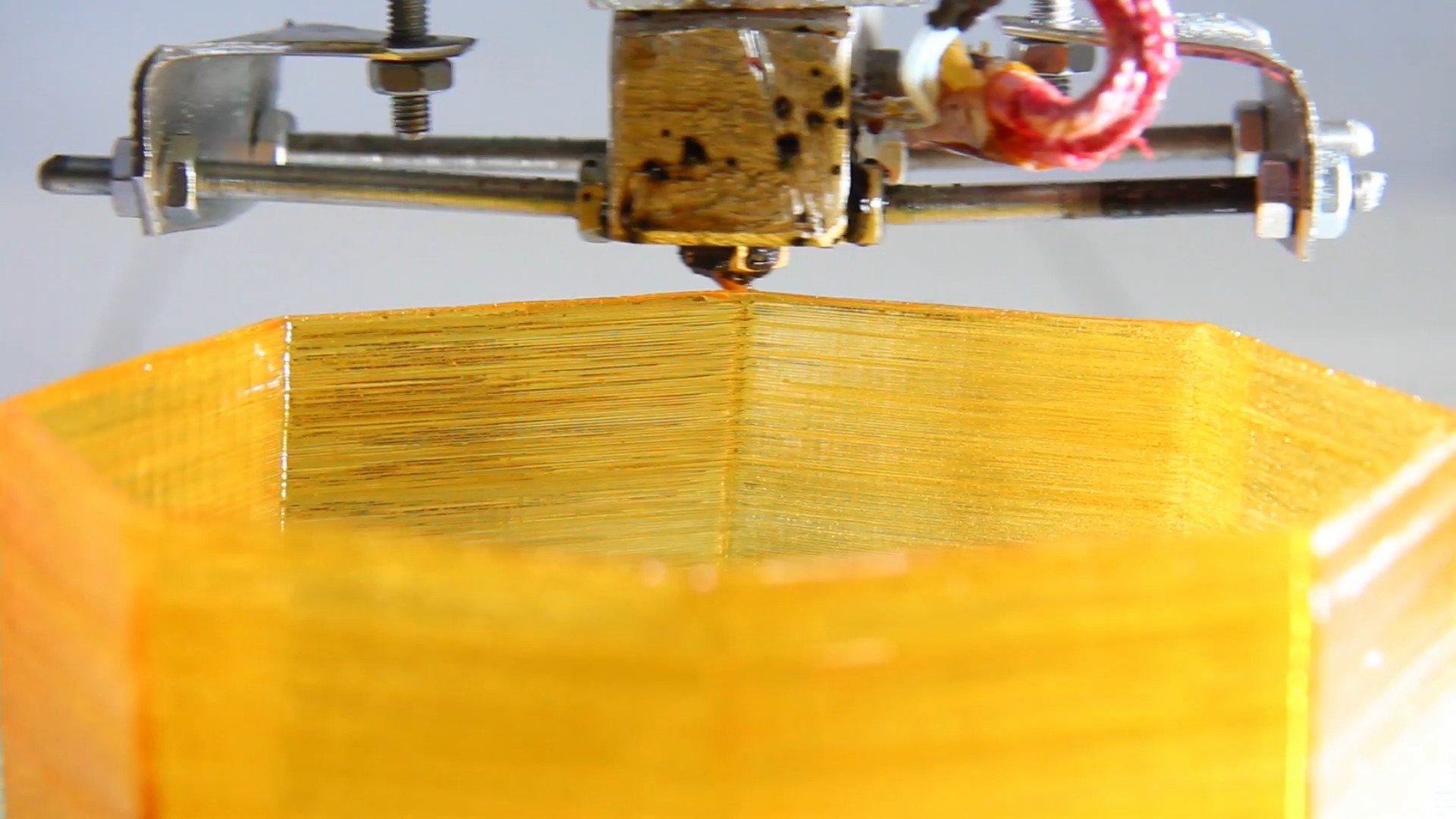

With my machines I aim to give students a better understanding of how technology works and of course I'd like to drive innovation as well. "Keep things simple" is the mantra that I follow. Simple to build, out of parts that are simple to source and bring it to live with simply some lines of software code.

I am fighting common thoughts that complex machines like 3D printers must be composed of complex parts manufactured with complex machinery. I am replacing expensive tool chains with my brain ;-) That often means breaking with conventional ideas.

Done:

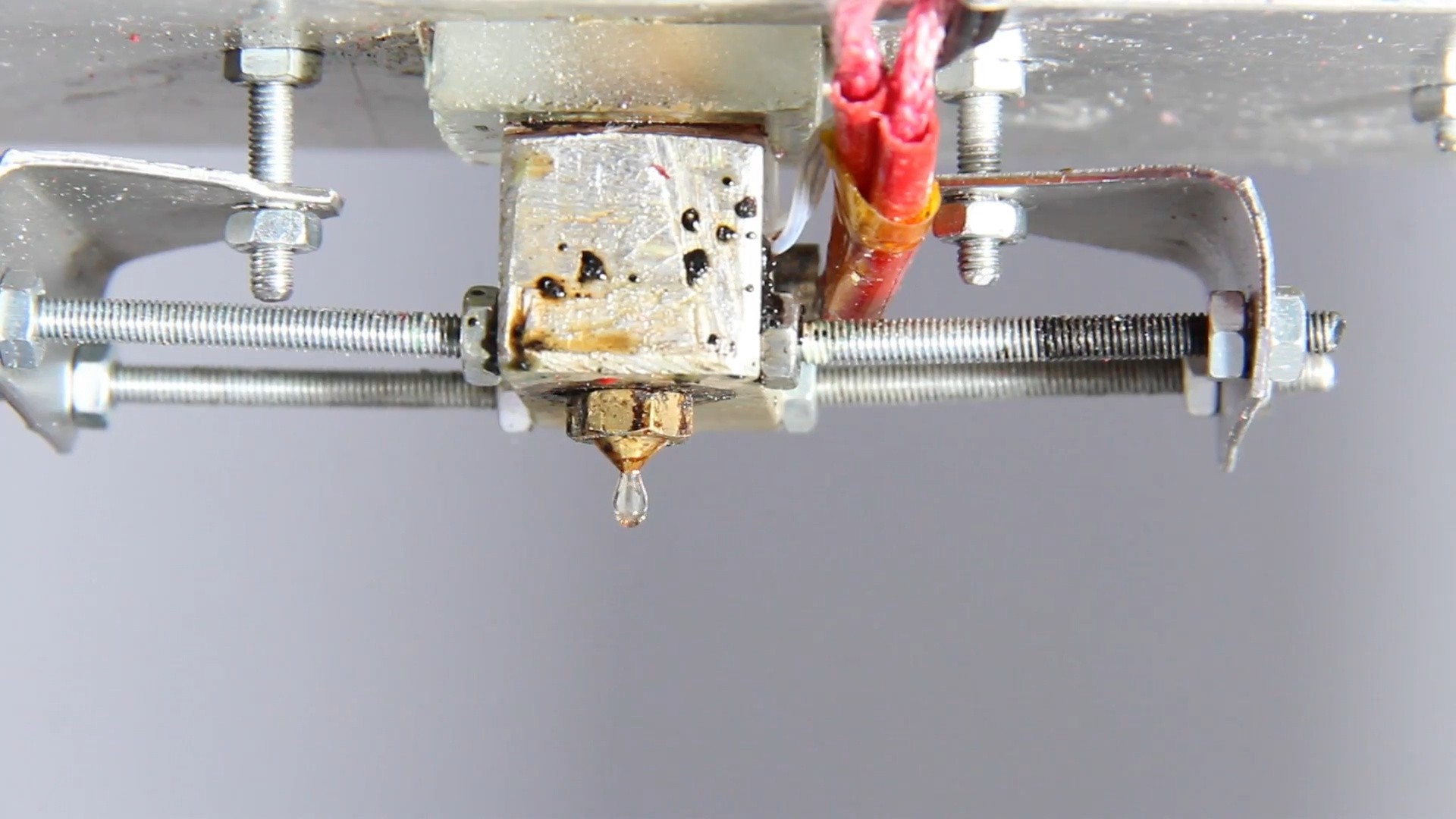

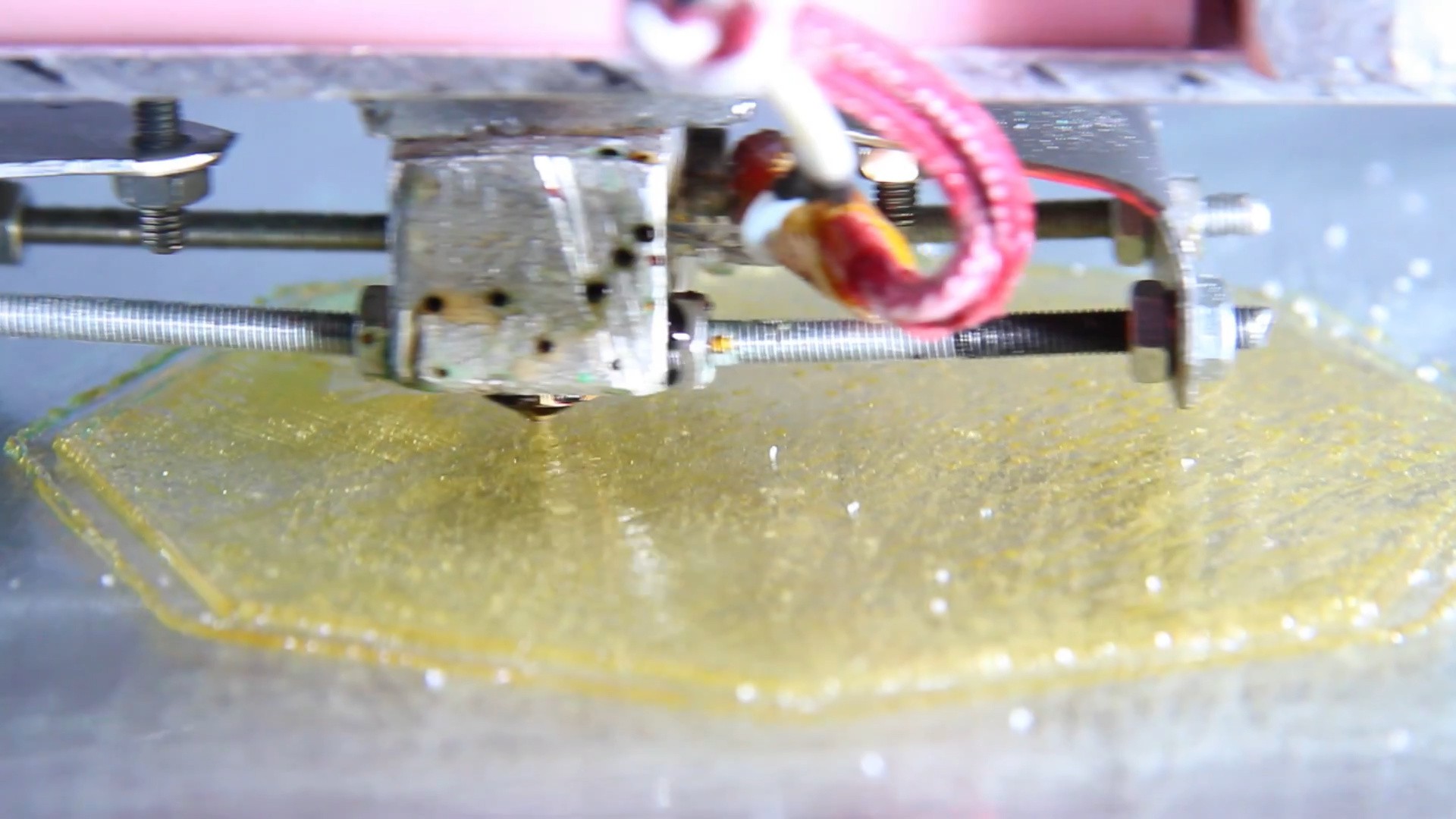

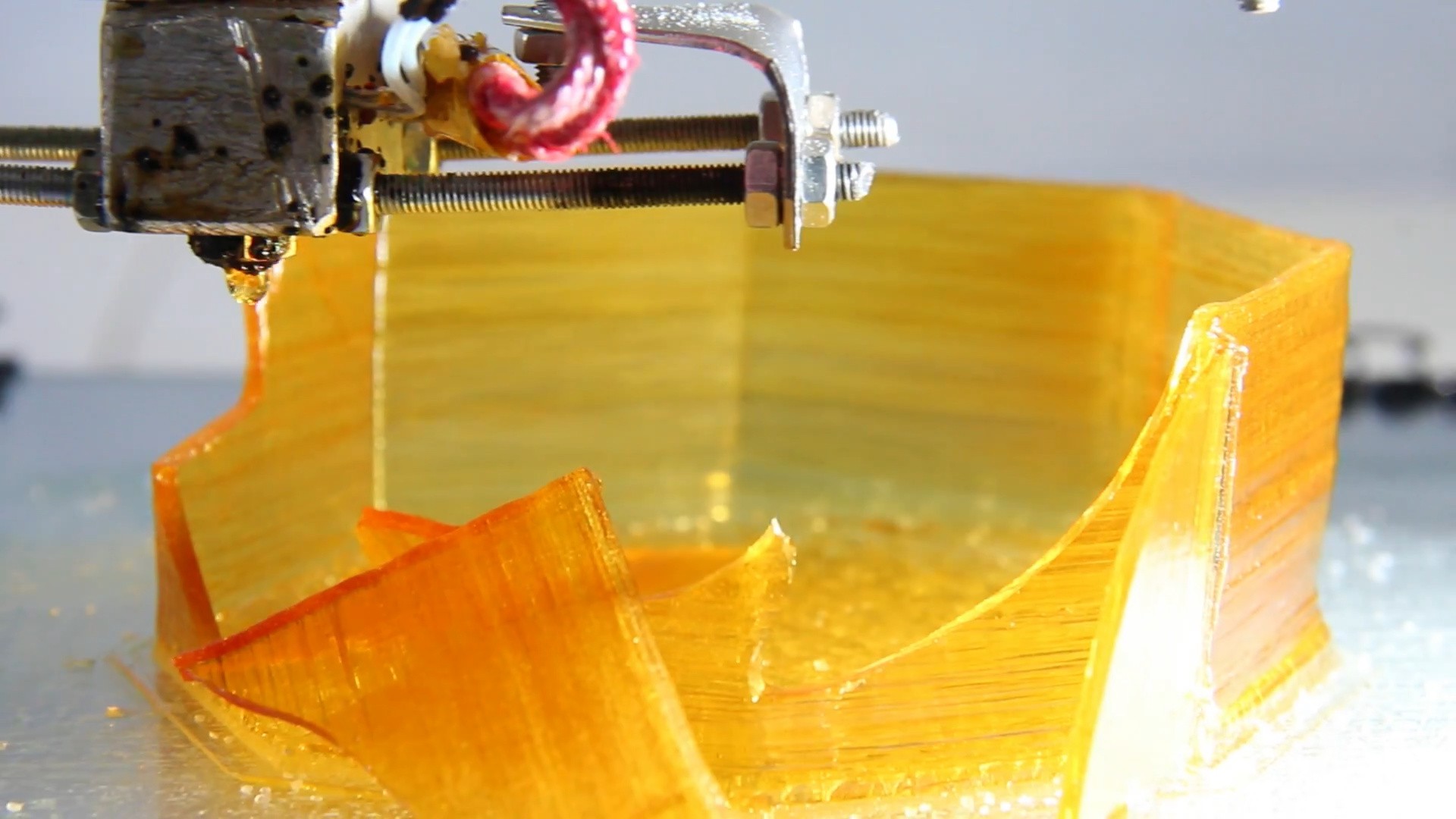

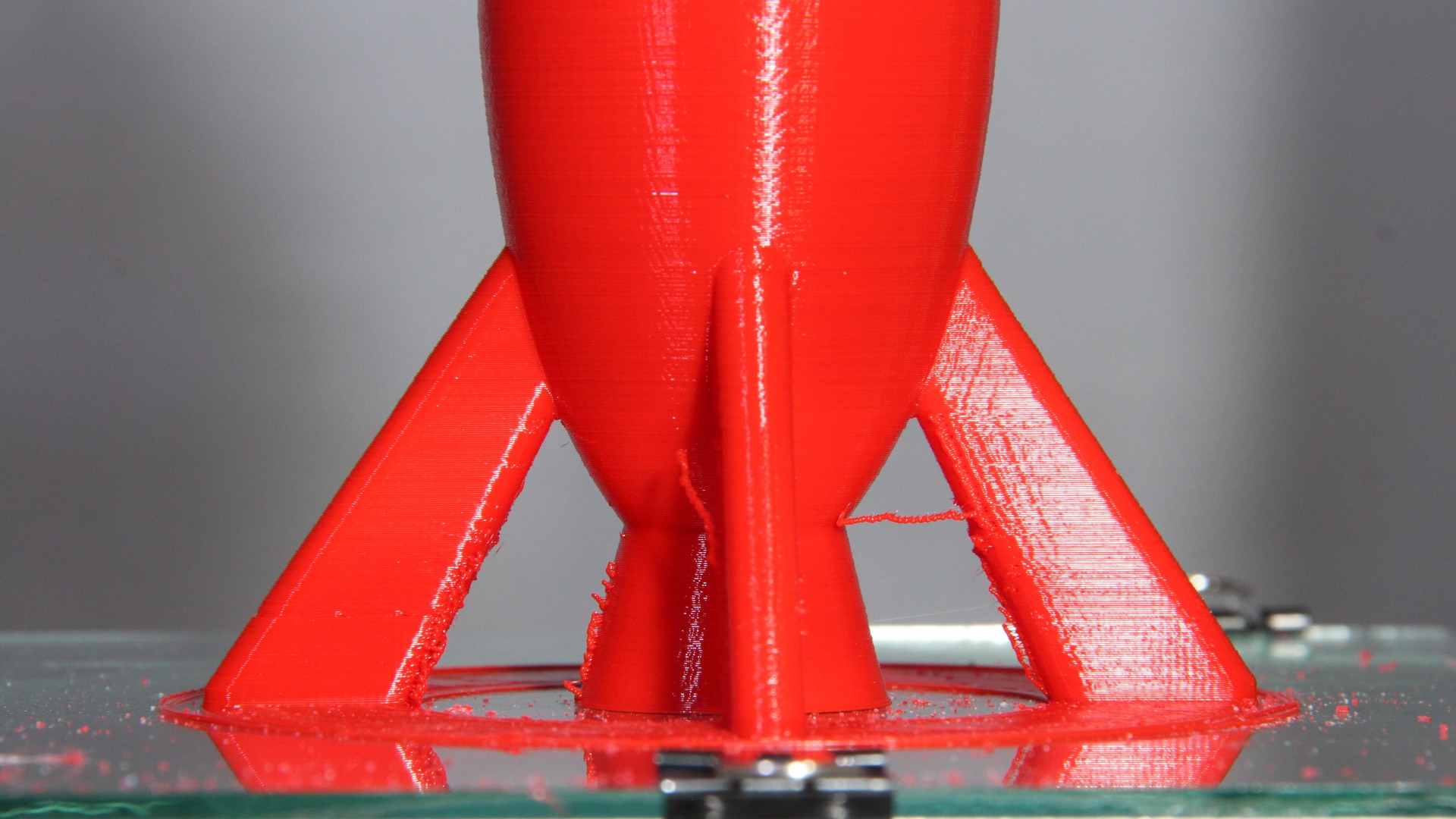

