Hackaday Prize 2021 comes to an end today. My project was voted into the final round and as part of the competition, an up to 5 minutes video for the jury has to be recorded. Here is mine:

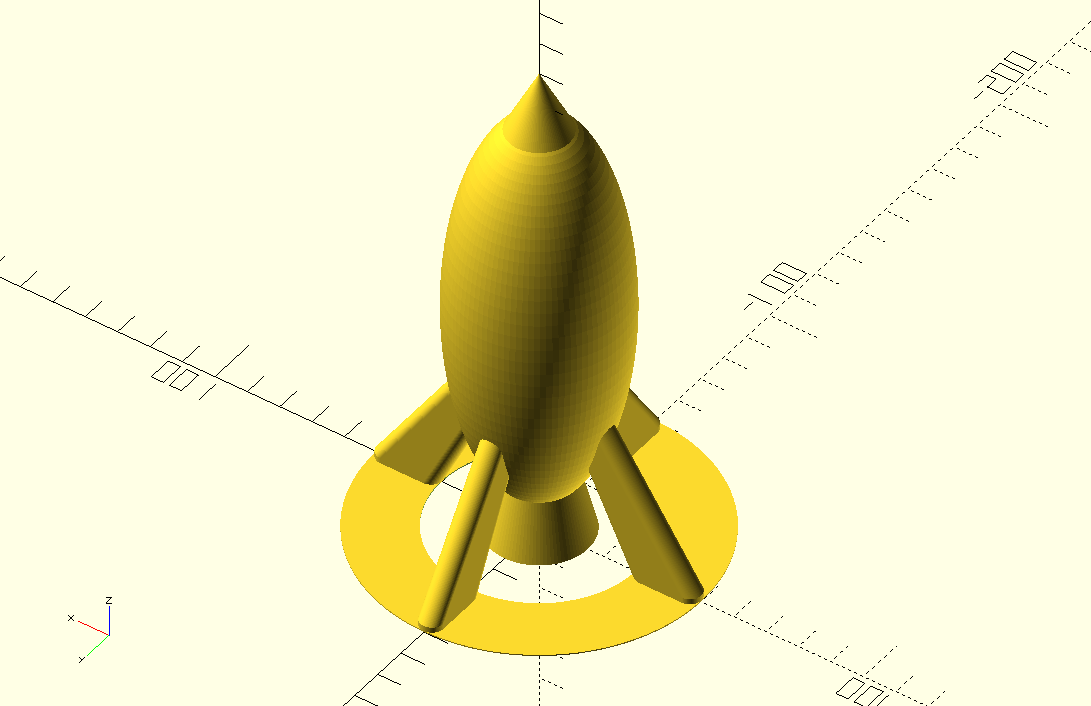

For this video I have created a "Rocket" in openSCAD ((see files section):

