DJI FPV Investigations

Things I've learned about the DJI FPV quadcopter.

Things I've learned about the DJI FPV quadcopter.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Based on my experience with the DJI RoboMaster S1's battery, I had assumed the FPV drone also communicated with the battery over I2C. I was wrong about this. The data transfer looks like CAN bus.

My logic analyzer doesn't read CAN packets so I'll need to figure out a way of reading this data. I thought I'd share this information in case any of you are interested.

Edit (April 1, 2021): Thanks to Andrew Young who informed me my logic analyzer was capable of decoding CAN. This is the exported text of the CAN data:

Time [s],Packet,Type,Identifier,Control,Data,CRC,ACK 2.111320843750000,0,DATA,0x554,0xE,0xEF 0xEE 0x93 0xE9 0x7B 0xAE 0x8D 0xBF,, 2.114893812500000,1,DATA,0x138,0xF,,, 2.126467750000000,2,DATA,0x153EFBE9,0xE,0x67 0xFE 0xD6 0x15 0xE9,, 2.310771906250000,3,DATA,0x554,0xE,0xEF 0xEE 0x93 0xE9 0x7B 0xAE 0x8D 0xBF,, 2.314893750000000,4,DATA,0x138,0xF,,, 2.515036843750000,5,DATA,0x138,0xF,,,

