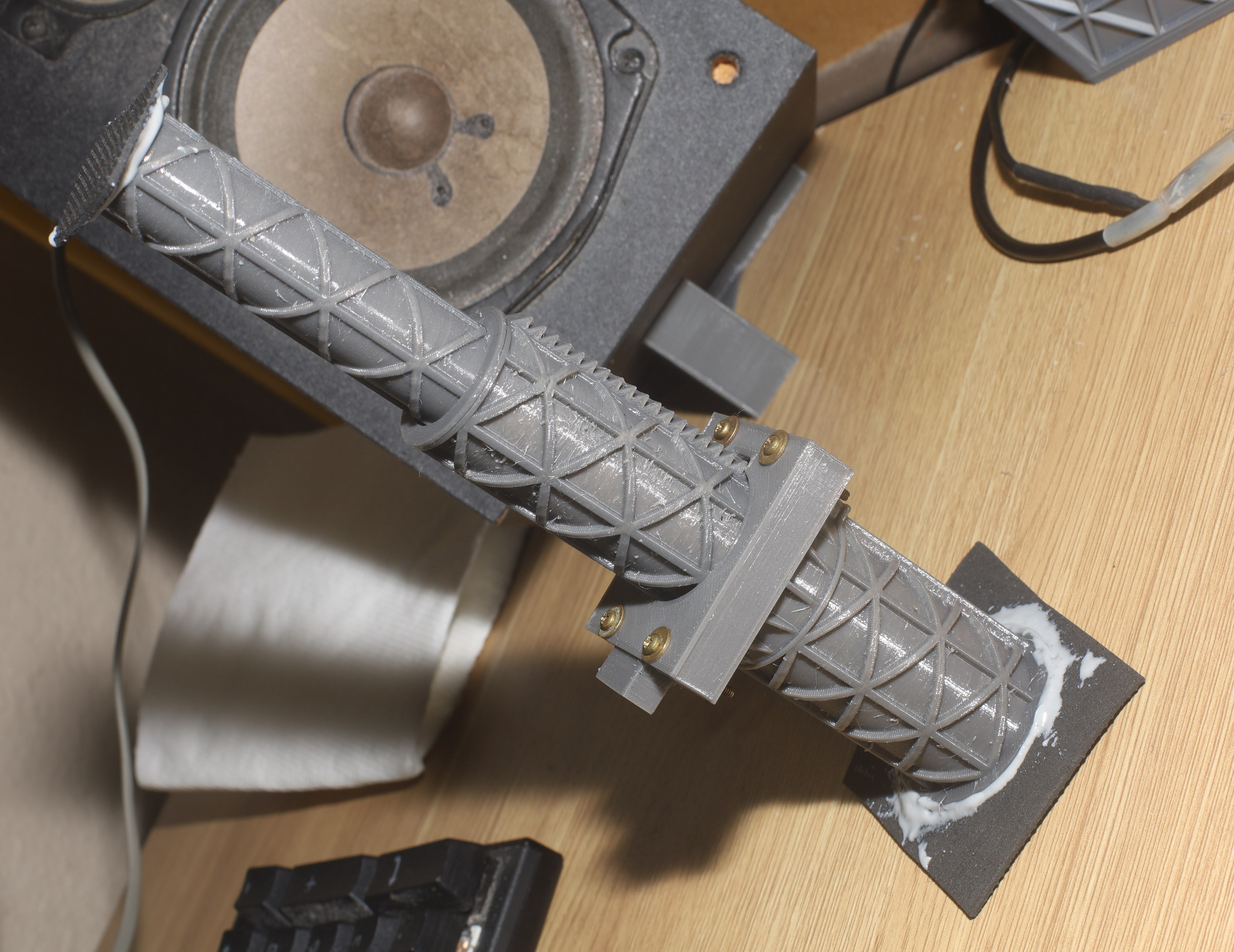

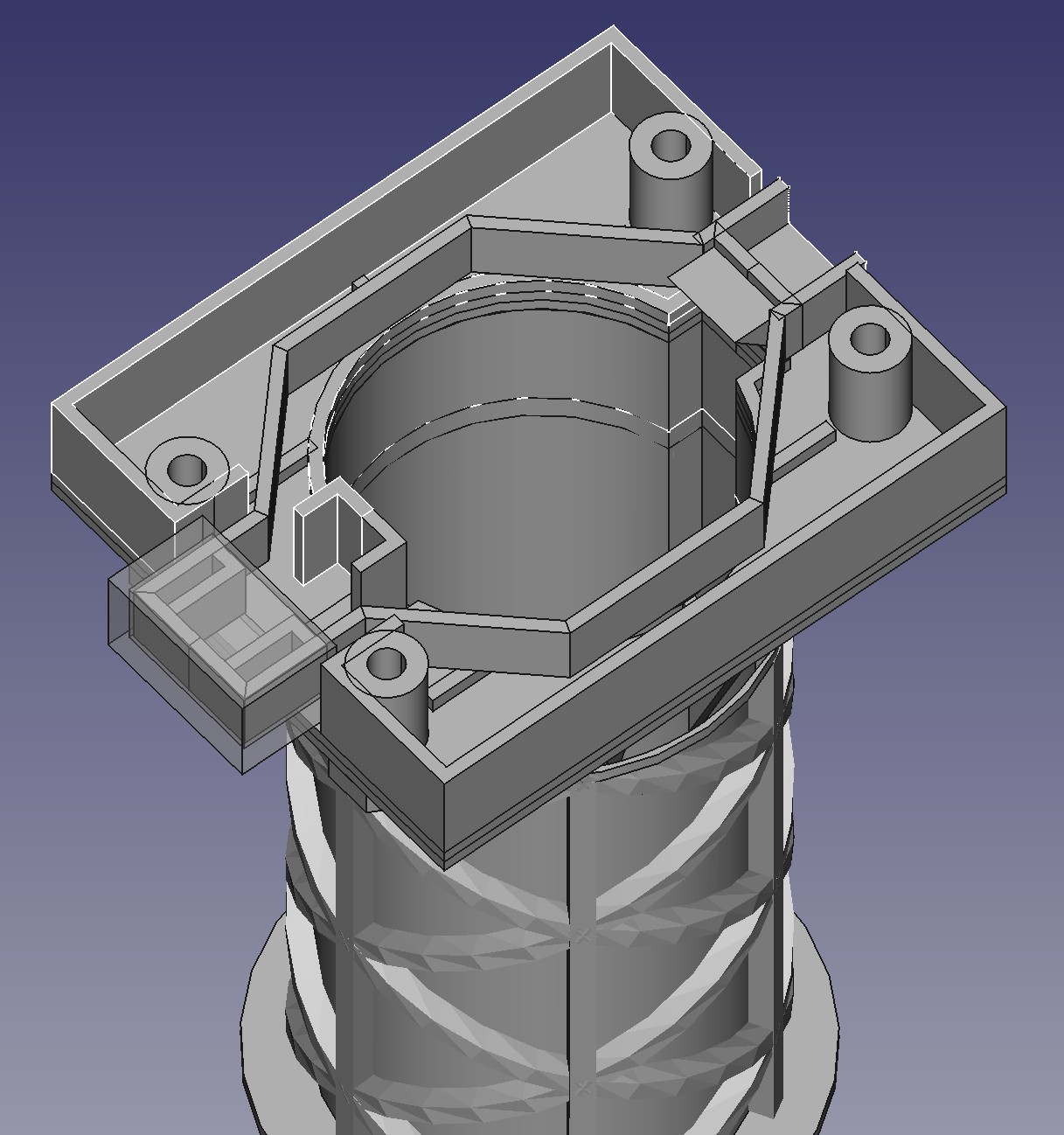

The next idea was a ratchet section paired with the spring section, to dial the spring to just the right tension. The ratchet mechanism was quite complicated, but seen as cheaper than printing a corkscrew.

Trying to make a timelapse of the printout was problematic, so sections got printed once in timelapse mode, thrown away, & again without timelapse mode.

Timelapse mode created blobs on 1 side. The blobs impacted the nozzle & broke the parts off the bed.

