UPDATE 01/12/2018 6:31:PM

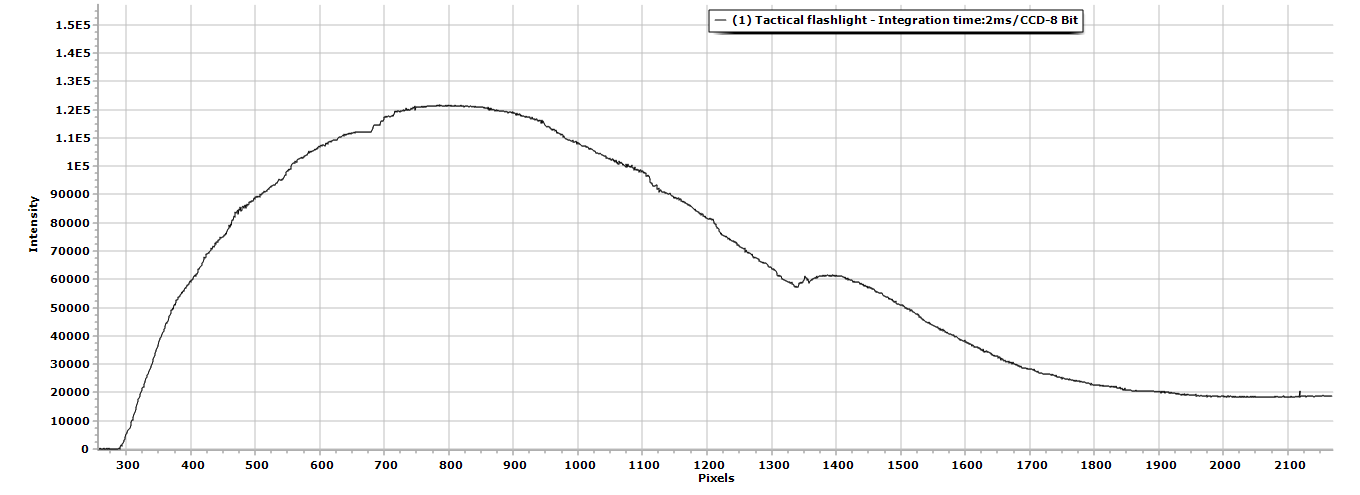

Tactical flashlight scan @ 2ms CCD 8-Bit (TCD1304DG) detector circuit test:

A better 1st mirror alignment and a 2nd 150mW laser line test:

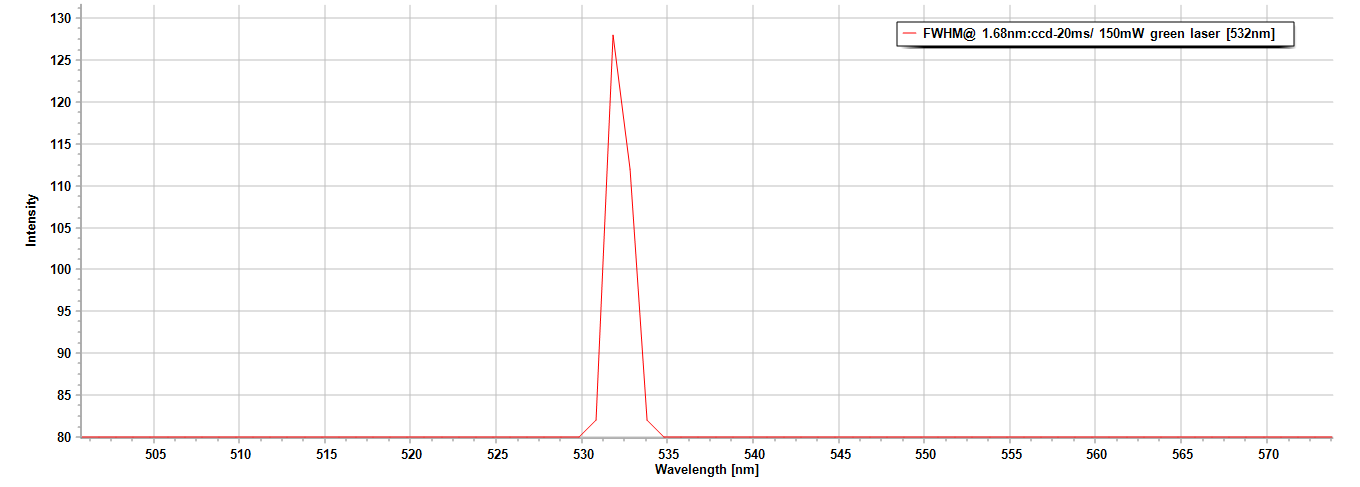

The plot above has a FWHM value of 1.005nm resolution.

Fixed the 1st mirror position, I have much better resolution now :)

