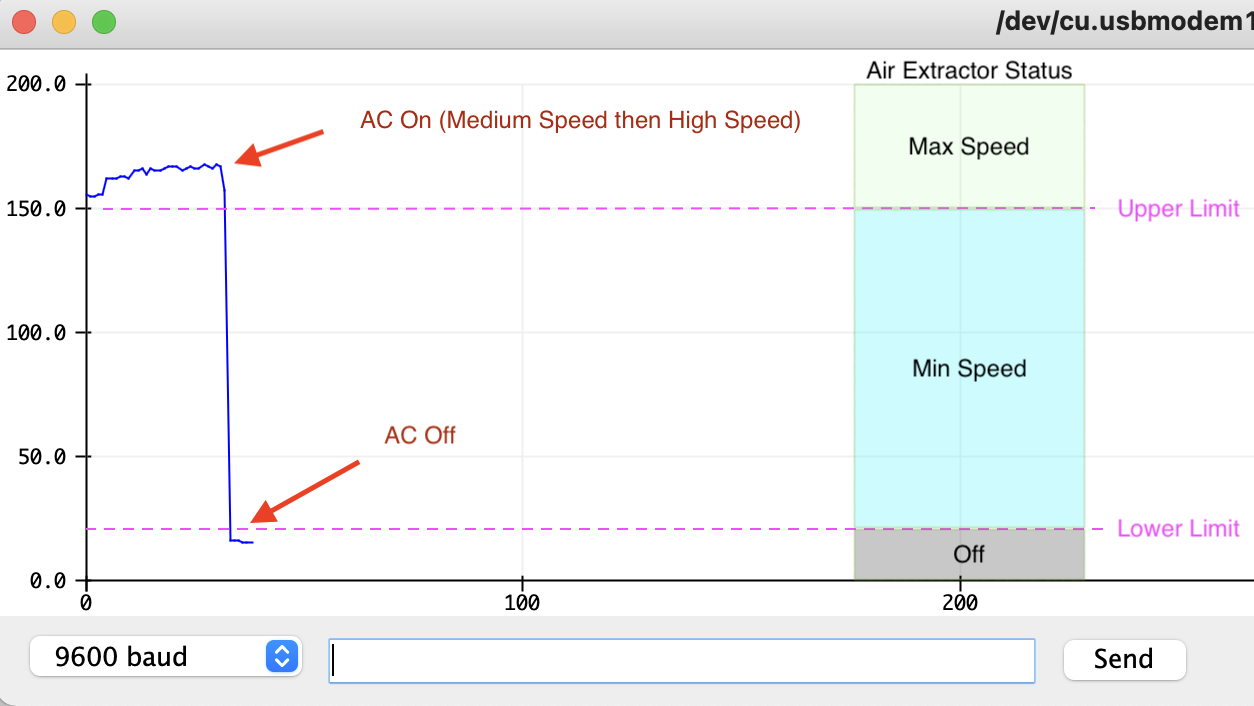

Here's a video of the unit working with the AC:

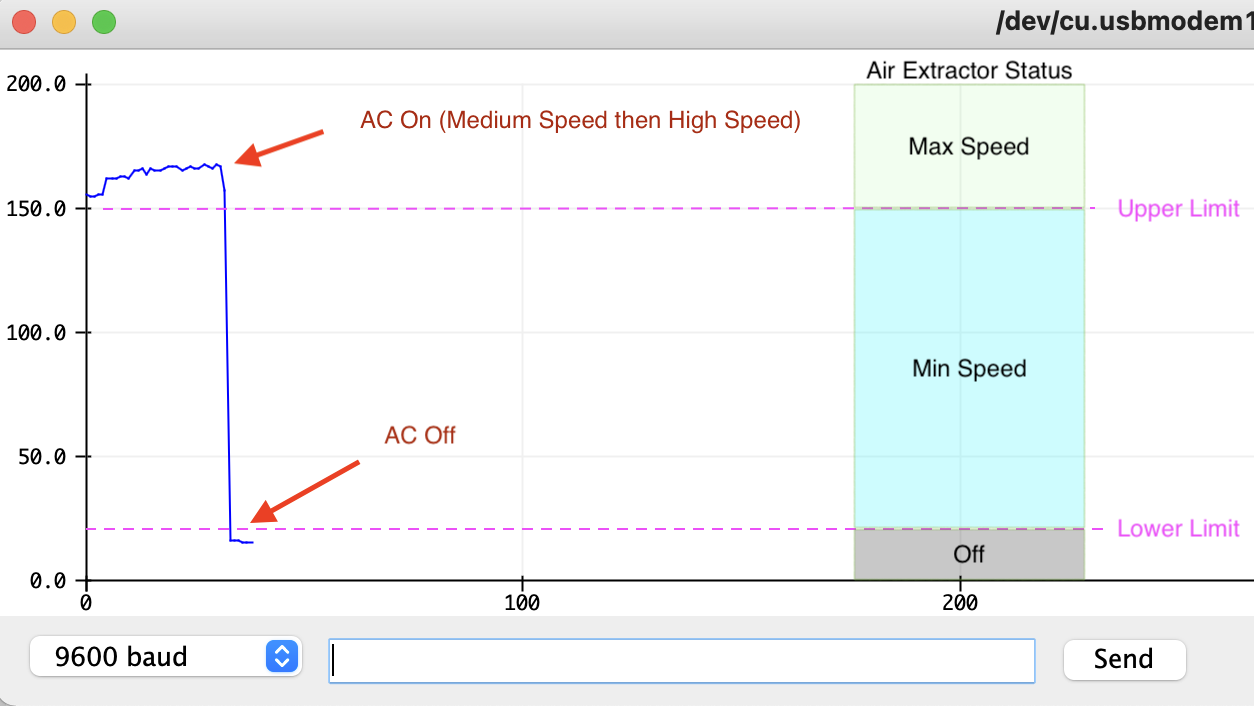

And its working range and settings from the serial plotter

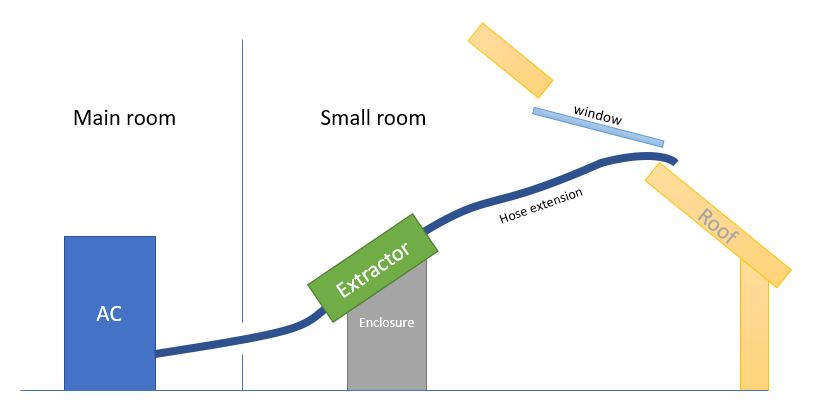

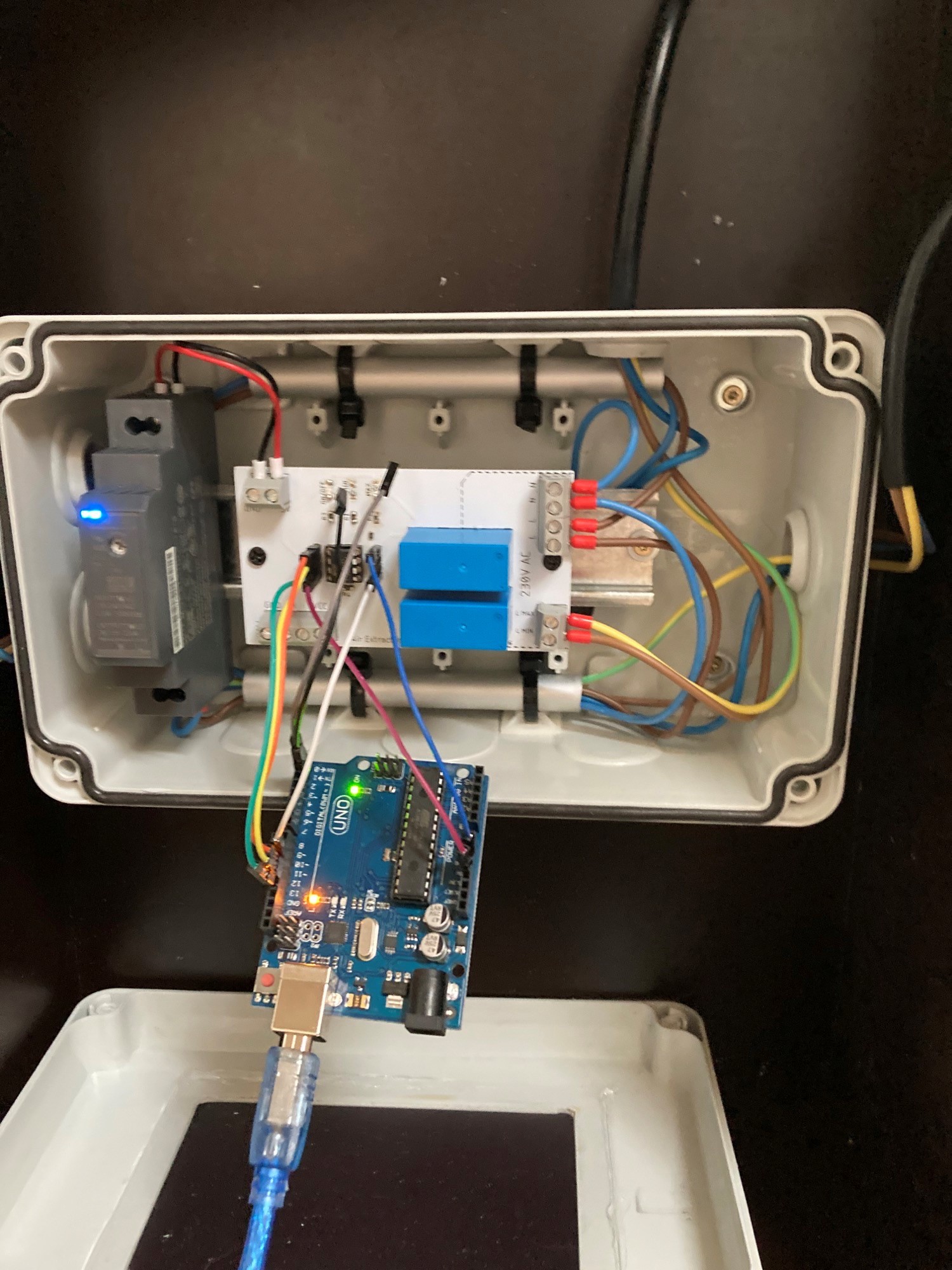

Here's the whole setup

Part one : Air Extractor Selection & Flow Considerations

The AC has the following throughputs (min-med-max) : 250/310/350 m3/h

The matching air extractor has the following throughputs: 280/360 m3/h

Therefore we will match the speeds as below:

| AC Speed | Matching Air Extractor Speed |

| 250 | 280 |

| 310 | 360 |

| 350 | 360 |

It's important to have slightly higher flow from the air extractor as we don't know how much back pressure either of the fan can handle. We will make sure there's a small opening for additional air intake just before the air extractor in order to avoid creating a low pressure between the two devices.

