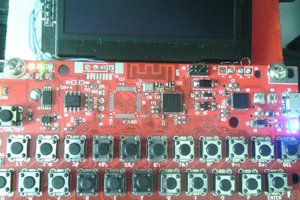

When the board comes out of the assembly line at the factory, it must be tested. We do this using a Fork that connects the board with needles. Here is a real stand of a real NOTA device.

Fork manages:

1. Measuring all important voltages on the board.

2. Connecting the reference RC and measuring their impedance (the stand evaluates the difference between the measured and the standard and decides whether the board is working or not).

3. Checks the Bluetooth functionality.

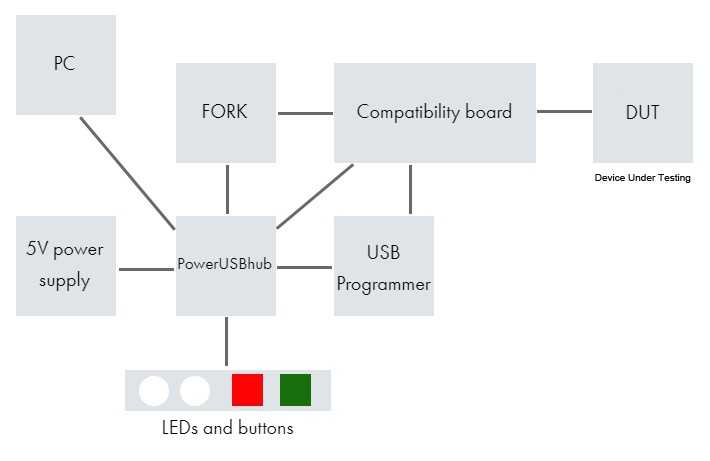

Block diagram of the stand

Stages of the stand operation:

1. Programming

2. Getting the serial number from the server

3. Write the serial number to the board

4. Calibration

5. Testing

Assembly

After the orange test fixture is fully assembled, the NOTA board is tested in the office. This is a mandatory step, since the stand will travel thousands of kilometers to production, and there will not be an opportunity to quickly correct something.

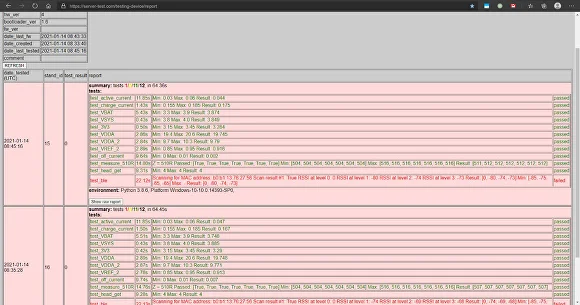

Example of a device testing report.

This is what a real-time test report looks like. Note that the production and testing are carried out in China. And we see this information in our office on the other side of the Earth, through our server.

A nice bonus from the server is that we can see online how testing is going, whether it is going at all, and how many boards were tested per day. Agree, this is important when the production is thousands of kilometers away from the development engineers! This is easy to do on a Fork, and when you buy a board, we will help you set up such a server.

forktestlab

forktestlab

Dave's Dev Lab

Dave's Dev Lab

vincenzo

vincenzo

Wim Van Gool

Wim Van Gool

HT3H5796-14

HT3H5796-14