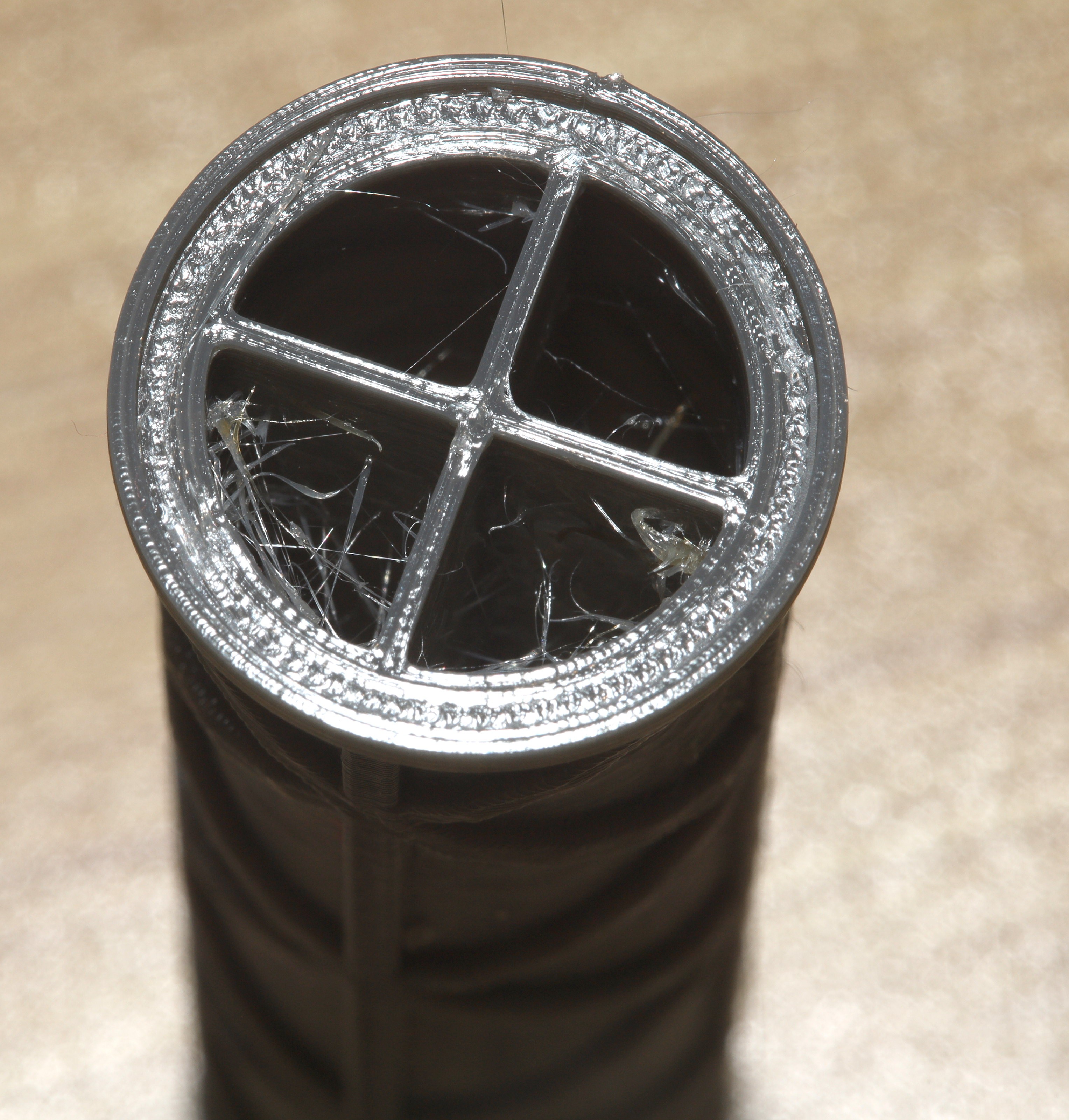

The thinnest cylinder was plagued by voids & eventually got more material added to compensate for the voids.

It solved the problem, achieved just the right pressure for any height, but definitely was lacking. That ratchet mechanism was complicated. The ratchet desperately needs a stopper to keep from falling out & bumper to make it extend in a straight line.

