At the moment the solenoid design works fine, but really doesn't offer much force. One way we can increase force is by increasing the turn count. To do that without sacrificing too much room, I can just use thinner gauge wire. Of course this will increase resistance, and therefore heat, but I'm not worried about that at the moment.

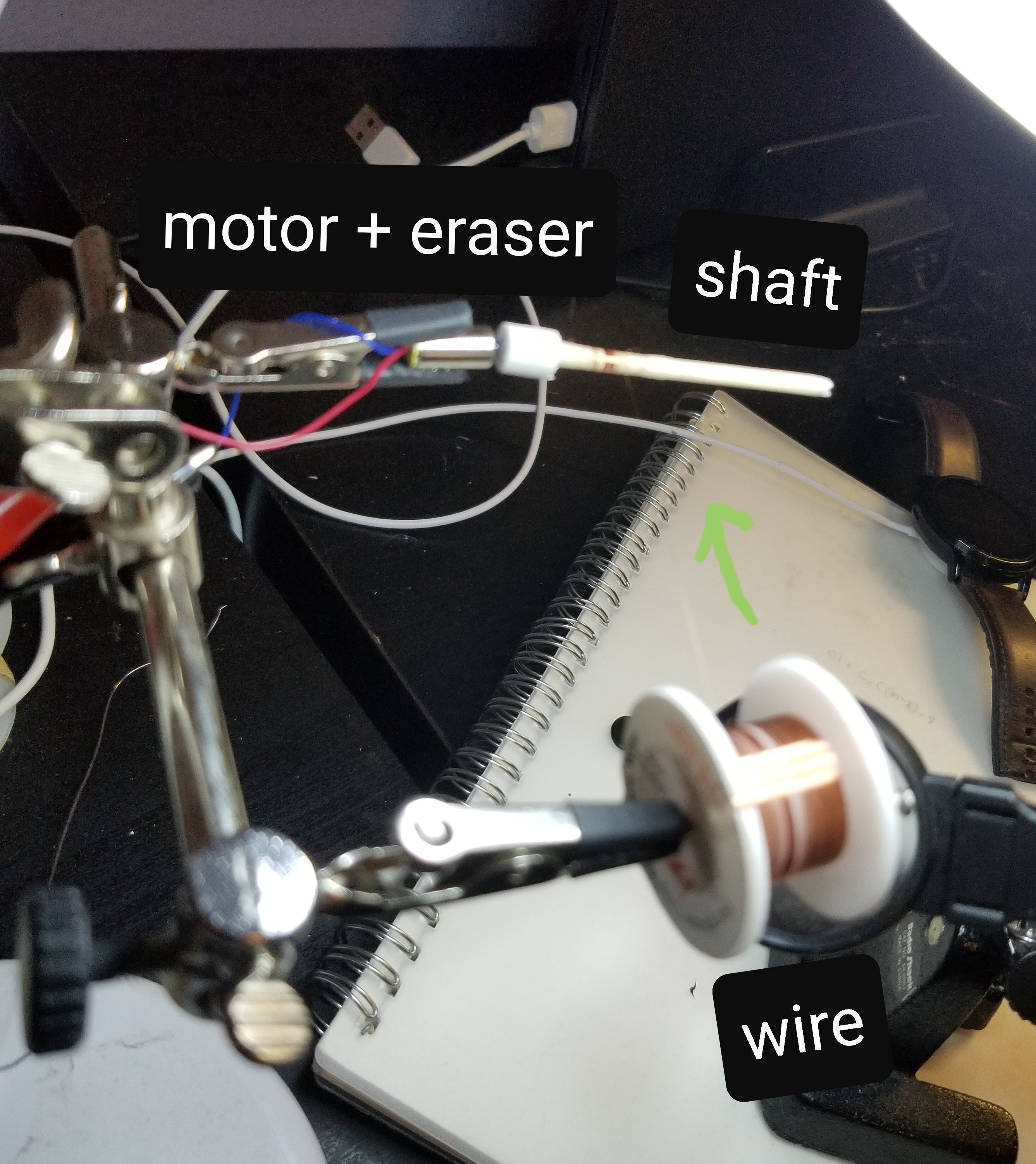

Naturally, I decided to find the thinnest, cheapest wire I could fine (.02 mm). This unfortunately turned out to be a nightmare. It is extremely tedious trying to use .02 mm wire. It is thinner that a strand of hair, so it kept breaking under barely any force. To deal with this I built a setup below. I used helping hands to hold the parts in place. The spool rotates on a nail while a tiny motor spins the shaft to wrap it. the shaft is made of a q-tip with painters tape wrapped facing sticky-side-out. I attached the shaft to the motor with a mechanical pencil eraser. I find that these make an ok-ish adapter when in a pinch.

All this actually would have worked pretty well if it wasn't for the fact that the spool was hopelessly tangled up. At most I got around 60 turns before the wire broke. So I just ordered some .05 gauge wire that will hopefully be less likely to break, and have been wrapped better. I will make another post once it arrives. In the mean time, I'm updating the python code to calculate the heat produced by the wire.

josh collins

josh collins

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.