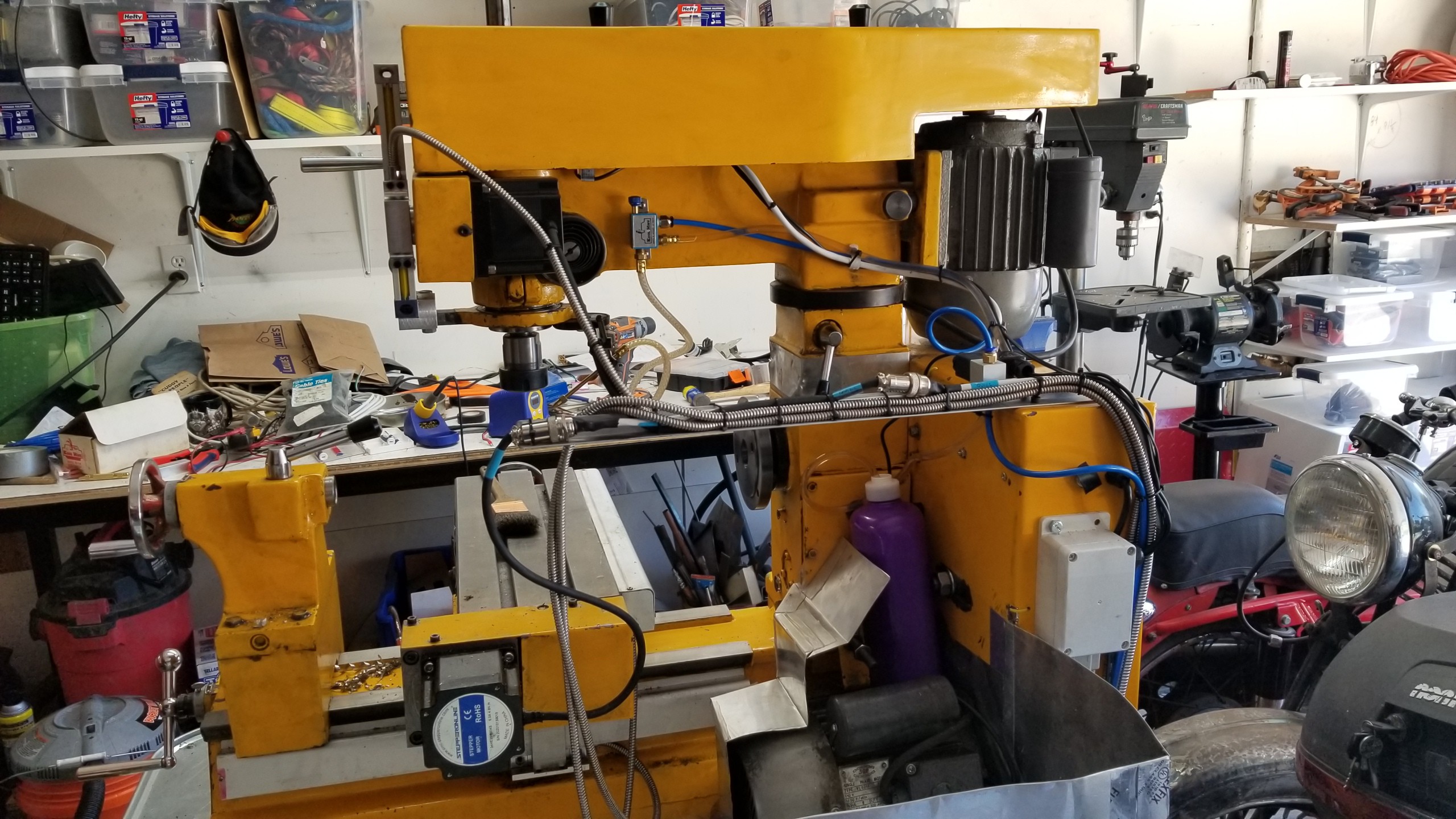

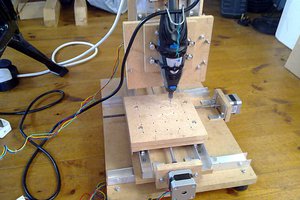

The current state of the project is:

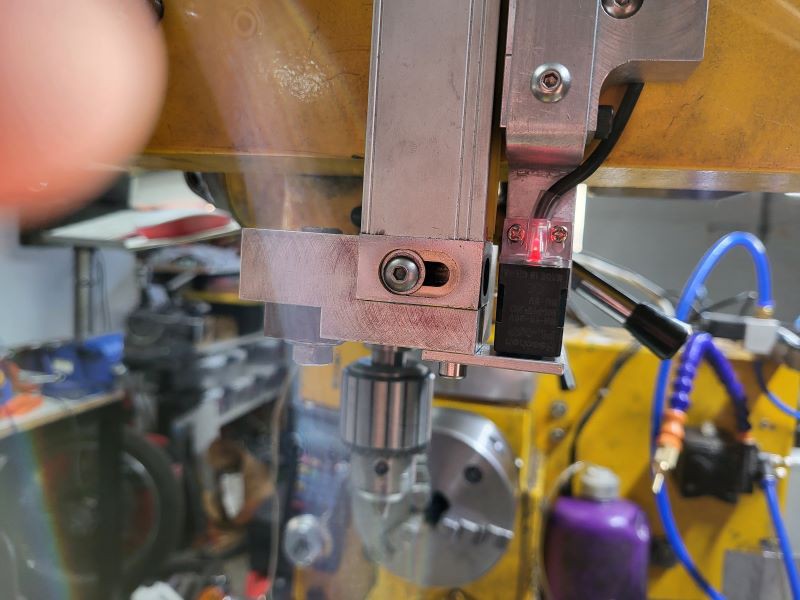

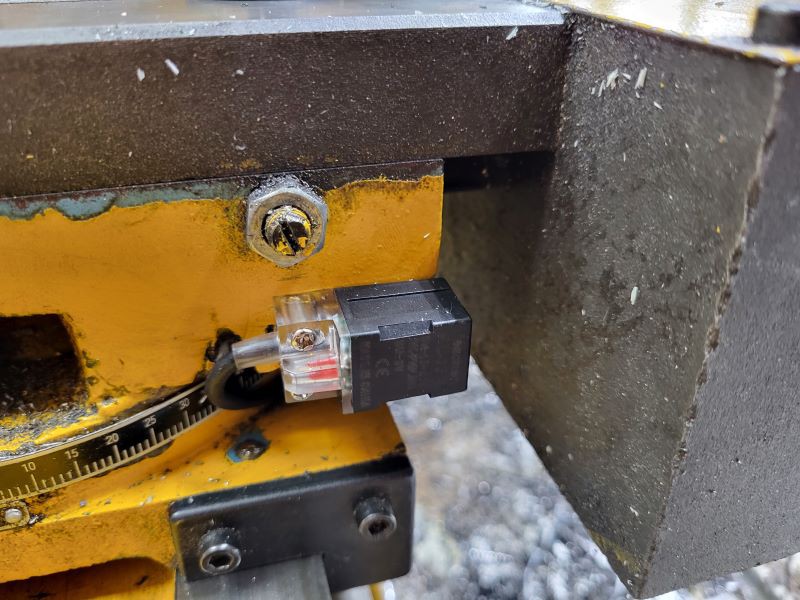

- This is generally completed and is in use...

Next steps:

- Play with it and make things

Future stuff:

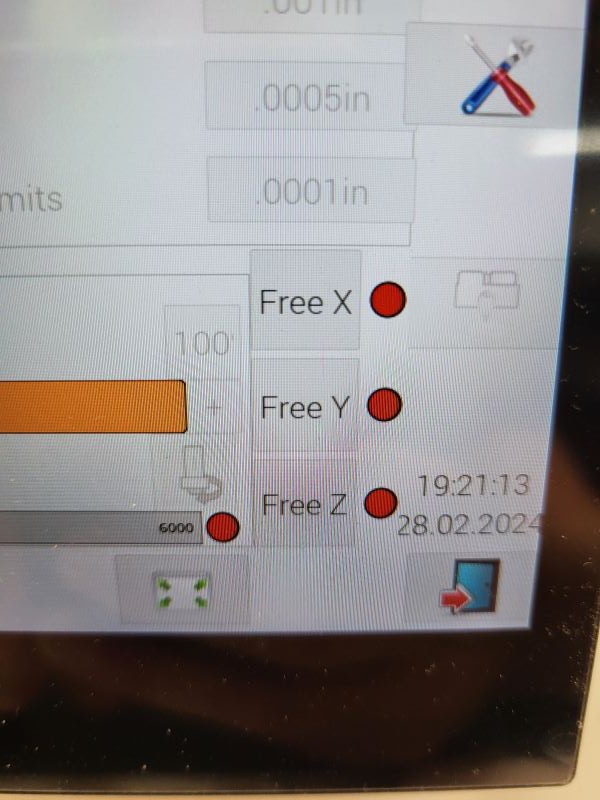

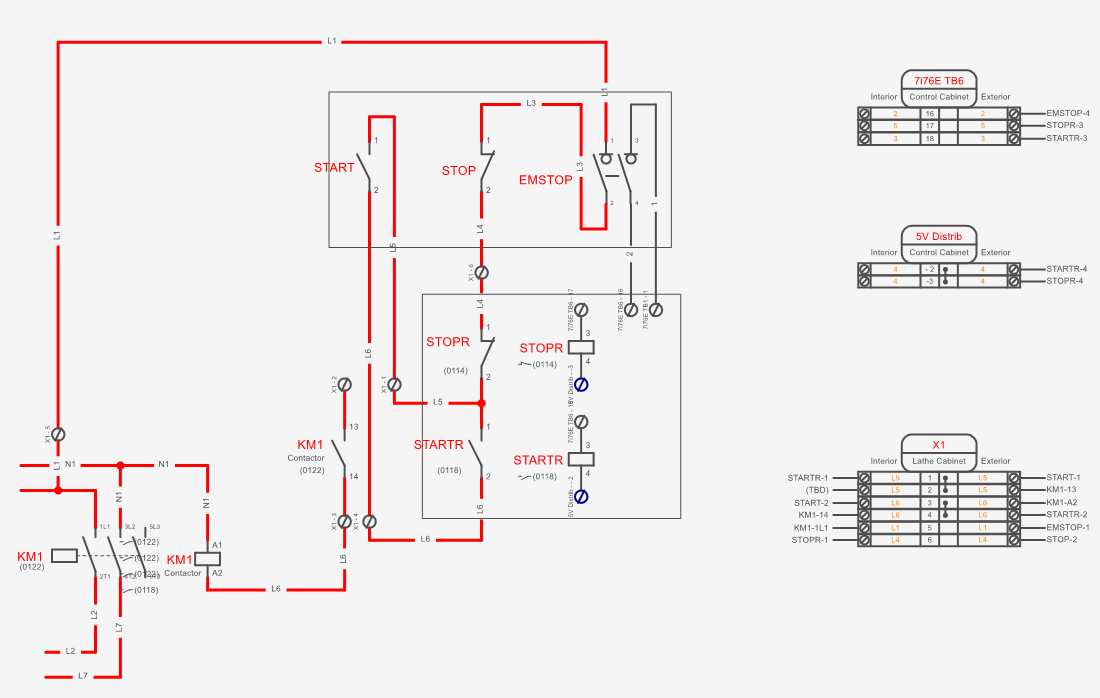

- tool setters

- look at upgrading linuxcnc and moving to 64 bit OS. The current install crashes occasionally when poking around the UI. Less annoying now I have homing sensors.

Alastair Young

Alastair Young

willbaden

willbaden

Saul Cozens

Saul Cozens

I went back and looked at my config and history. It looks like I just started with the minimal base 32-bit Raspbian image then added the X package and then followed the steps in the LinuxCNC install instruction (added the current RT kernel package and LinuxCNC). The only config tweak is to limit the memory to 3GB - there is some bug that breaks the USB above that as I recall. I don't get the onboard Wi-Fi or the power button, but I've addressed that with external components. I do get occasional servo loop RT warnings, which seem to mostly happen when pushing buttons in the UI. As I have encoder feedback and the mesa card is tracking the encoders, I'm not fretting about that too much.

I do have it set up dual-boot with a vanilla Raspbian so I can fix what I break on the LinuxCNC image.

There is a thread out there now about 64 bit kernel for Pi that looks very promising. I'll probably circle back an try that out at some point. At the moment the Pi side of things is working good enough and I'm focusing on things like estop, spindle encoders and coolant setup. And maybe actually making things.