The mowing system turns out to be one of the toughest parts to work out. Of course the robot can't mow as fast as it's gasoline powered competitor, therefore it needs to be very silent to compensate the longer noise-frames and not annoy the neighbours.

I decided to ditch the bearings since exactly aligning the motors with the bearings while maintaining a connection withstanding the tremendous torque was beyond my capabilities. (note that my most advanced tool is a cordless electric screwdriver / drill ). This shouldn't be too much of a problem, since one motor of this kind costs ~2.5€ and these probably need to be replaced anyways at some time since they have brushes.

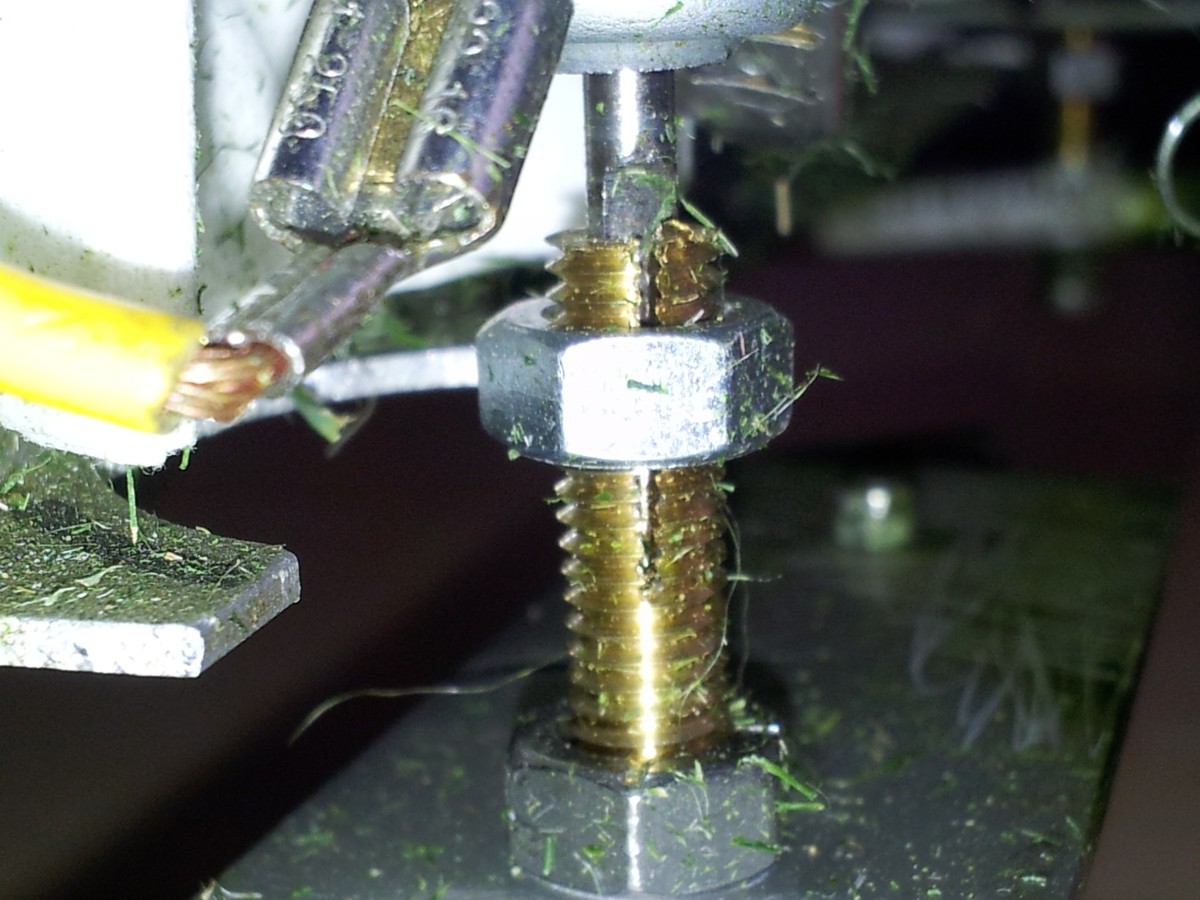

This is how the shaft of the motors is connected at the moment:

(I can't see the bend when looking at the real thing - not sure whether camera or eyes broken..) To minimize vibrations I'll craft these once again as precise as I can and mount laser cut mowing platters to them:

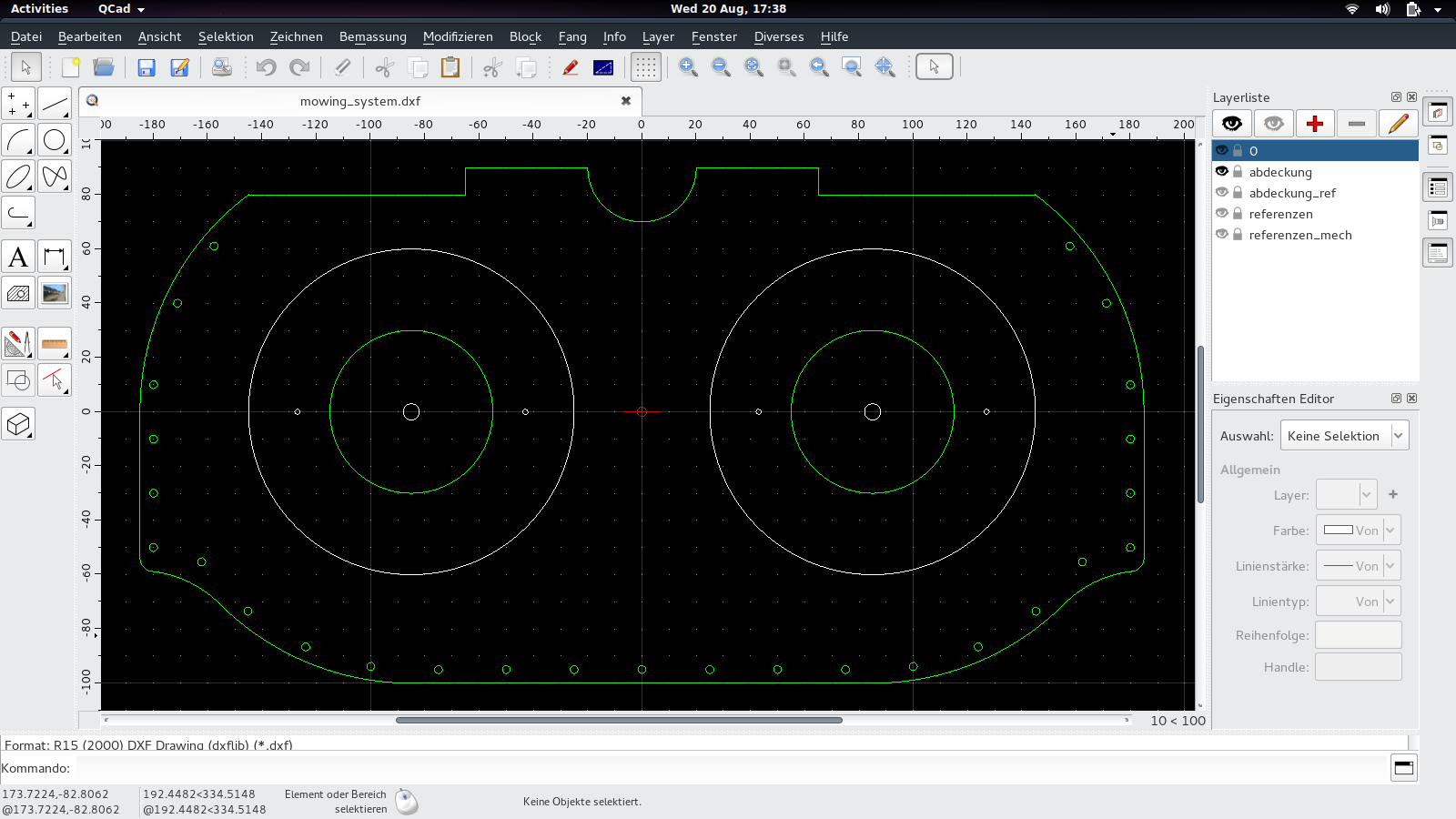

The hood (green) will also be lasercut from aluminium. The straight sides are for mounting vertical flaps. They will not only prevent grass (and slugs..) from flying around, but also sense if the blades are about to touch the ground. Our garden (and probably most others too) has lots of little holes in it. That's not a problem with the rear wheels (front tips up a bit), but with the front wheels it occasionally happens that the blades get stuck. The design isn't finished yet, but the company that run this service are on operational vacation anyways.

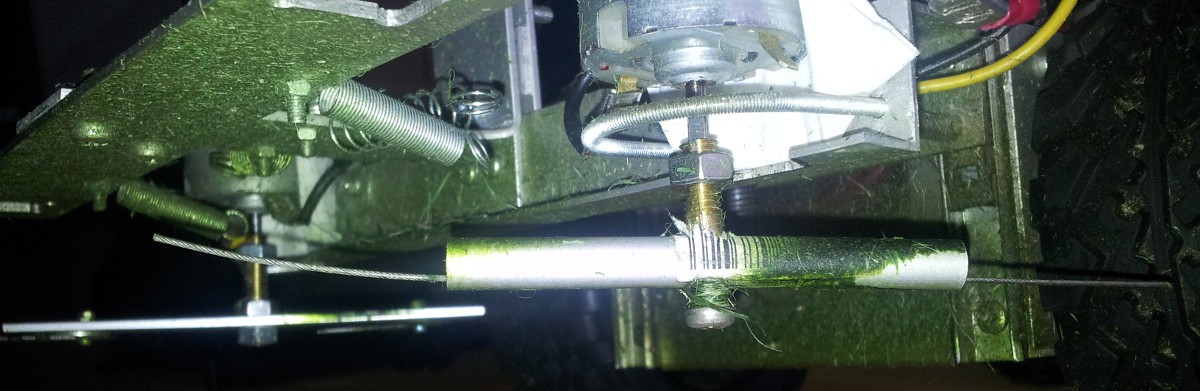

JohnsonFarms.us wrote a comment whether I considered to use a string trimmer instead of blades. I built one and tried it out

Here's a video on that:

( Sorry for occasional brain overflow - either forgot how to English or to move the cam accordingly. The string trimmer is almost invisible since tiny grey surfaces move damn fast )

In a longer test I did previously the string trimmer (had strings on both motors) turned out to use just too much energy. The RPMs need to be very high to actually cut the grass and not just bend it, which makes it noisier than the blades. The idea is great, but I'll stick to blades.

schuhumi

schuhumi

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.