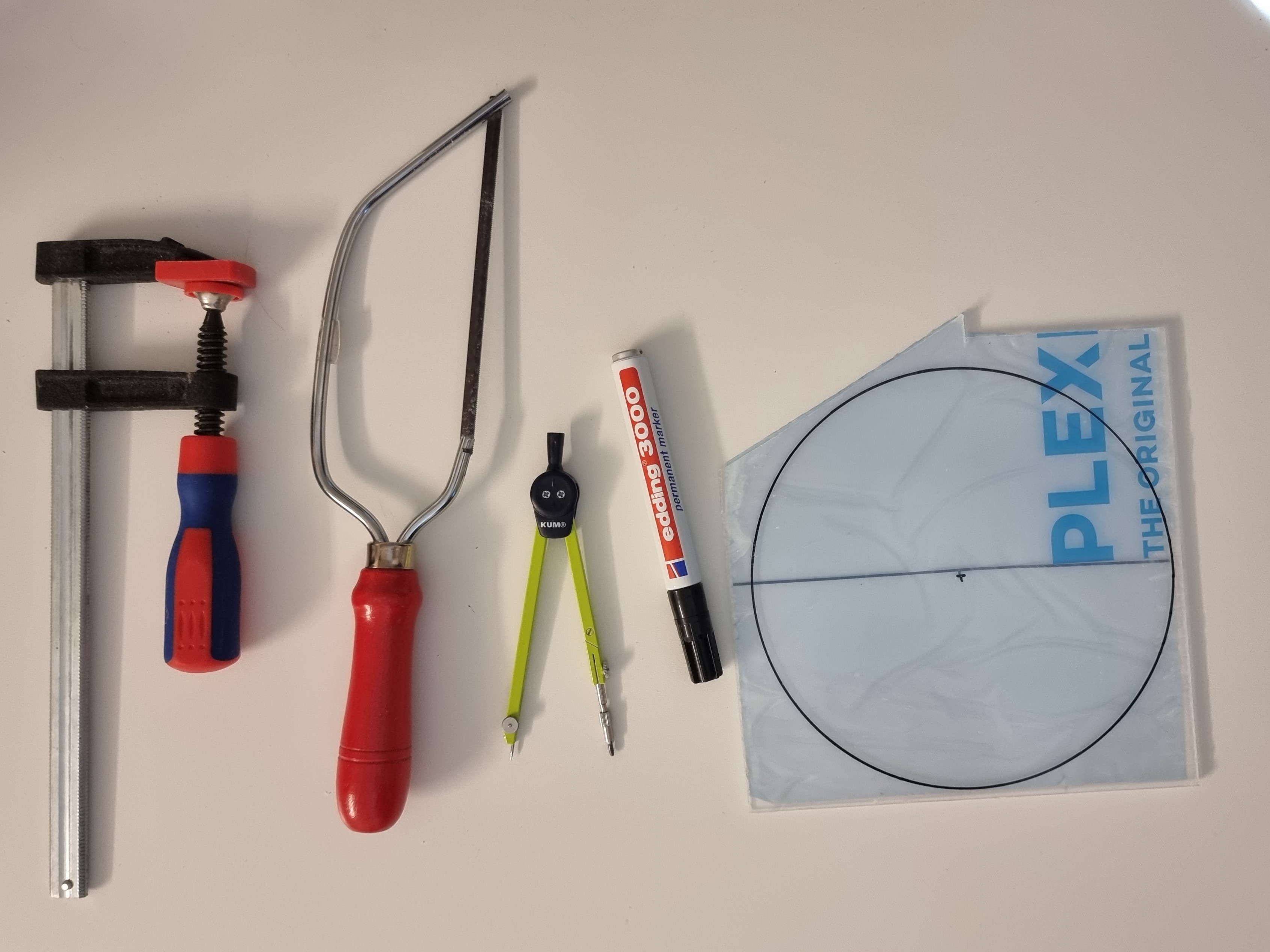

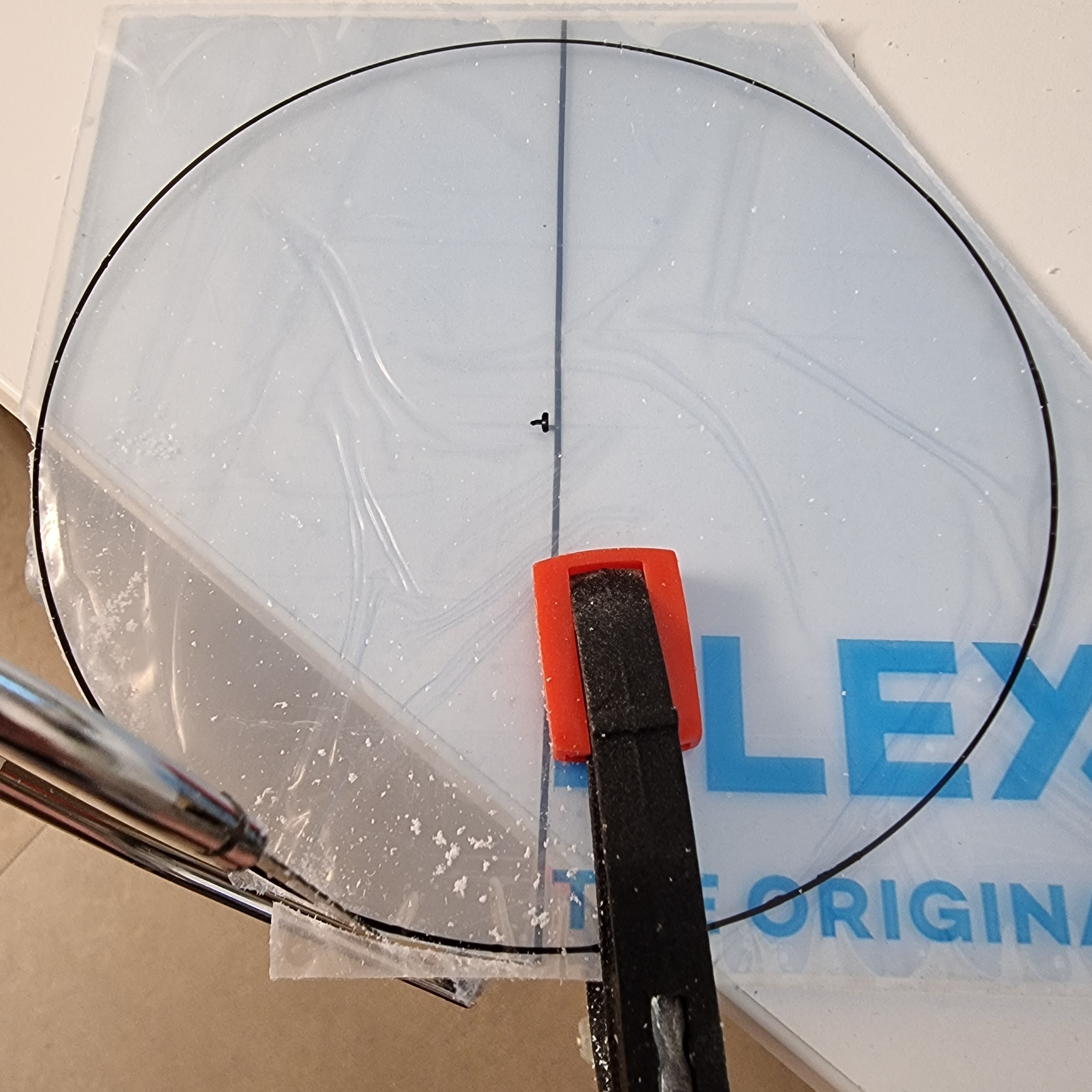

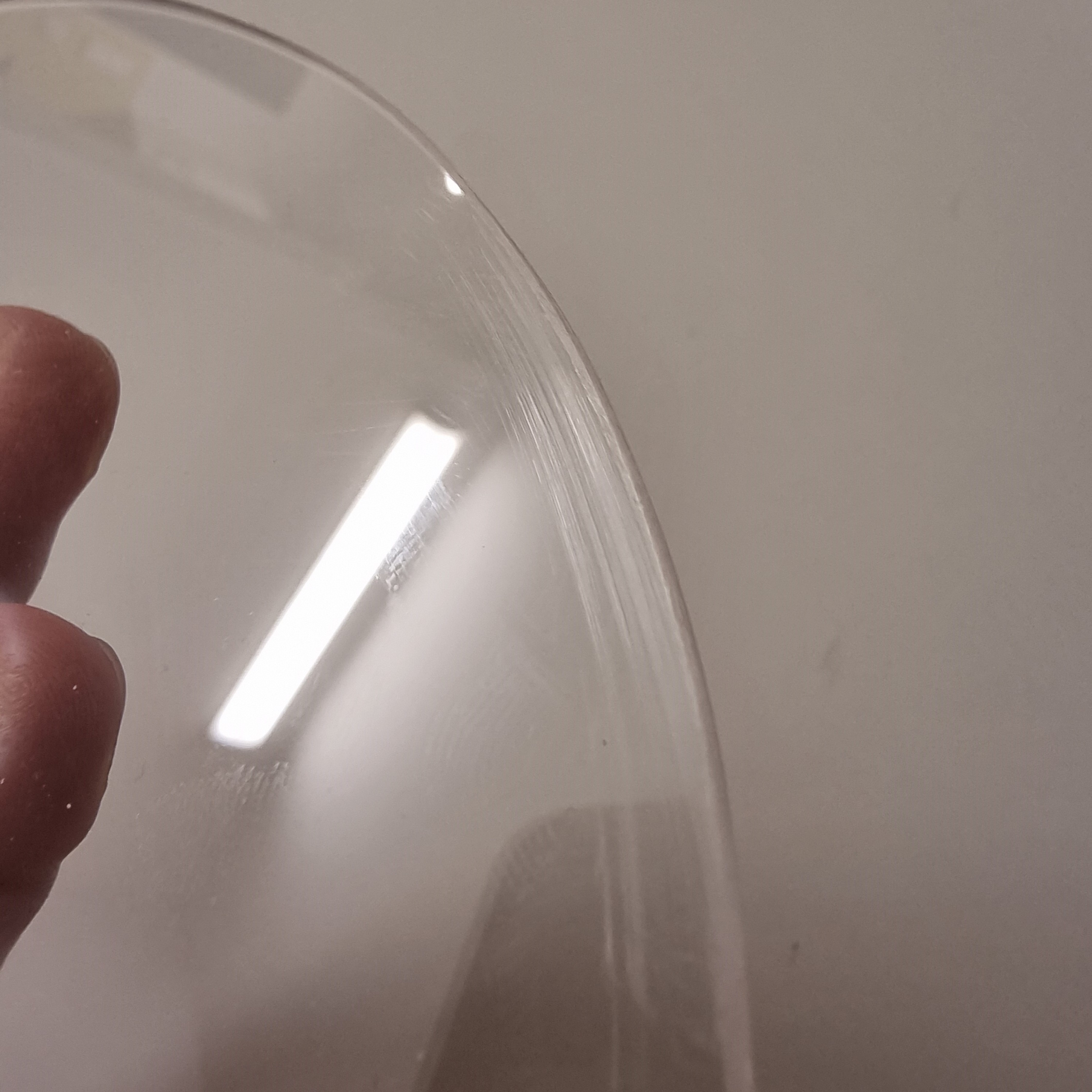

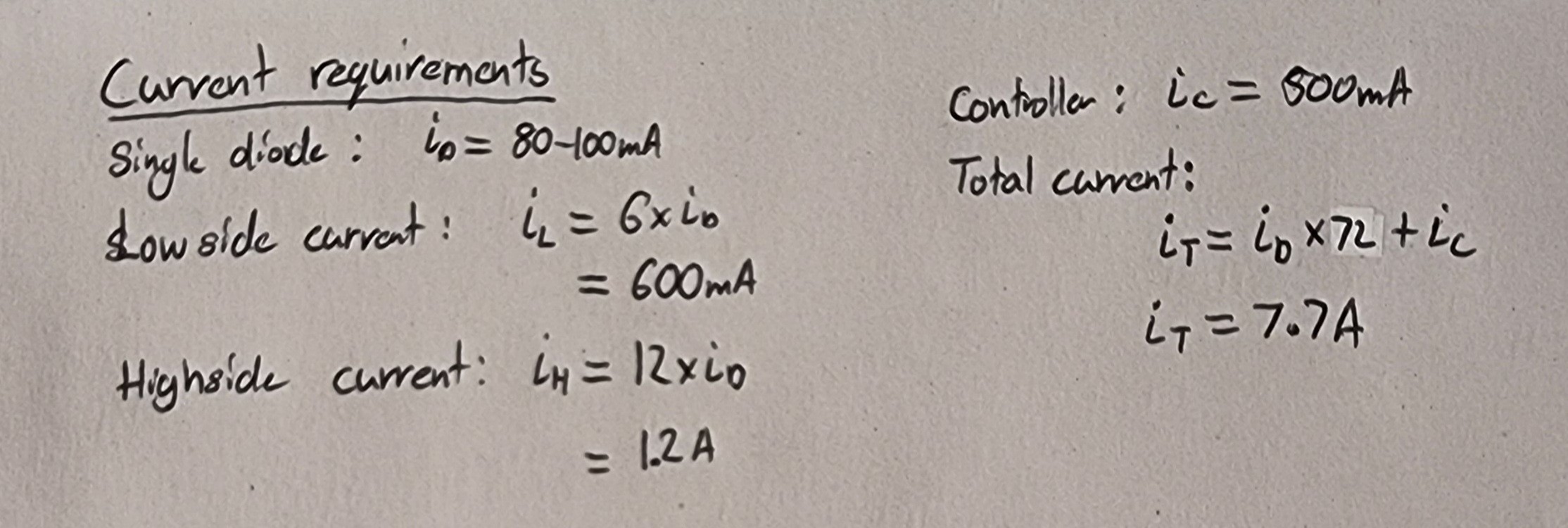

