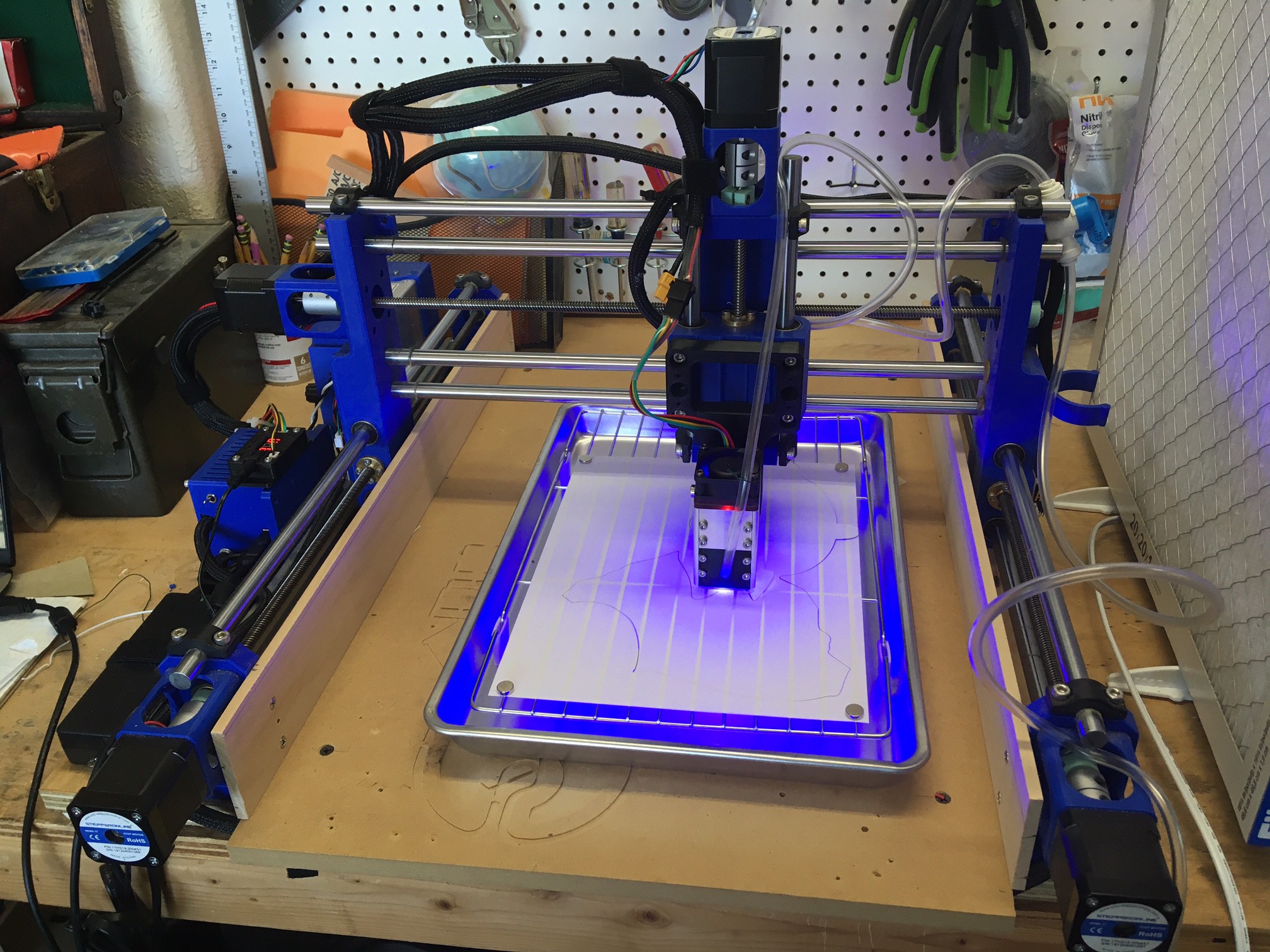

A while ago I built myself a DIY 3D printed CNC machine called the MultiBot. Recently I picked up a NEJE 30w laser module and have been trying to explore how to use this diode to the best of its abilities. Air assist has come up and I have been struggling to work out how much air I really need. I have a Bostitch 6 gallon pancake compressor that is capable of 90 psi, so I have plenty of air available. However this is a ridiculously loud compressor and I need to wear hearing protection when operating it. So I am on the hunt for something that is almost as good but much quieter.