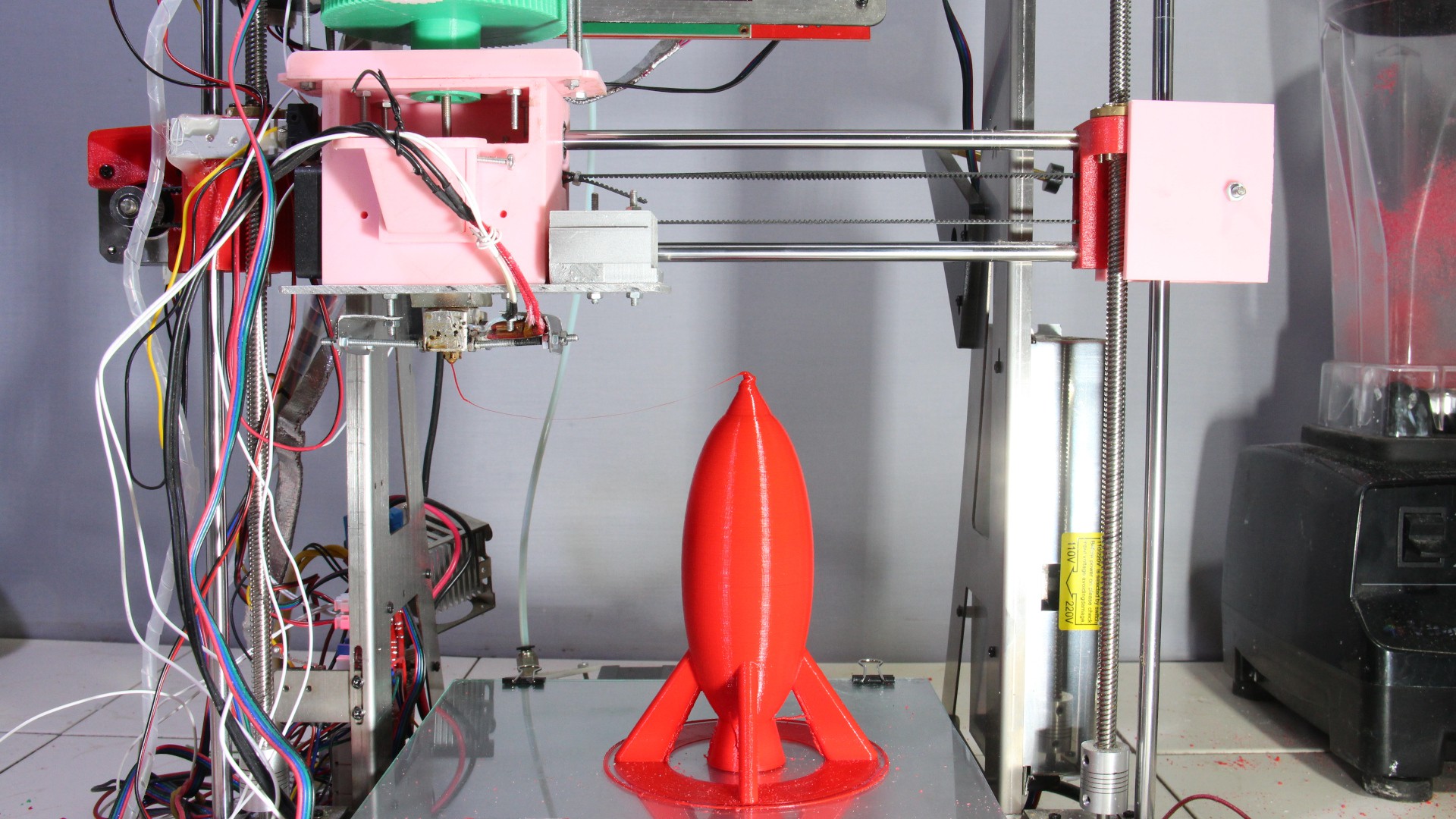