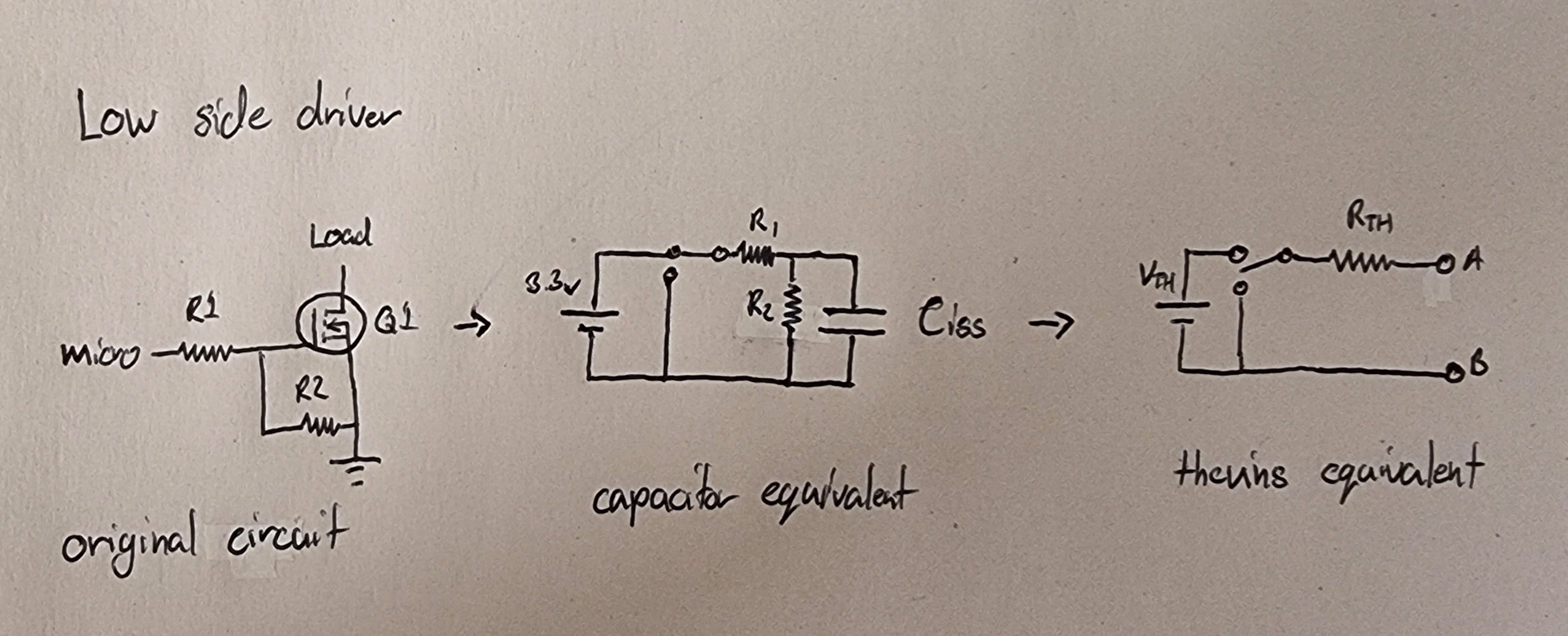

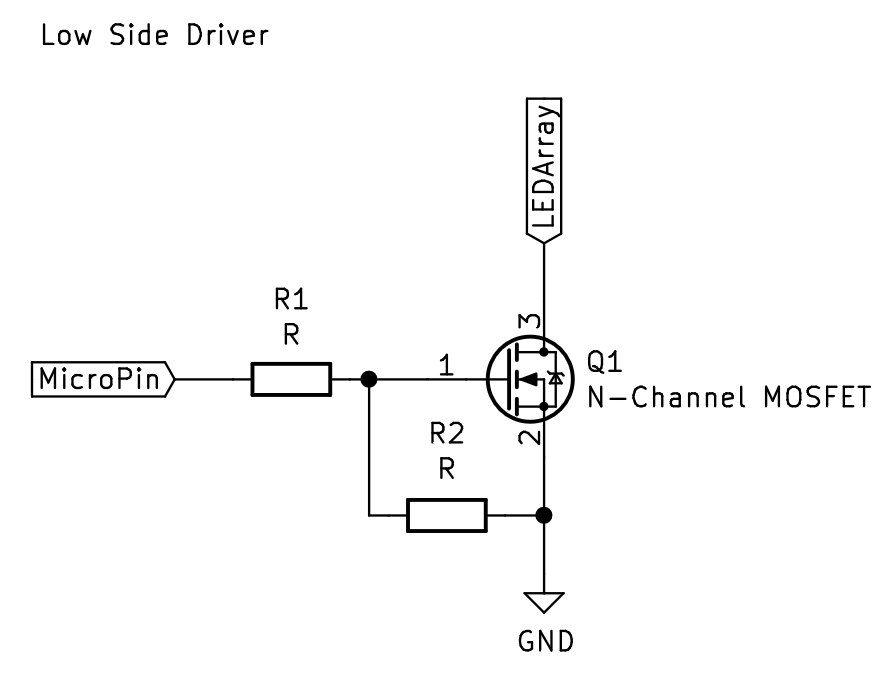

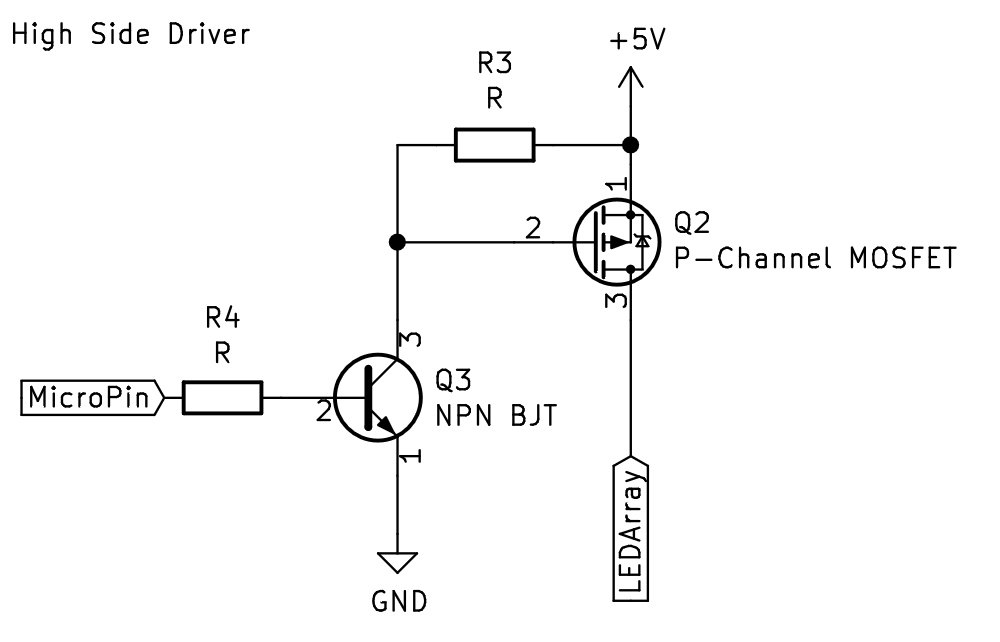