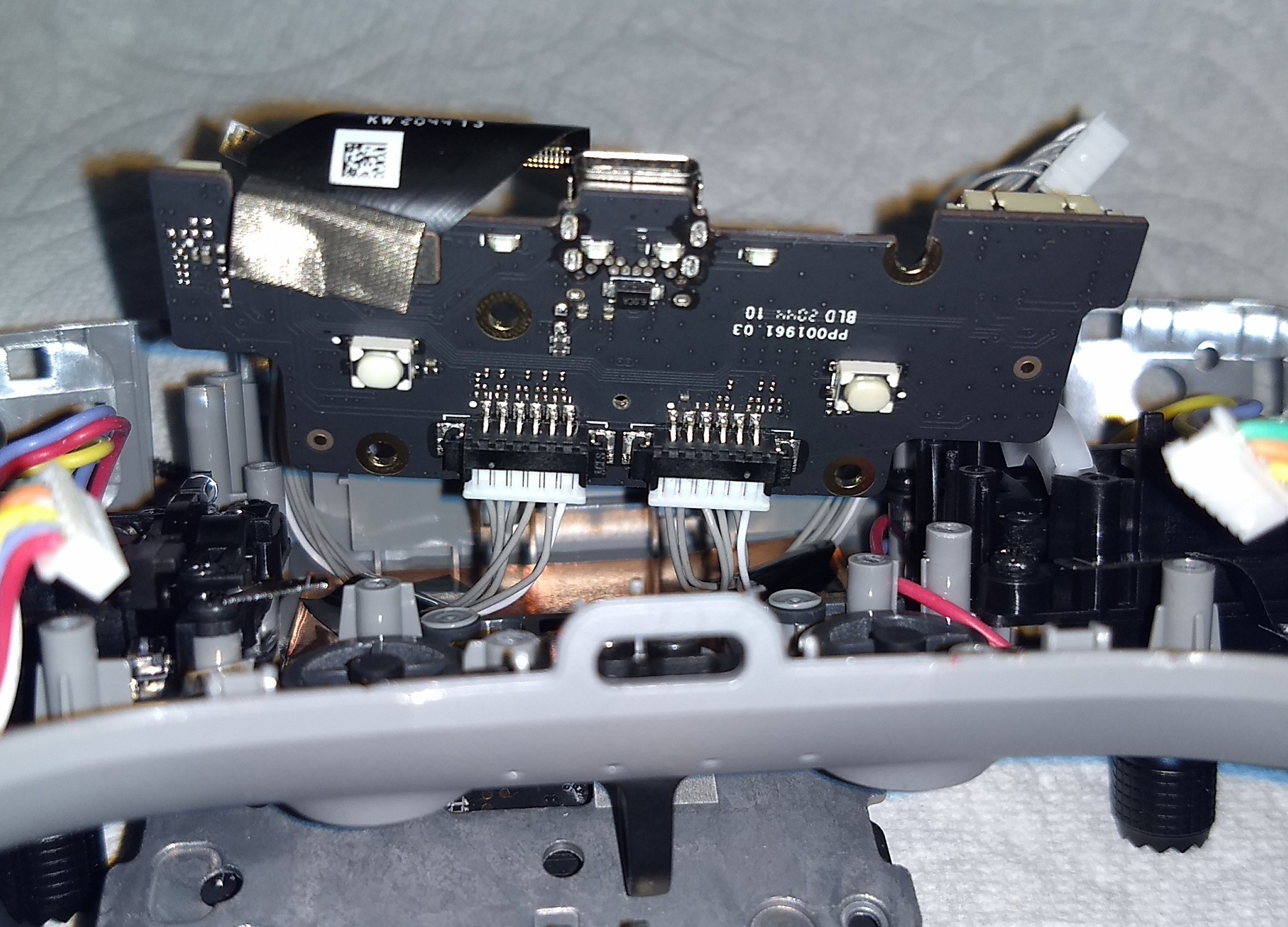

Here are some photos of the chips inside the controller. As I was cropping the photos I realized they weren't as clear as I had hoped. If anyone more better photos of any of the chips, let me know. I don't promise I'll get better photographs of the chips but a request will make such an event more likely.

The heart of the controller has two large heatsinks. There's a black one near the back of the controller and bare metal one just behind the top of the controller. Between these heatsinks are two PCB with cans covering portions of the board. Above you can see the top of the smaller square PCB with the can removed. The can also acts as a heat spreader. It was interesting to see the four similar rectangular chips are cooled from the opposite side of the PCB.

While most of the buttons can be removed from the controller, the C1 and power buttons have plastic attachment points which have been melted to hold them captive.

The two wire harnesses seen in this last photo are sandwiched between the copper tape inside the top of the controller and bare metal heatsink.

I have plans to examine more of the components which come with this drone in the near future.

As mentioned in an earlier log, the gimbals use Hall Effect sensors. Below shows the magnet with the sensor PCB removed.

The gimbal in the photo below has one sensor PCB in place and the other sensor PCB removed.

The small button is on a flat flex cable. The cable connects to the USB board. The above photo has arrows pointing to the two connectors which are normally mated when assembled.

Below is the left gimbal with the flax flex cable show at the bottom of the photo. The small switch is not in view in this photo.

The small button and white plastic friction liner have been removed from the left joystick in the photo below. The two small buttons are circled.

Below is a rubber light shroud to isolate the LED on the PDB with the USB connection.

Above shows the USB PCB rotated 180 degrees. The charge state LEDs and two buttons are on the other side of the PCB. This PCB has connector to accept the flat flex cables with the small switches.

To be continued.

I initially thought the controller was going to be really hard to open but I was pleasantly surprised to find four Philips screws at the bottom of holes under the back rubber grips. The red circles in the photo below show the location of these four screws.

I was able to pry the shell open but starting where the rubber stick holders are sandwiched between the two halves. It wasn't easy to pry the controller open but it wasn't much worse than many game controllers.

I took about the button and the potentiometer located in the top shell.

The camera angle control dial has a cool return to center gizmo.

I took mine apart so you don't have to. It's a bit of a trick to reassemble. I've seen other return to center pots before but I think this mechanism is more involved than other gadgets I've taken apart. The yellow shape near the center is a plastic tab which is likely used to make assembly easier and faster.

The lower section of the remote has a lot more going on inside.

There are two 18650 Li-Ion cells inside. These cell each have a thermistor to monitor their temperature. I haven't figured out if the cells are in series or if they're parallel yet. My guess is they're wired in series.

After removing the batteries, I removed the bottom heatsink. A good portion of the weight of this controller is from the heatsinks. There's a round cutout in the heatsink to allow the buzzer to pass through it.

The two main PCBs rest on the black heatsink above. The back of the top heatsink can be seen still in the shell in the photo above. The top heatsink has been removed from the shell in the photo below.

Above is the PBC which has the USB connection, two buttons, and the power LEDs.