You can pick up my latest air assist nozzle from Thingiverse.

The air sources I tested were as follows:

- Bostitch 6 gallon pancake compressor set to 15 psi ($150)

- Simple Deluxe 1189 fish pump compressor ($45),

- Sunrise (DeVilbiss) model 46502 compressor/nebulizer (recycled)

- Aqua Culture 20-60 gallon air pump ($15)

- 24v radial fan from an ender 3 to see if an air compressor is even needed ($1)

First for the noise, I just happen to have a Pyle dB meter laying about. I measured the dBA right next to each compressor as well as 5 feet away, all within my enclosed garage.

I also measured the max PSI each compressor could produce when no air flows, as well as the PSI when air is flowing unrestricted through my 2 mm nozzle. Previously I had measured the CFM of the Sunrise and Aqua Culture air pumps along with my compressor. The results are summarized below.

| Name | 0 ft dB | 5 ft dB | psi (air off) | psi (air on) | CFM at 0 psi |

| Bostitch 90 psi (15 psi regulated) | 91 | 81 | 15 | 15 | 7.90 |

| Simple Deluxe | 64 | 52 | 5 | 3.5 | 2.64 |

| Sunrise | 78 | 68 | 19 | 3 | 0.34 |

| Aqua Culture | 46 | 35 | 3 | ? | 0.14 |

| 24v fan | 54 | 42 | ? | ? | ? |

The ambient noise in the room was hovering between 30-50 dB, any measurements below 50 dB are probably not very accurate and can be considered basically inaudible.

The Sunrise compressor is capable of producing a surprising amount of pressure, but once you let the air flow the pressure falls dramatically. That plays out below with it not working as nicely as the simple deluxe air pump. The big news is that the simple deluxe manages to be significantly quieter than the Bostitch. It can't compete on the pressure level but if it can get the job done it will be great.

