Goals

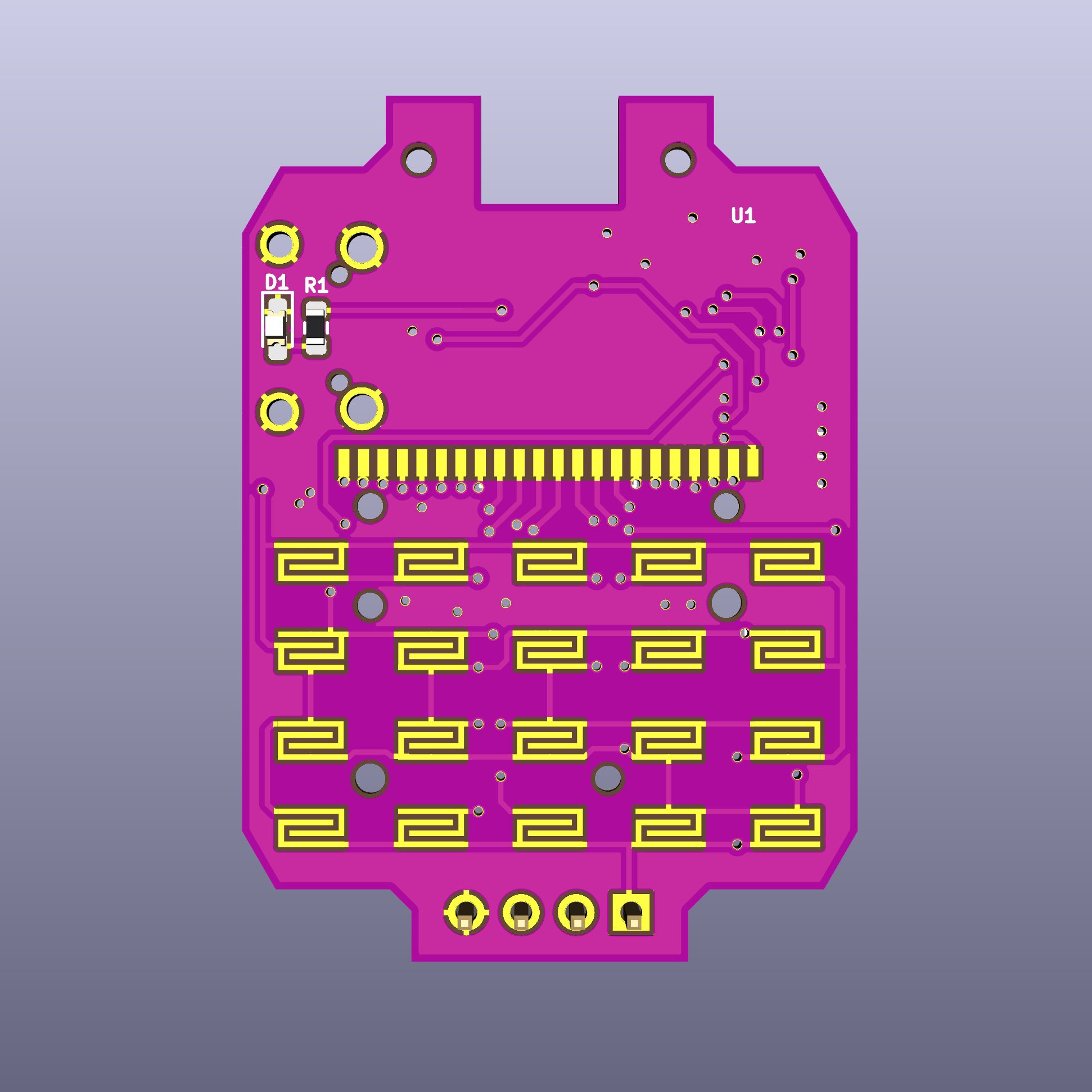

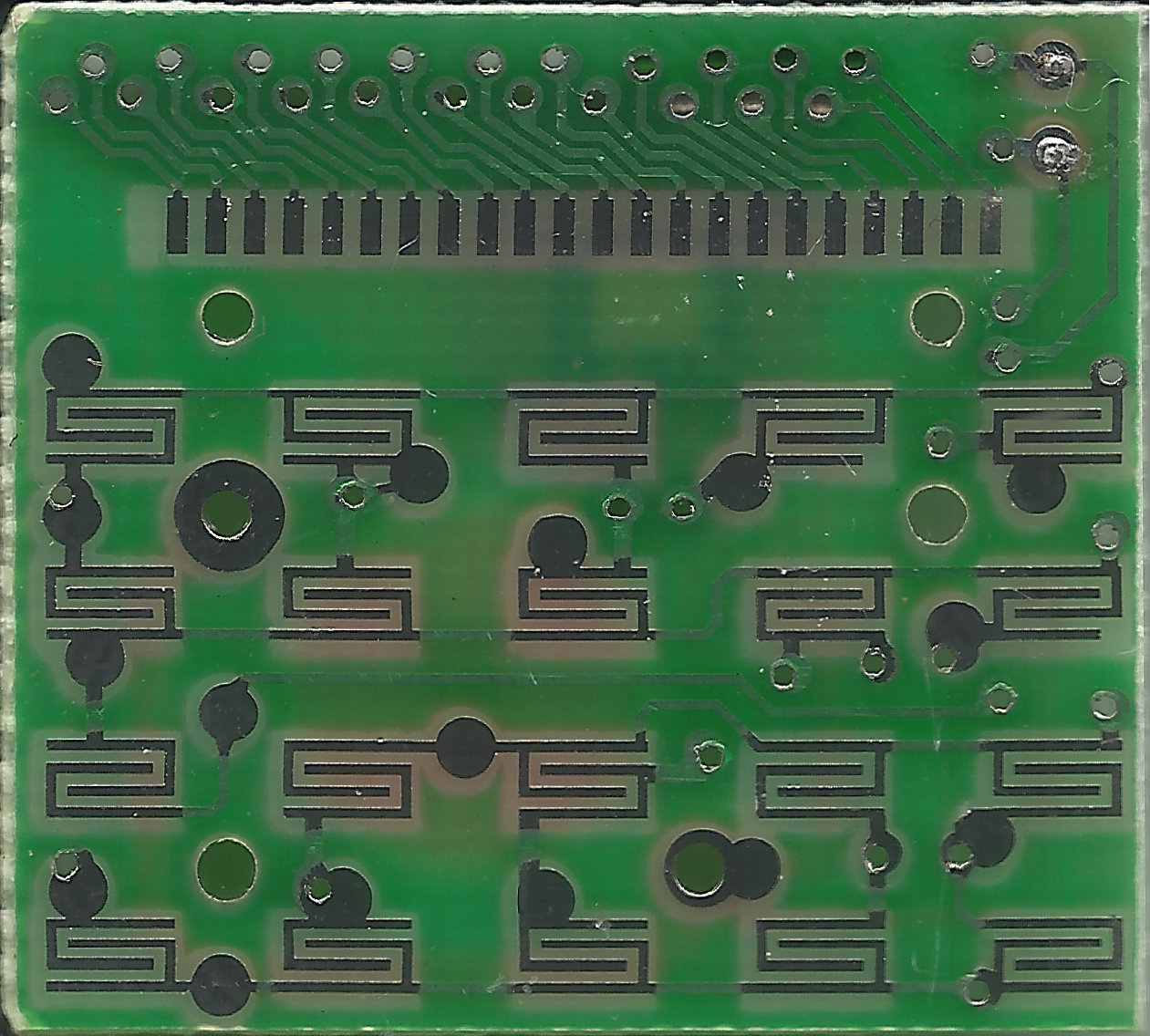

