Project files on Github: https://github.com/JKR-31/JK_M0nkey_Keyboard

So in this project i wanted to solve a luxurie problem of mine :P

--> Having a nice mechanical keyboard that fulfills all my wishes I would ever have for one.

What I wanted:

-Teenkeyless layout (don't need that number pad)

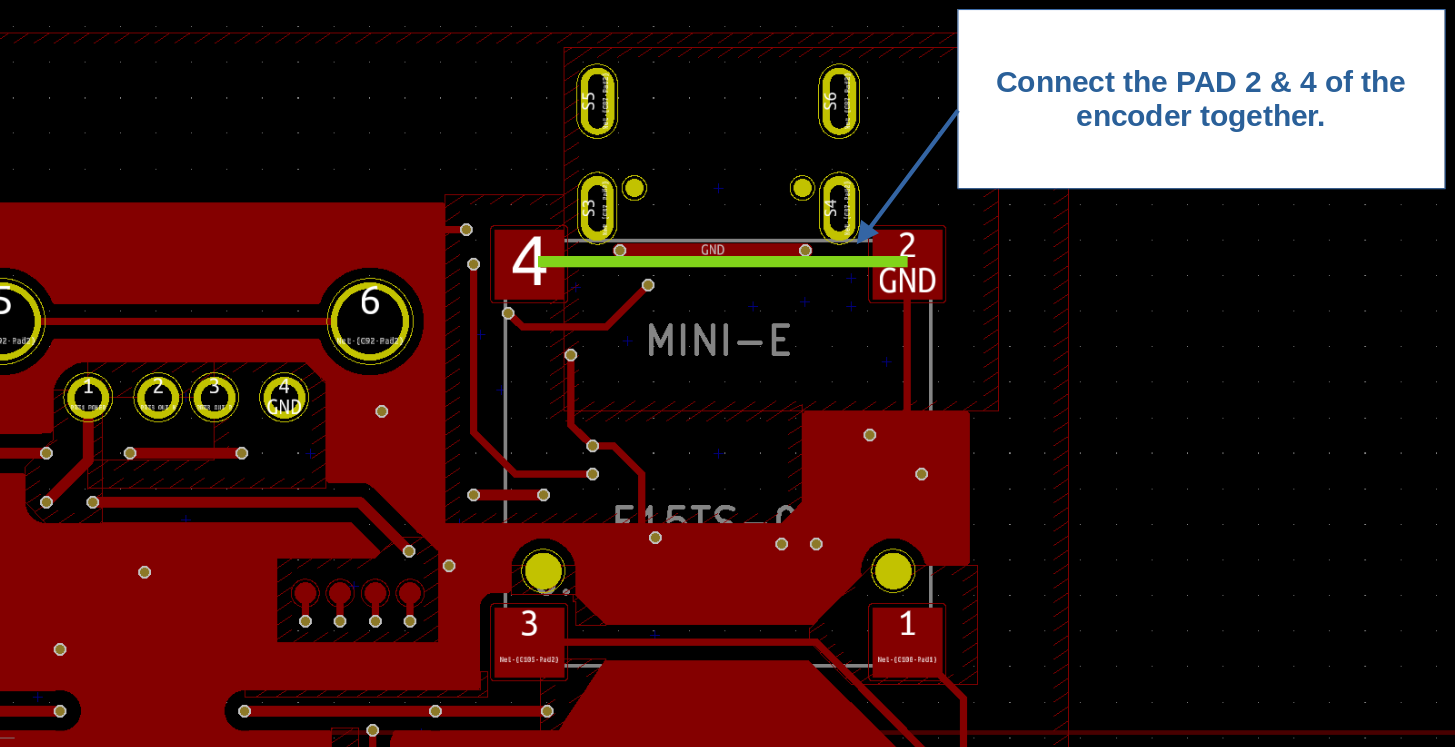

-An Encoder for volume adjustment

-RGB back lightning with possibility of having animations like fading & rainbow

