric motor which is installed inside the hallow shaft that powers the rotation of the blades, each blade will drop the Sargassum they collected on a conveyor which is powered by the electric motor through one of the pulley system that connects the rotating shaft of the blade with the conveyor system. The main purpose of the conveyor system is to transport the collected Sargassum from the blades to the holding tank structure. The two end of the conveyor are connected through the second pulley system. The system have two larger wheels at from for better stability of the blades and two small wheels at the back. At the back there is a handle that that is used to push and pull the device from one location to another. As an option depending on the performance of the electric motor, it can be connected to the wheels to drive itself through a gear system which will complete the automation of the system but since the mechanism will not have higher weight a human labor can operate the system by pulling and pushing it. This will increase the efficiency of workers who consistently collect the piled up Sargassum with the aid of shovel.

Constrain to overcome

The main limitation this design needs to overcome is the noise of the electric motor on operation that may create some sort of uncomfortable sounds for the tourist nearby but this can be managed if we used good performance electric motors like the Tesla car electric motors. The other limitation might be the weight of the system that may bring question on can human being push it easily. In order to solve it we can make the handle force multiplying hydraulic system than can be used forward and backward.

Anteneh Gashaw

Anteneh Gashaw

Nolan Hergert

Nolan Hergert

Aleksey

Aleksey

Rory

Rory

G. Rosa

G. Rosa