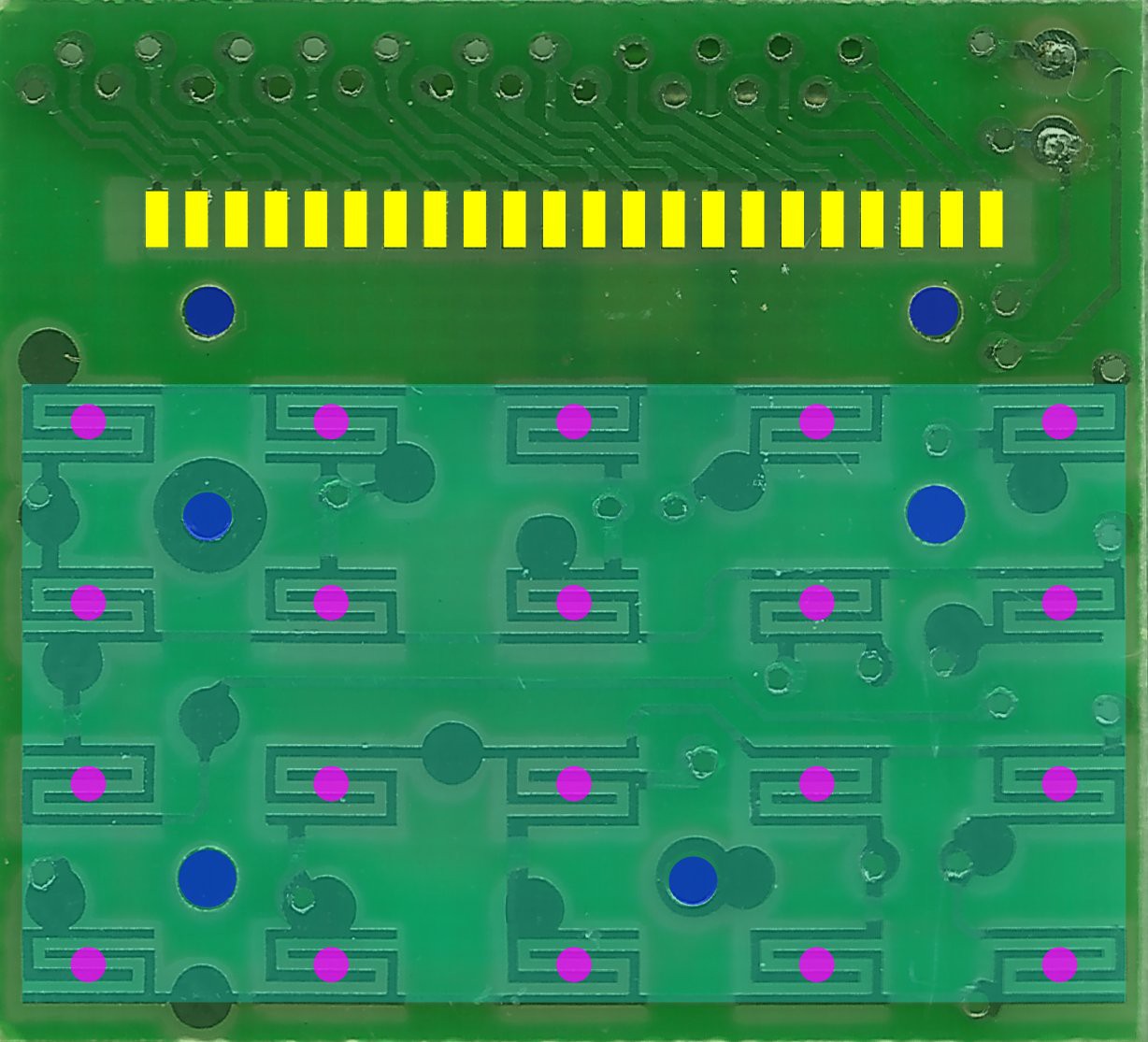

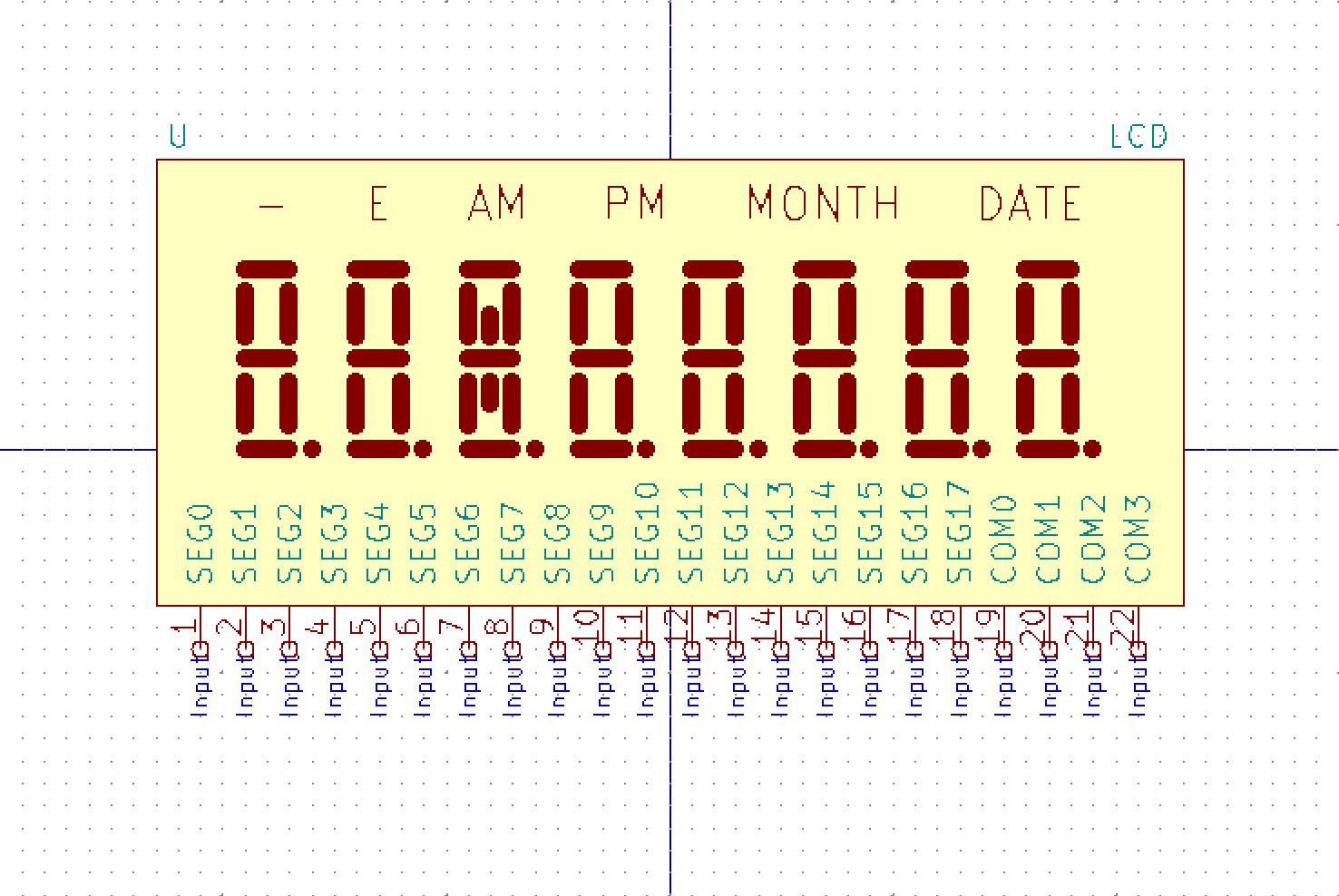

- keep the LCD and find out