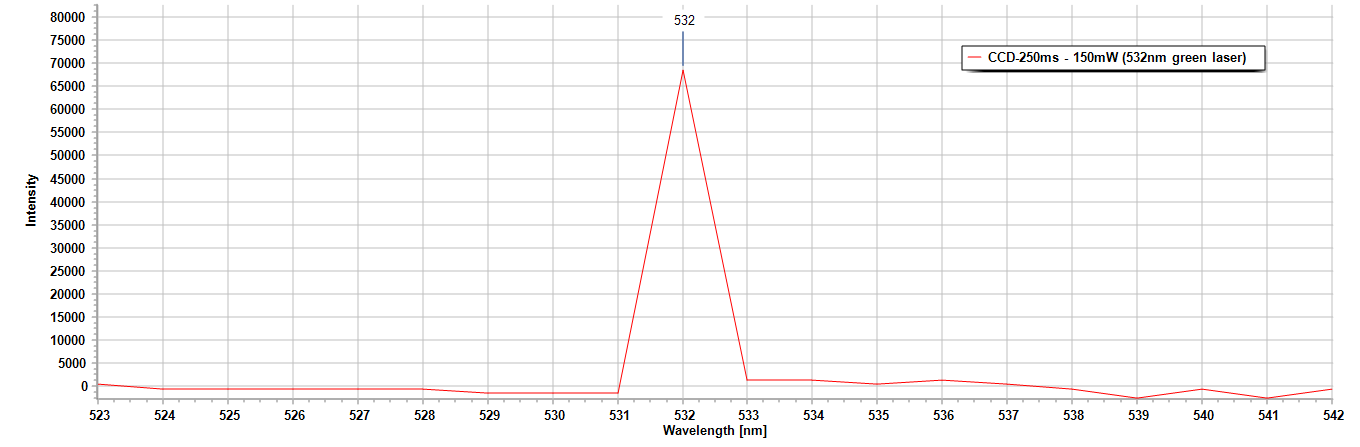

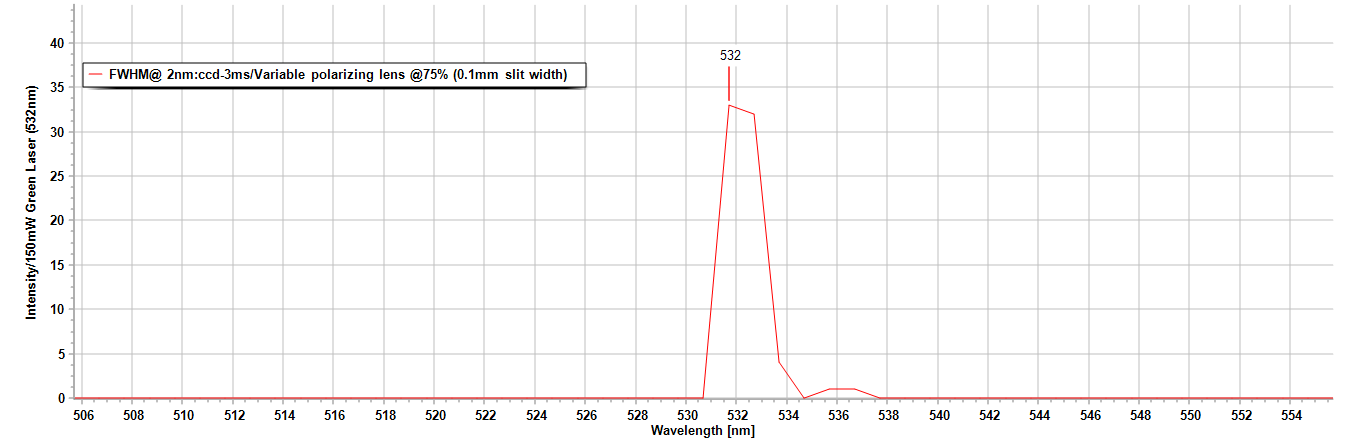

Another test scan today using my Aries 150mW green laser and a 0.1mm slit width @ 3ms integration time:

A little bit of clipping can be seen even though I had the variable polarizing lens at 75% still got a resolution factor of 2nm :)

