Problem

1 tone of coated magazine paper consumes over 15 trees and 1 ream of paper (which is 500 sheets) will use 5% of a tree to be manufactured. When you consider how many magazines, newspapers and office papers are used or printed and distributed across the world, it is difficult to visualize the number of trees being used. According to precise statistics estimations over 2 million trees are felled every day for global paper consumption, meaning over 4 billion trees are cut every year to serve our paper needs. To solve this problem there are a few ways the world implements, which are the following

Recycling - Some percentage of the papers are recycled worldwide except some like thermal papers, and sticky notes.

Reduce consumption - Using digital forms, print on both sides, think before printing, reduce printing font and adjust margins.

Reuse - Shred and reuse it as packing material, reuse for decoration, reuse for gift wrap and other.

But all these approaches are not working because trees are being destroyed at faster rate than being replaced. Even if we plant many trees we are providing more raw materials for paper manufacturers; not solving the problem.

Solution

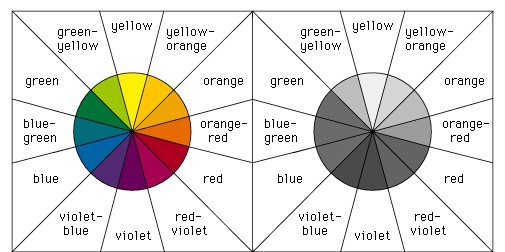

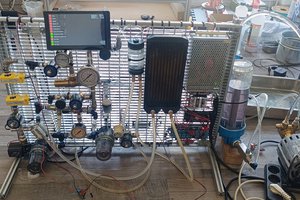

This project is about building white ink printer that scans paper to find colors other than white color so that it prints white ink on top of it to reuse the paper multiple times before it’s used beyond repair. First the scanner search any ink other than white color on the paper and when it finds it automatically tells the data to the white printer information like kind of color, the strength of that color and the location of the color on the paper. The white printer receives this information and prints white ink on top of the colors accordingly. This will save white ink consumption because not all colors consume same amount of white ink to be completely covered. For example printing on top of yellow color takes much lower amount of white ink than black color. Knowing the locations and strength of each color is also important because it prevents printing white ink on unnecessary spots with needless strength. This will transform us from high to low paper consumption and low to high ink consumption. It’s a green transformation because inks are made via inorganic pigment dissolved in chemical solvent and papers can only be made from trees. According to “X” toner specifications, you can print around 2,300 pages before a white toner runs out which is basically 13¢ per page. This price can be even lowered at large variation if ink manufacturers were not greedy because the material they use is very cheap and the total manufacturing cost of ink reaches from 20€ to 40€ per litter depending on brand. This indicates that if printing ink (only white color) is sold at appropriate pricing, turning a printed or used paper in to new usable paper prior to recycling and reusing for other purposes is financially feasible and Anteneh’s green printer will achieve just that task.

Anteneh Gashaw

Anteneh Gashaw

Dominik Meffert

Dominik Meffert

carbono.silício

carbono.silício

cprossu

cprossu