The air extractor selected : S&P TD-350/125 Z

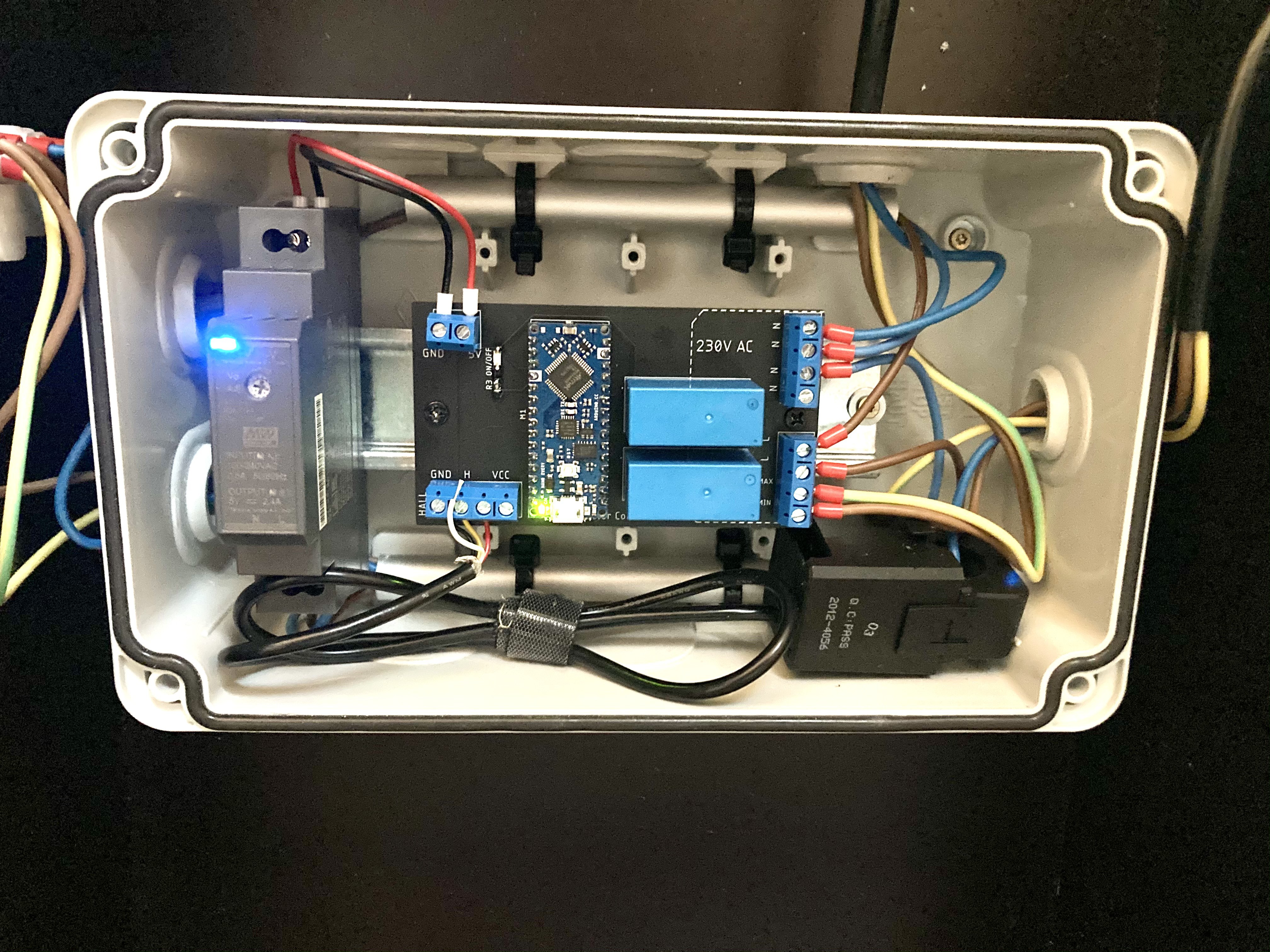

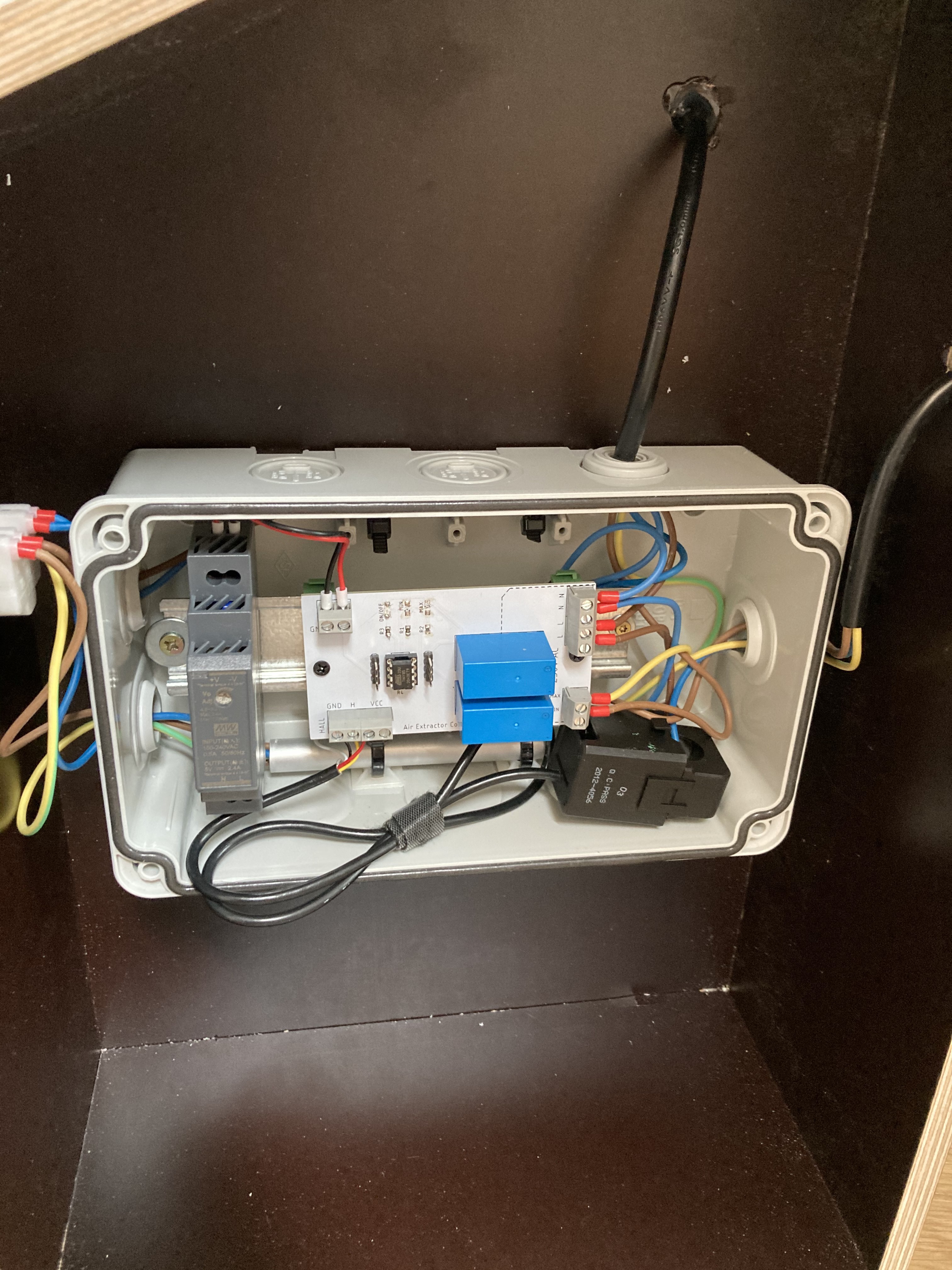

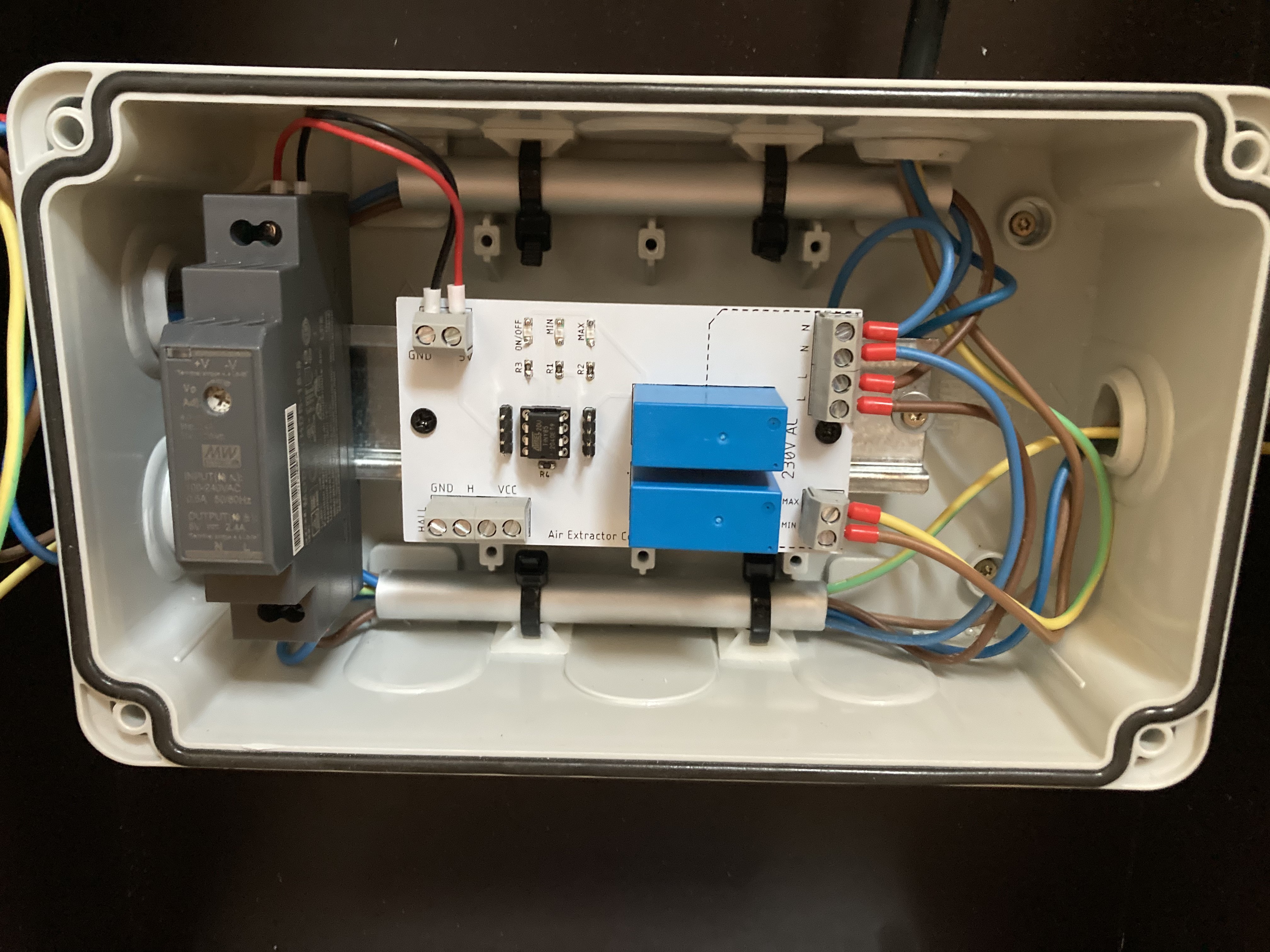

Part two : Controller

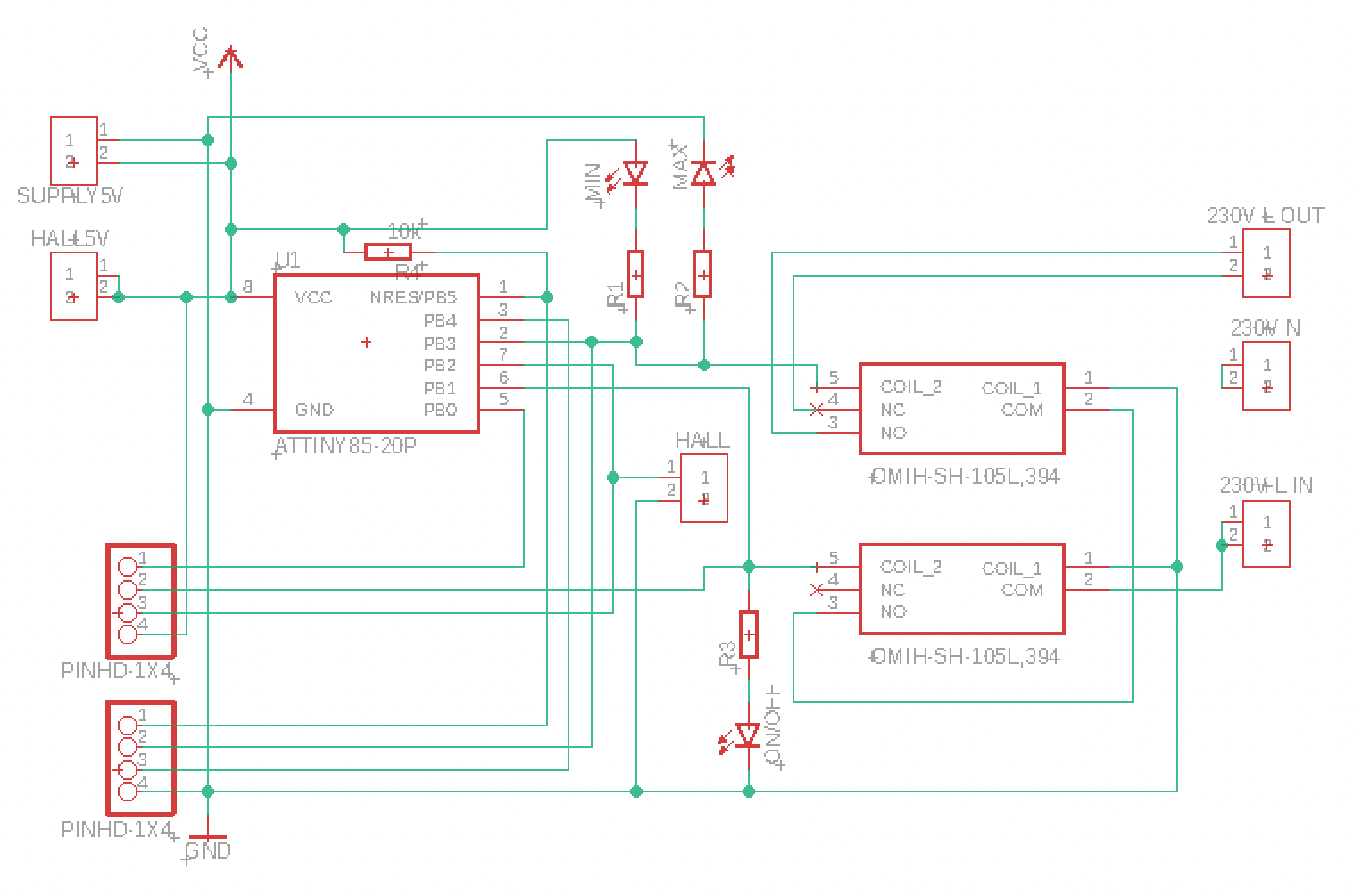

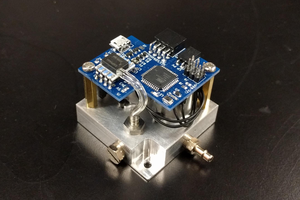

In order to to determine at which speed the AC is running, we will measure the current using a hall effect sensor on an extension cable.

Since this is an AC current, we need to determine the RMS value or the Vpp and therefore need to use a microcontroller.

This microcontroller will control two relays : One for the on/off switch and one for the min/max speed selection.