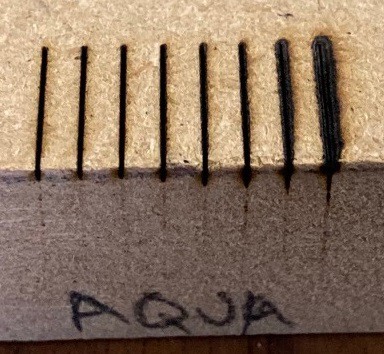

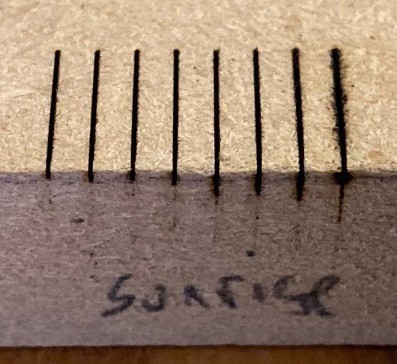

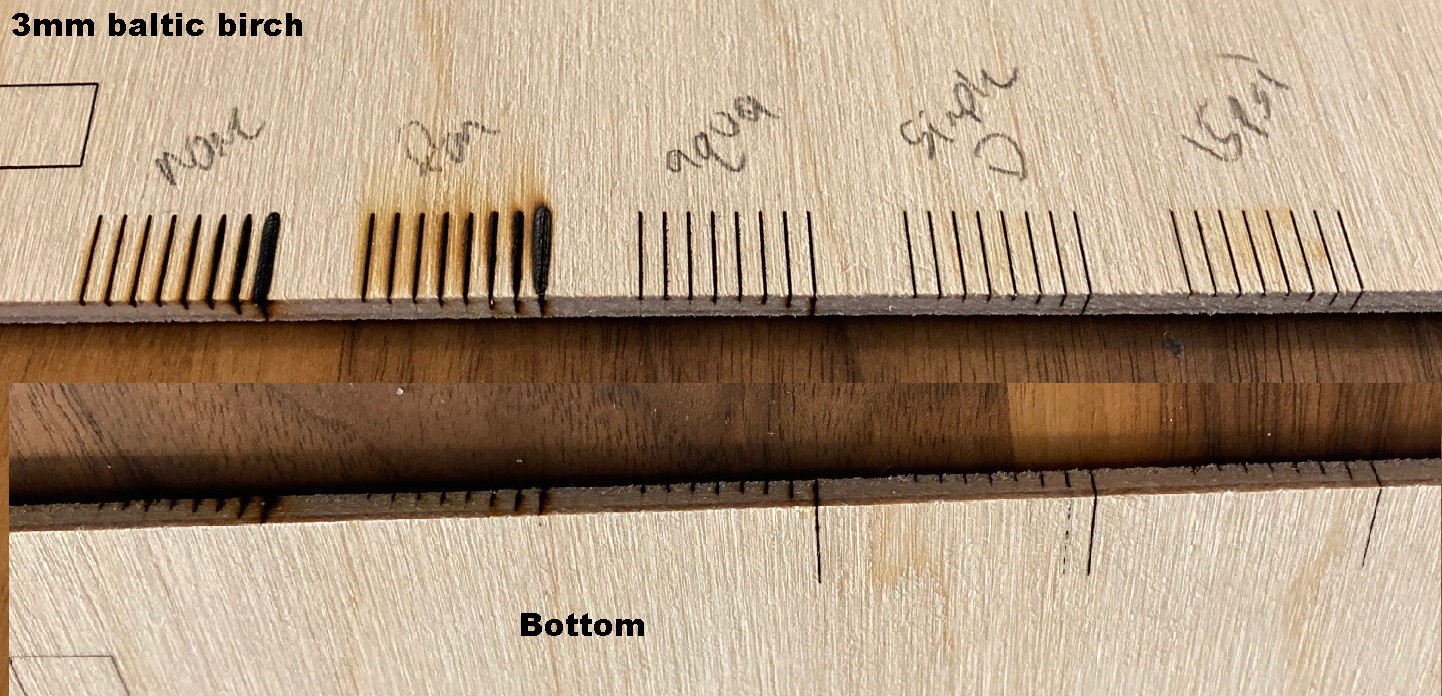

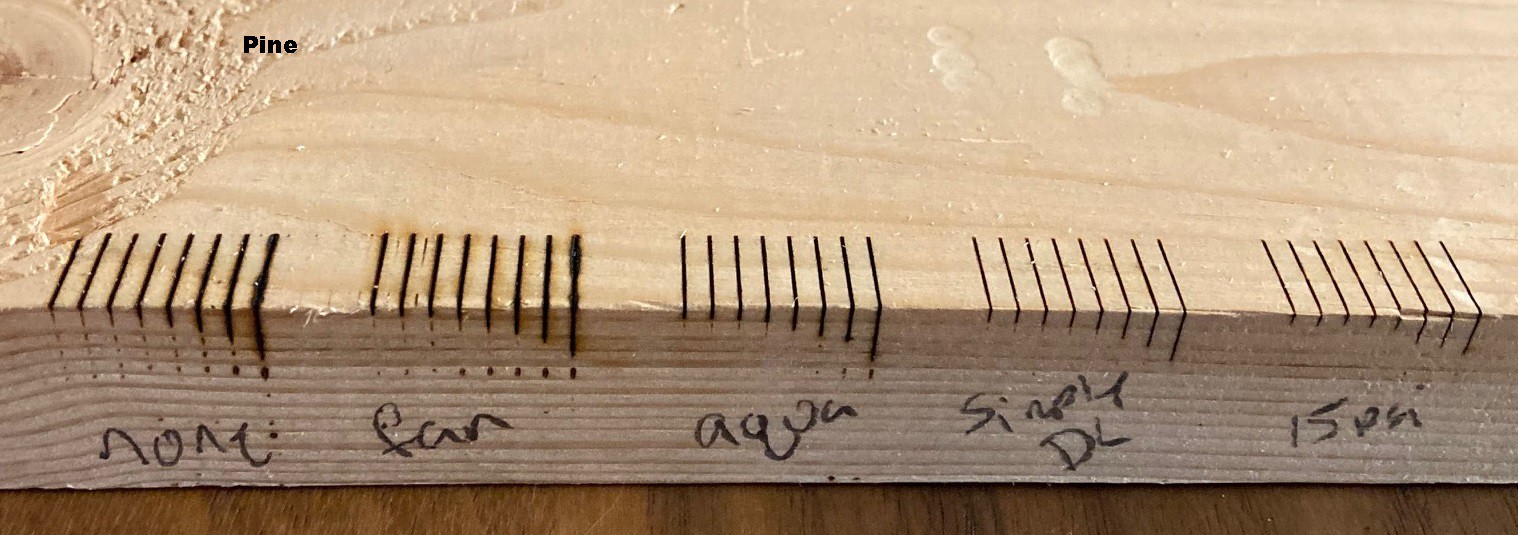

The next step was to evaluate how each works when pushing air through my over the lens nozzle with a 2 mm orifice (or blowing at the side in the case of the fan). To test this I wrote a program to draw a series of lines, focused at the top of the work piece at 80% power and at speeds from 400 mm/min to 50 mm/min in steps of 50. The test pieces are shown below.