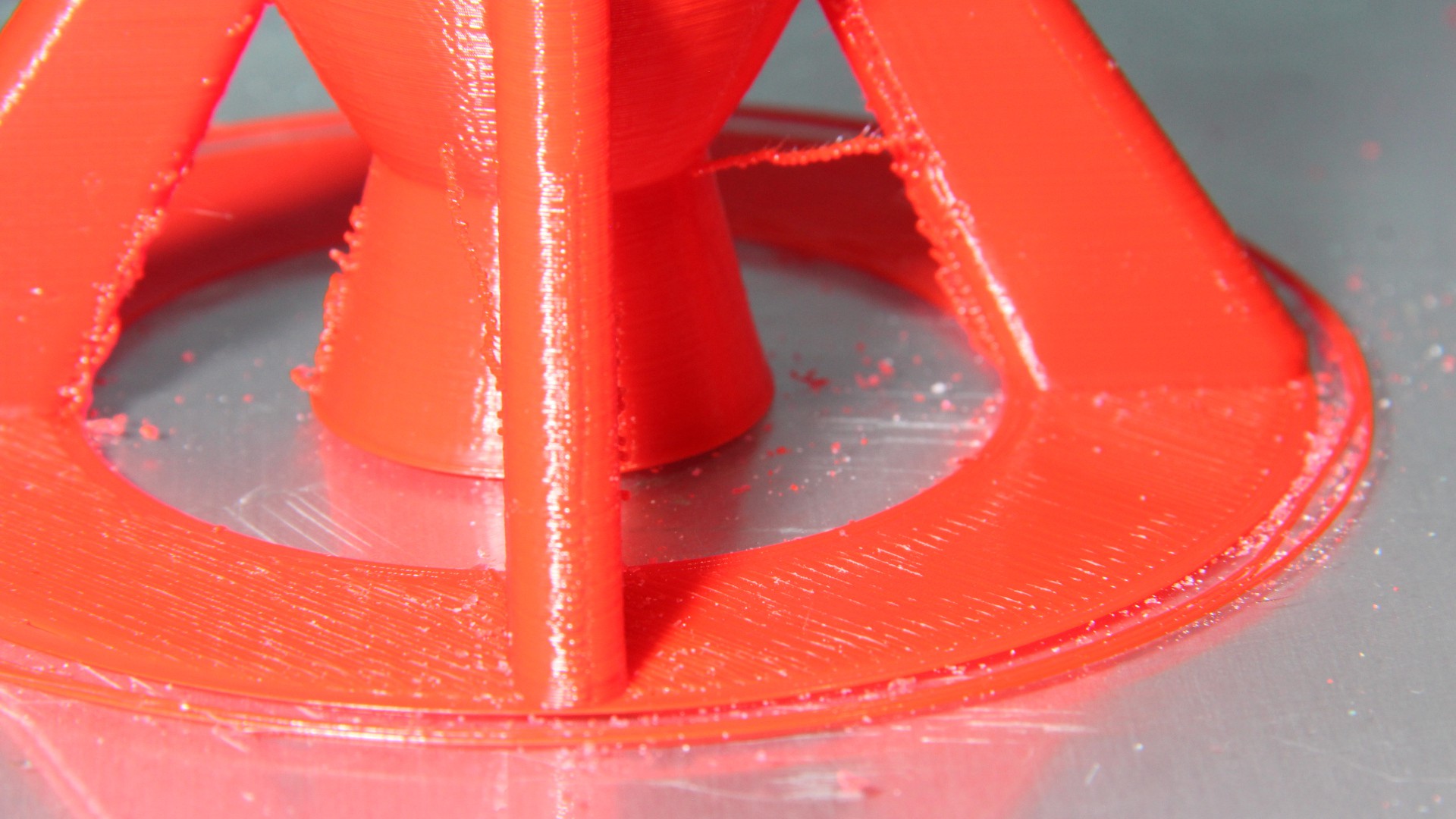

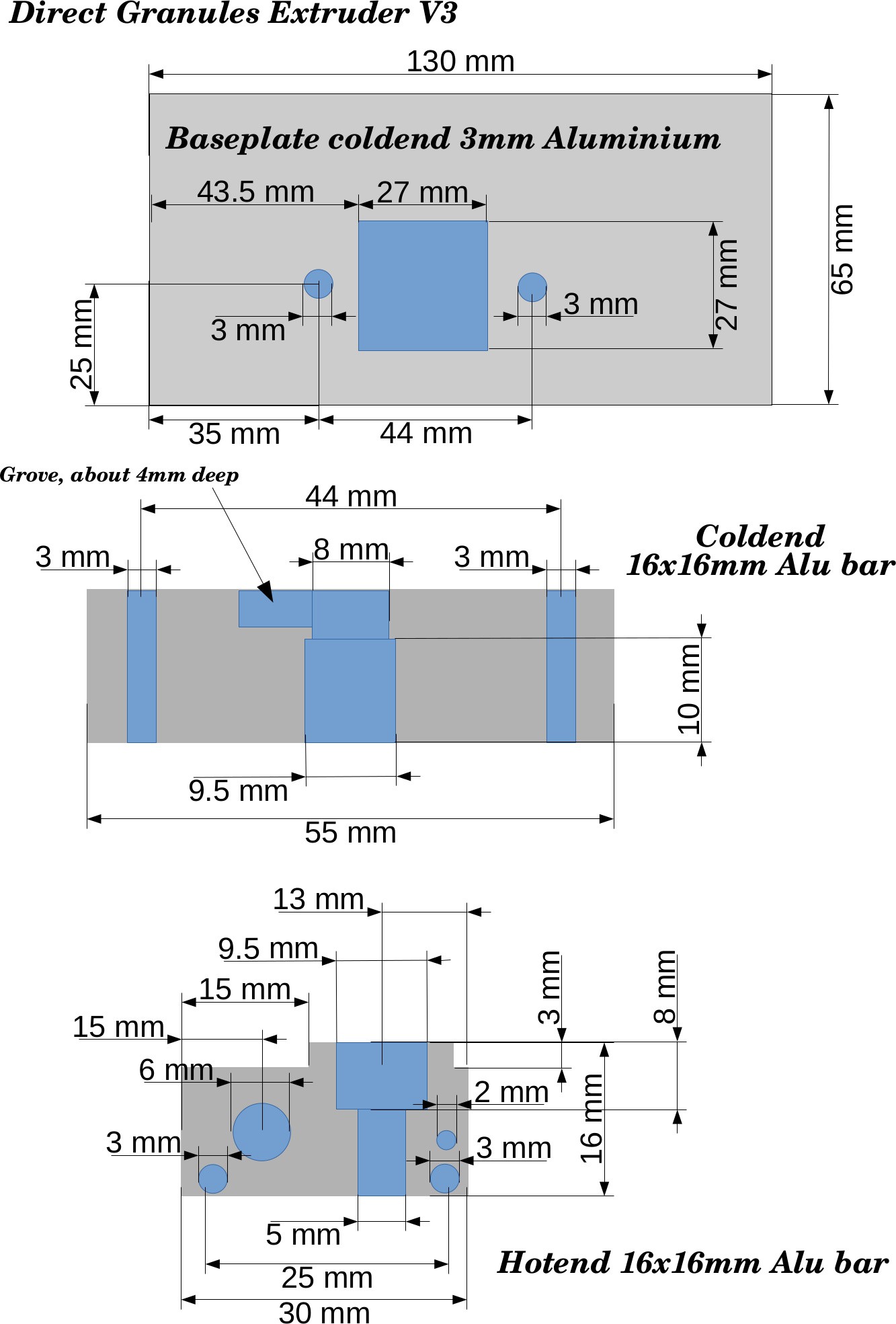

- Build a reliably working extruder prototype (V3).

- Create build instructions (including video), even so it is a prototype made following my intuition.

- Explain in detail how the extruder works and so why normal wood screws are better than anything else: In contrast to conventional extruders, the forwarding happens in the cold zone only.

