For more information about the keyboard, see the github repo.

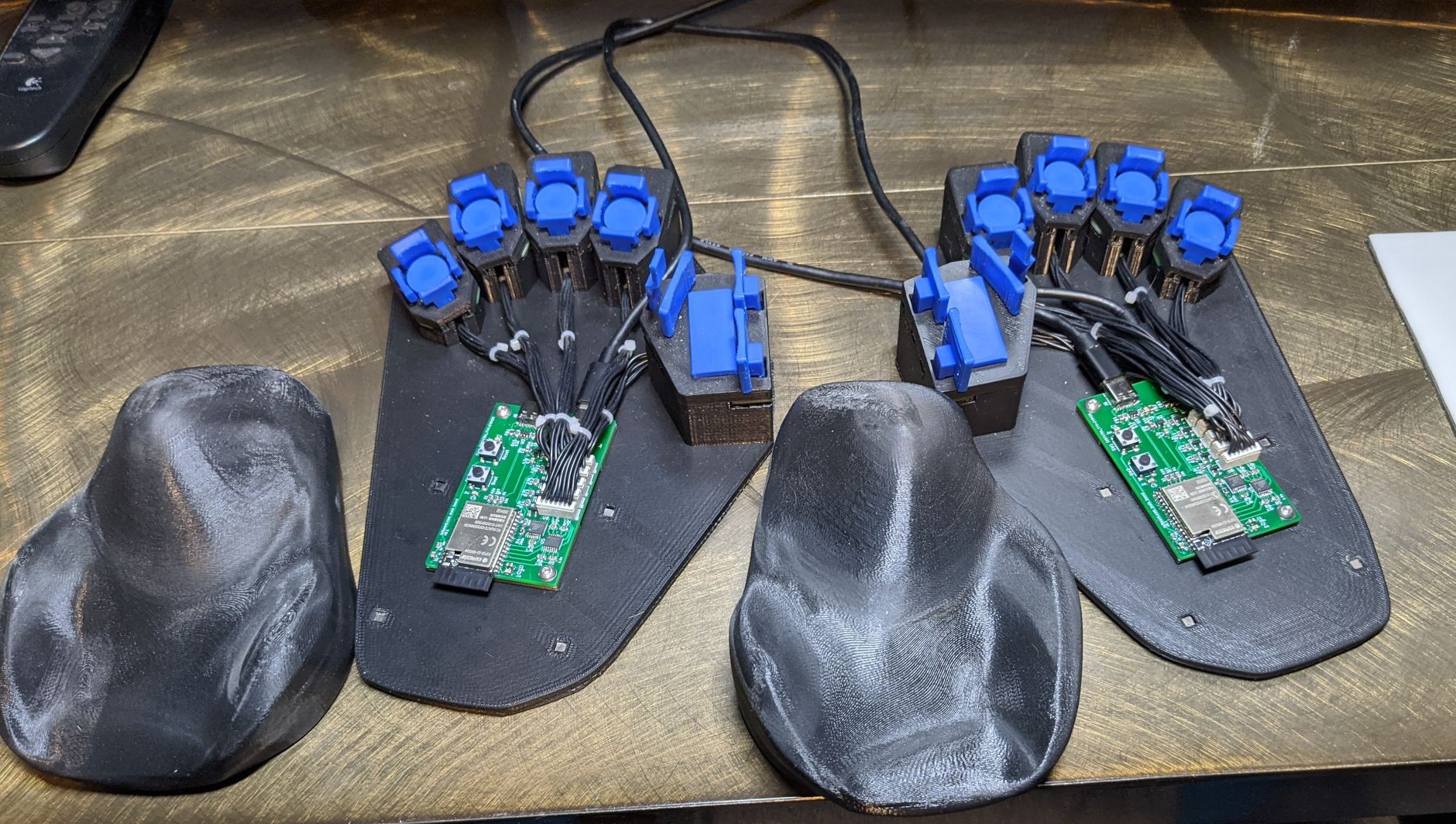

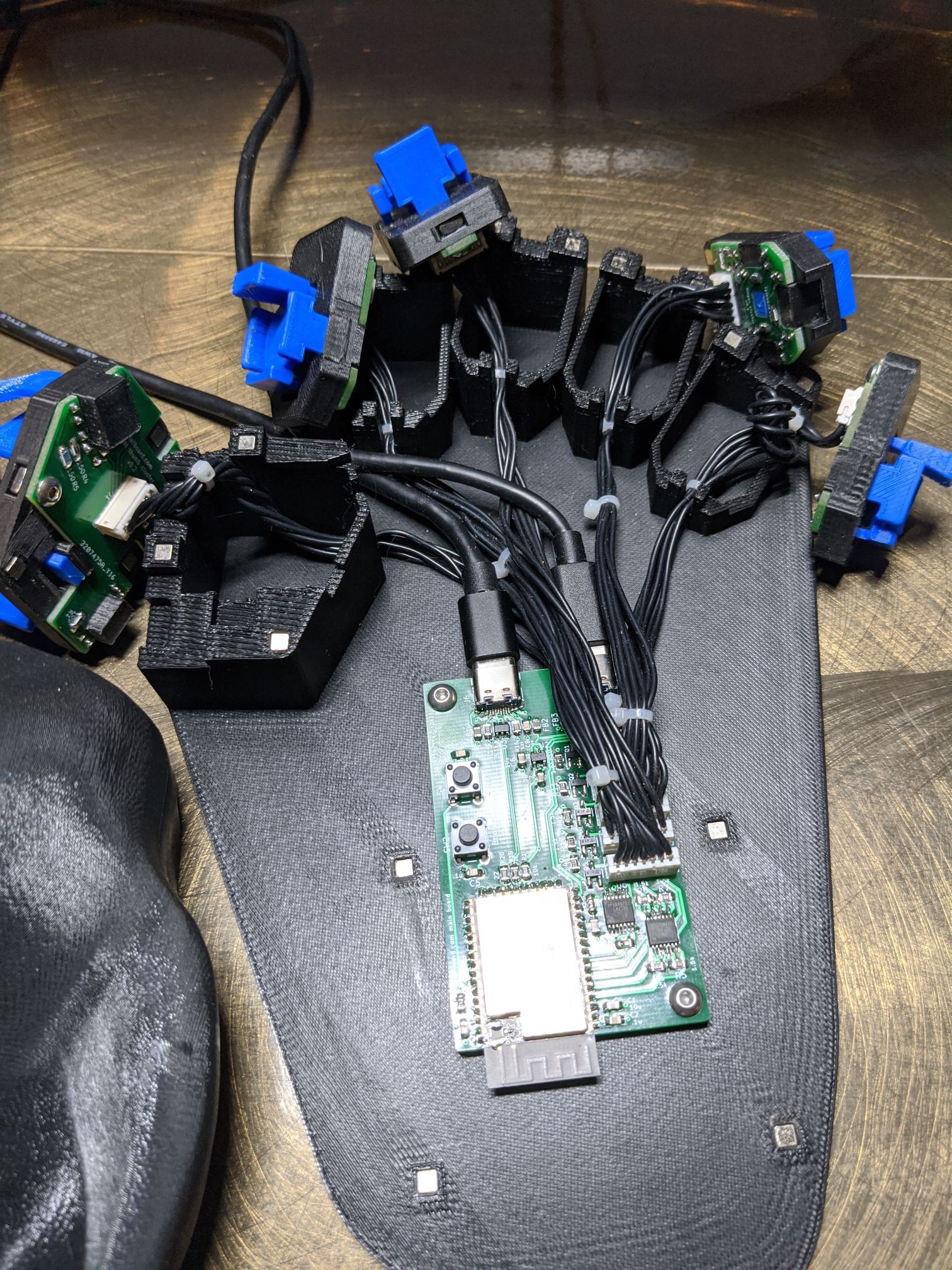

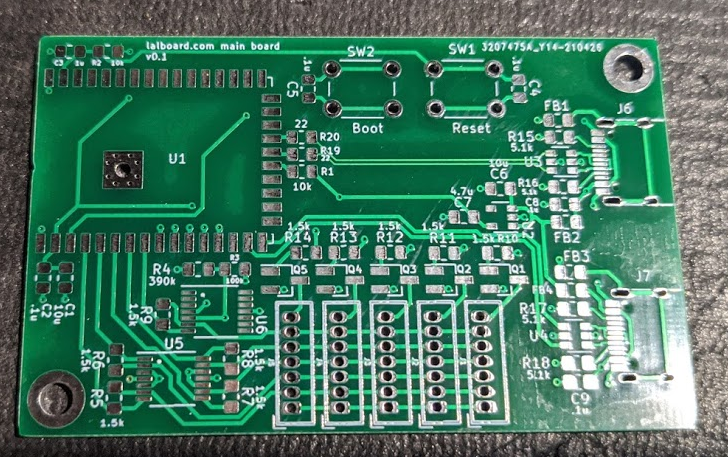

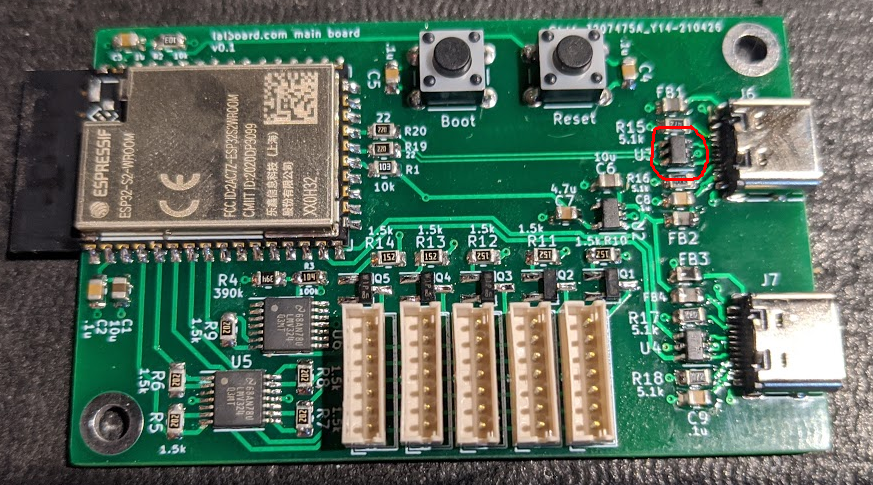