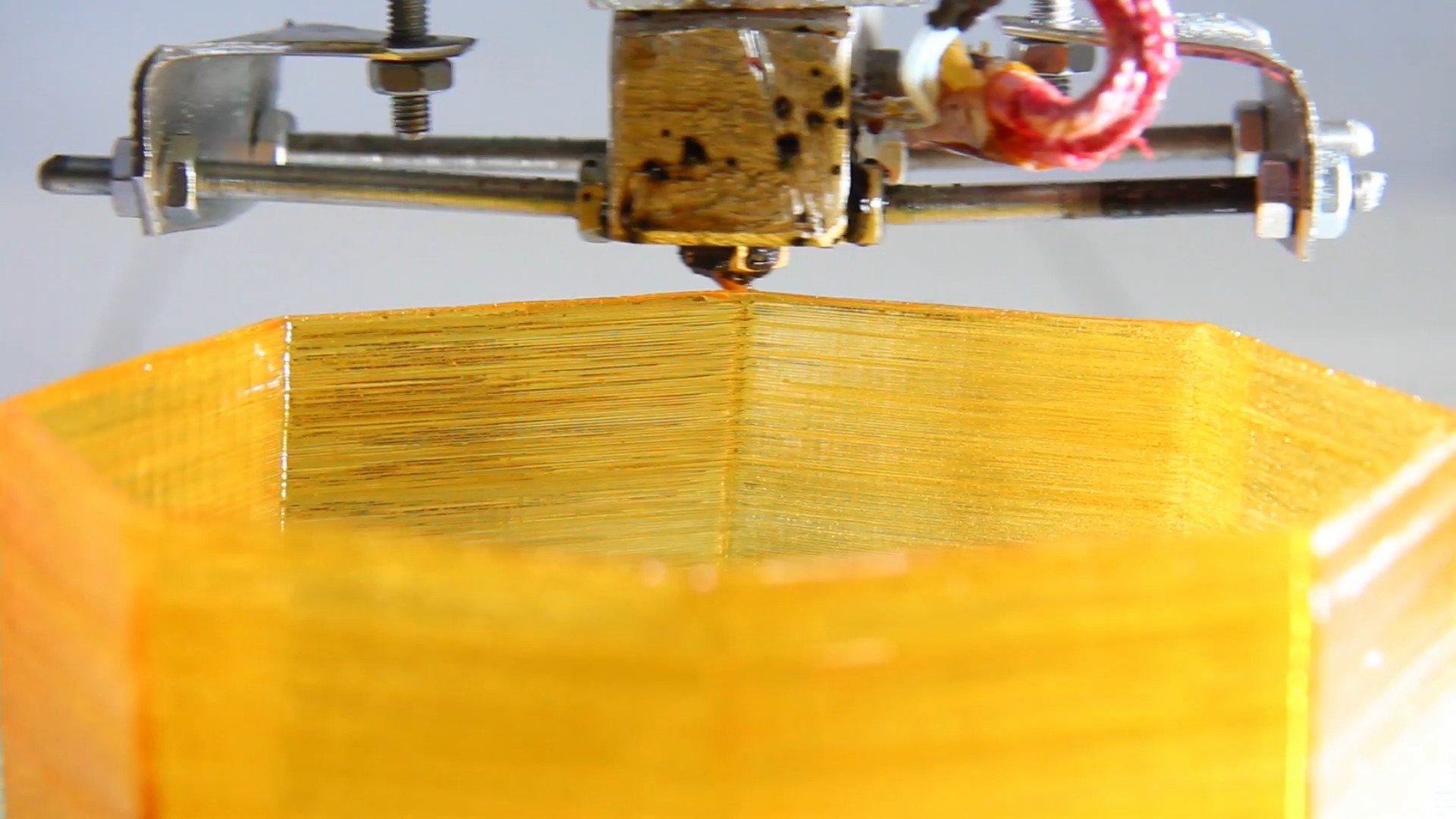

The printer settings were:

Hotend temperature: 181°C

Bed temperature: 65°C

Layer height: 0.2mm

Layer width: 0.5mm

Infill: 0%

Rocket dimensions: 100x100x150mm

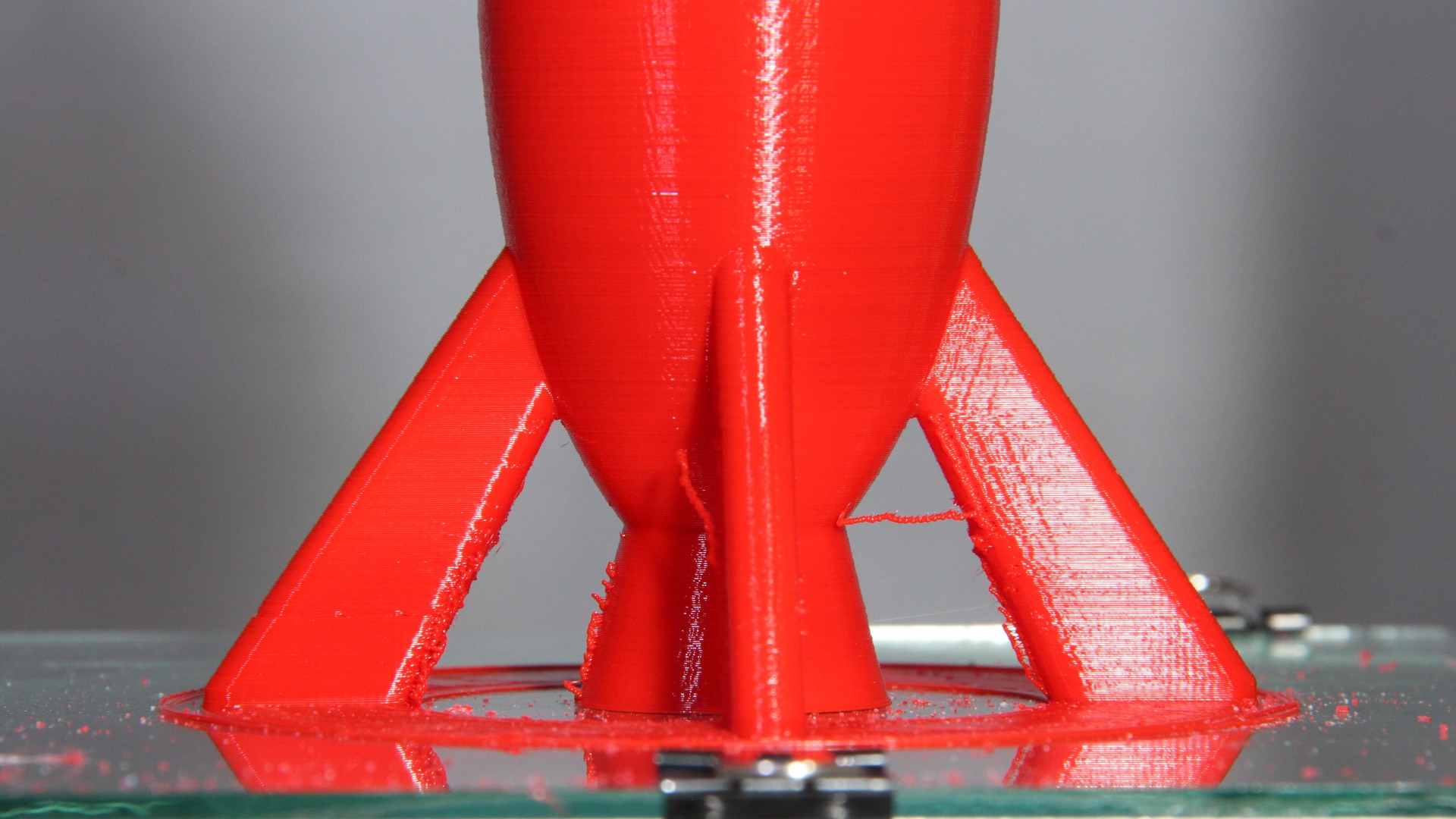

Lets have a closer look at the result, my extruder delivered:

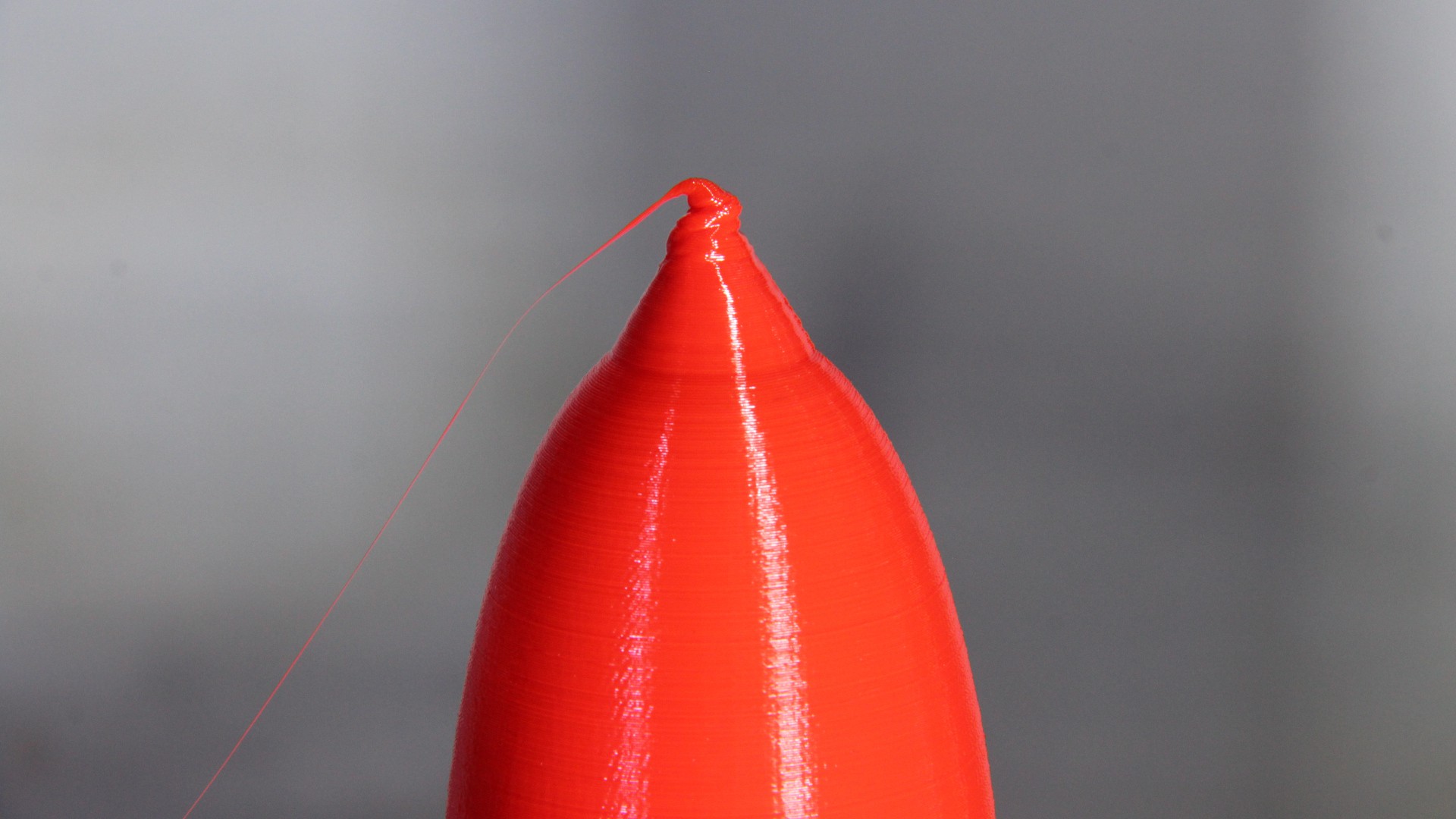

First thing you will notice is the tip of the rocket:

This is definitely where a part cooling fan would be helpful. Even though there is one implemented in my Extruder design, I did not screw it in place. The reason is, that is blocks the view on the nozzle and this is why I rarely used it during my test runs. These tests were always about the extruding capabilities, rather than about the overall print quality of the whole printer. So forgive me not to have added the fan before starting the print...