how to talk to it

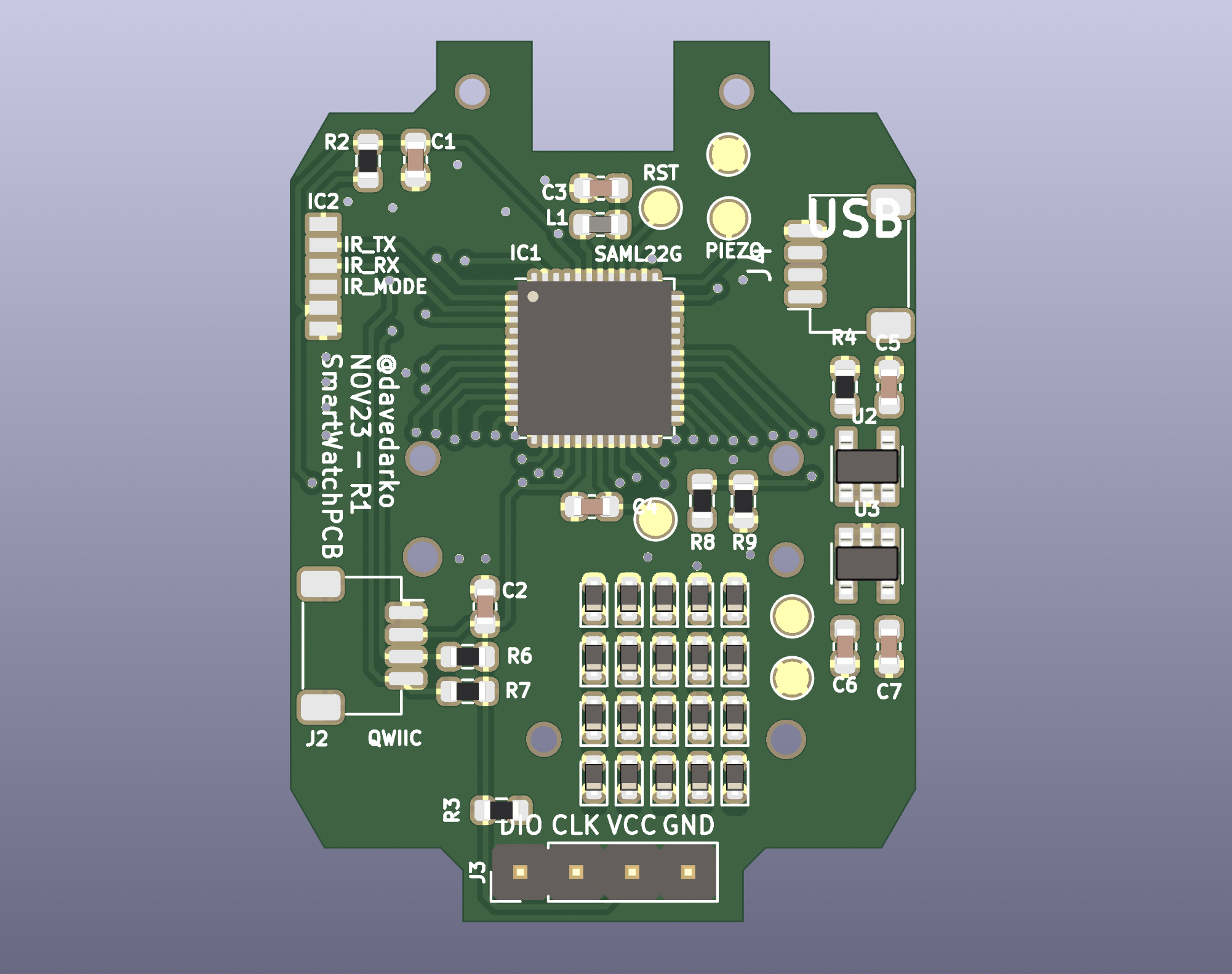

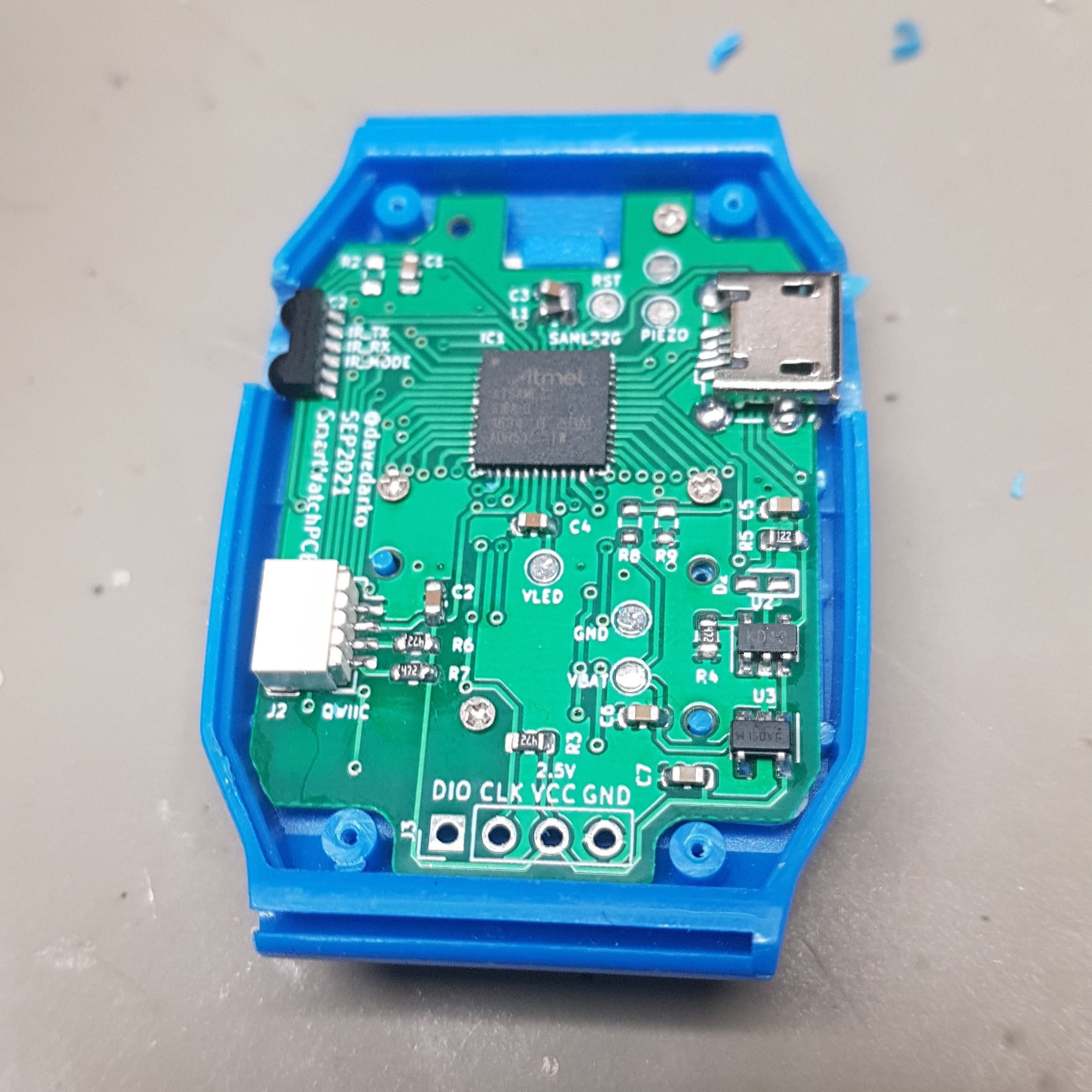