-hardware that supports QMK-firmware

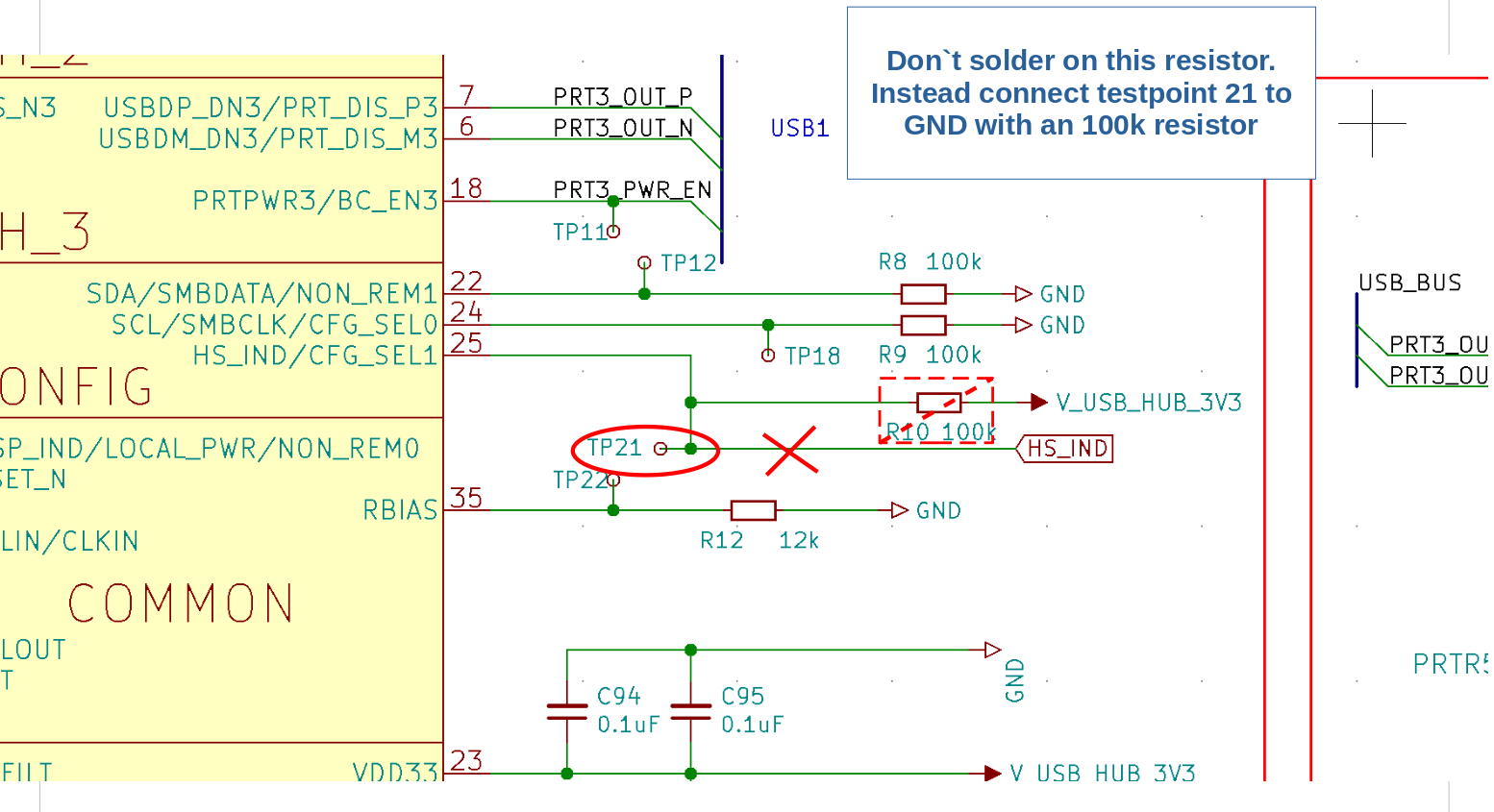

-A USB-Hub to plug in a mouse and for example an USB-Stick

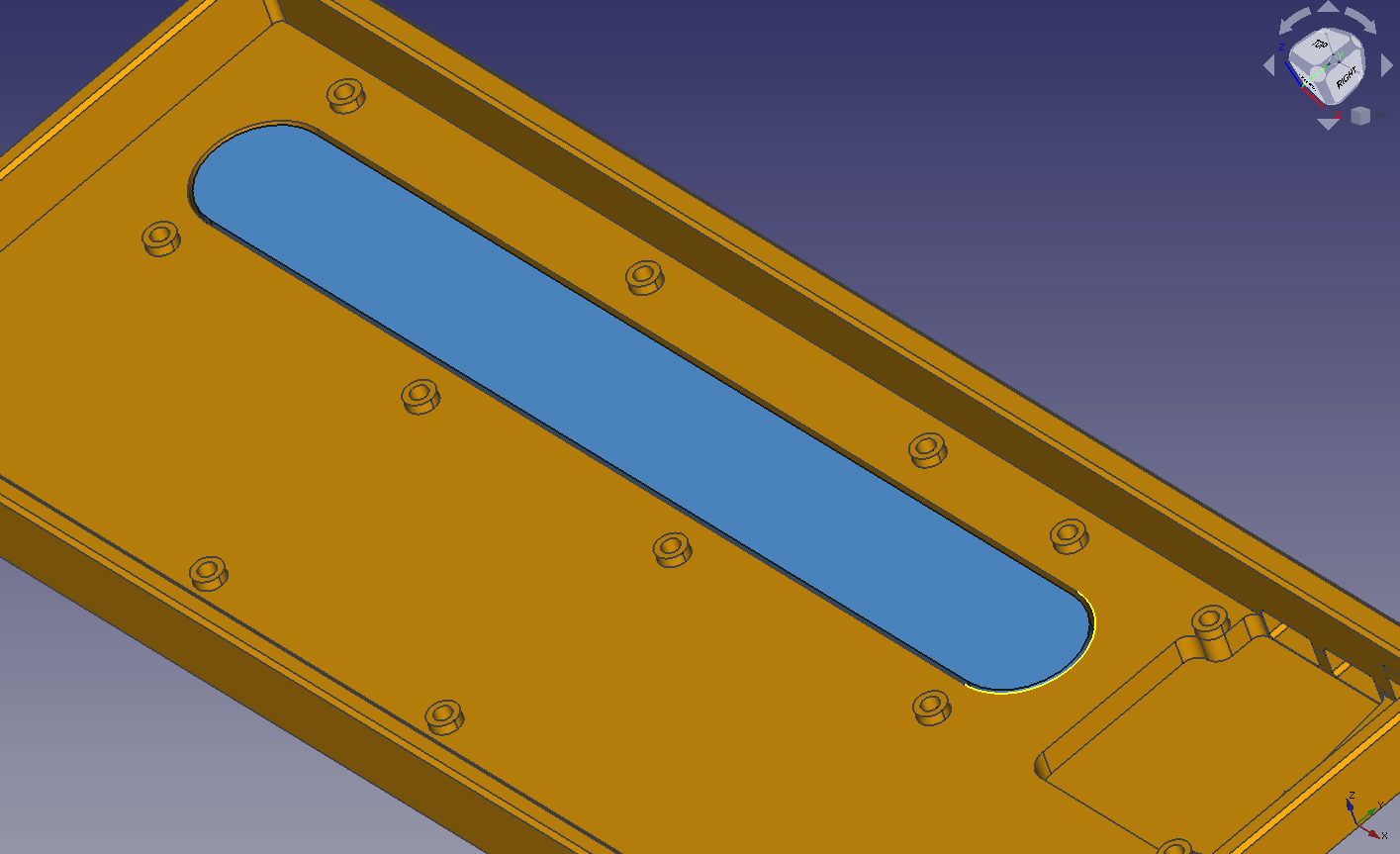

-Not cheap looking (metal plate and nice finished housing)