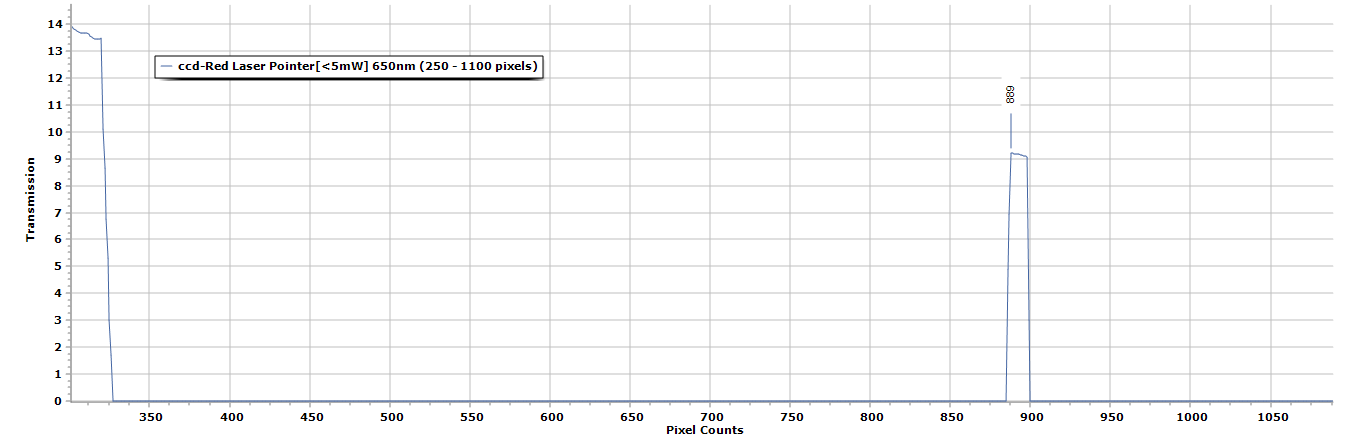

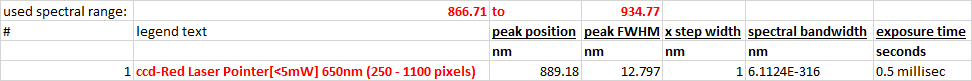

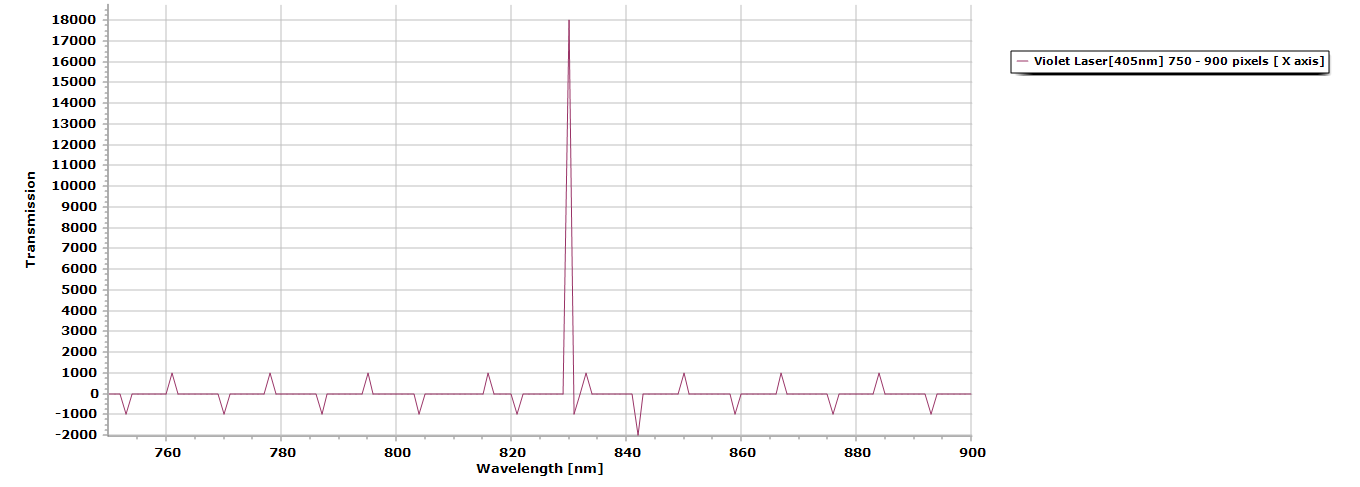

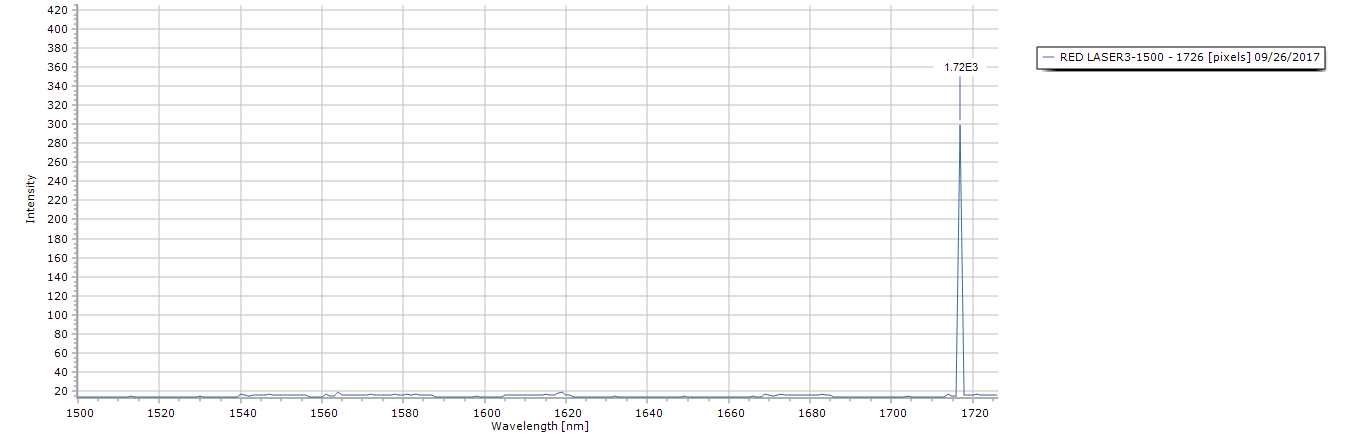

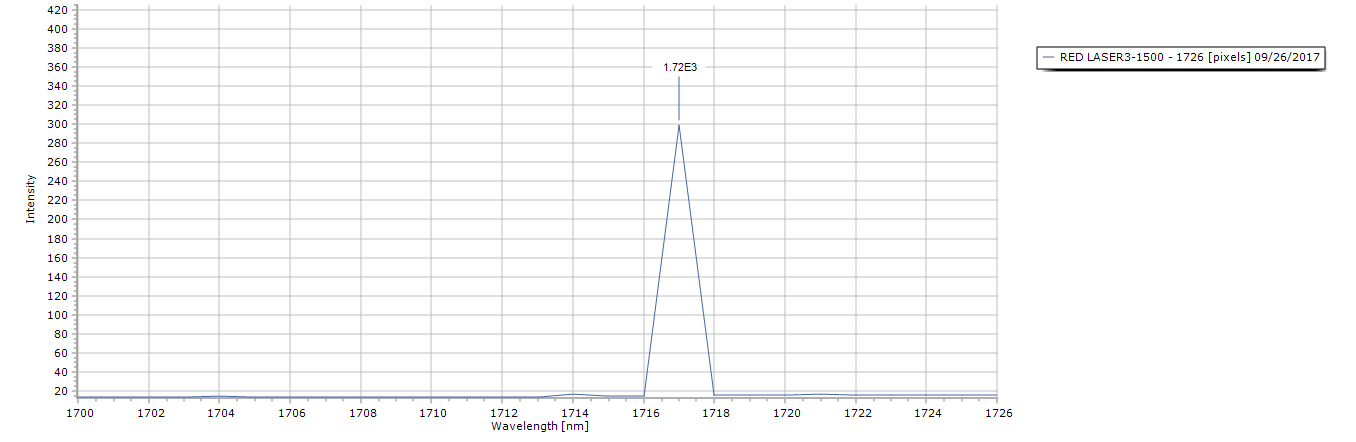

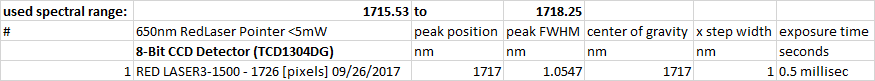

New test scans using the 8-Bit CCD detector (TCD1304DG)

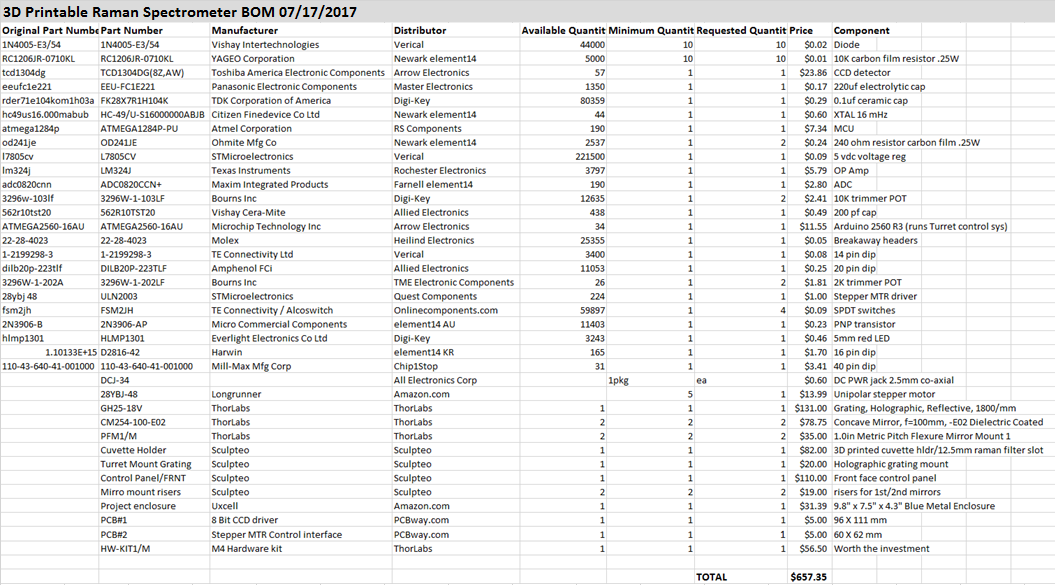

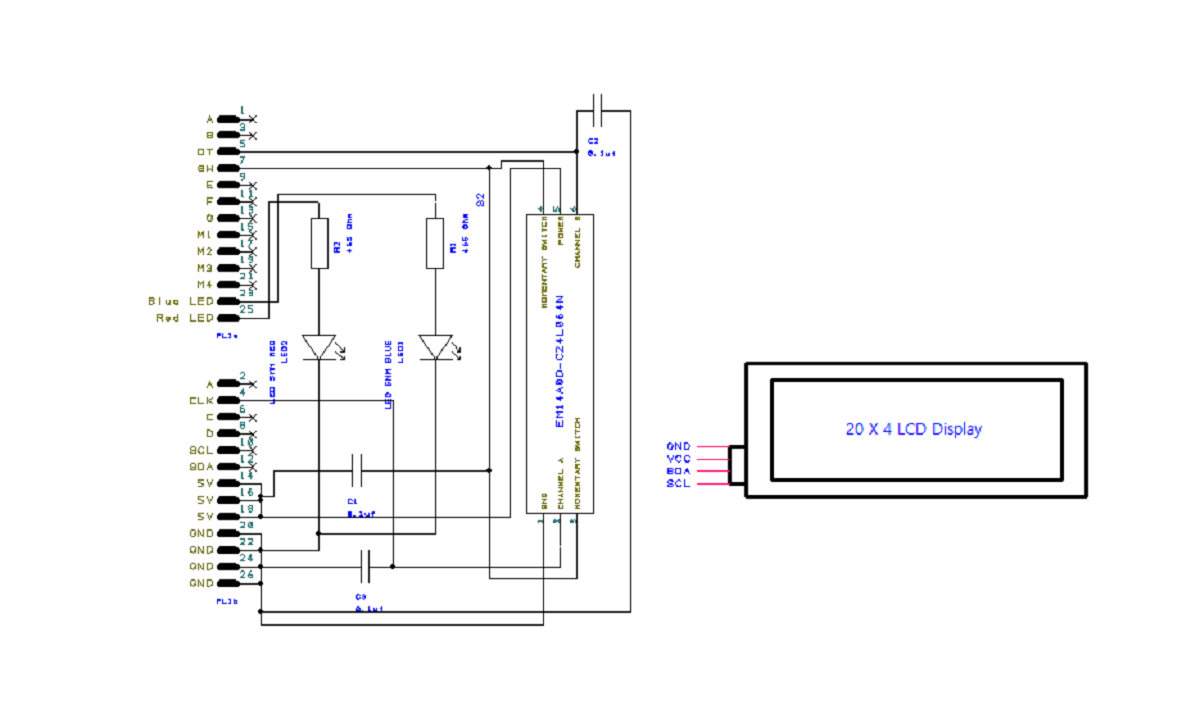

Final version of the Motor Control Targeting Interface unit for the diffraction grating turret control system:

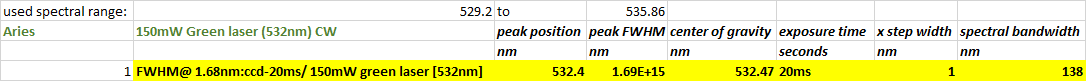

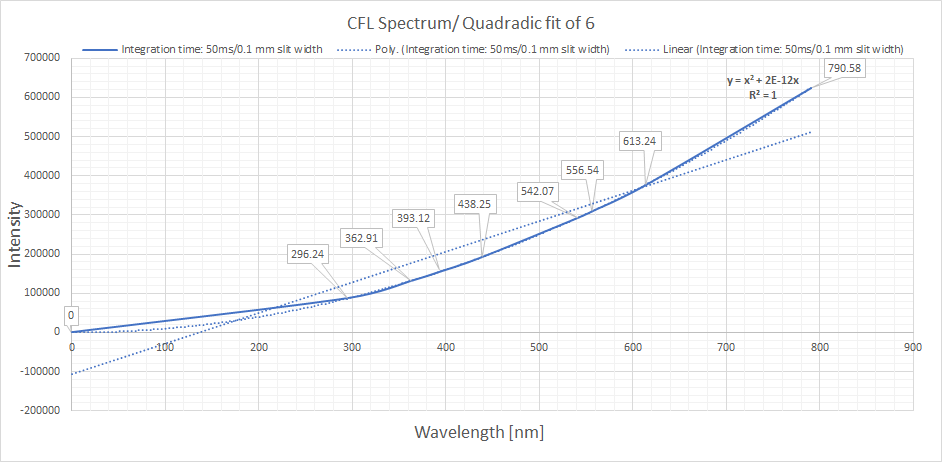

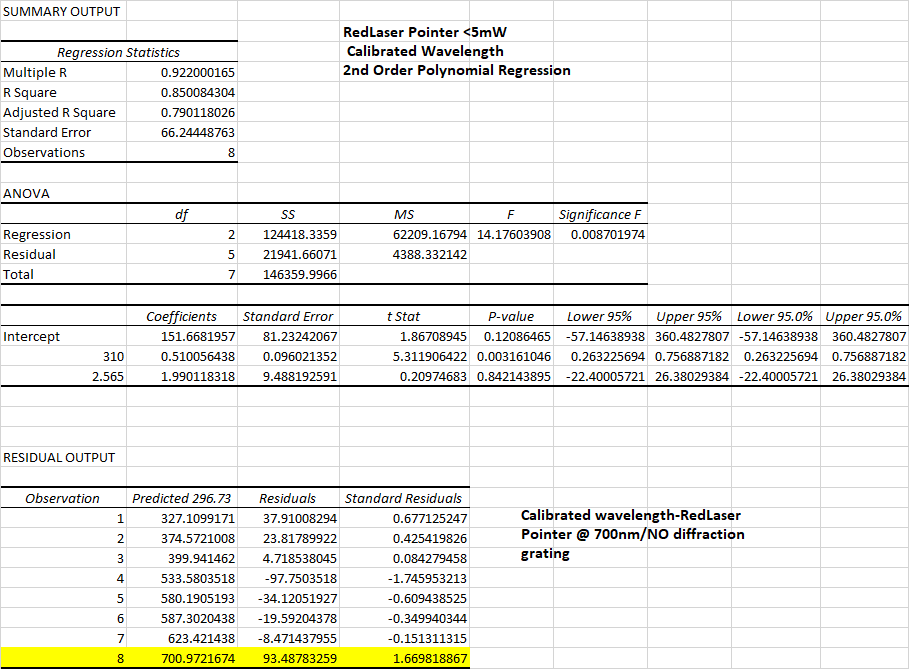

Excel chart data:

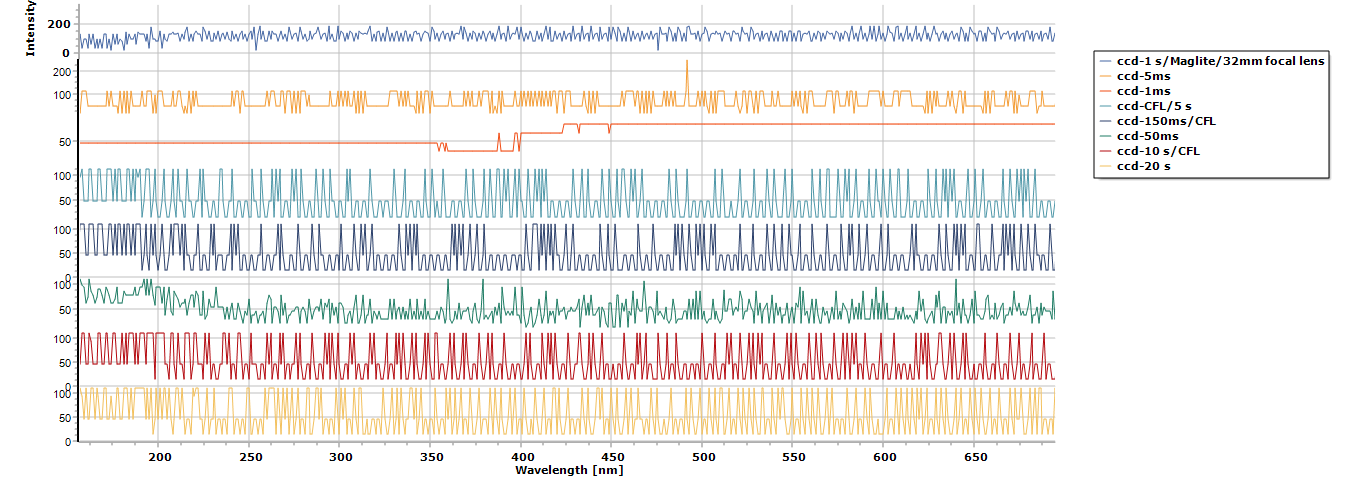

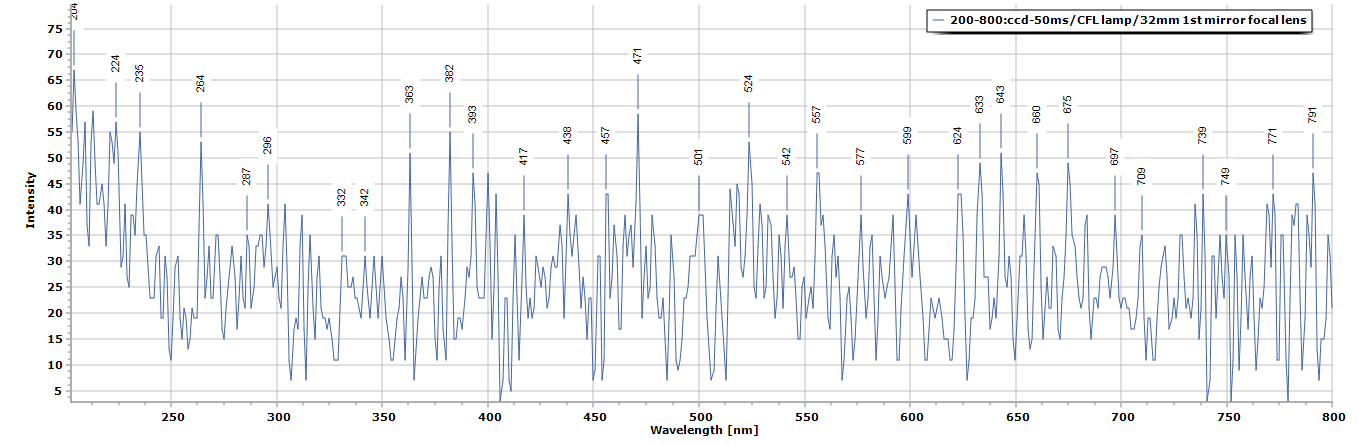

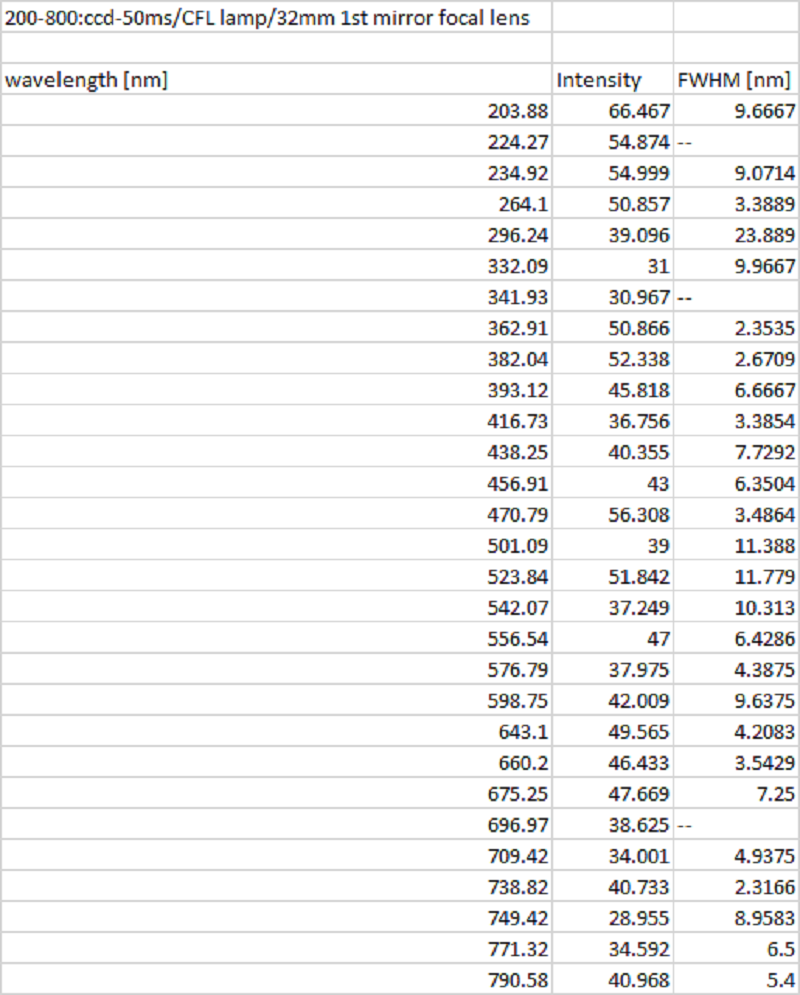

New CCD scans using a 32mm achromatic coated lens @ the 1st collimation mirror and a compact fluorescent lamp, below is the raw data of various scans:

Below is the processed data of my CFL lamp:

and finally, the FWHM data from the above spectrum:

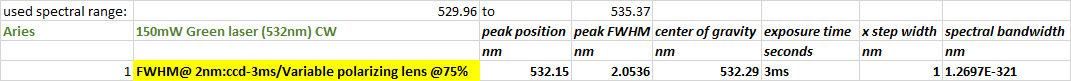

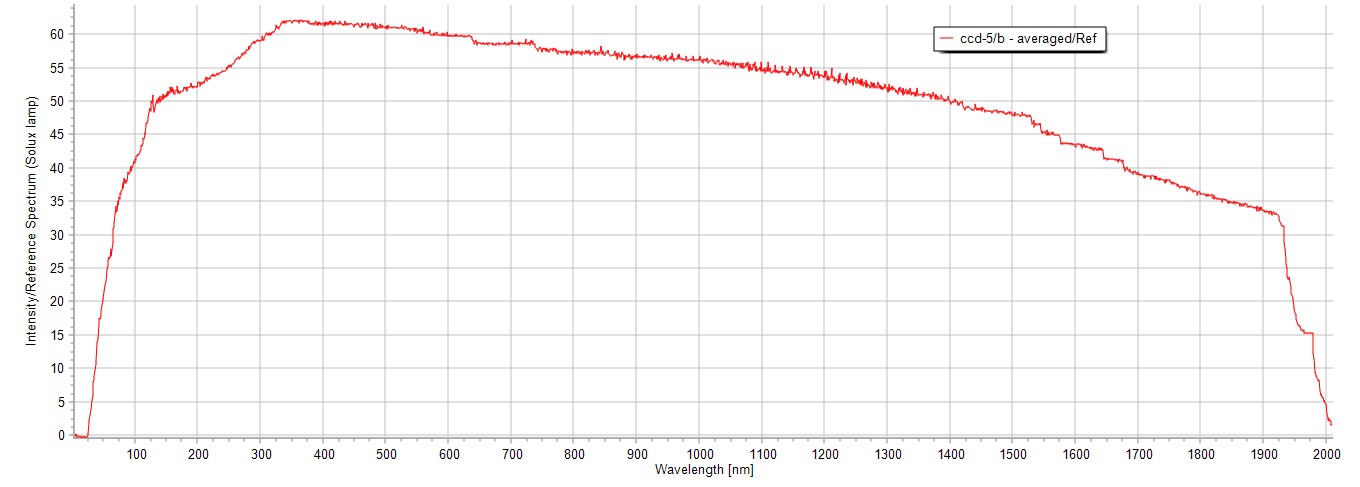

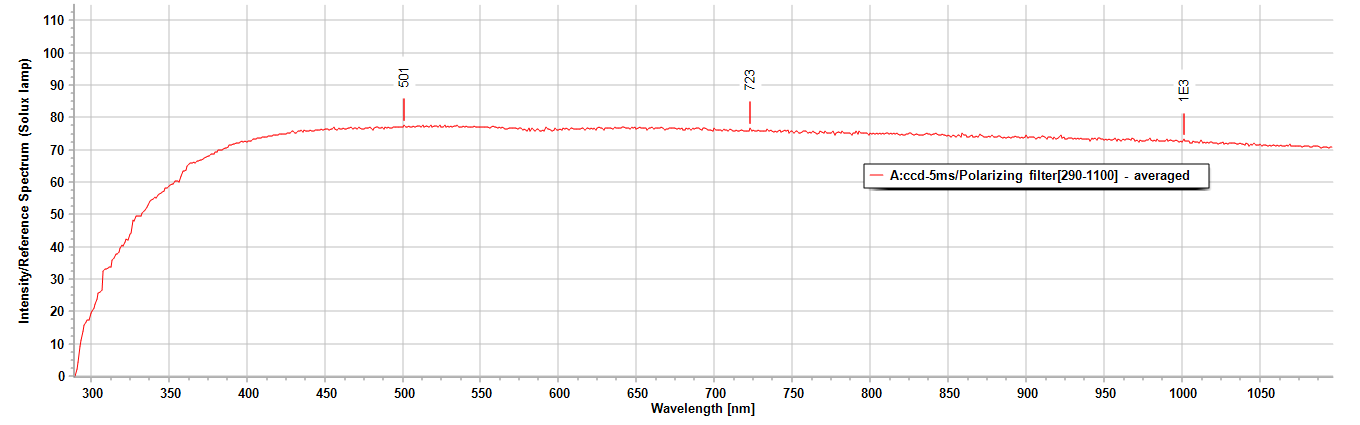

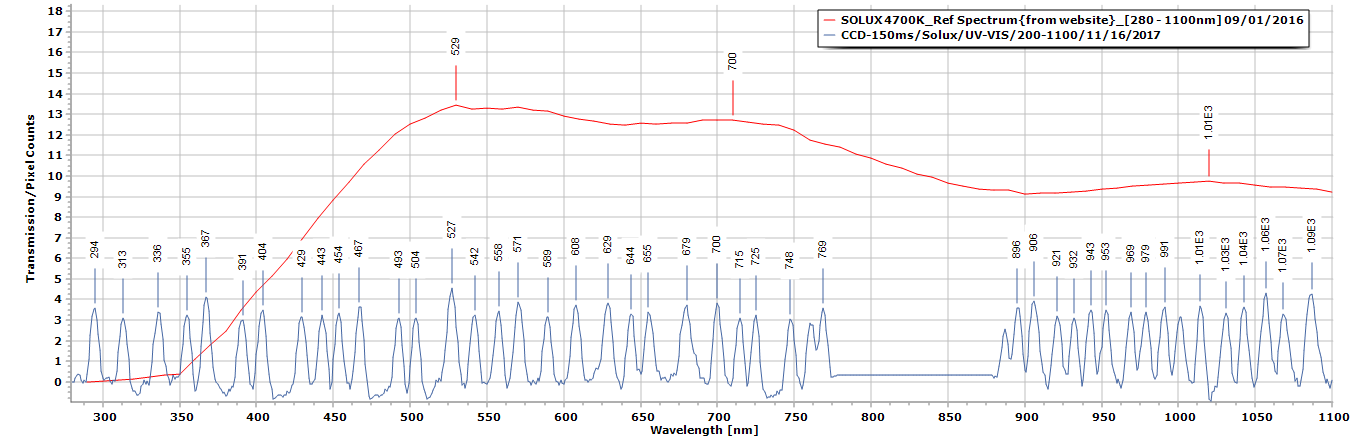

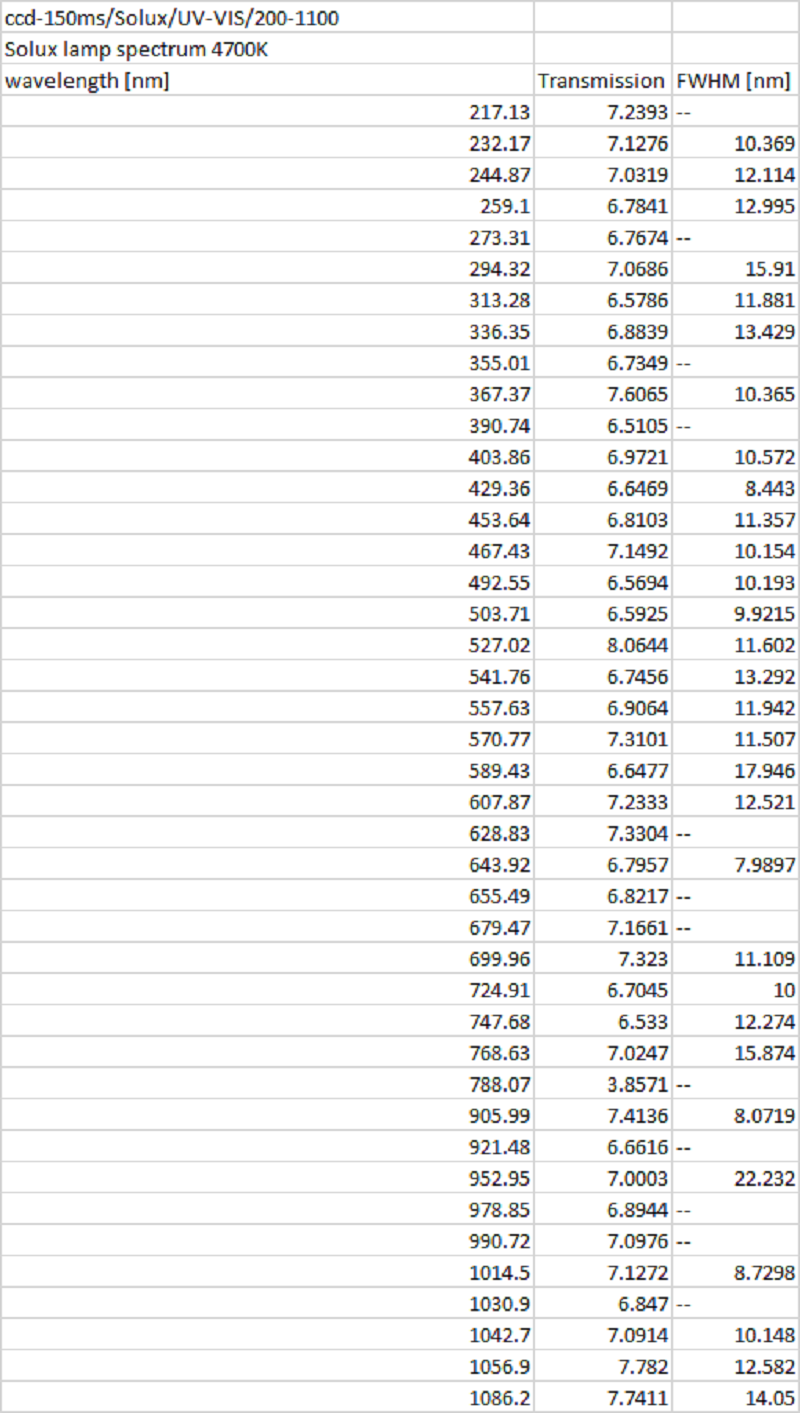

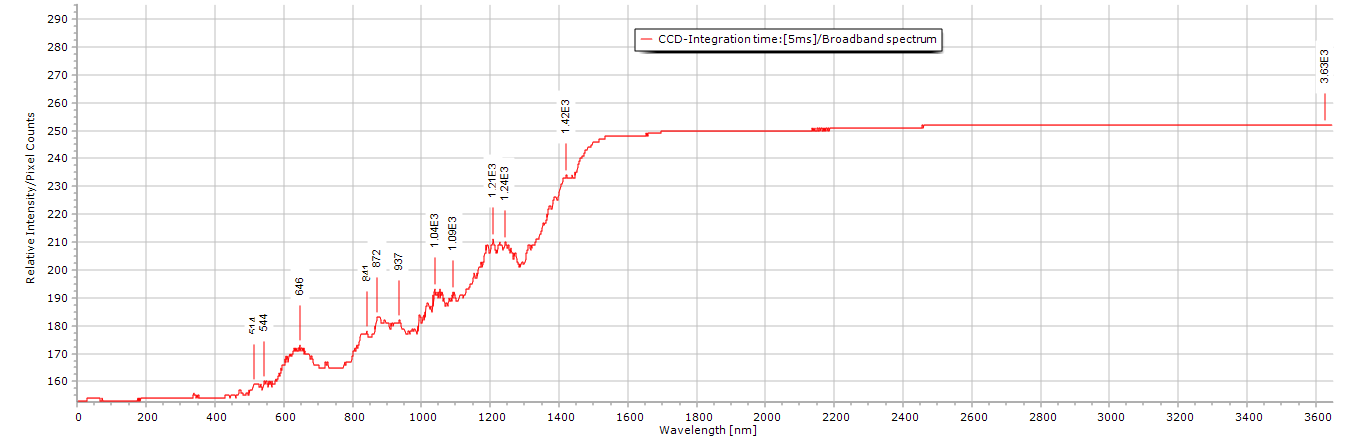