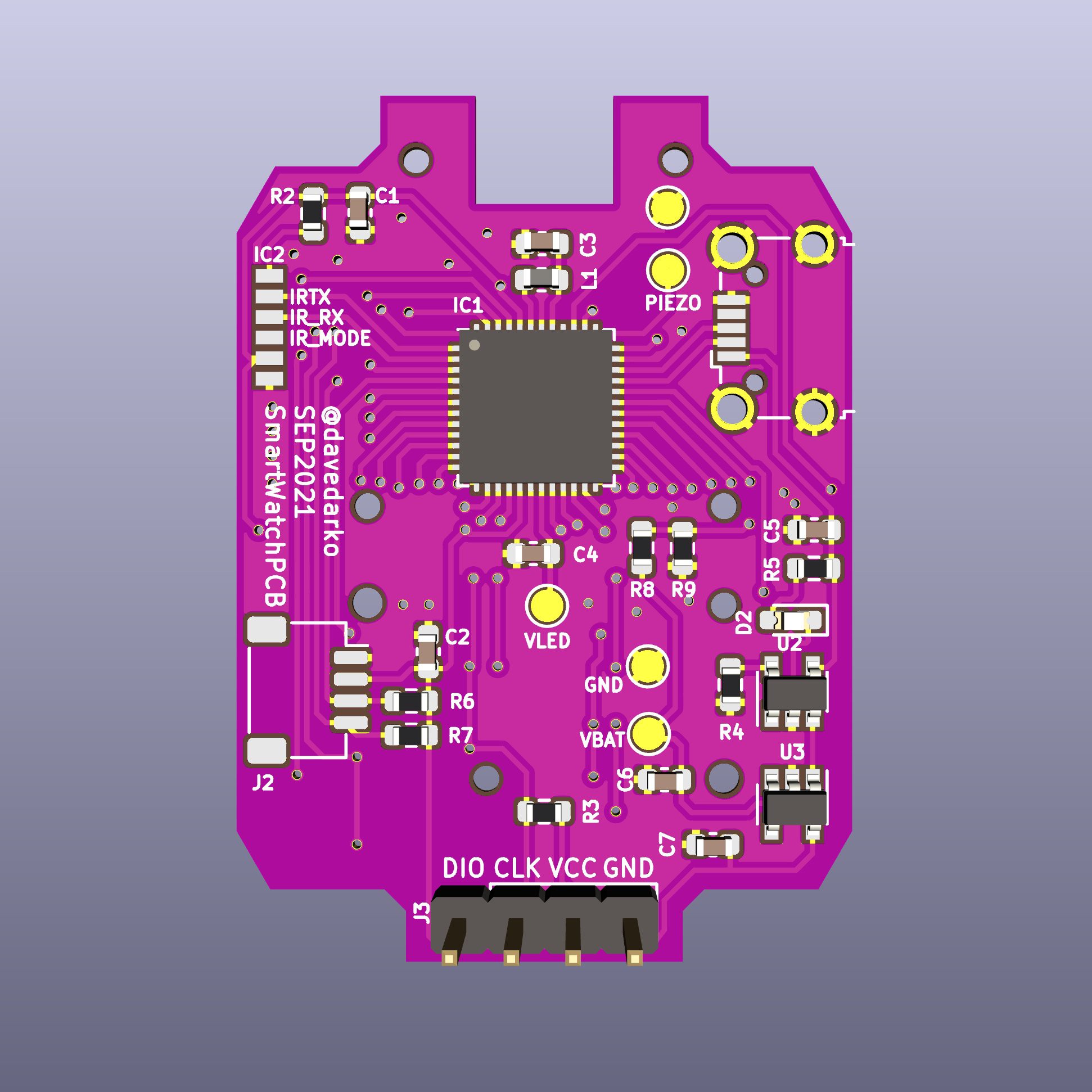

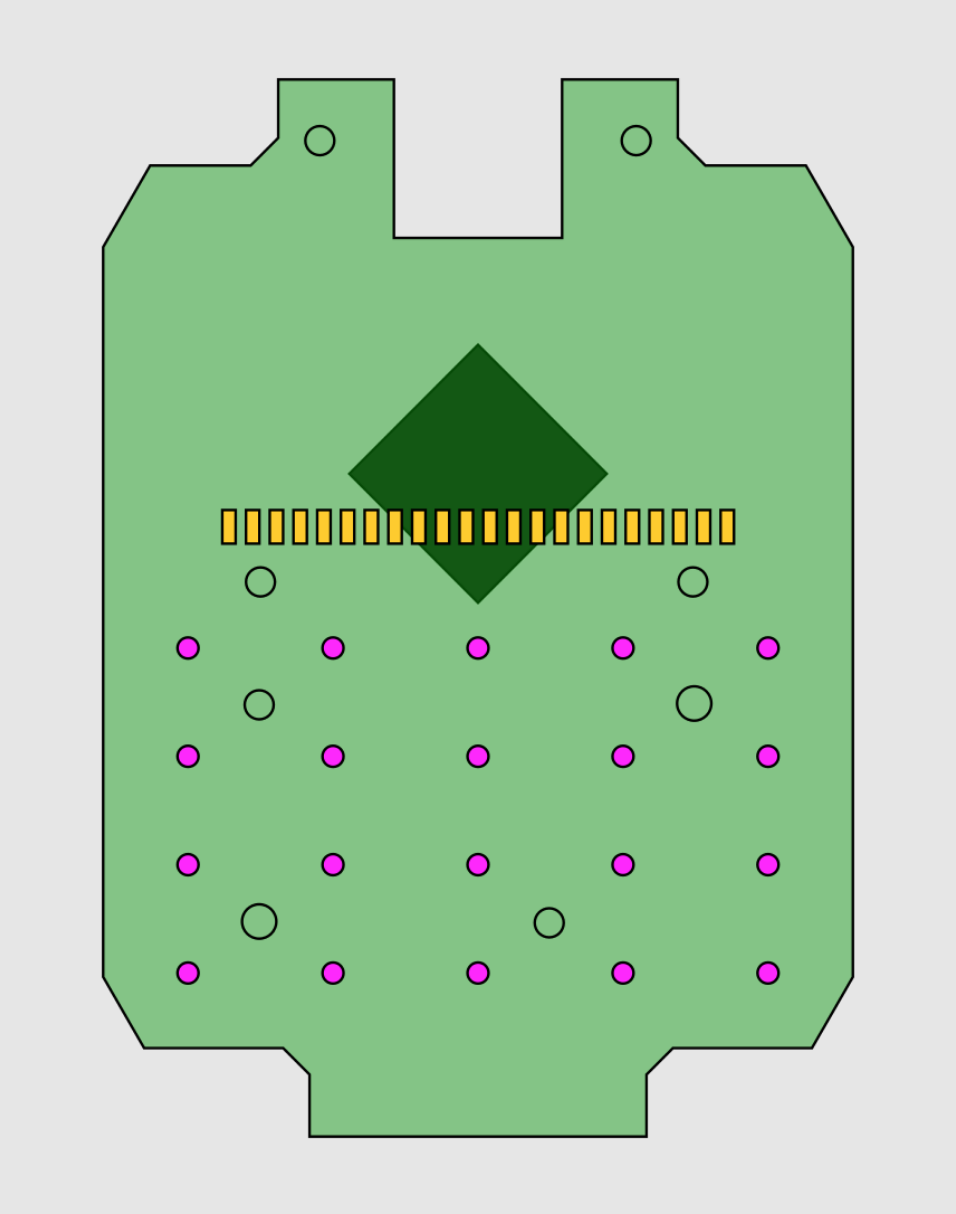

- make the PCB as big as it can get inside to maximize real estate

- make it tell the time in 24h mode

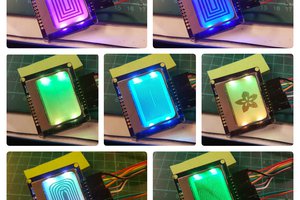

- add a pink backlight LED (or a color of your choice, maybe RGB?)

