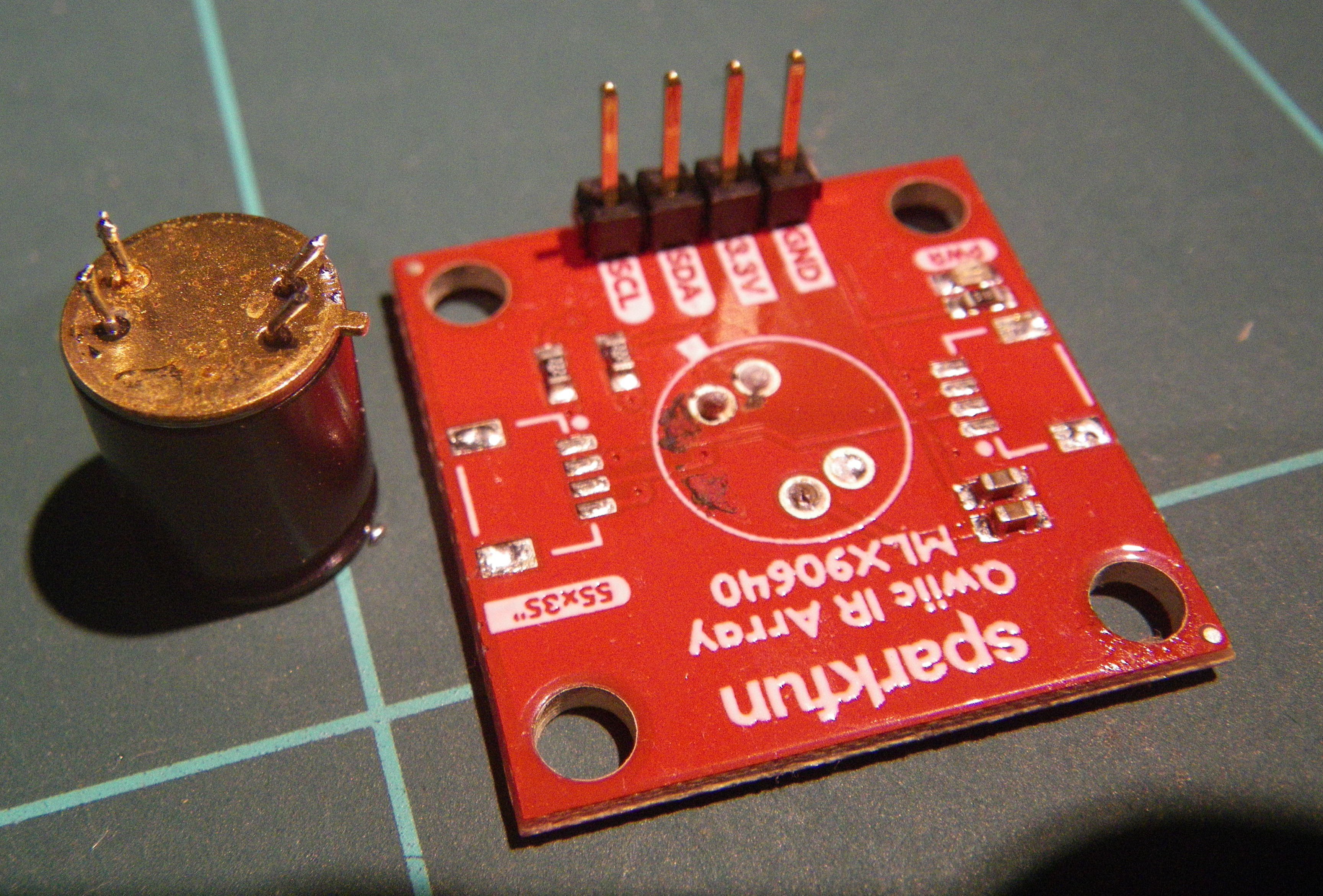

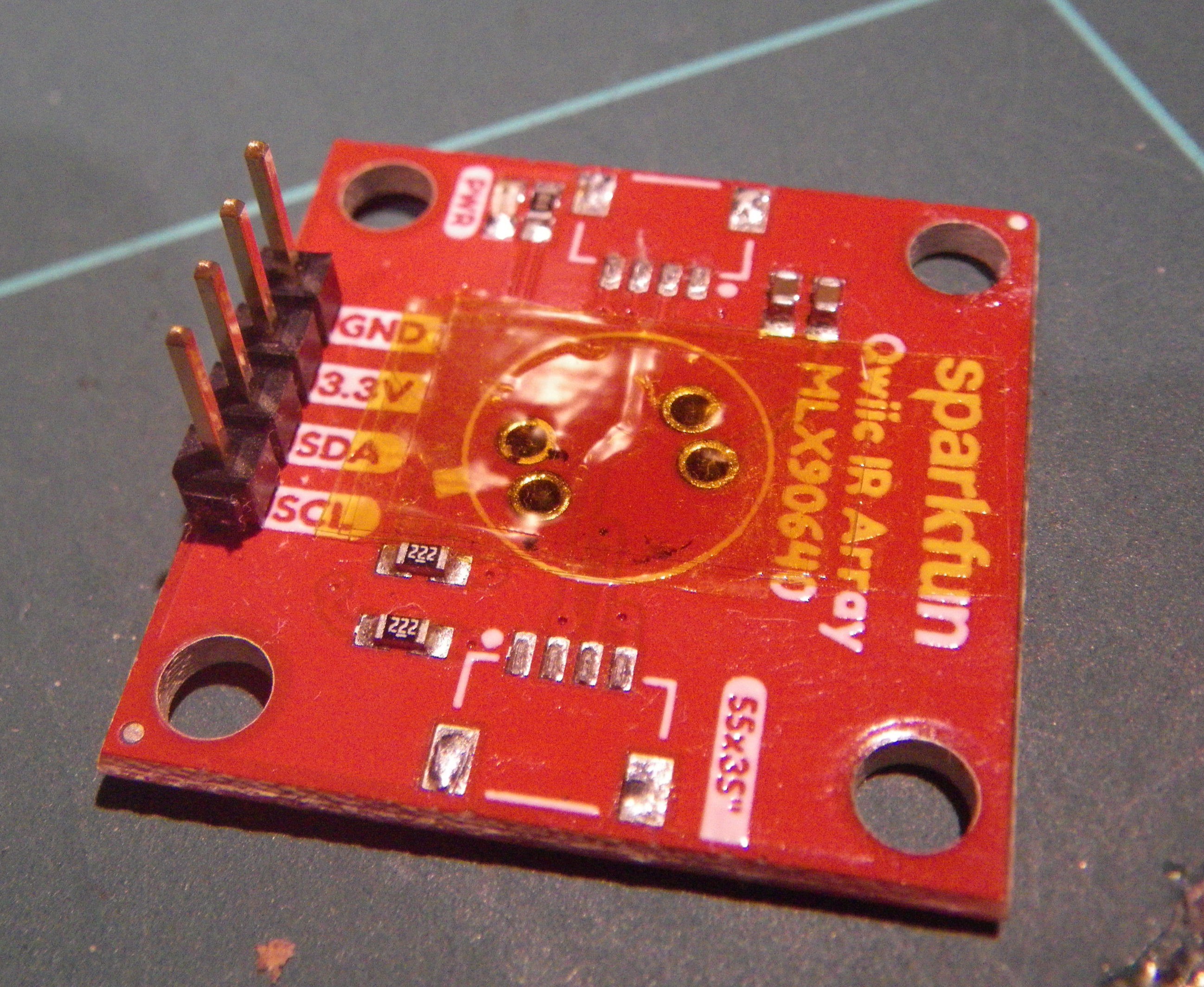

TL;DR: The sensor was shorting against the groundplane of the red breakout PCB. By desoldering the sensor from the breakout board, adding some insulation to the PCB, then re-attaching the sensor, I was able to fix the intermittent fault where the thermal camera would hang during startup....

-----------------------------------------------------------------------------------------------------------------

To troubleshoot the sensor, I first downloaded a simple arduino sketch to scan the I2C bus. Search for "i2c scanner arduino" to get something similar. The scan detected my sensor every time, so I could be confident that the sensor wasn't 100% dead. However, the next step, to query the sensor for its serial number, usually failed. After reading through many threads online, I eventually emailed Sparkfun's tech support. Their reply was very quick, and helpfully pointed me to the thread at https://forum.sparkfun.com/viewtopic.php?f=147&t=55997&p=227179&hilit=90640#p227179

To be honest, nothing in the thread looked like the fault that I was seeing with my setup. I measured the resistances as suggested in the thread and everything checked out OK. But this is the trouble with an intermittent fault - sometimes it _looks_ OK! Being too impatient to wait for a replacement breakout board, it seemed worth a shot to to attempt the rework. I desoldered my breakout board from the thermal camera PCB. I then (carefully!) desoldered the sensor from the breakout PCB. After cleaning up the excess solder from the holes in the breakout PCB, I added a few layers of Kapton tape to insulate the breakout PCB from the sensor, then soldered the sensor back onto the PCB. I then resoldered the breakout PCB to the main PCB of the thermal camera. Success!

I was very surprised when this worked - intermittent faults are often difficult to isolate and repair, but this one was a win. I think for version 2 of my camera PCB, I will add a footprint for just the bare sensor and do away with the breakouts altogether. They are great for prototyping, but for such a simple circuit there's no advantage to using a breakout in the final product. This also aligns with my goal of trying to work around the global parts shortage - it seems foolish to design a PCB to be reliant on the third-party vendor of the breakout boards.

Having said that, I have been very impressed by the technical support from Sparkfun - thanks again!

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.