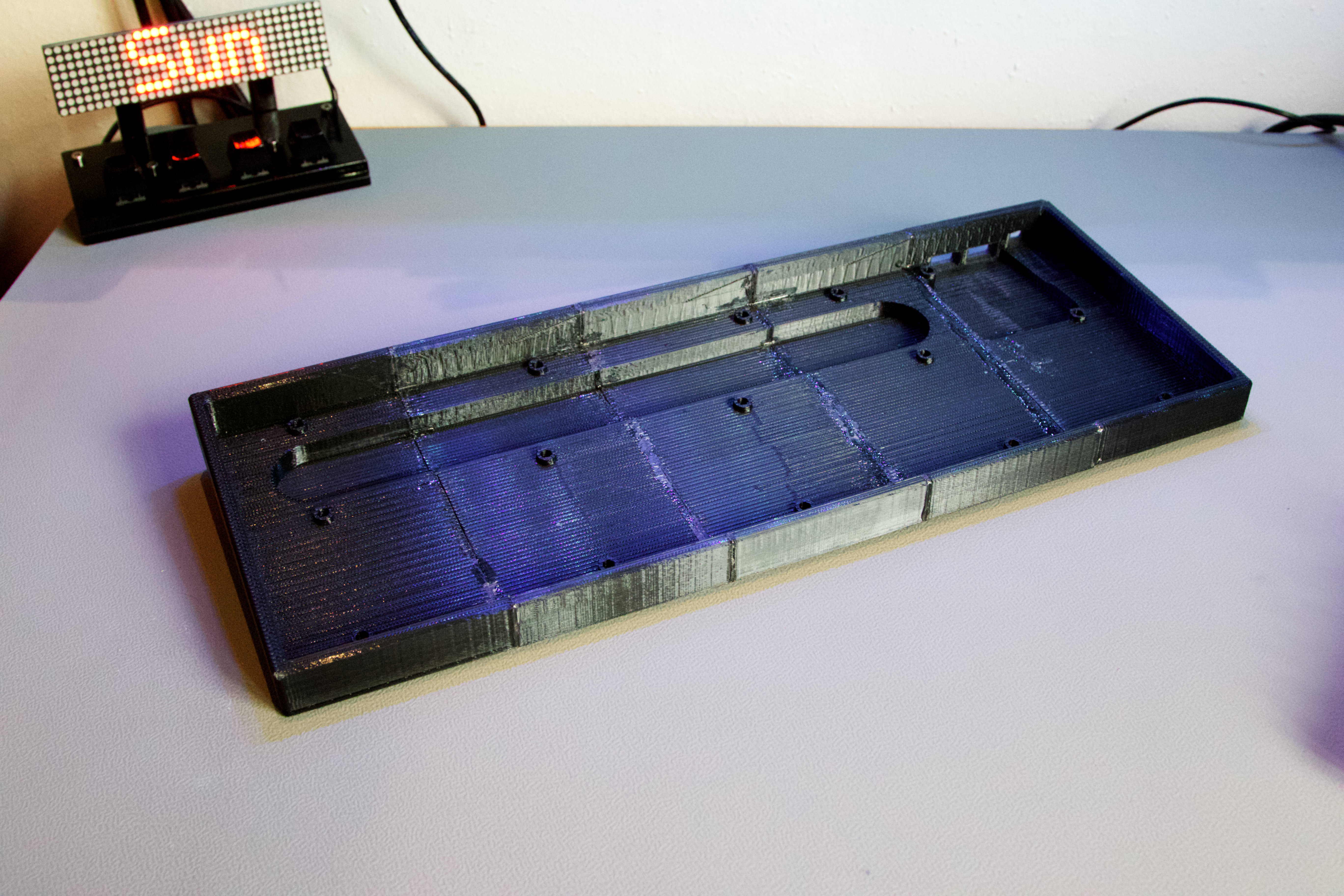

-use 3D-printing in the project

-as low profile as possible with cherry mx

-give possibility of using cherry mx low switches (didn't work, maybe in a future projects)