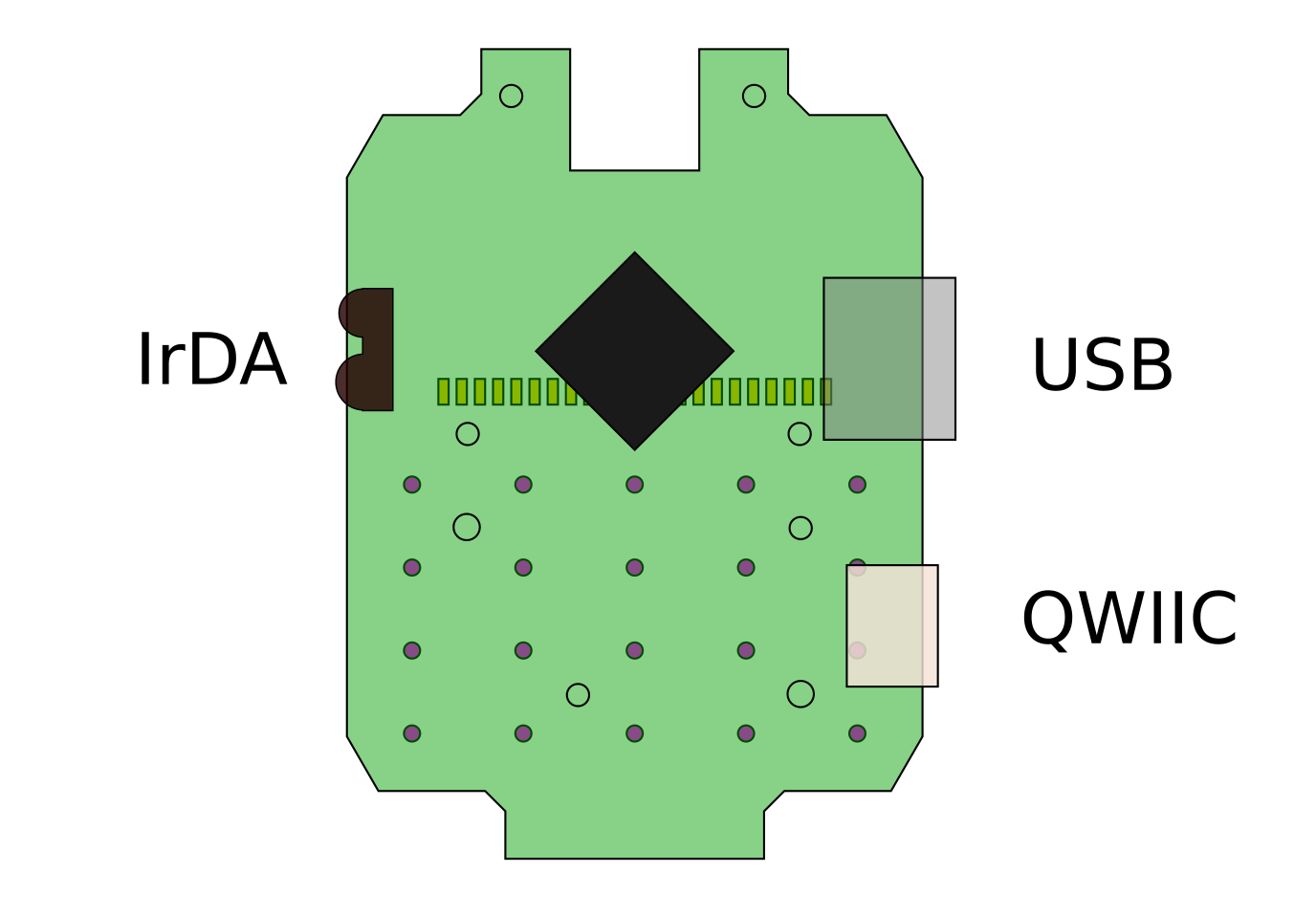

- get IrDA on SERCOM1 working

- get I2C on SERCOM5 working

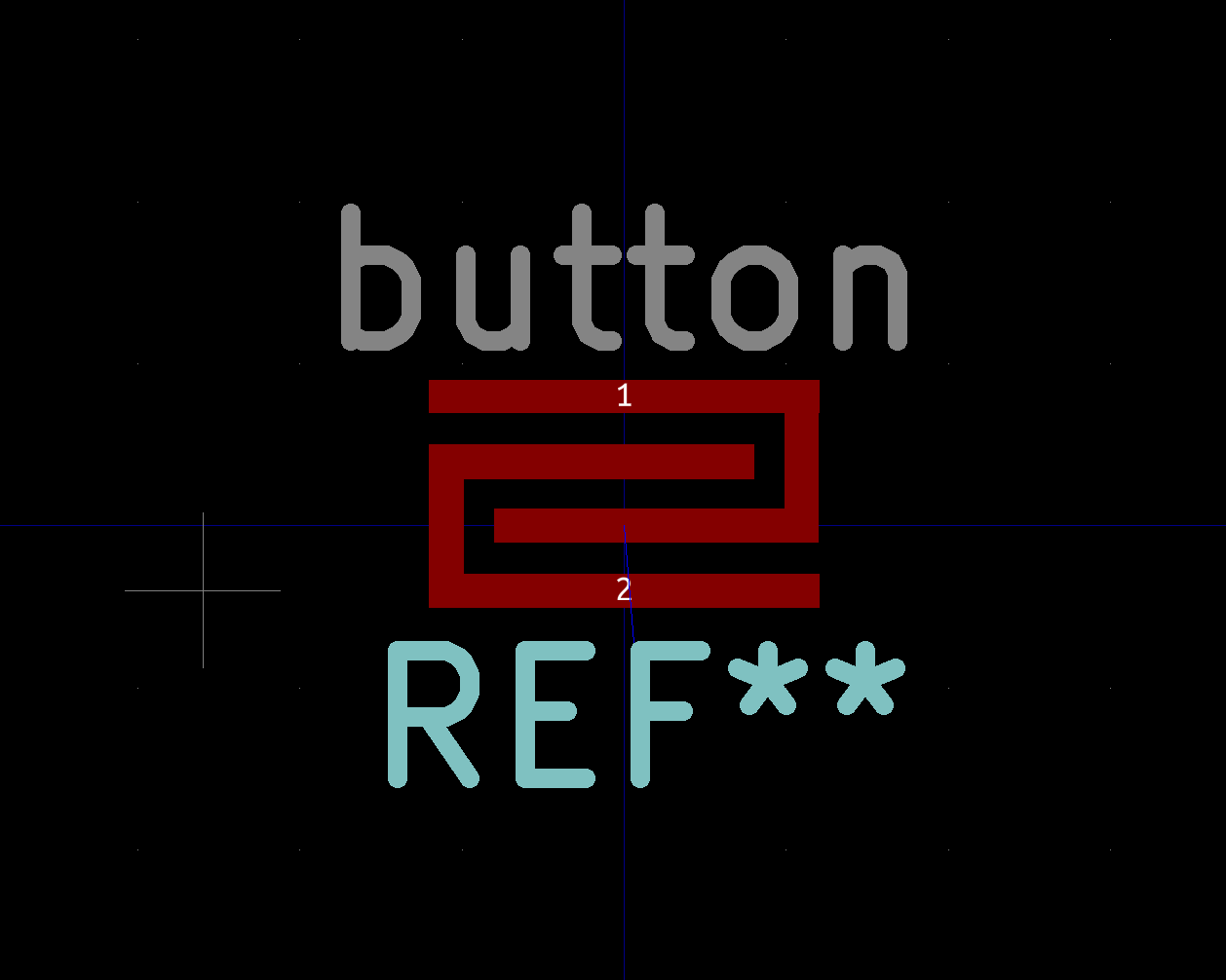

- use https://github.com/gregdavill/KiBuzzard/

- get everything into Arduino somehow

- personal: use more open source software and learn about ARM chips

LCD

currently the plan is to use an SAML22 chip, as it has an LCD controller inside

Watch

buy one here, they have 70k laying around: https://www.aliexpress.com/item/4001351603141.html

davedarko

davedarko

Thomas Capricelli

Thomas Capricelli

arturo182

arturo182

This is a really cool project. Are you selling these boards so we can build one with you?