The adhesives bond rubber, but not PETG. PETG facing rubber needs holes to take up adhesive.

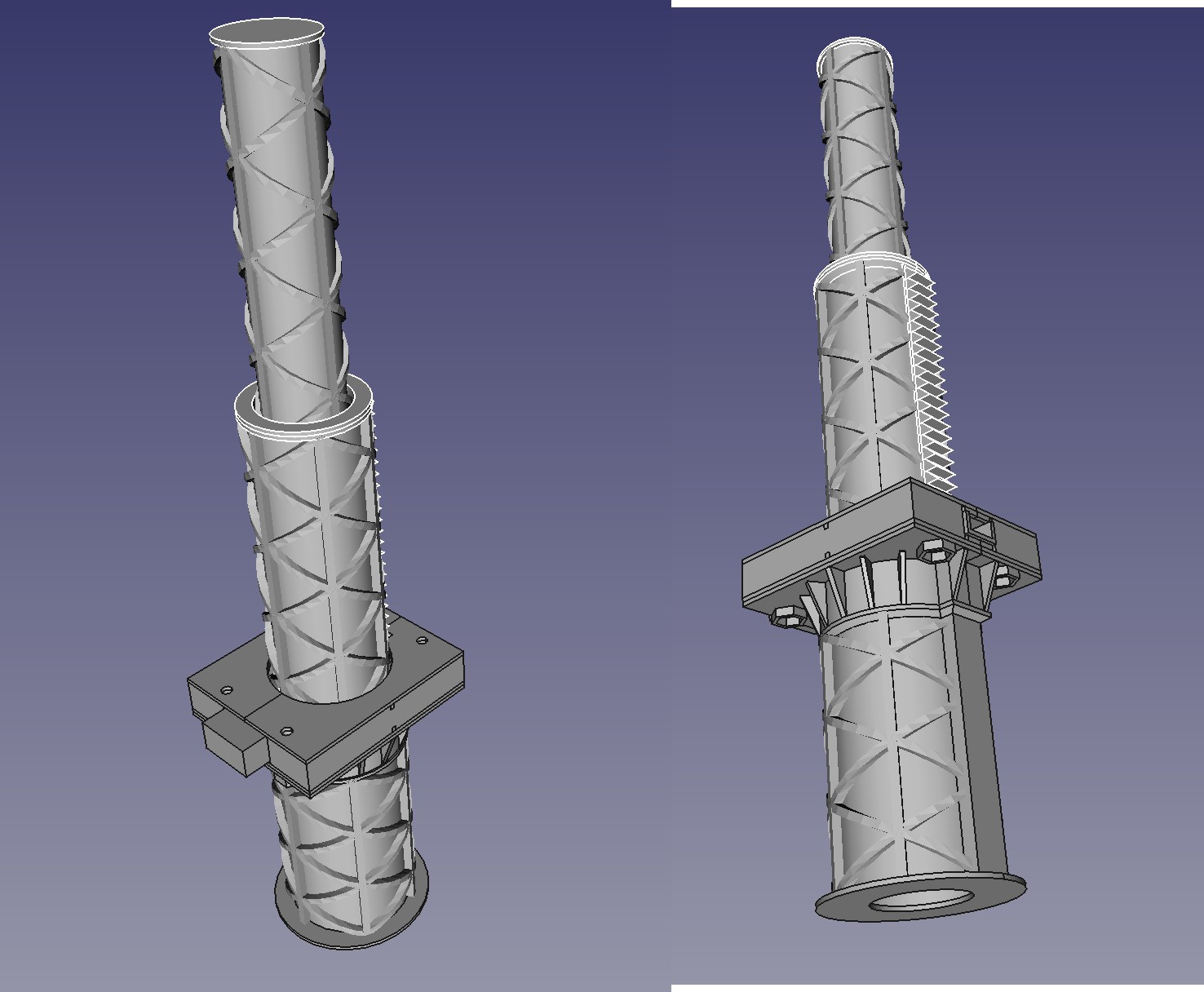

A corkscrew would definitely be simpler than the ratchet & probably use the same amount of material, but it would be harder to use & harder to look at. 1 section could have a corkscrew. Another section could have a tab stick into the corkscrew.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.