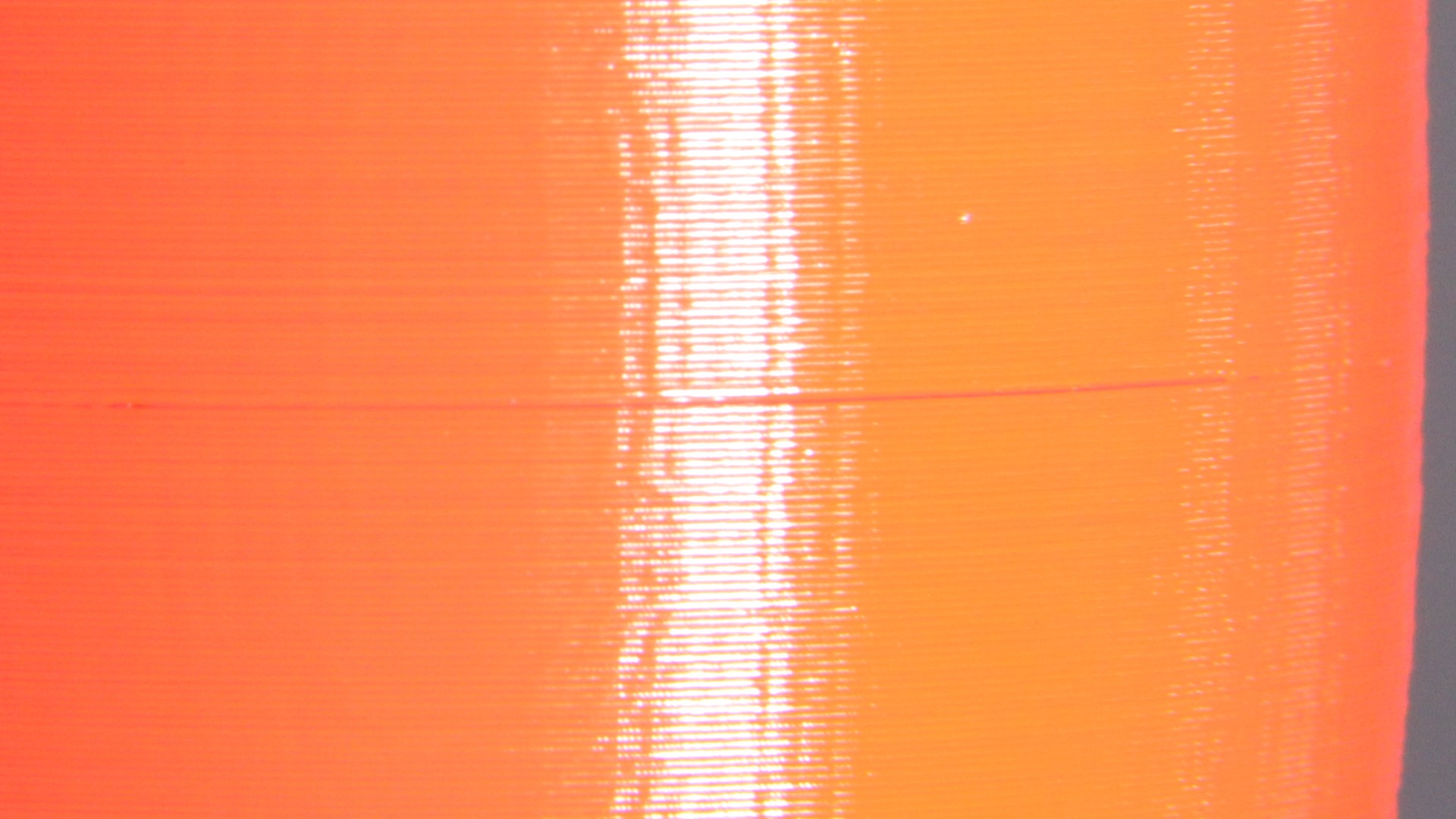

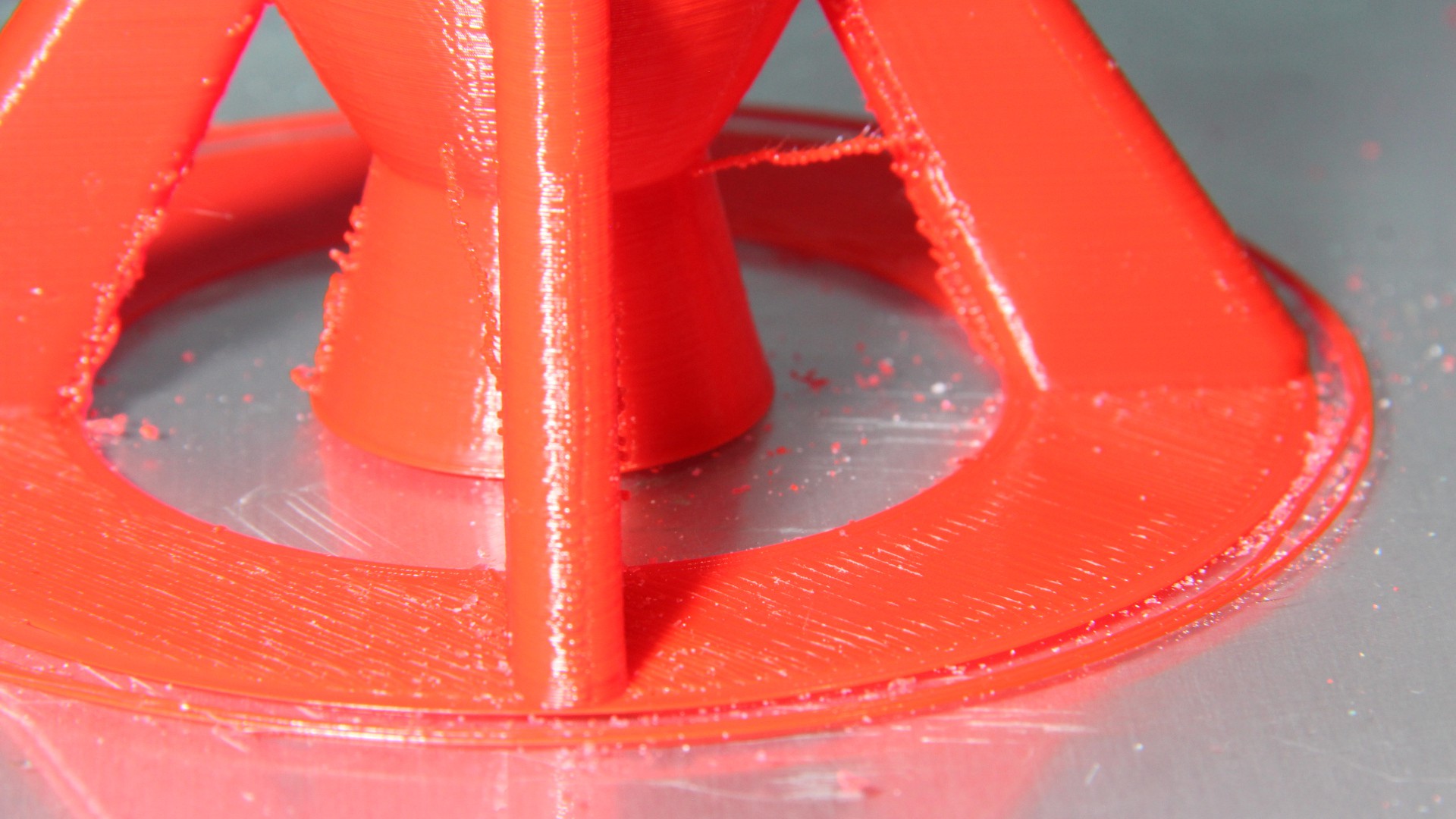

While talking about the extruding capabilities, a smooth surface is a result of constant extrusion and that is what a good extruder MUST deliver.

The detailed look at the surface demonstrates, that the surface is a it should be. What seems to be a crack in the surface at a first look is in fact nothing else than a single grain of non red color that entered the extruder (I didn't clean the blender nor the hopper that carefully).

Stringing is not addressed, yet:

In the video about the construction details (see previous blog entry), I have demonstrated how it works. The issue is that the screw squeezes out an extra portion of plastics when going intro reverse. That must be addressed in an additional parameter in the slicing software, but doesn't exist, yet. More on that in a coming video/blog entry.

Ghosting can be seen on the right fin of the rocket. This is due to the weak printer mechanics, not due to inconsistent extrusion.

The first layer looks good, which is also an indication of constant extrusion:

All in all, the quality, this handmade prototype delivers, is better than anything I have seen from a direct pellet/granules extruder. It only can get better with a better printer mechanics, a part cooling fan and a more precise machined extruder following this design (that is under construction).

More on the sugar print will follow, soon:

Norbert Heinz

Norbert Heinz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.