Above is the PBC which has the USB connection, two buttons, and the power LEDs. Based on the wires, it's pretty clear this controller has two antennas. I was surprised to see the shape of these antenna.

Based on the wires, it's pretty clear this controller has two antennas. I was surprised to see the shape of these antenna.

There's a wide 15mm x 30mm antenna in the base of the antenna and an 8mm x 30mm in the left side of the antenna. The right side of the antenna housing is empty.

The plastic spacer holds the unconnected PCBs 5mm from the wired PCBs.

To be continued.

DJI FPV uses a 6-cell 200mah LiPo battery.

Taking apart the battery is much easier than taking apart the battery in the DJI RoboMaster S1. The FPV battery is held together with two screws and liberal amounts of double sided tape.

After removing the two hex screws the top panel needs to be pried away. I used a flat head screw driver but this did leave marks.

Hopefully the following photos will allow anyone else to open their battery with less damage than done to mine.

The rest of the battery enclosure is held on with double sided tape. I was able to carefully separate the various parts with a bit of prying.

The white blob in the center of the battery pouches is a thermistor held in place with a bit of Silastic. The back side of the battery is sitting on the top cover to keep the double sided tape from sticking to my background paper. The smaller black rectangle on the left of the photo is the piece which would normally be connected to the back of the battery pack.

The photos above and below show the battery management circuits.

This last photo shows the plastic shell used to protect the battery.

The battery has what looks like five connections. I see only four wires coming from the connector which are soldered to the PCB.

I plan to investigate the communication between the battery and the quadcopter as well as the communication between the battery and the charger.

Create an account to leave a comment. Already have an account? Log In.

About the replacement for the gimbals, do you know if they are compatible with the jumper T-pro ?

I've tried to connect old ski gimbals from old black remote - they are won't work for some reason. I've tried to reduce voltage to match R2 levels - doesn't work too. 3d party hall gimbals I've tried (TX16S) works fine after calibration.

Hi Duane - have you found a way to send navigation commands to the controller -> left,right, up, down, turn etc

No I haven't tried sending commands to the controller. I think the easiest way to do this would be to use multiple DAC channels to replace the inputs from the Hall sensors.

Hi,is there anyway to anylize the protocal about the controller 2?So we can make our own recevier for this? I think afterall they should make it to sbus protocal on board or comunicate with the air unit.

Hello !

to get more photo from DJI FPV remote controller V2,

you can follow the links

https://fccid.io/SS3-FC7BGC2006

or : https://fccid.io/SS3-FC7BGC2006/Internal-Photos/Int-Photos-5014197

all dji products : https://fccid.io/SS3

Hi, I have this drone and I can help.

I have also a CAN bus analyzer and if I do an adapter I can log more messages to investigate the protocol.

Do you have the pinout of the connector?

I mean:

the big pin connected to the red wire is the Vbatt signal;

the big pin connected to the black wire is the GND;

the other 3 small pins are:

1. CAN H ?

2. CAN L ?

3. logic GND ?

The pin in the corner of the "L" shaped three pins is logic ground. As you'd think, this connects to the battery ground as well. The other two pins are the CAN lines. I'm not positive DJI uses normal CAN protocols. I've heard they use a variation in some YouTube comments.

There's a post in the DJI forum discussing the battery protocol in more detail. I will try to find the post and add a link here.

ok so the CAN signals are accessible from the top of the esc board into the drone. Have you found a CAN transceiver near the microcontroller on the battery?

Hi Duane, I found your phots ;) Have you noticed the S1 chip? do you think it could be the Surge S1 Xiaomi processor?? You can see that it's near the Ant1 and Ant0 inputs.

It is possible that it is used also for the SDR

Hello Raffaello, Indeed DJI is facing a strong chips restriction. I don't know if its the xiaomi processor, but I read that DJI design it. Did you get more information ?

Thanks

DJI-S1-信息同步传输芯片 https://kanzhaji.com/news/56579.html

Become a member to follow this project and never miss any updates

Andrey Kalmatskiy

Andrey Kalmatskiy

tomcircuit

tomcircuit

what are dimensions of main battery cells?