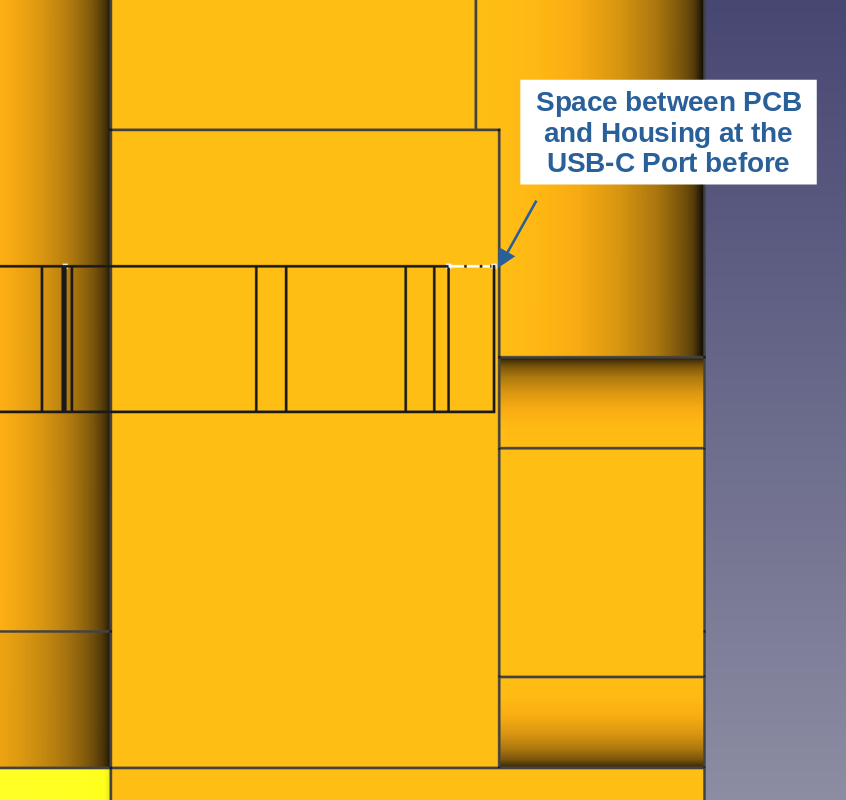

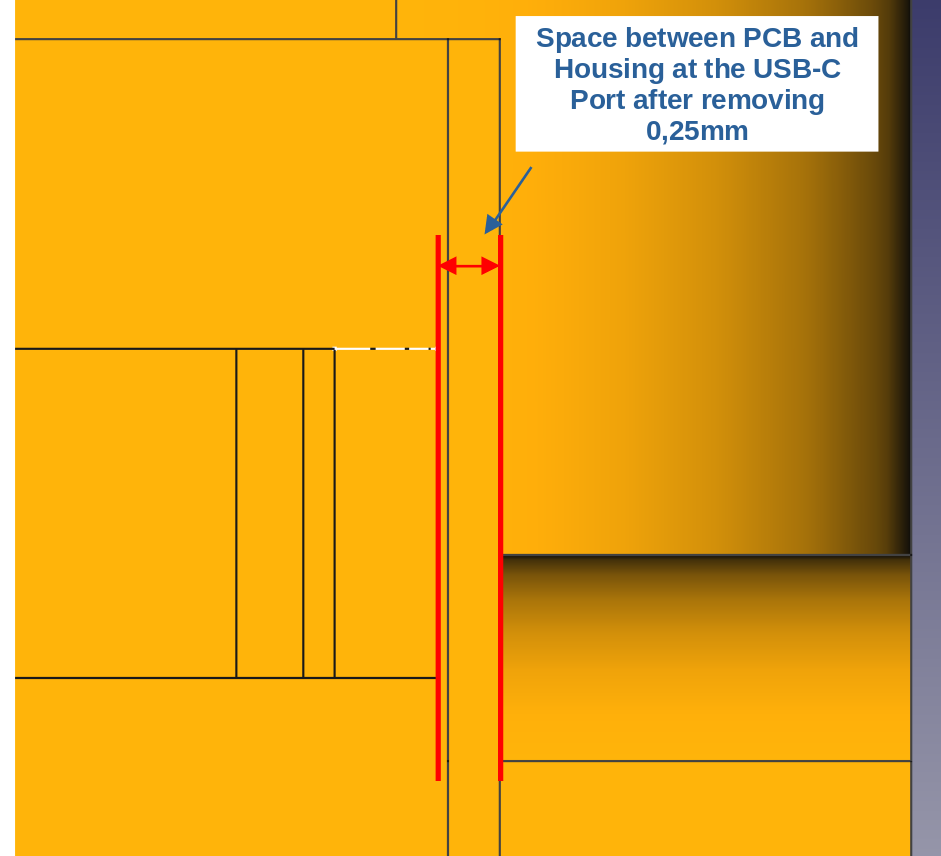

Hard parts of the project:

-Fitting 2 USB-A port and a USB-C port in a keyboard wasn't that easy, in the end had to remove two switches in the upper right corner

-Second challenge was to program this much for the first time except writing a blink program for an arduino

Licences:

This project is open source from my side.

Link to QMK-license: https://qmk.fm/license/

Link to Freecad license: https://wiki.freecadweb.org/Licence

Link to KiCad license: https://www.kicad.org/about/licenses

Jonas Kraus

Jonas Kraus

Alex

Alex

whoobee

whoobee

Brent w

Brent w

Tillo

Tillo