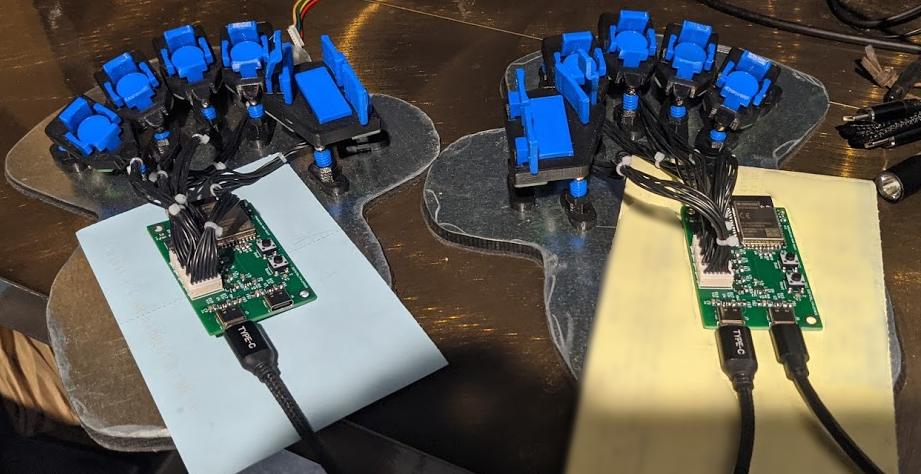

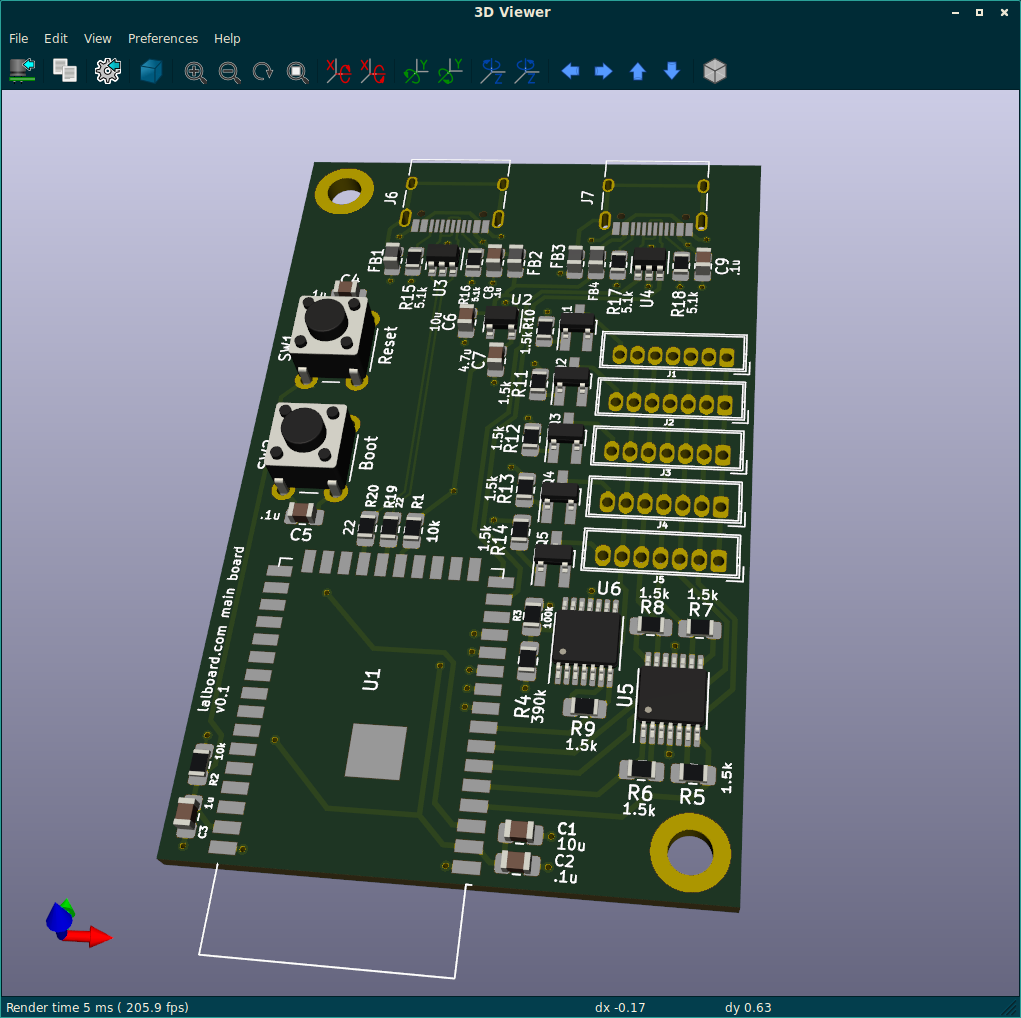

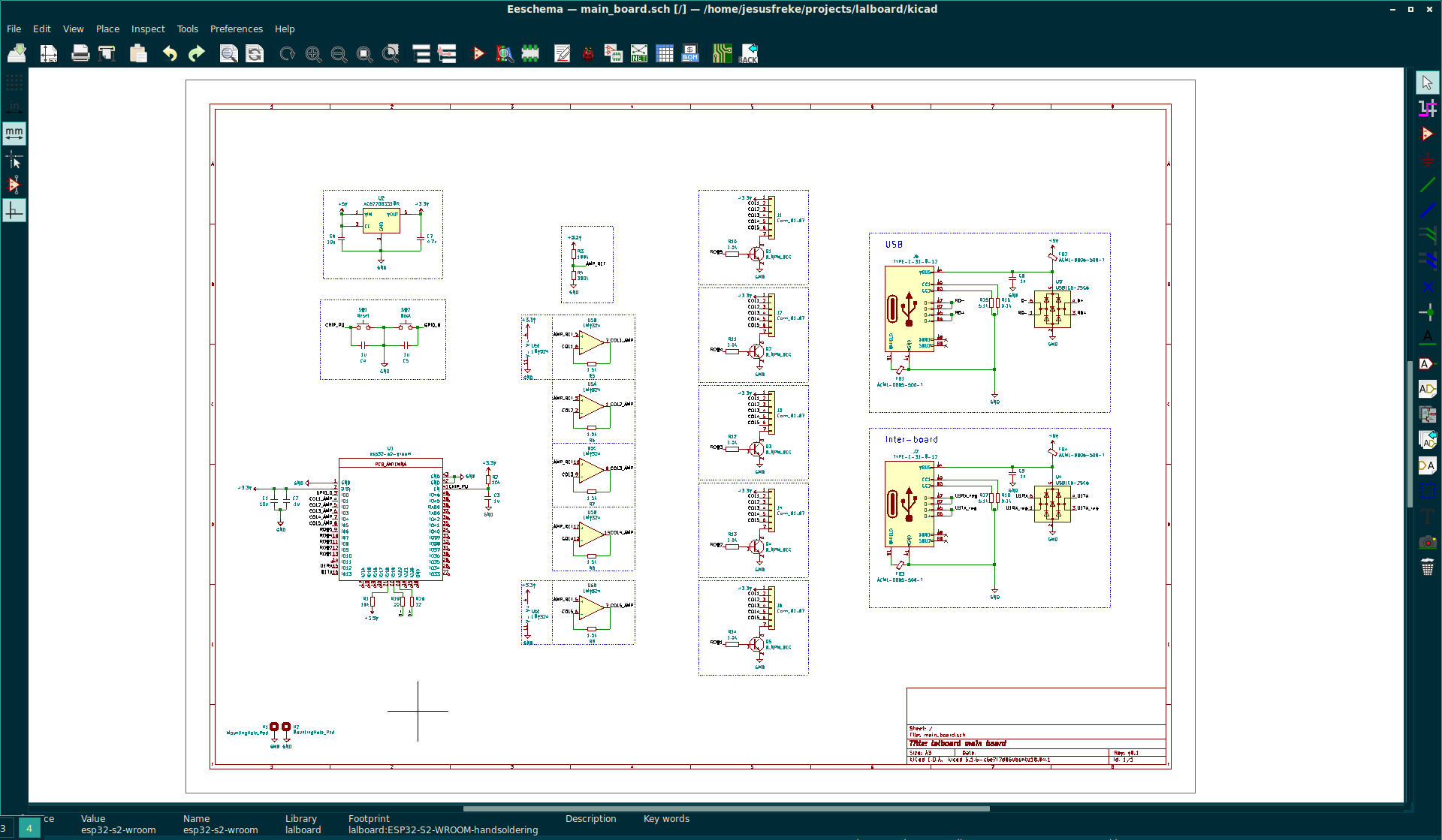

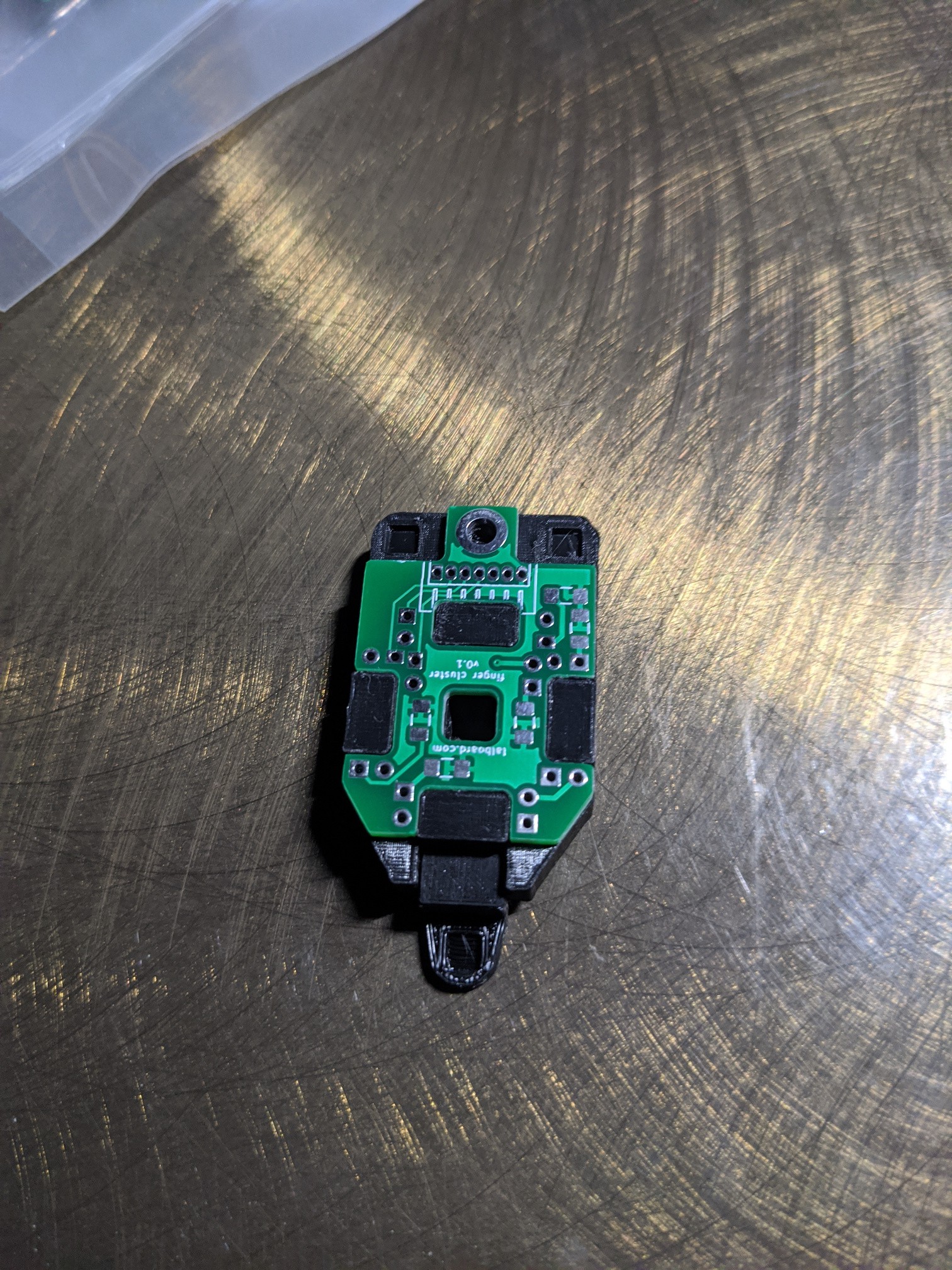

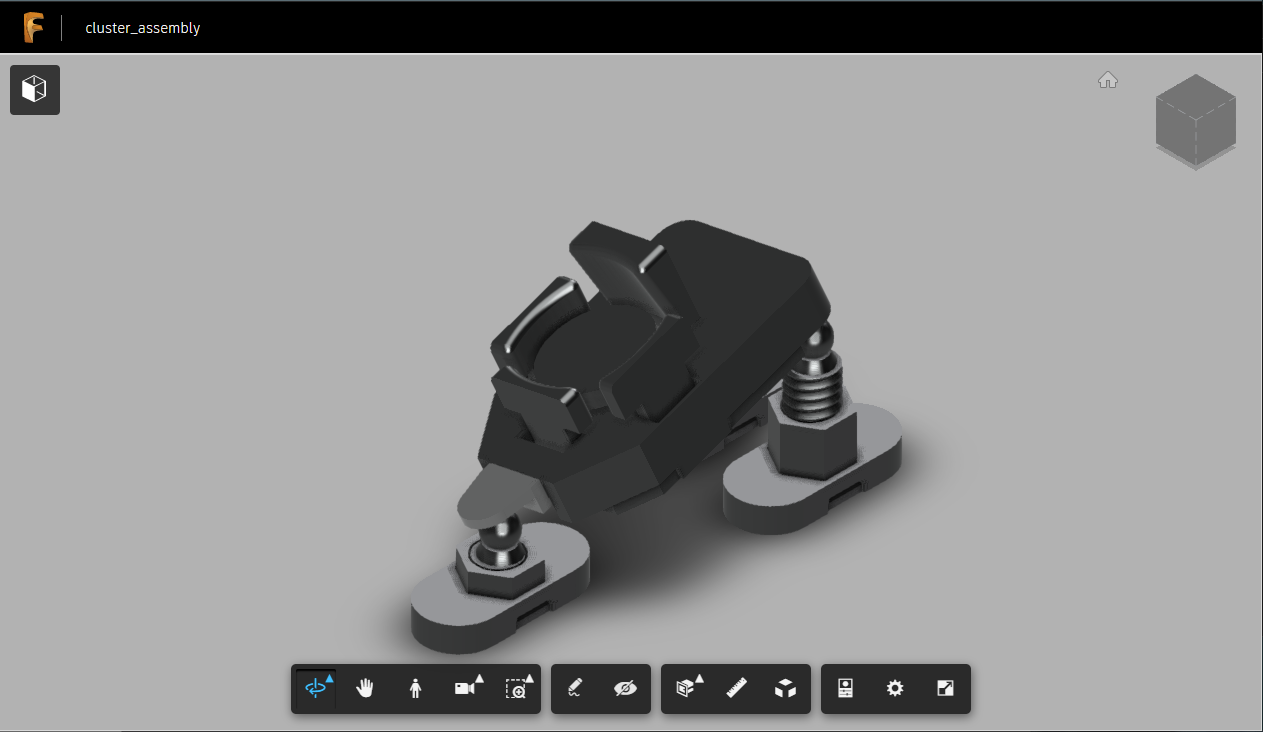

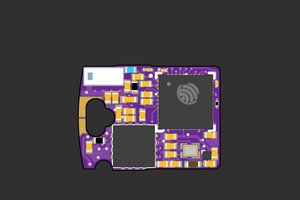

The initial version of the lalboard was completed and published in early 2019. But since then, I've been thinking about/planning/designing/working on a significant update to the design.

Up till now, I've mostly just posted about the status of the project occasionally on the geekhack thread. But that's a big thread, with a lot of other discussions happening, so I wanted to have somewhere a bit more focused. I plan on using this page as a central place to post project logs/status updates/etc.

The best place to chat about this project now is the "Datahand/lalboard/svalboard enthusiasts" discord server.

Ben Gruver

Ben Gruver

zakqwy

zakqwy

thpoll

thpoll

femtoduino

femtoduino

Hi Ben! Great progress on this since we last spoke.

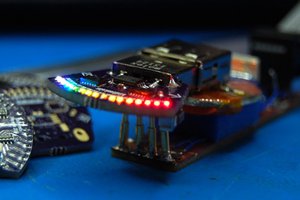

REALLY happy you switched to QMK, and the latest changes last year really improved it.

I've settled nicely in Thailand now, so I've resumed where I left off and I'll get the boards printed after some initial testing.

I was still using the more modular design for fingers from ironfox, which worked quite well, but I'll probably switch over to your design now since it'll be easier with more consistnecy.

