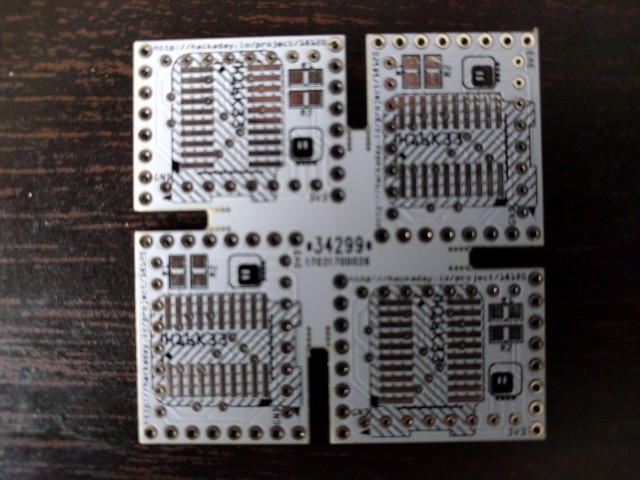

Remember when I wrote that I ran out of mistakes to make in this project? Was I ever wrong. The PCBs just came from DirtyPCBs:

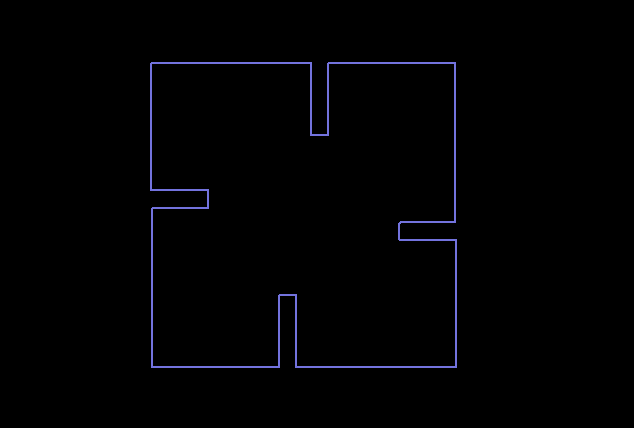

That's not the kind of panelization that I expected... Of course I immediately downloaded back the zip file with gerbers and checked it:

Yup, that's what I sent them to make (unless they do some processing to it). Of course I didn't notice a problem, because the preview at DirtyPCBs is broken since they switched to the new website, and doesn't show the board outline.

Now I have a few days of dremeling before me.

deʃhipu

deʃhipu

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

How many of those panels have you got? = About 10 :-)

Maybe a Hacksaw would also work okay :)

BTW: Why did you panelize the PCBs in 5x5cm?

I played around with the calculator and it seems it was the cheapest solution for ~40 PCBs ;-)

But for 20$ you would have got 100 PCBs, if a single PCB is smaller than 20x30mm :-)

Are you sure? yes | no

Dremel worked well, they are all assembled already. Yes, I was aiming at ~30 boards, because that's how many matrices I have -- they are actually the most expensive part of this. I don't want to be making and selling those in large quantities -- just enough to get other manufacturers interested in this, so that they will start producing it cheaper and with free shipping.

The boards are exactly 25.5x20.4mm.

Are you sure? yes | no

Great. Thats nice. Thank you for your reply! Have a nice Weekend!

Are you sure? yes | no

That's why I usually use 0.8mm PCB... They are easy to just score once on each side with a box cutter knife and then just snap apart.

Sure, the pcbs become a little bit more flexible but it's hardly noticeable on a 5x5cm or smaller.

Are you sure? yes | no

Yeah, but of course I picked 1.6mm here...

Are you sure? yes | no

See step 1: https://hackaday.io/project/6929-smt-assembly-on-the-cheap

Also: http://www.eevblog.com/forum/eda/clean-way-to-cut-fr4-pcb/

A good snip (bottom right) can do the rough cut for FR4. 2 good pairs of piers would let you snap a much thinner strip of FR4. i do that all the time for trimming size of toner transfer PCB.

Are you sure? yes | no

Ah, that should be much faster than dremel!

Are you sure? yes | no

I take that back. It *would* have been faster, if they were straight lines from end to end. However, it's this swastika shape, and the dremel is actually faster for that.

Are you sure? yes | no

you *could* drill a hole where the groves end to stop the cutting

Are you sure? yes | no

nice throwing stars :(

Are you sure? yes | no

Impressive...

I feel for you :-(

Are you sure? yes | no