The original backlight had 16 tubes, 25.5" in length.

Other ideas were to just solder together loose LEDs or solder together cool white LED tape instead of RGB tape. The cool white stuff couldn't be repurposed for indoor lighting but would be denser & require a lot less wiring. LED rope wouldn't have a small enough turn radius to be useful & would be dimmer.

A polarizing filter would have to be applied to the front of the glass to make it a reflective backlight. It would be very dim.

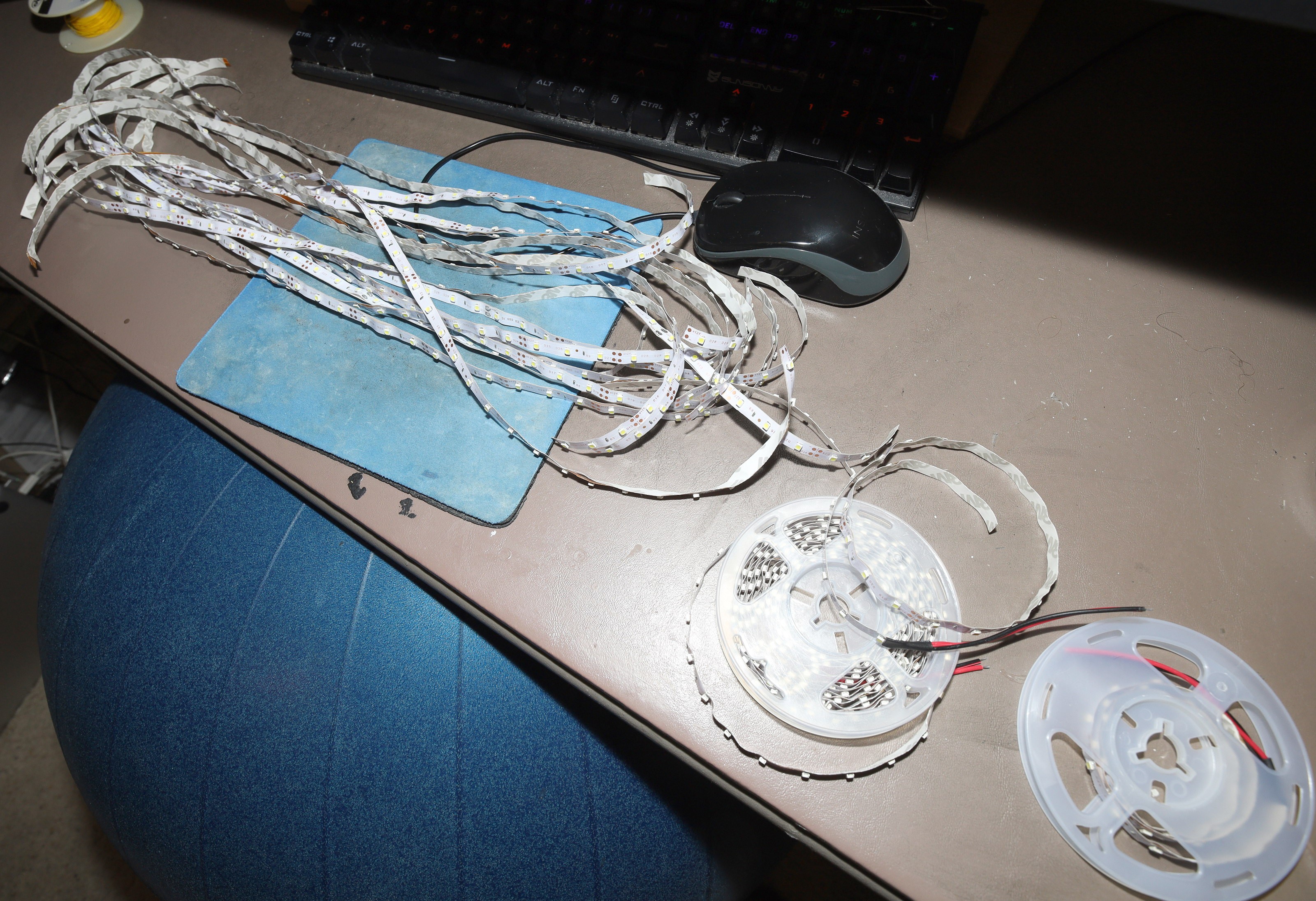

The next step was another batch of LED tape.

3 5m rolls, for a total of $16, bringing the project total to $36.

