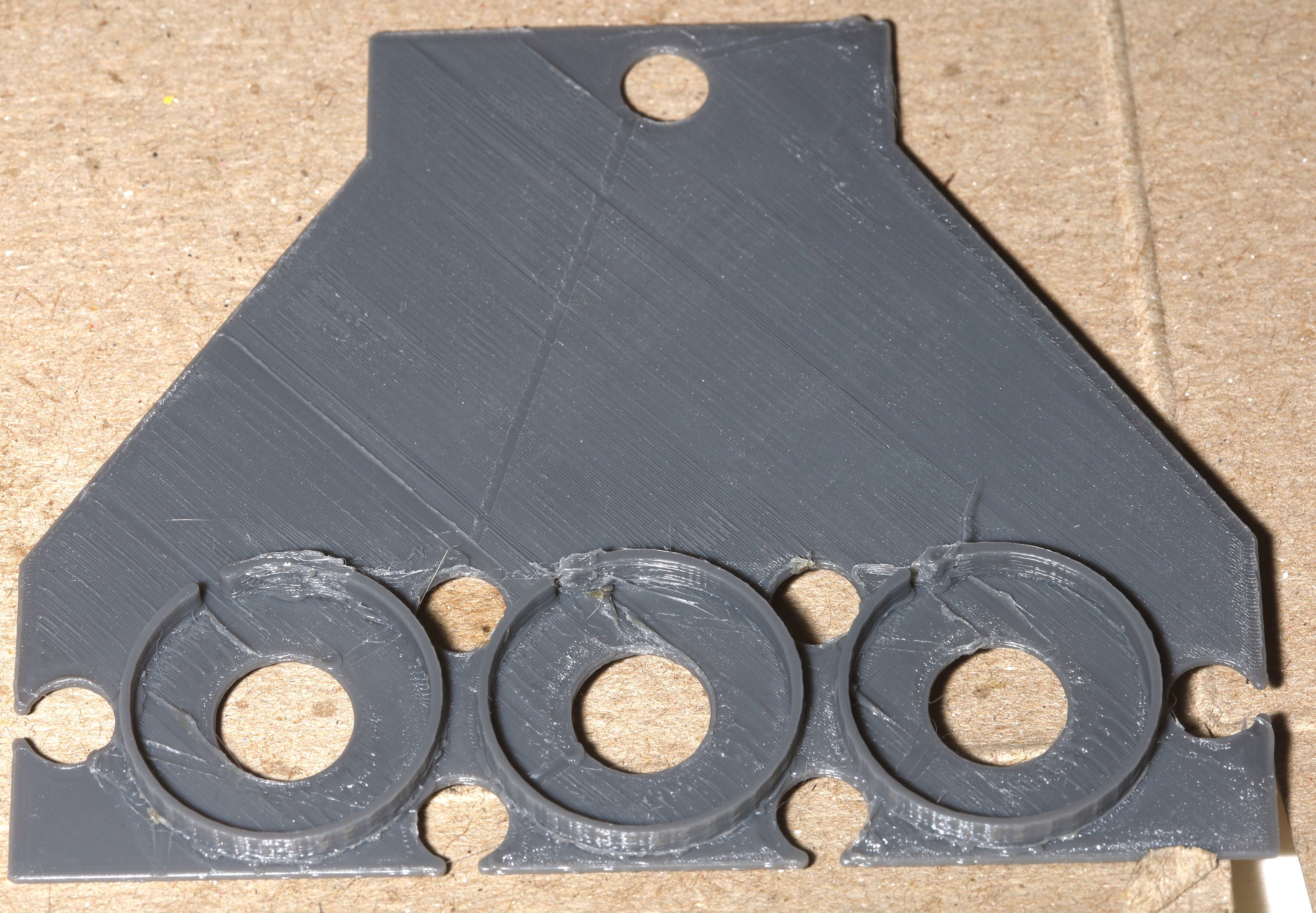

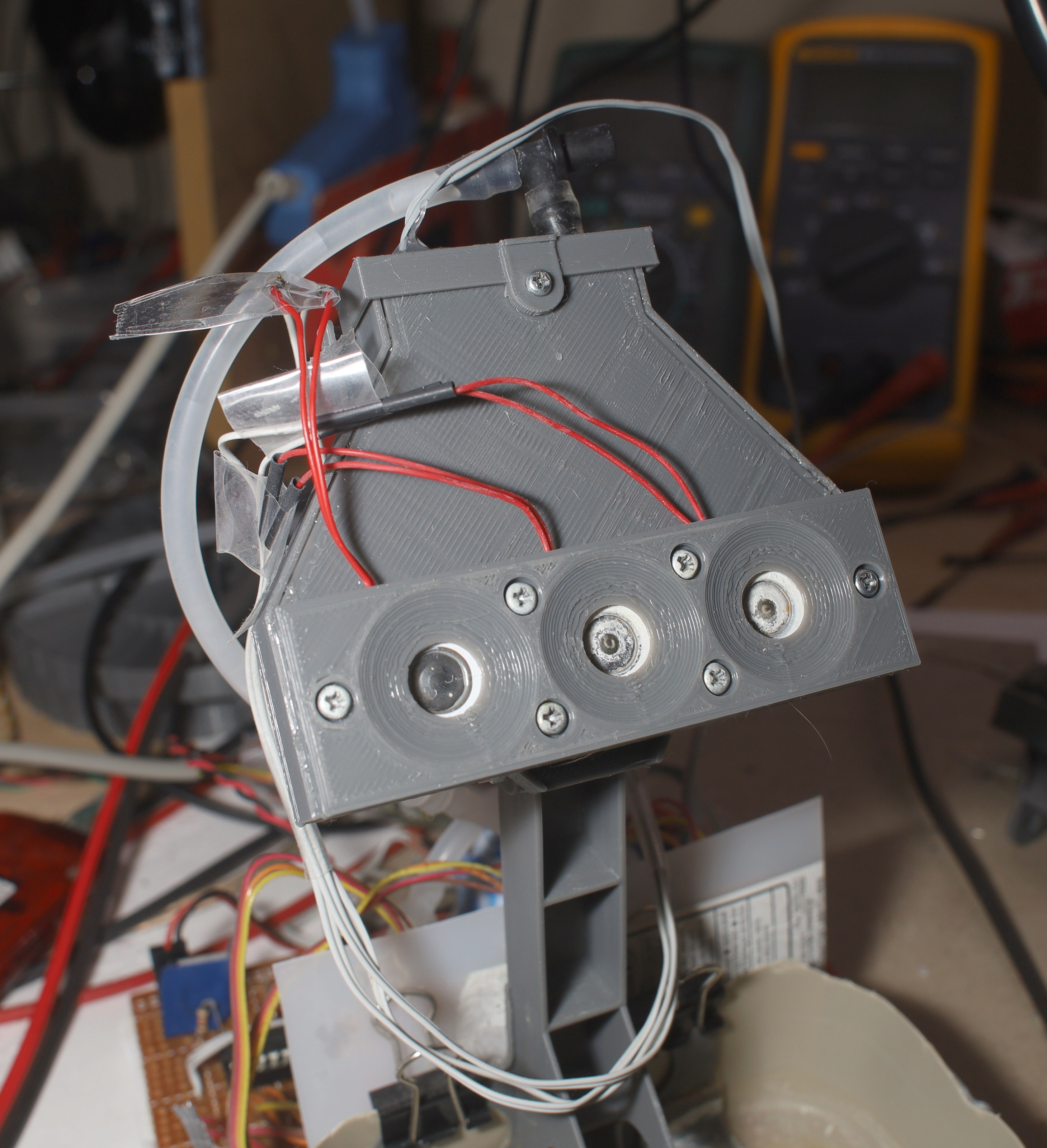

The screw holes appeared to be leaking because they were cracked. The decision was made to scrap the year old enclosure.