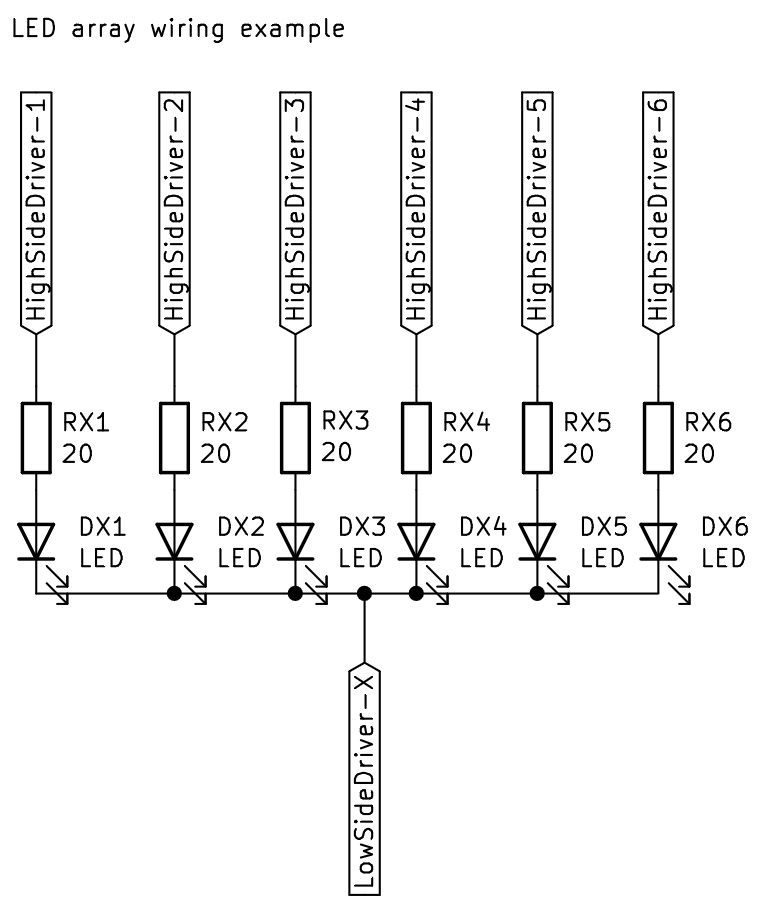

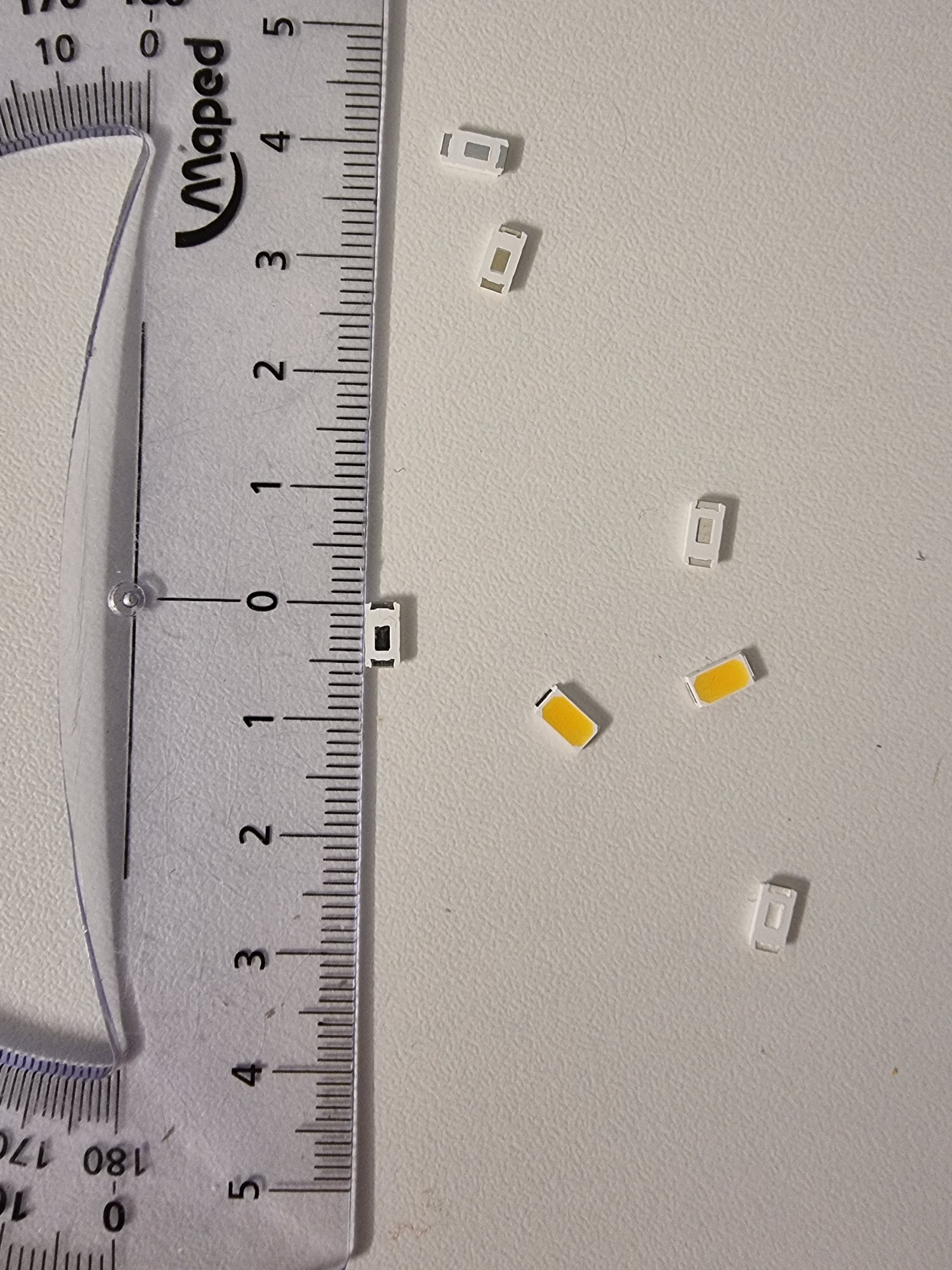

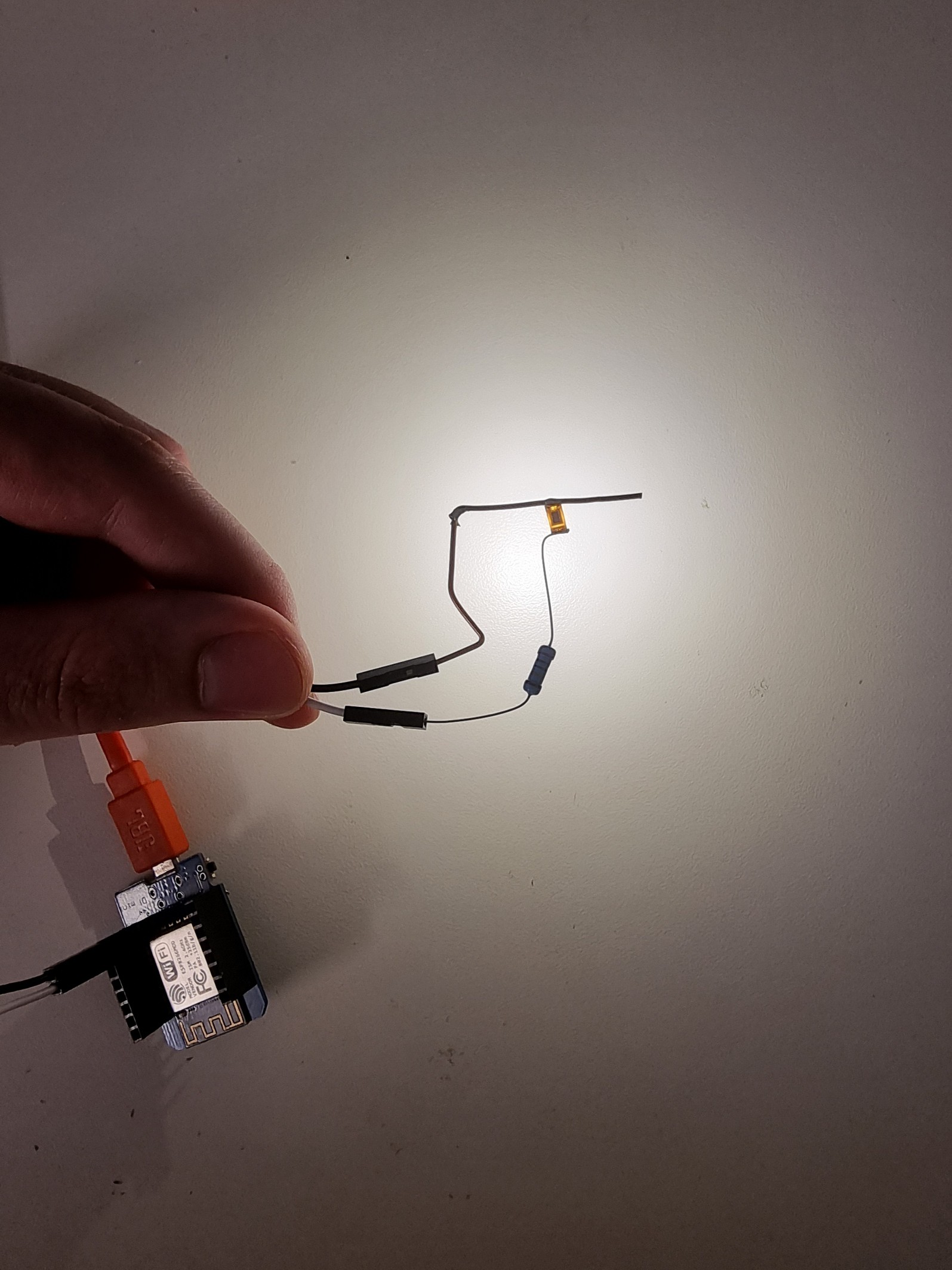

The basic concept is a free form circuit LED array sandwiched between two clear sheets of acrylic with an ESP32 controller. The array consists of two rings of LEDs, the outer ring containing 60 white SMD LEDs for displaying the minutes and the inner ring has 12 LEDs for displaying the hours. The LEDs are multiplexed using 12 low side rails and 6 high side rails. Everything is controlled using an ESP32 WROOM. Other features not displayed in the concept sketch, but may be included later is a rotary encoder for interfacing with the clock, an LDR for light sensing and a speaker for alarms or notifications.

Not-so-dull free form clock

A smart, connected, free form circuit clock and bedside lamp for sleep scheduling

Simon Merrett

Simon Merrett

Thomas Countz

Thomas Countz

Keith

Keith

Yann Guidon / YGDES

Yann Guidon / YGDES