Looking at these results, the radial fan is worse than no air assist. It blows the smoke back onto the workpiece and just makes a mess. No air is not very good, even the fastest cut on the left side has a lot of extra scorch damage. The Aqua Culture pump is where we start to really see the value of air, it is more than enough to improve the lines as long as the laser is moving fast enough that we don't start a fire. However at slower cutting speeds (deeper cutting depth) we still see a lot of scorching. The great news is visually the simple deluxe pump is almost as good as the compressor at 15 psi. We know from previous tests that the compressor at 30 psi cuts even better, so the compressor is always the winner but a $45 aquarium pump is both dramatically quieter and still good enough for most work.

| Name | 400 mm/min | 150 mm/min |

| Bostitch 90 psi (15 psi regulated) | 0.8 mm | 1.5 mm |

| Simple Deluxe | 0.5 mm | 1.4 mm |

| Sunrise | 0.7 mm | 1.1 mm |

| Aqua Culture | 0.7 mm | 1.2 mm |

| 24v fan | 0.8 mm | 1.3 mm |

| no air assist | 0.6 mm | 1.3 mm |

I tried my usual trick of using feeler gauges to measure the depth of the cut. However for some reason I am not seeing a significant change between the cuts. There is a large jump in depth with power, but going form no air to 15 psi only saw a 0.2 mm increase in cut depth. Part of the problem may be that I used a larger 0.1 mm thick feeler gauge rather than the 0.02 mm thick gauge I used last time. The 0.02mm gauge is paper thin and I was worried about damaging it. Cutting the speed in half did roughly double the cut depth.

It is also possible that the particle board I am testing with is not ideal for this type of test. There is a lot of glue in the material and that can monkey with the results, and in my experience with the CNC the material has a different density at different depths below the surface. I need to run this again on a soft wood of some sort.

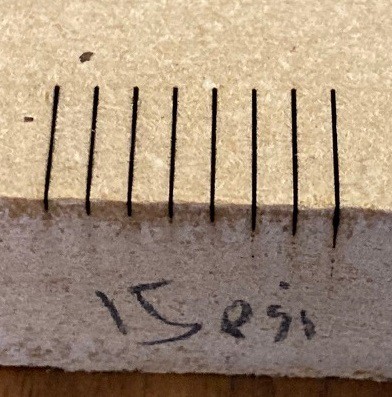

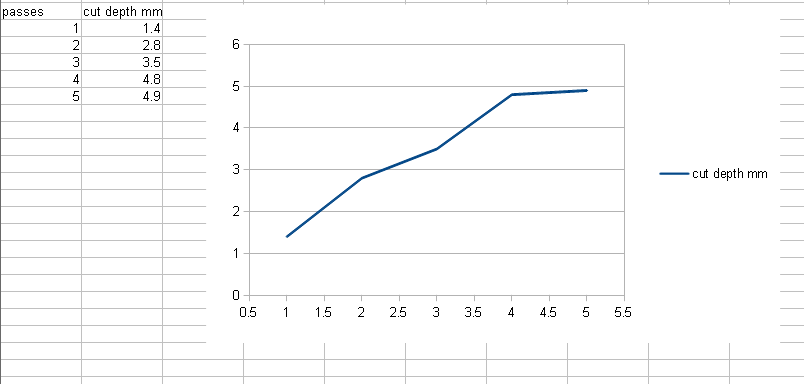

I wrote one more test program that runs the laser at 150 mm/,min, 80% power, with 15 psi of air and that takes 1 to 5 passes across the material, lowering the laser by 1 mm on each subsequent pass. This proved to be very effective, with each pass deepening the cut by approximately 1 mm. Things seemed to flatten out on the 5th pass, it is not clear if that is just the end of what the laser can do or if the bottom of the cut was just deep enough that we would need a 6th pass to bring the laser back into focus on the bottom of the cut.

Going forward I will split my time between the $45 simple deluxe air pump and the compressor set to 15 psi depending on how critical it is that I get a great cut. That should strike a nice balance between saving my ears and getting top notch results.