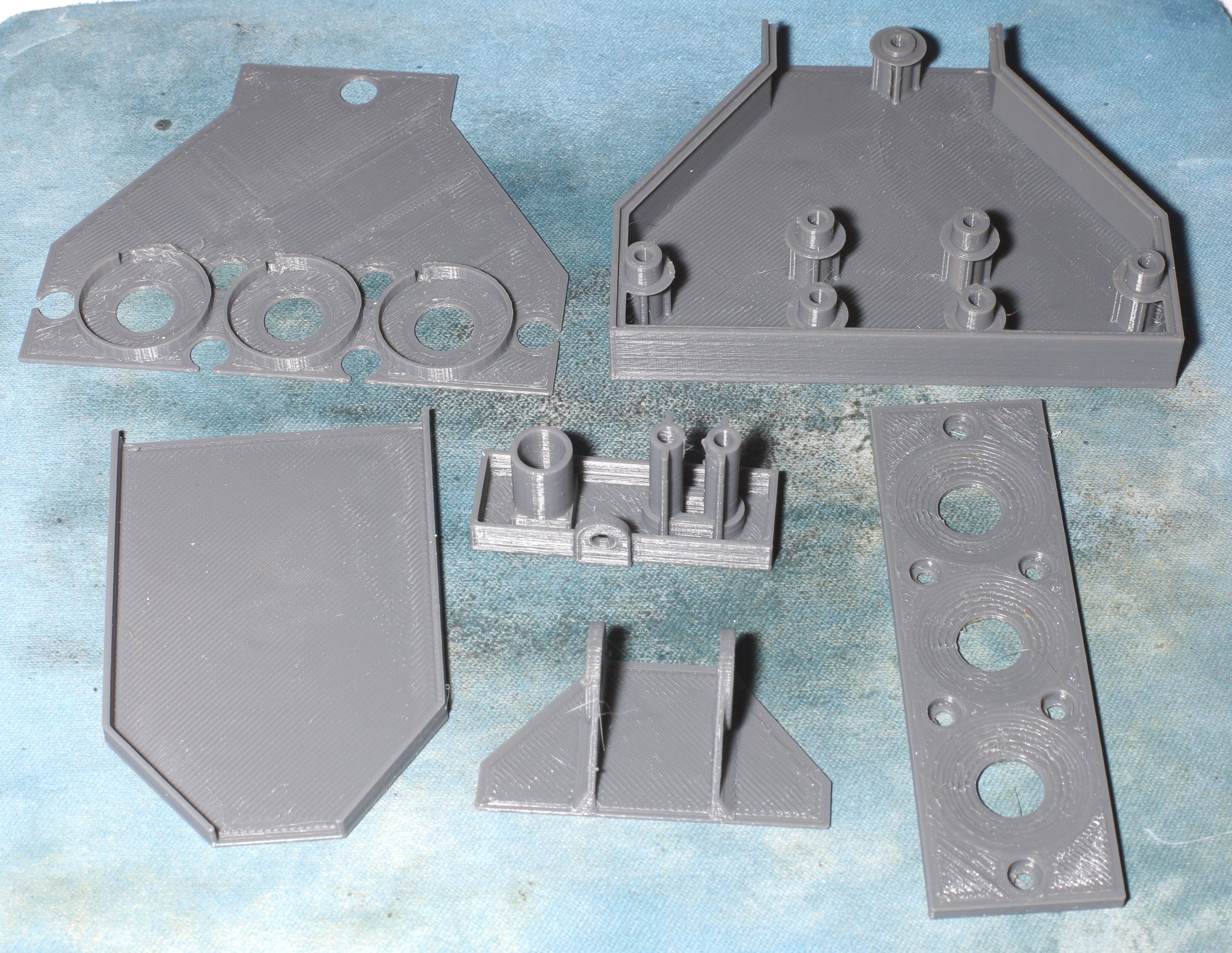

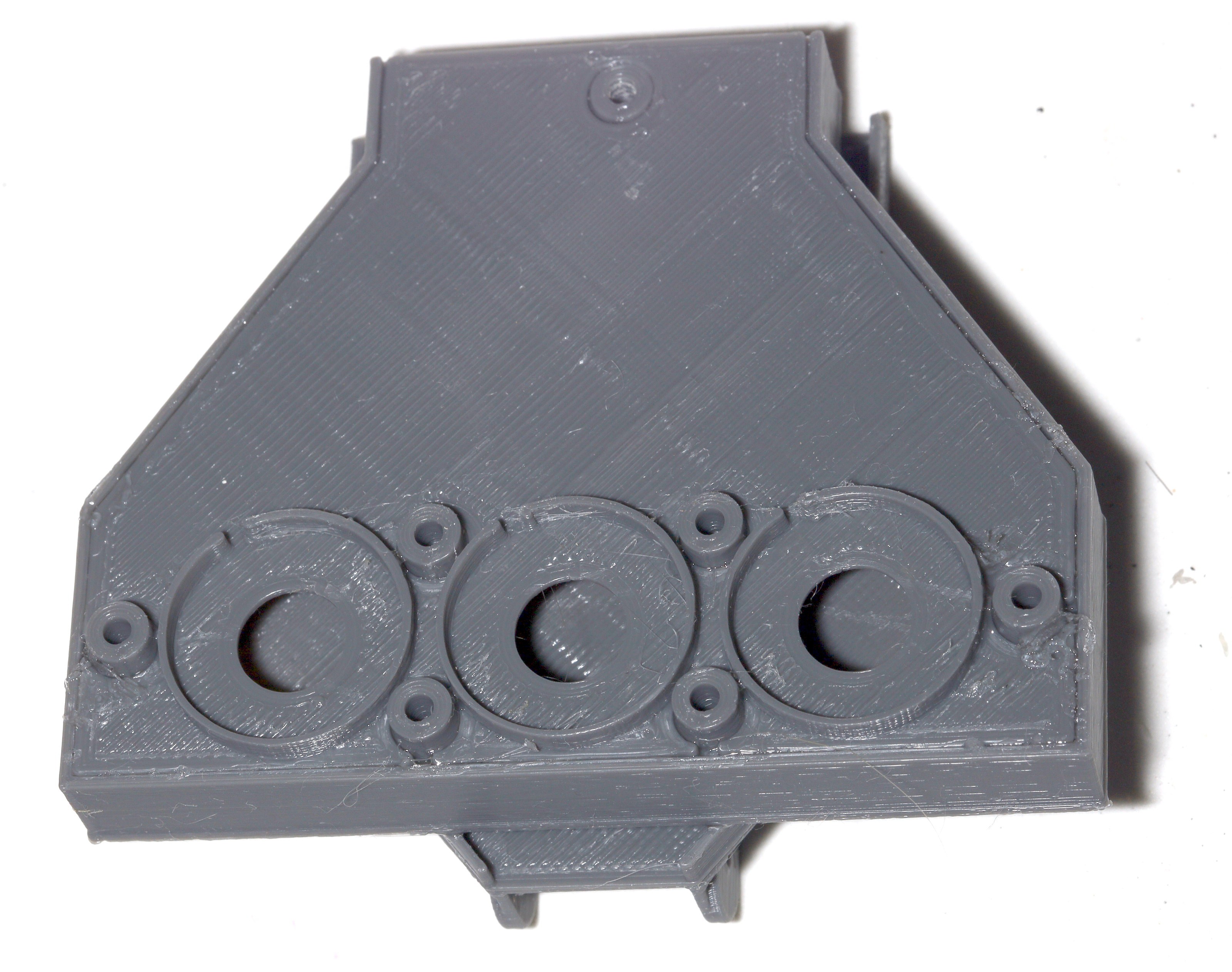

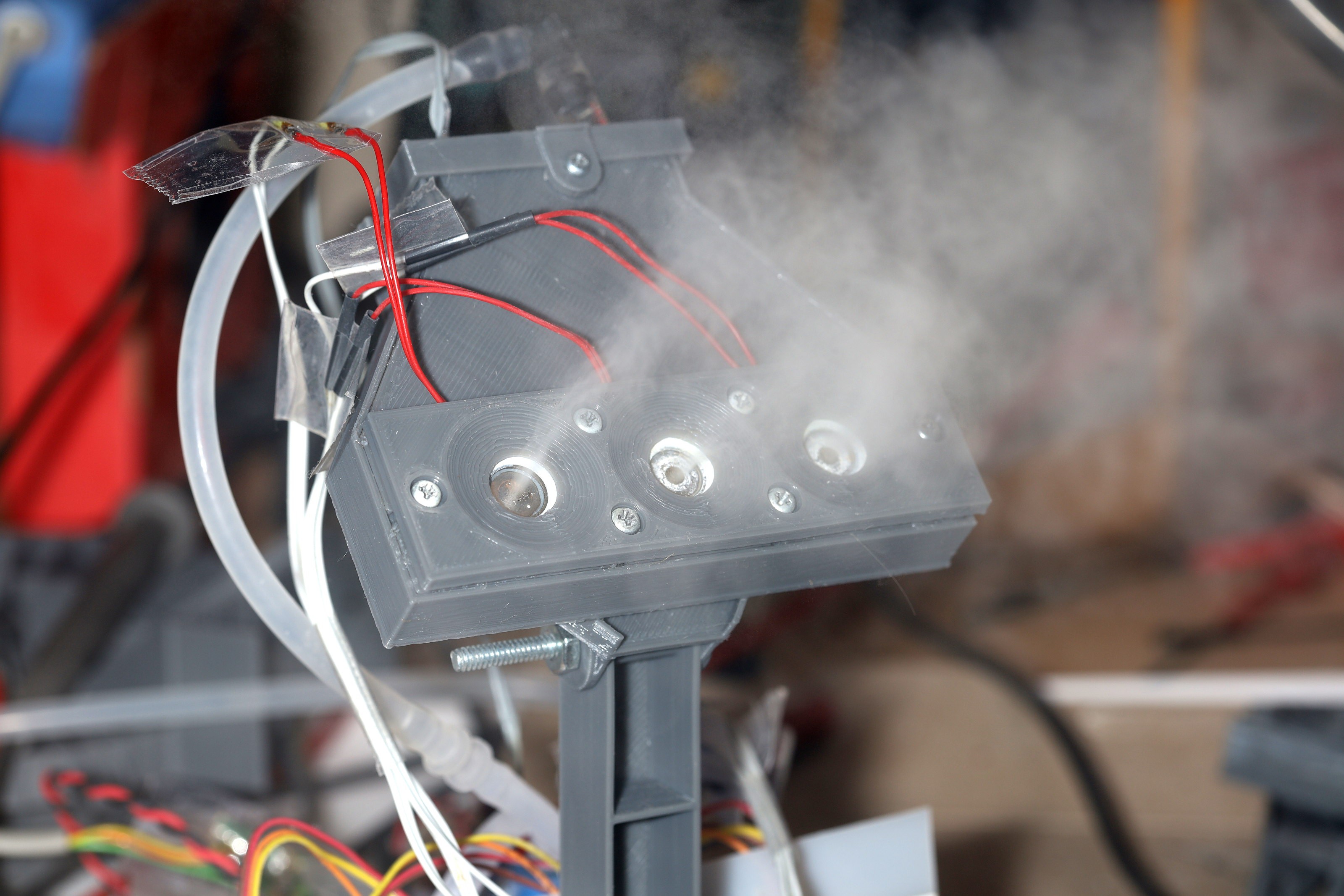

1 discovery made was ironing does not make a smooth surface for the transducers to sit on. It leaves blobs. The best seal is still going to be plumber's grease or balloon rubber. There's a problem of plumber's grease clogging the transducers. There was an attempt to make the screw holes more water tight. The old screw holes were 2 pieces glued together. The new screw holes are a single piece.

Instead of clamps, it should have panels screwed in the existing screw holes with scraps of rubber pressing down.