The schematics

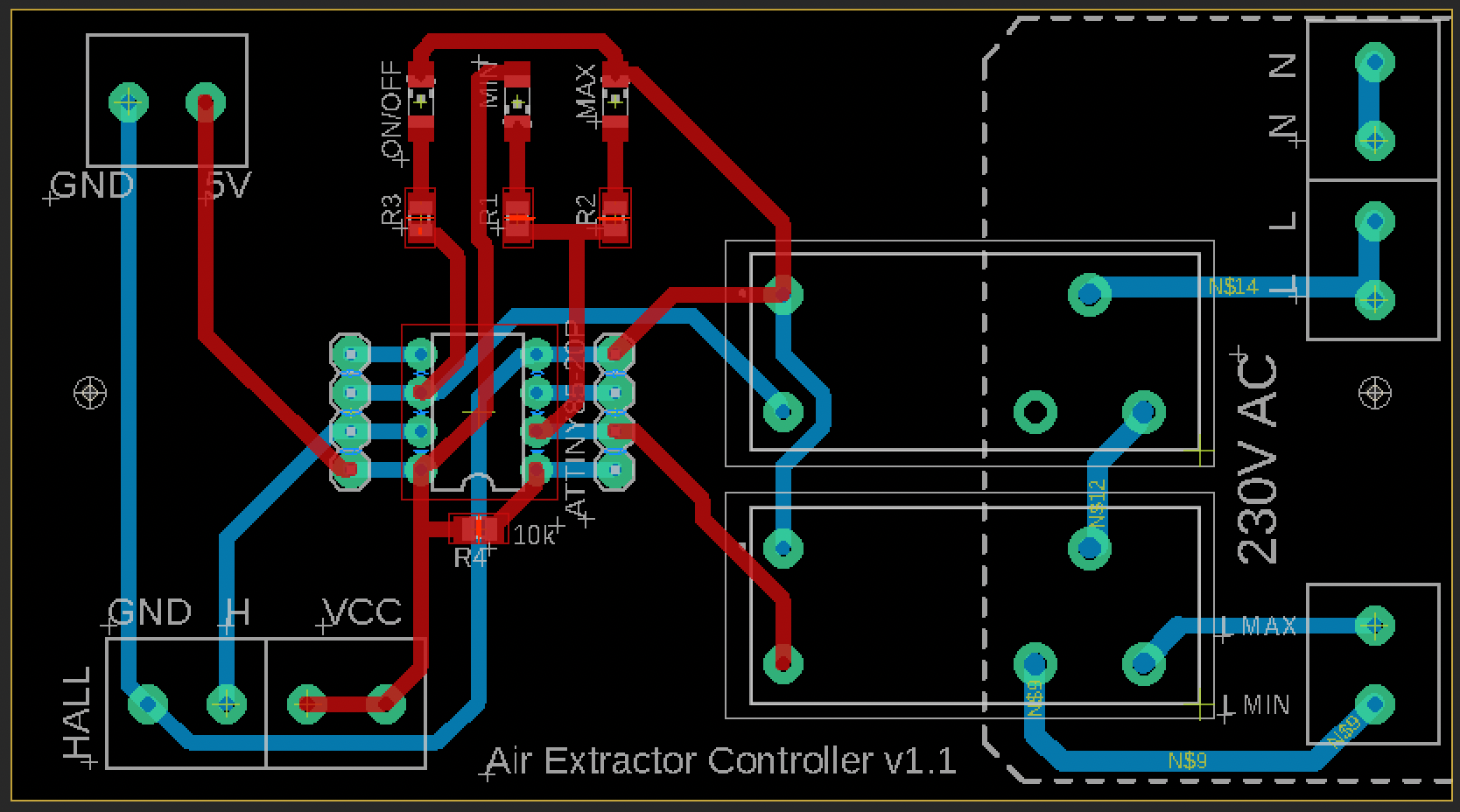

The PCB

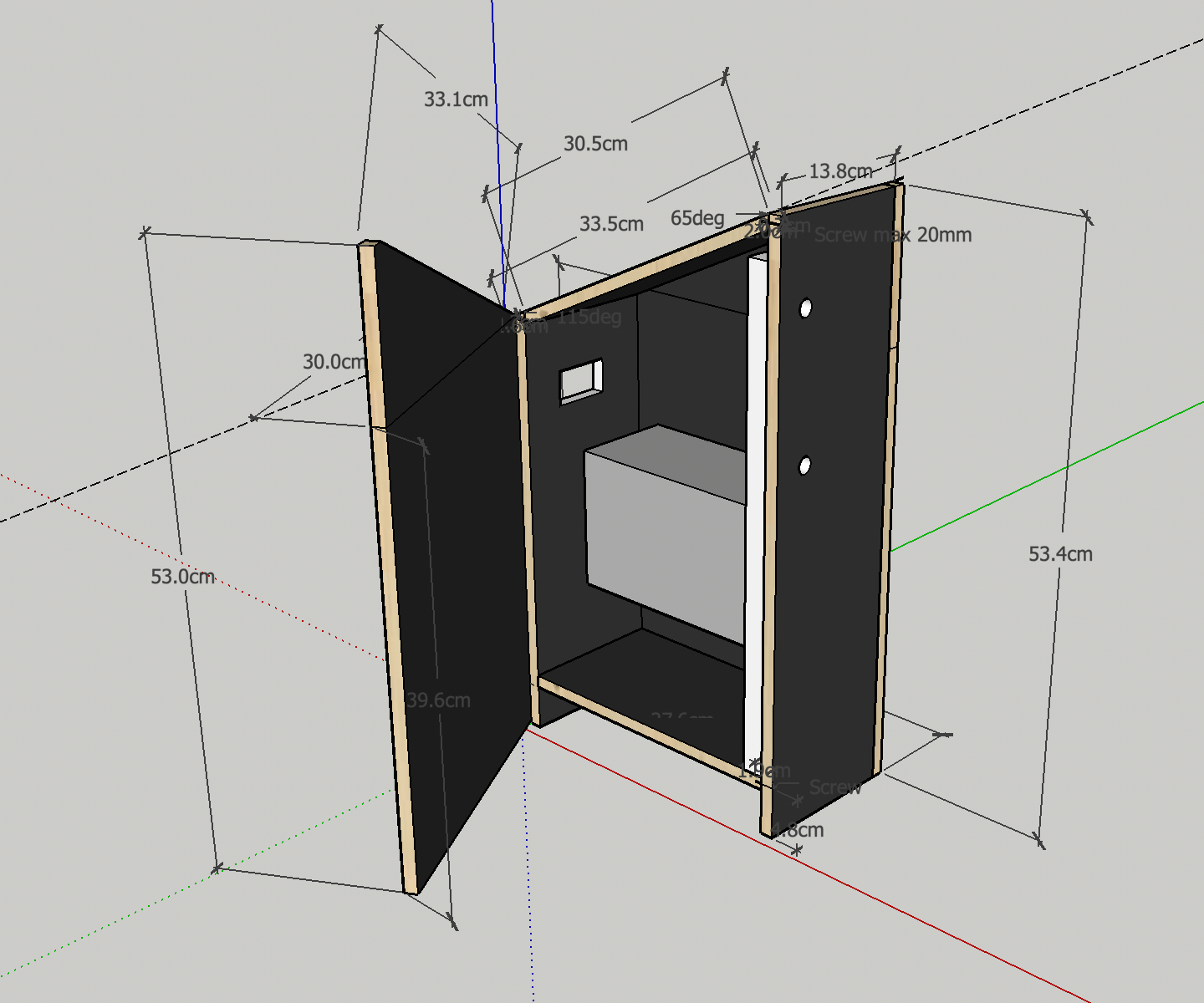

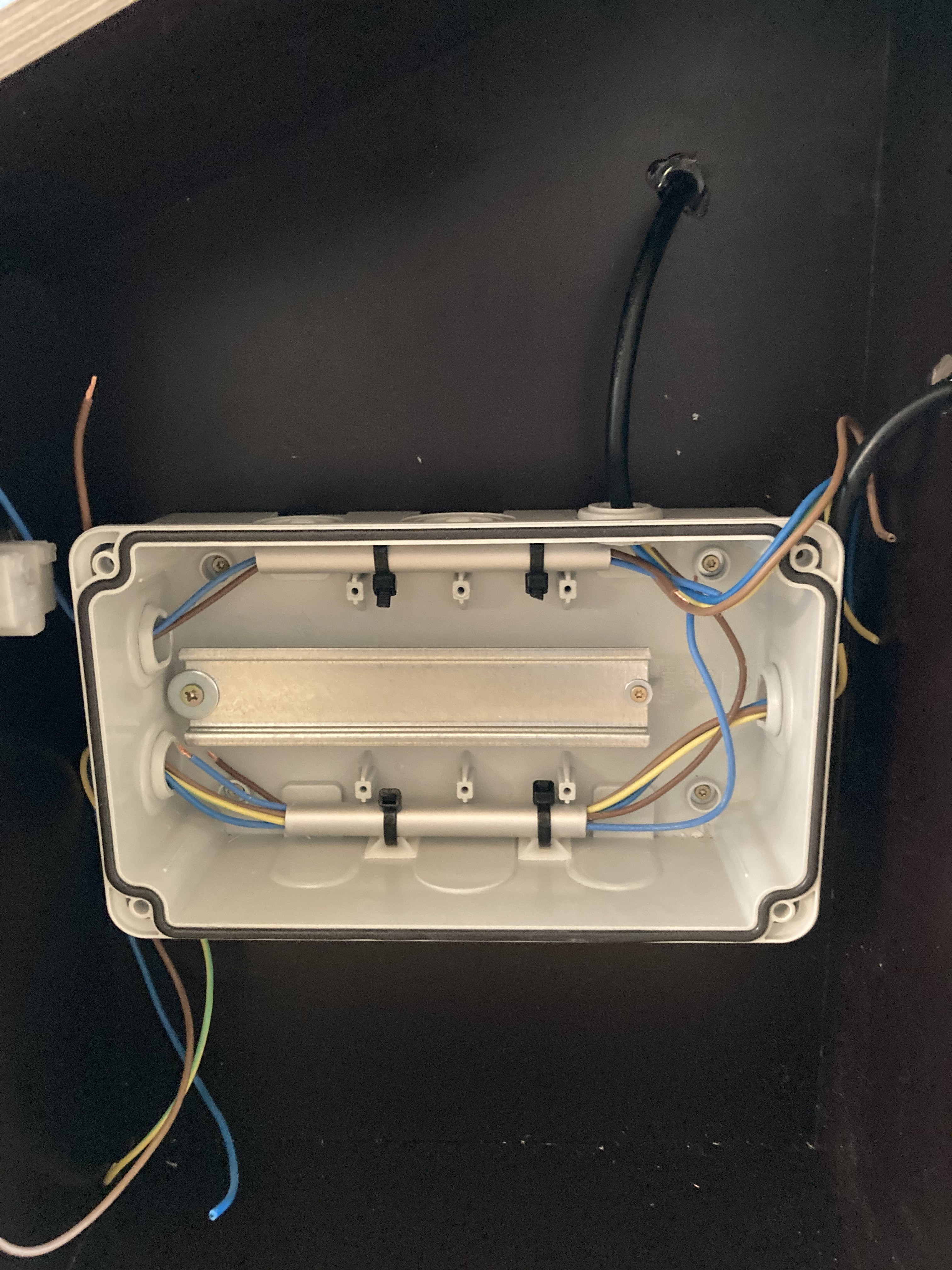

Part three : Enclosure

The exit of the duct is quite high up (about 2m/6ft) and we need to avoid right angle bends. The enclosure below will support the air extractor on top at a gentle angle.

vincentmakes

vincentmakes

Capt. Flatus O'Flaherty ☠

Capt. Flatus O'Flaherty ☠

Craig Watson

Craig Watson

Amitabh Shrivastava

Amitabh Shrivastava

Hey, cool project. I am hoping to also add an extractor fan to my delonghi portable air conditioner.

I was curious: how long of a hose did you use to extend your air con's reach? I am thinking about 5m for mine. Also, how did you calculate how much extra fan speed you would need? It makes sense to match it but I wonder if there's a way to calculate per metre of hosing.

Thanks!