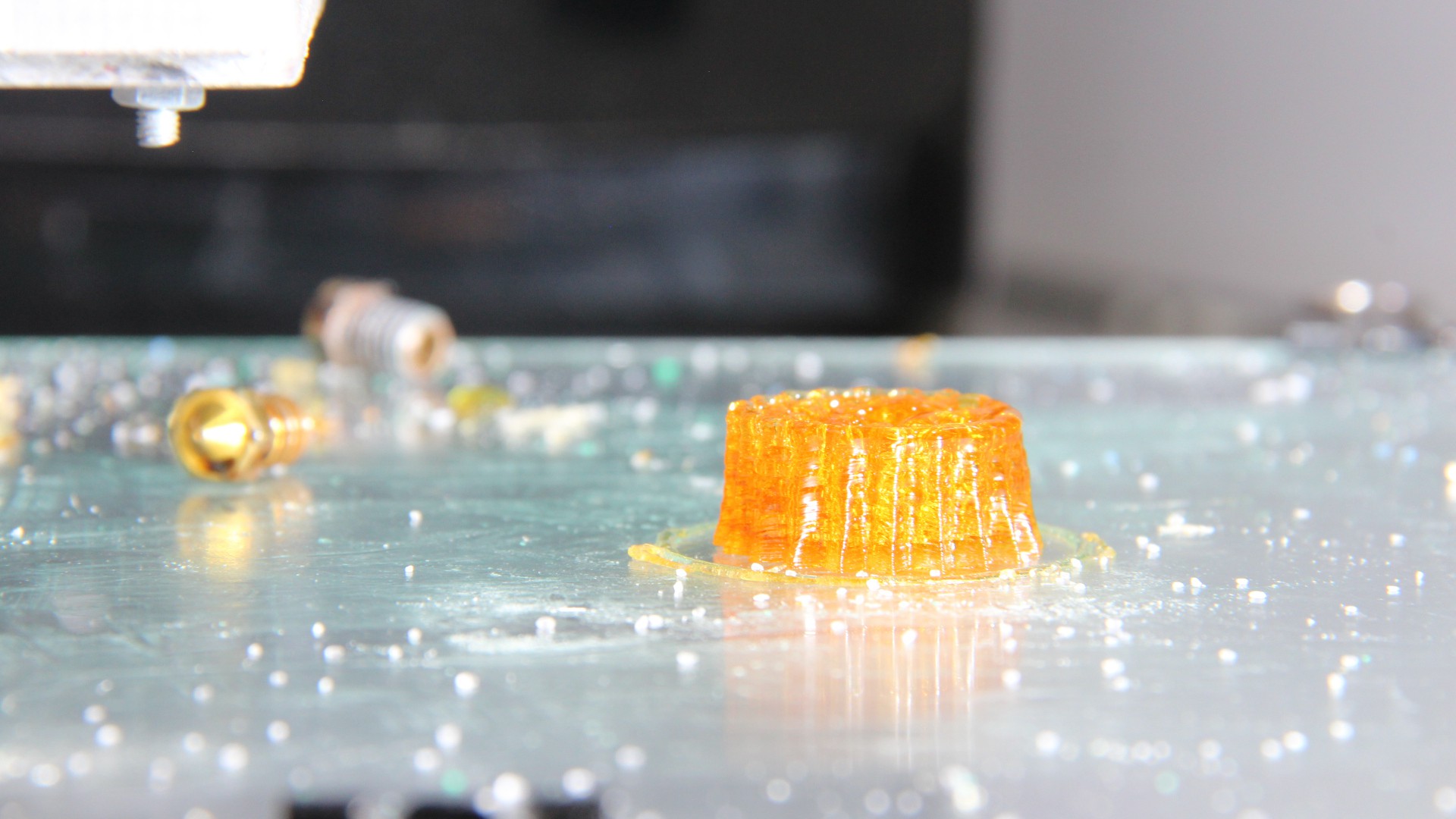

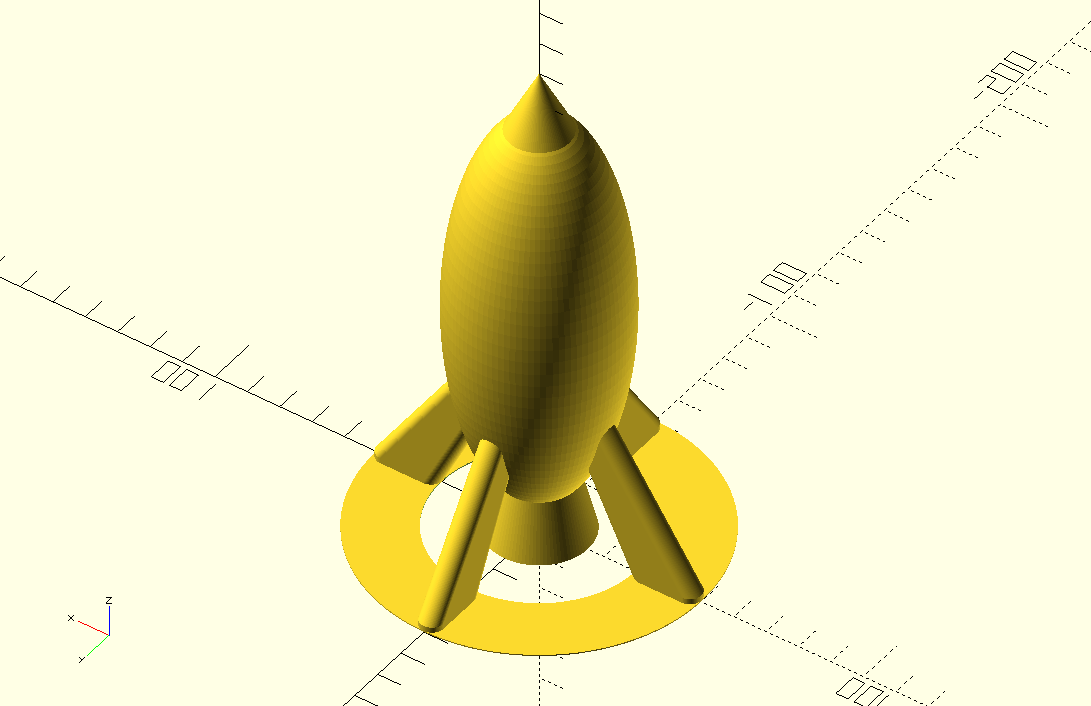

- More details about how to print with household sugar and so using materials with essentially different properties than common FDM materials.

Done, but not explained in detail, yet:

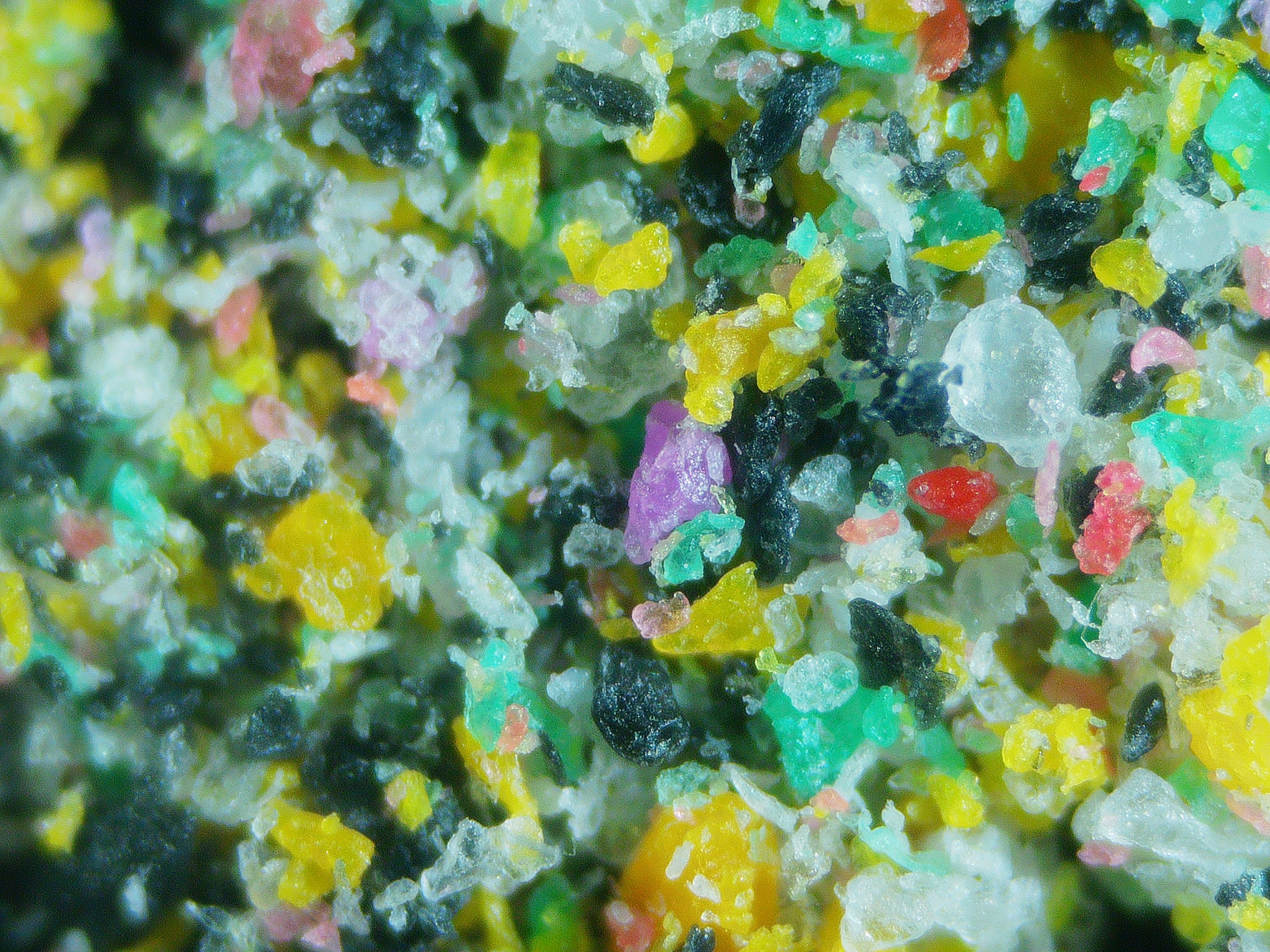

- What to consider when preparing raw material

- How to feed the extruder with conventional, industrial pellets

- Find ways to convert waste prints into new raw material for the extruder

To do:

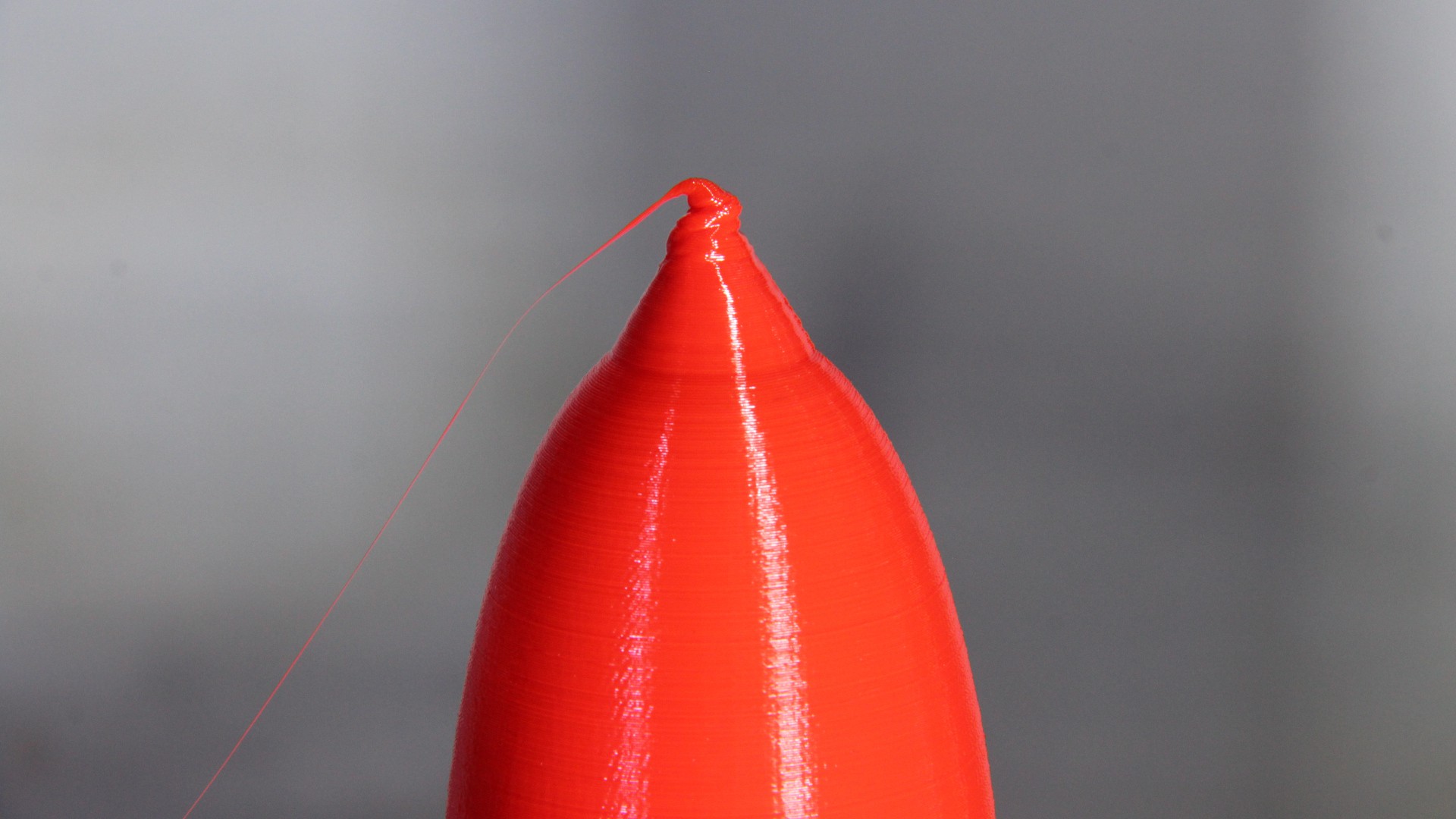

- More print tests with a larger variety of raw materials

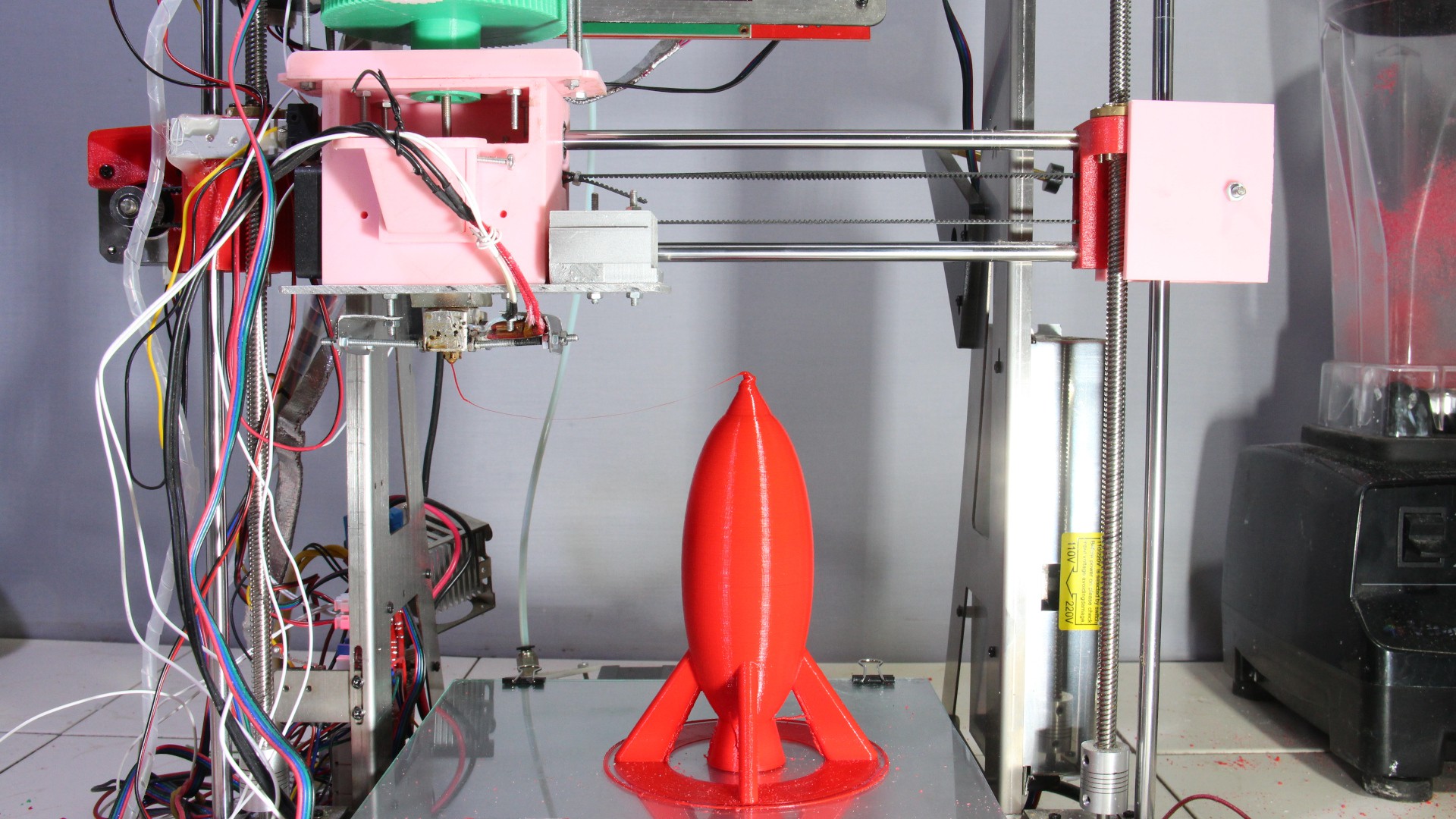

- Build version 4 with series production in mind instead of the handmade version 3

Norbert Heinz

Norbert Heinz

Can't wait to see it working!

Can't wait to see it working! To make my extruder replace filament printing, there is still a lot more to tell about what I have figured out. Previous attempts, using "classic" extruders have failed. I must explain in more detail, what my extruder is different in and why I used the design I am using. The knowledge about the working principles must become more mainstream. Open source doesn't end in publishing CAD files or drawings...

To make my extruder replace filament printing, there is still a lot more to tell about what I have figured out. Previous attempts, using "classic" extruders have failed. I must explain in more detail, what my extruder is different in and why I used the design I am using. The knowledge about the working principles must become more mainstream. Open source doesn't end in publishing CAD files or drawings...

Michal Wojciechowski

Michal Wojciechowski

Swaleh Owais

Swaleh Owais

Atte Linna

Atte Linna

Tomas Starek

Tomas Starek

1 can we vote for you?

2 one problem with design is ptfe tube for use with recycled ABS, or Nylon or anything above 260 degrees celcius , other than that this brilliant

3 could you please explain warping python script ?