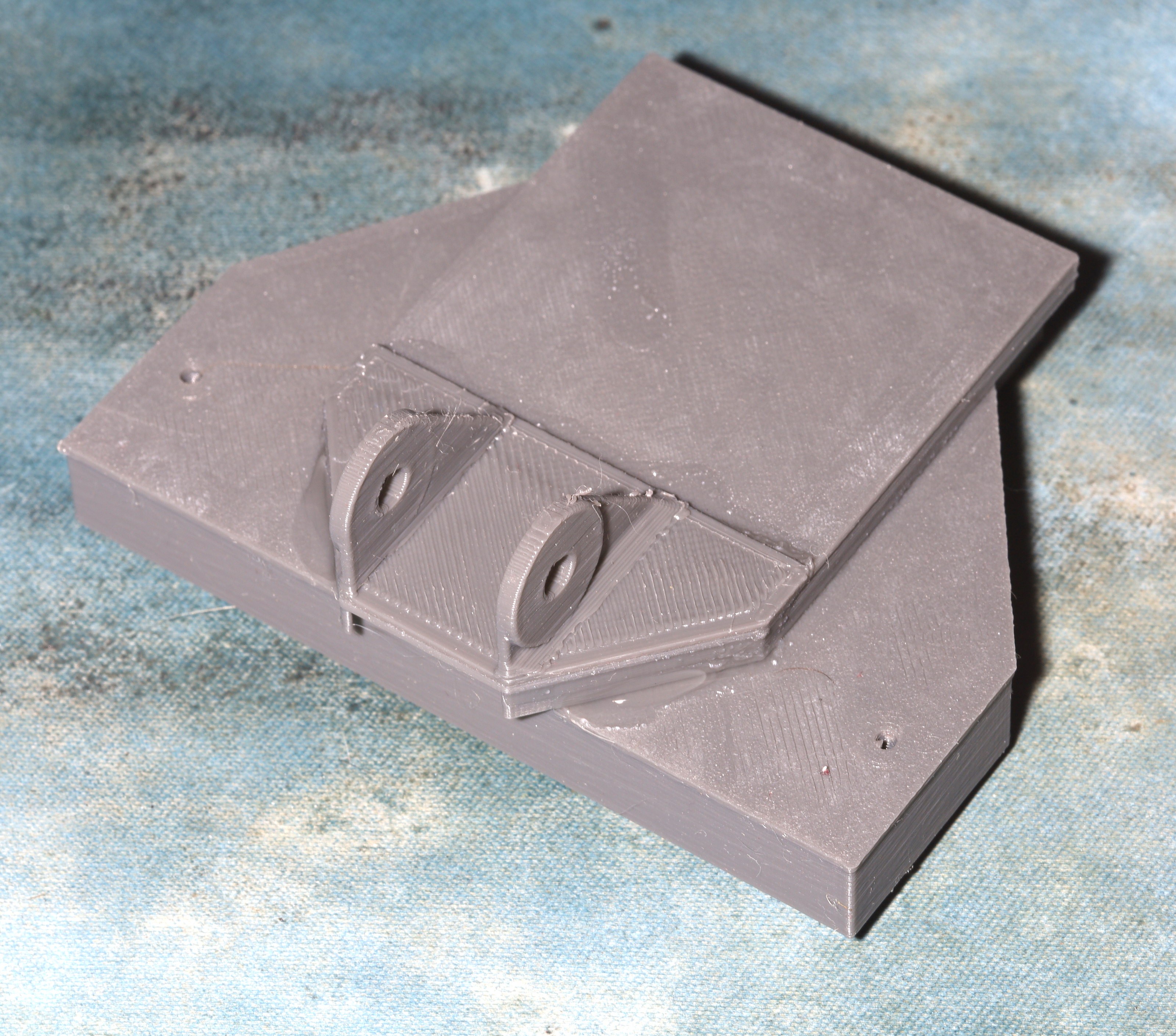

The drain & pivot are now glued on the enclosure. The drain needs a channel to glue into. It continues to be a source of dread. It needs to move water farther from the stand. It interferes with the screw holes. It's hard to model the channel. Printing temperature is now 230C instead of the 210C originally used. Getting a good seal with the overlapping areas continues to be problematic.

New panel was a lot easier to model but looked a lot better.

Initial results with a new transducer show the transducers are matched to the driver boards, but time will tell. The new drain doesn't work as well as the old one. It needs to be wider & extend more in front of the pivot point, but so far no drain has ever been needed.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.