Going forward I will split my time between the $45 simple deluxe air pump and the compressor set to 15 psi depending on how critical it is that I get a great cut. That should strike a nice balance between saving my ears and getting top notch results.My guess is the $30 Simple Deluxe 602 air pump (1.3 cfm) would probably get the job done as well, and of course one of the more expensive $96 Simple Deluxe 1744 air pump will probably work better, however I feel the $45 Simple Deluxe 1189 pump is a good compromize between price and performance.

---

Edit, I was worried the MDF was skewing the results a bit so I ran this test again using 3mm Baltic Birch plywood, a piece of scrap pine and a broken bamboo cutting board. All have similar results to the MDF, however the Aqua Culture did fair better with the tougher wood. I suspect this has to do with how flammable the material is, my guess is cardboard would do worse than the MDF and need more air to keep the flames at bay. Notice that with decent air assist the 30w NEJE module was able to cut through 3 mm ply at 50 mm/min at 80% power.

---

I have taken the time to measure the depth of each cut and have plotted the results at this page. The results are interesting, but the short answer is if the cut looks good then the depth is good as well. There does not seem to be much improvement to the cut depth with more air beyond the basic improvement of putting out the flames.

---

You can read up more on all my laser experiments at the links below.

https://hackaday.io/project/176110/log/189770-lasers

https://hackaday.io/project/176110/log/189771-new-controller

https://hackaday.io/project/176110/log/189945-lasers-part-two

https://hackaday.io/project/176110/log/189982-quantifying-laser-power

https://hackaday.io/project/176110/log/190356-youll-shoot-your-eye-out

https://hackaday.io/project/176110/log/190386-cnc-shield-clone-conversion

https://hackaday.io/project/176110/log/190849-focus

https://hackaday.io/project/176110/log/190850-progress

https://hackaday.io/project/176110/log/190913-smoke

https://hackaday.io/project/176110/log/191196-laser-calorimeter

https://hackaday.io/project/176110/log/191197-better-air-nozzle

https://hackaday.io/project/176110/log/191312-laser-calorimeter-take-2

https://hackaday.io/project/176110/log/191372-misc

https://hackaday.io/project/176110/log/191432-lightburn-take-2

https://hackaday.io/project/176110/log/191513-danger

https://hackaday.io/project/176110/log/191545-baltic-birch

https://hackaday.io/project/176110/log/191668-pressure

https://hackaday.io/project/176110/log/191708-science

https://hackaday.io/project/176110/log/191743-regulation

https://hackaday.io/project/176110/log/191745-sealed-it

https://hackaday.io/project/176110/log/191747-flow-flow-flow-your-boat

https://hackaday.io/project/176110/log/191987-bernoulli

https://hackaday.io/project/176110/log/192100-blowing-off-steam

https://hackaday.io/project/176110/log/192103-noise-noise-noise

https://hackaday.io/project/176110/log/192161-ignore-the-man-behind-the-curtain

https://hackaday.io/project/176110/log/192162-simple-deluxe-manual

https://hackaday.io/project/176110/log/192191-data

https://hackaday.io/project/176110/log/192215-more-data

https://hackaday.io/project/176110/log/192266-cut-above

https://hackaday.io/project/176110/log/192379-gray-scale

https://hackaday.io/project/176110/log/192403-inkscape-take-1

https://hackaday.io/project/176110/log/192565-fusion-360-for-laser-cutting-take-1

https://hackaday.io/project/176110/log/192566-laser-post-mortem

https://hackaday.io/project/176110/log/192825-collimation-of-events

https://hackaday.io/project/176110/log/194694-focused

https://hackaday.io/project/176110/log/194737-focused-er

https://hackaday.io/project/176110/log/194921-measuring-the-kerf

https://hackaday.io/project/176110/log/195057-plane-and-simple

https://hackaday.io/project/176110/log/195571-focal-length

https://hackaday.io/project/176110/log/195572-fly-me-to-the-moon

https://hackaday.io/project/176110/log/195816-spaceboy-ive-missed-you

https://hackaday.io/project/176110/log/196350-codify

https://hackaday.io/project/176110/log/196383-cut-above

https://hackaday.io/project/176110/log/196578-lather-rinse-repeat

https://hackaday.io/project/176110/log/196666-rough-cut

https://hackaday.io/project/176110/log/196734-choices

https://hackaday.io/project/176110/log/198120-dust-in-the-wind

https://hackaday.io/project/176110/log/198146-dust-up

https://hackaday.io/project/176110/log/201337-spot-the-difference

https://hackaday.io/project/176110/log/201501-merry-christmas

David Tucker

David Tucker