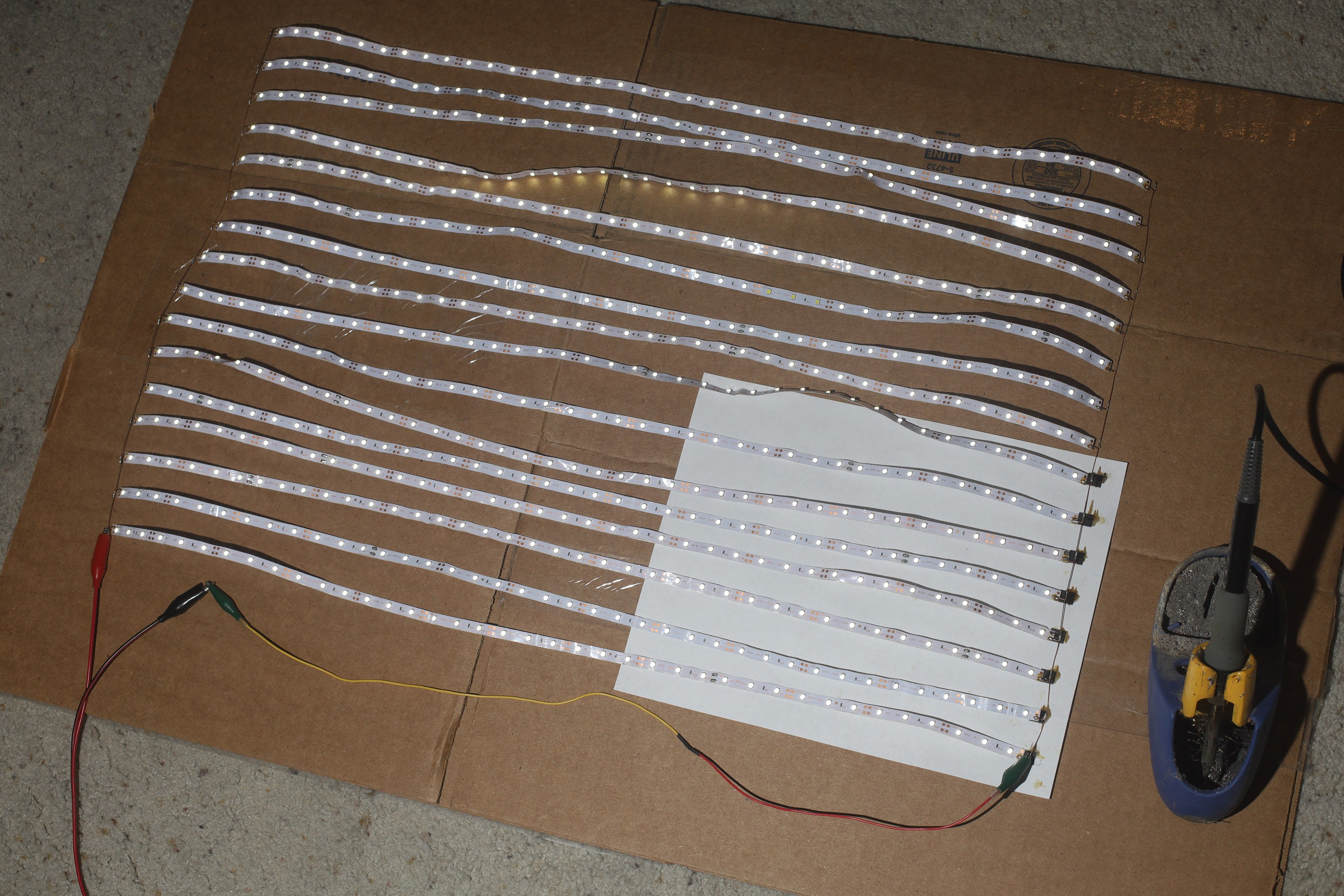

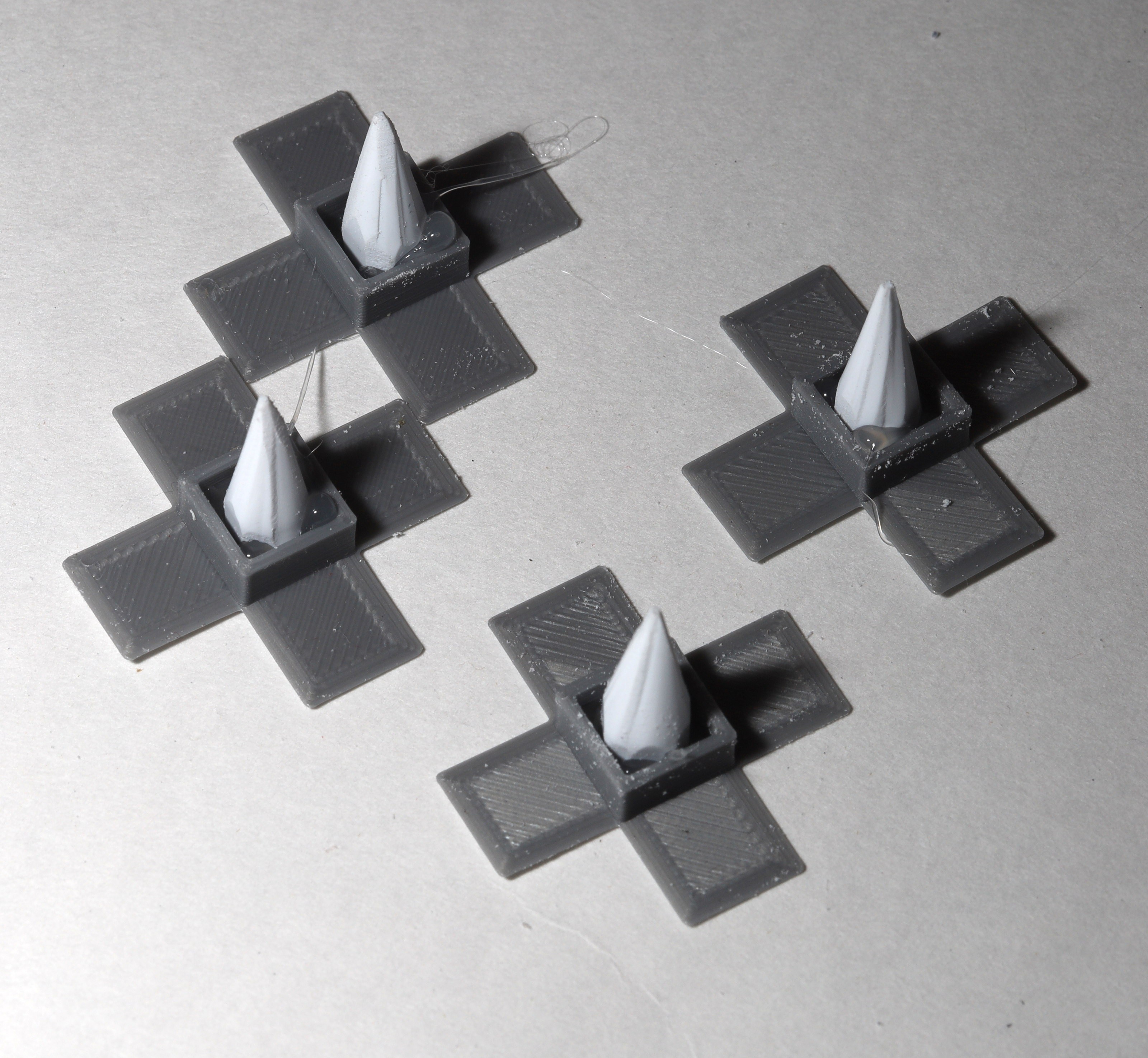

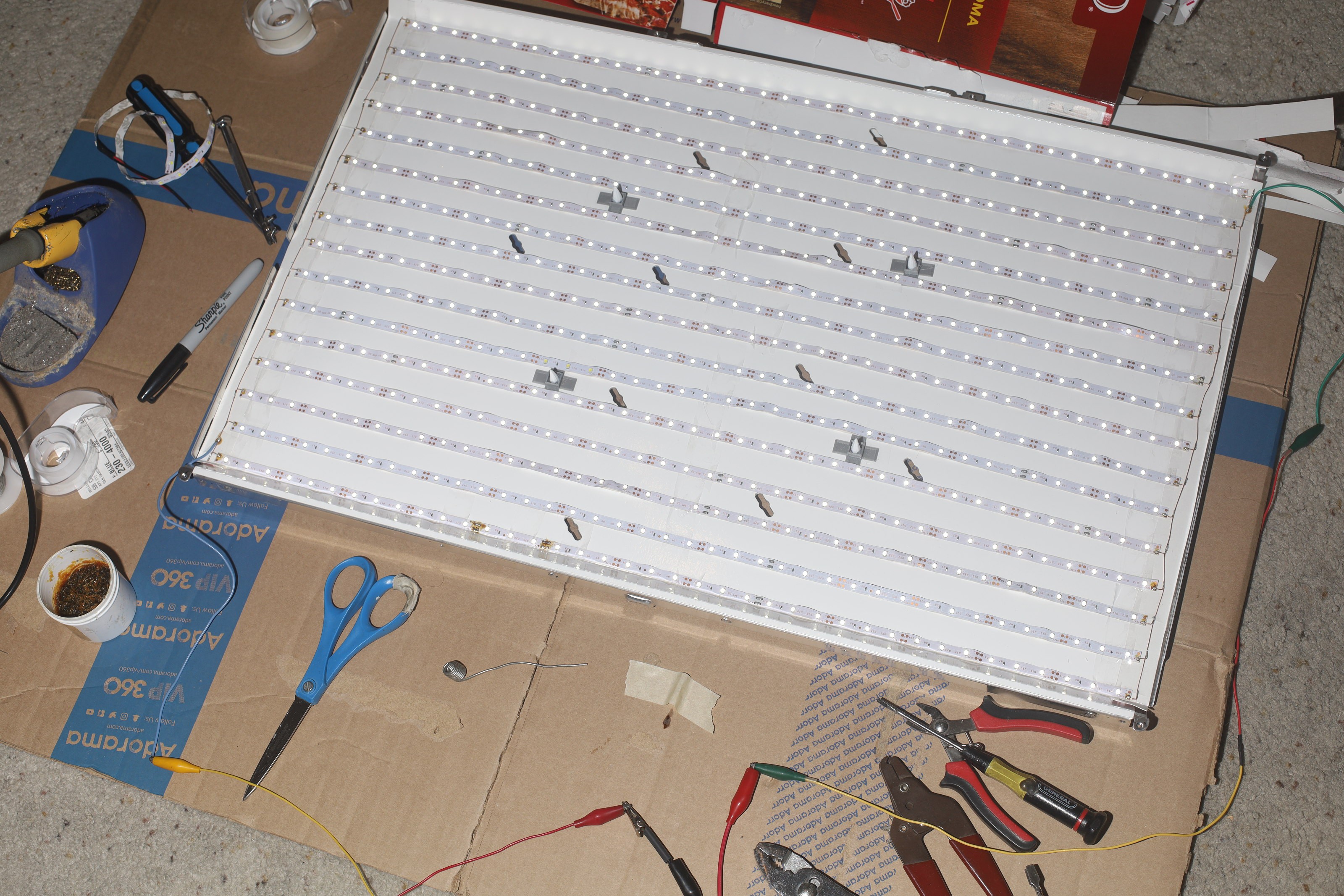

This was cut into 16 horizontal strips & 1 vertical strip. The next problem was creating new conical spacers. The lion kingdom figured it could print 2 to replace the original 10. To avoid spending $20 on a roll of white PLA, the next idea was printing a farstener for some kind of white rod.

To align them properly, finally took the plunge & learned how to draw an alignment pattern in python. It seems rather pointless to learn how to do the same thing in python that lions already did in C, when there was also the java craze, the ruby craze, the node.js craze & the go craze, but python seems to have won the battle to become the jellybean platform independent language. CAD modeling, game programming, machine vision have all standardized on python.

Tested with 1A at 11V.

For standoffs, spending $30 & waiting 2 weeks for white PLA would never do. The lion kingdom took whatever polystyrene hobbylobby had & sharpened it in a pencil sharpener to get new standoffs.

Then, they were hot snotted into some PLA things for farstening to the backlight. It seemed like hot snot would keep them attached. The backlight needed to be a total of 19-20mm behind the glass, but it was really just a guess.

After 2 hours of scotch taping the strips, replacing dead LEDs & repairing jumper cables, it lit up. LEDs started dropping like flies at only 11V. Called it quits after replacing a few LEDS & didn't replace them all.

The camera made it look a lot more even than it was. It was still hideous, uneven & yellow, even with all the diffusion filters on & the standoffs separating everything properly.

A diffuser for each LED strip could be printed out of translucent PLA, for a lot of money. Being just a static picture frame rather than a working monitor, it might be acceptable as is. The next step is to hook everything back up & fire up the raspberry pi.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.