Making the case pretty would be much easier if you have a laser cutter or a CNC mill. I have neither! I've tried to minimise the number of straight cuts and square holes required, by using round buttons wherever possible.

I suppose you could also 3D print a case, to avoid any cutting at all. If there is demand, maybe I will design one! For now though, the Serpac “HP65” series of

enclosures seem quite easy to find, cheap to buy, and reasonably straightforward to modify.

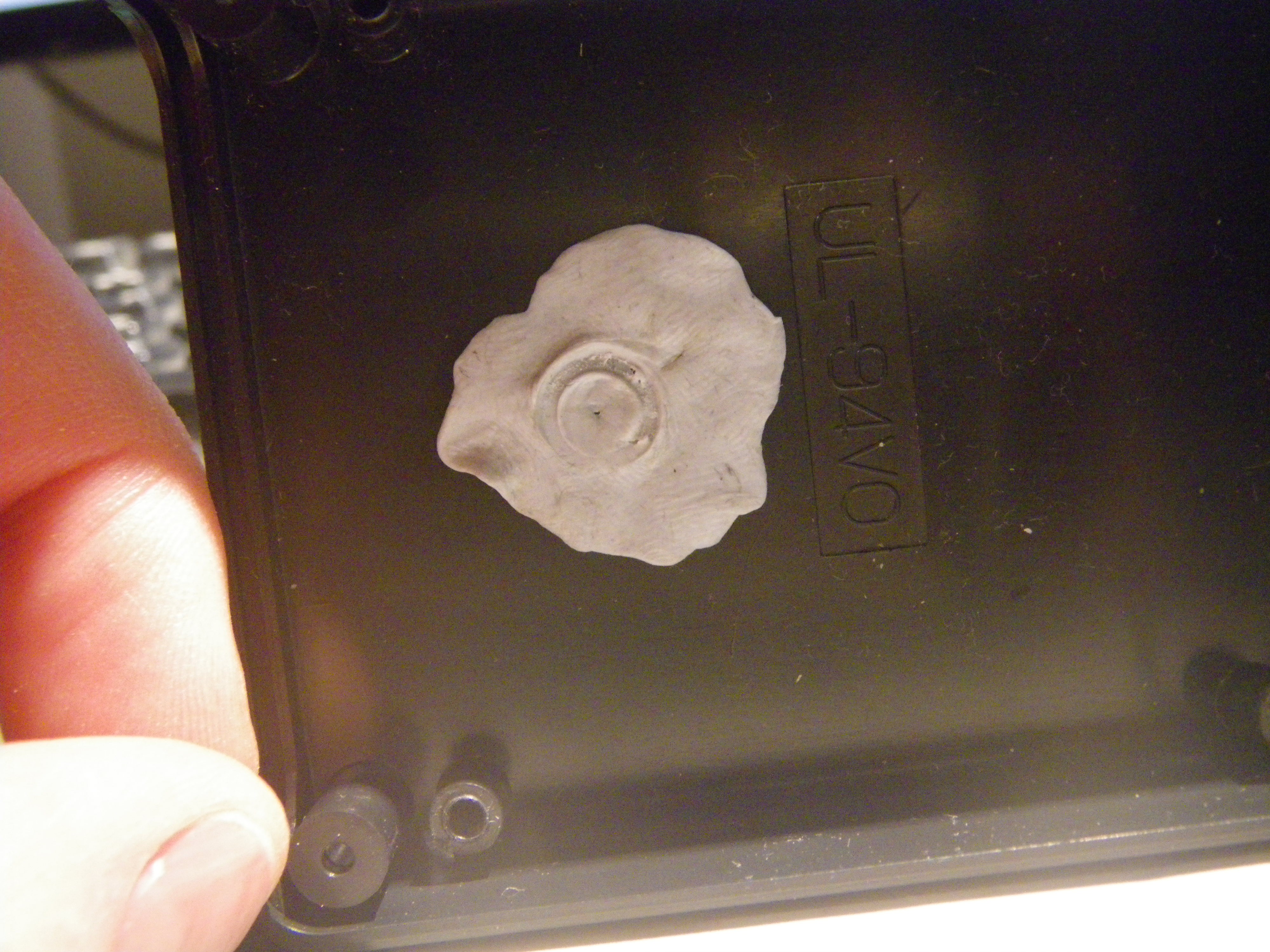

One thing that gave me trouble was getting a well-placed hole for the lens to poke out the "back" of the camera. I achieved this after attaching the Sparkfun MLX90640 breakout to the main PCB carrier board. Then I put a ilttle bit of Blu-Tac on the case where I thought the lens would go. I smeared the Blu-Tac out so it was flat and covered a few square centimetres. Then I carefully laid the carrier board over the case, so the lens left an impression in the soft Blu Tac. this gave me a location for a pilot hole. When the pilot hole was drilled, I could remove the Blu-Tac and enlarge the hole to suit my lens. If your hole looks a bit messy, I've made 3D printable bezel to hide the cutout.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.