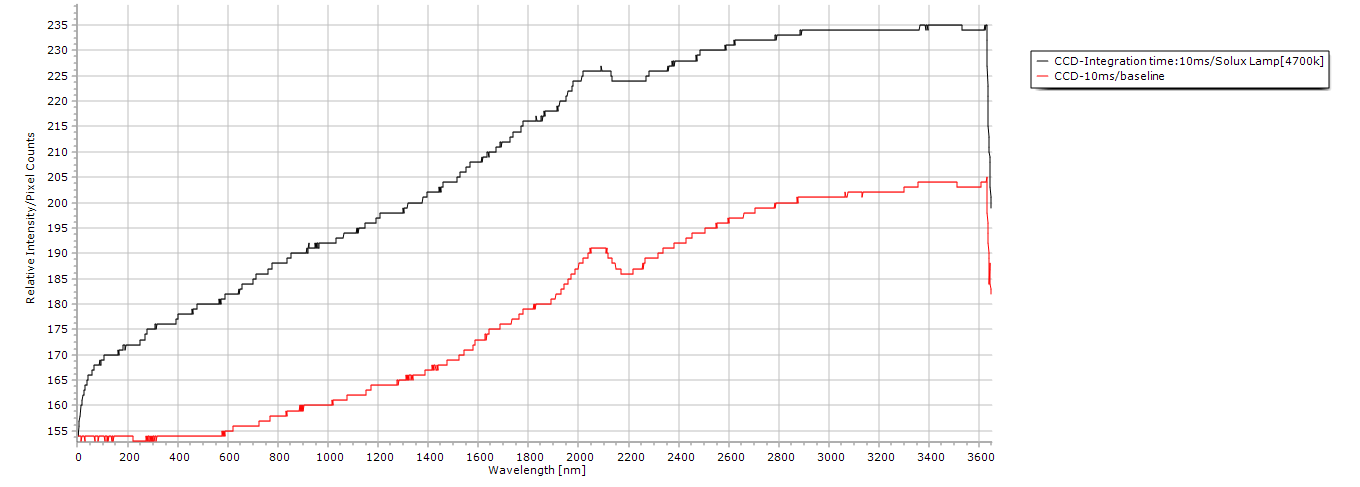

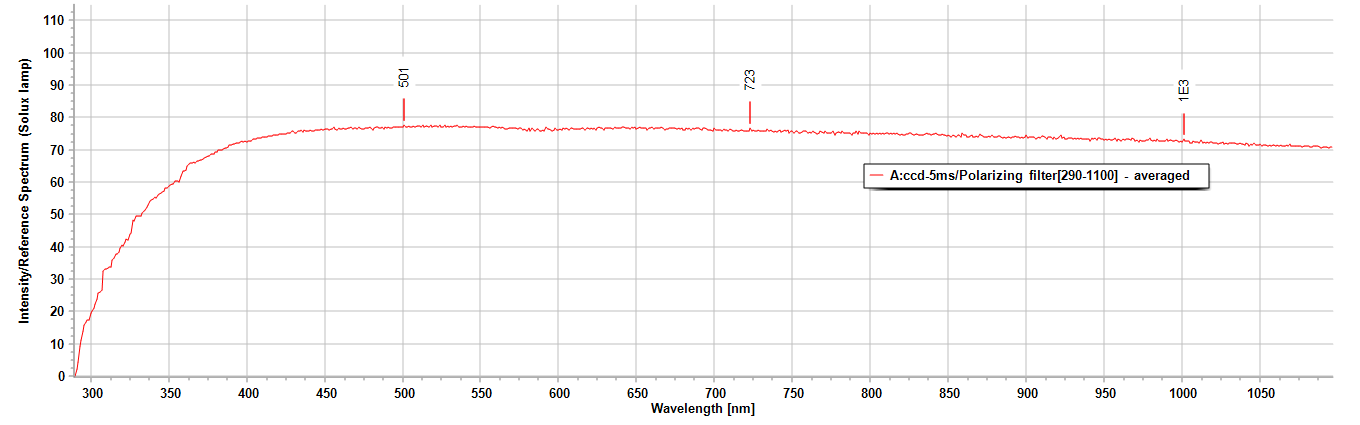

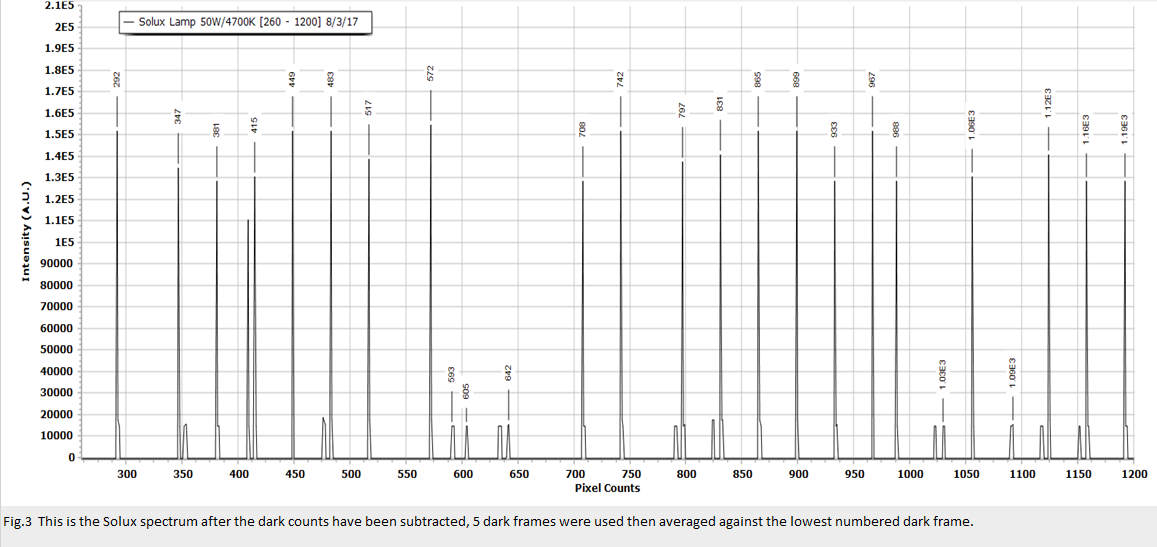

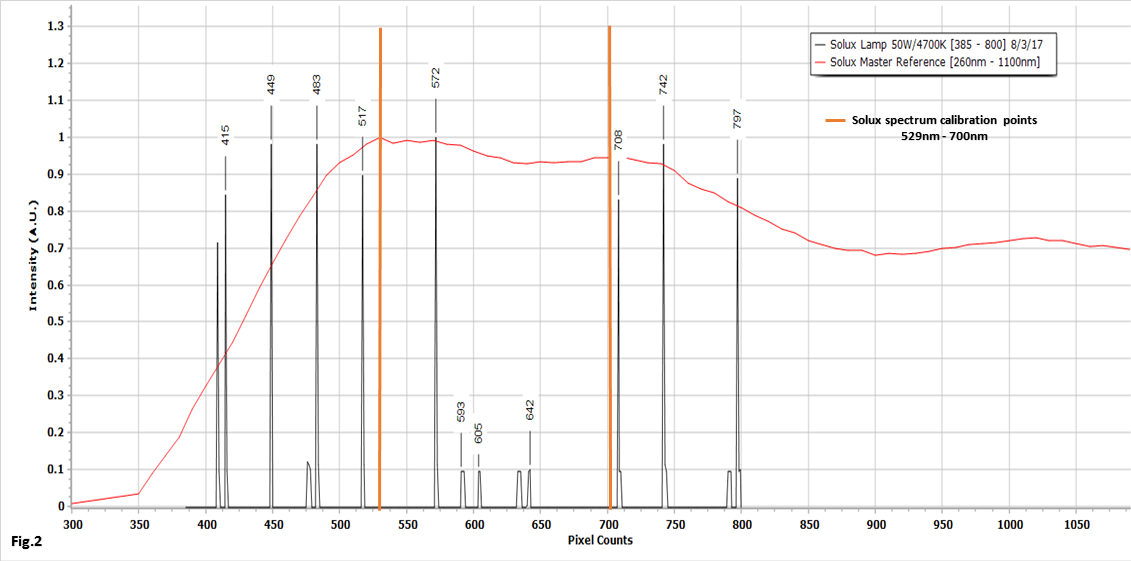

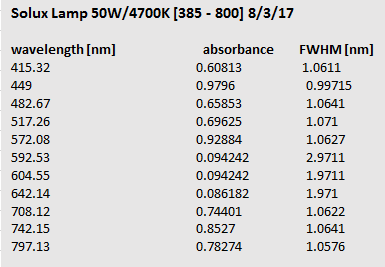