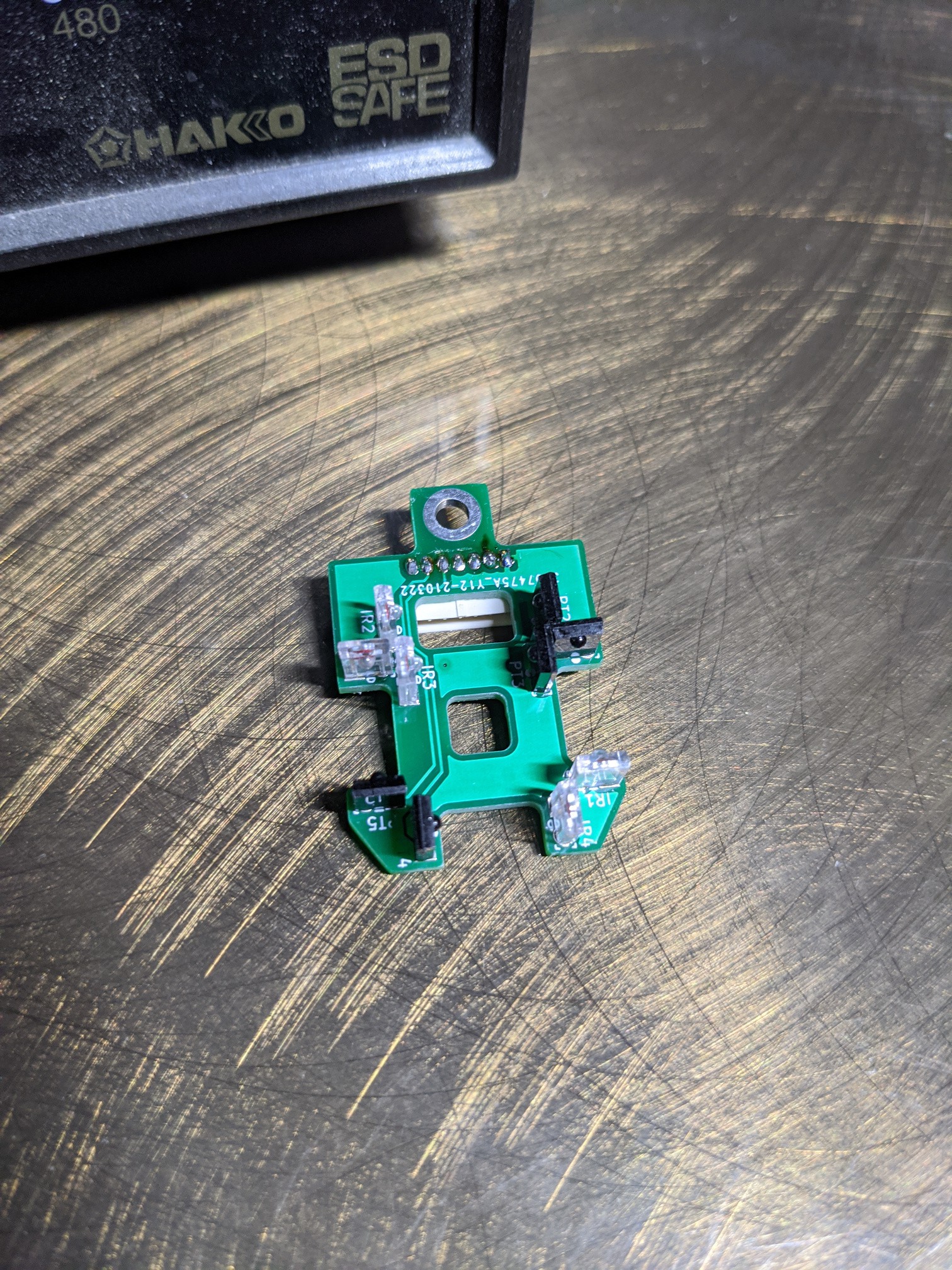

The one thing I really liked from his was the central button design.

Let me know if there's any gotchas I need to be aware of.