A calibrated Solux lamp spectrum (mine,) 4700K/50W/12vdc/1.2A/0.10mm slit width

Turret @ zero position (baseline) 0.00 nm/ Integration time: 150ms

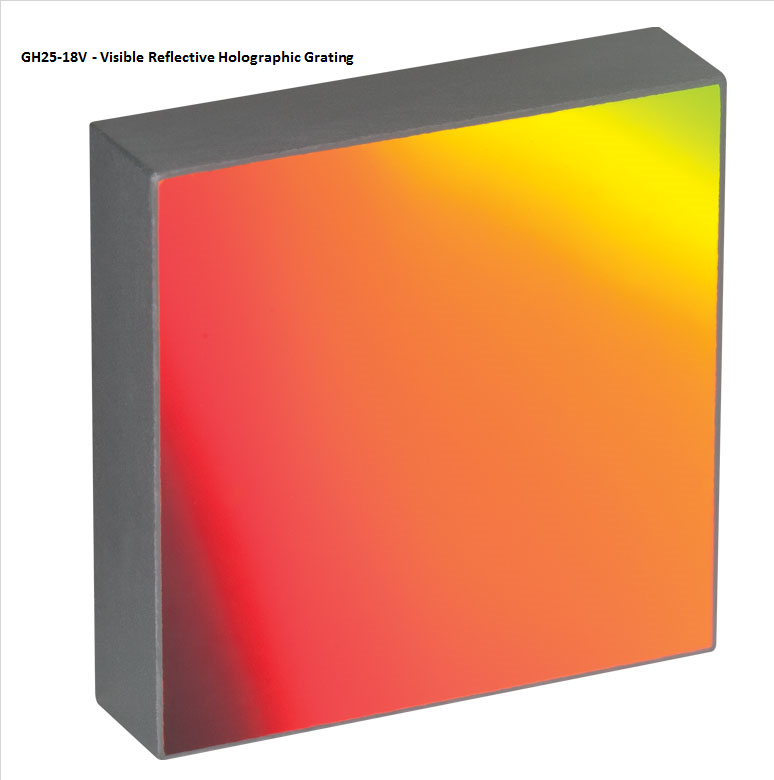

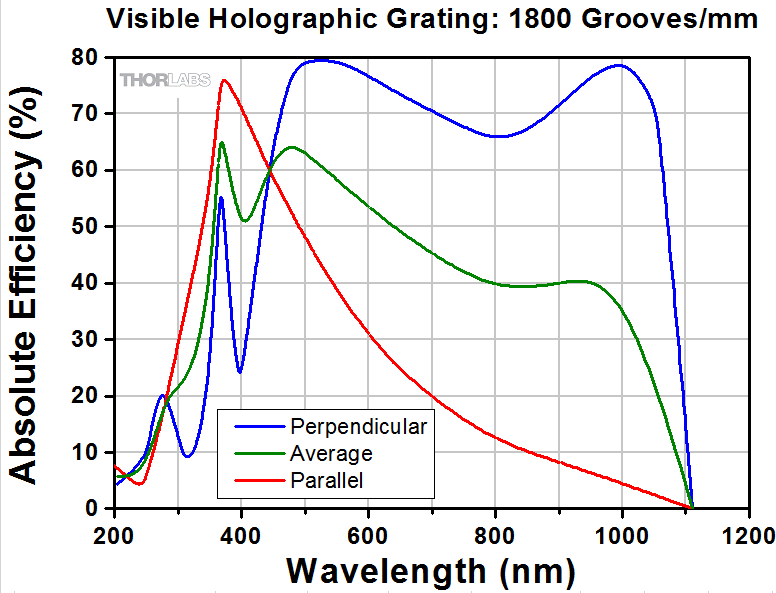

2400ln/mm diffraction grating:

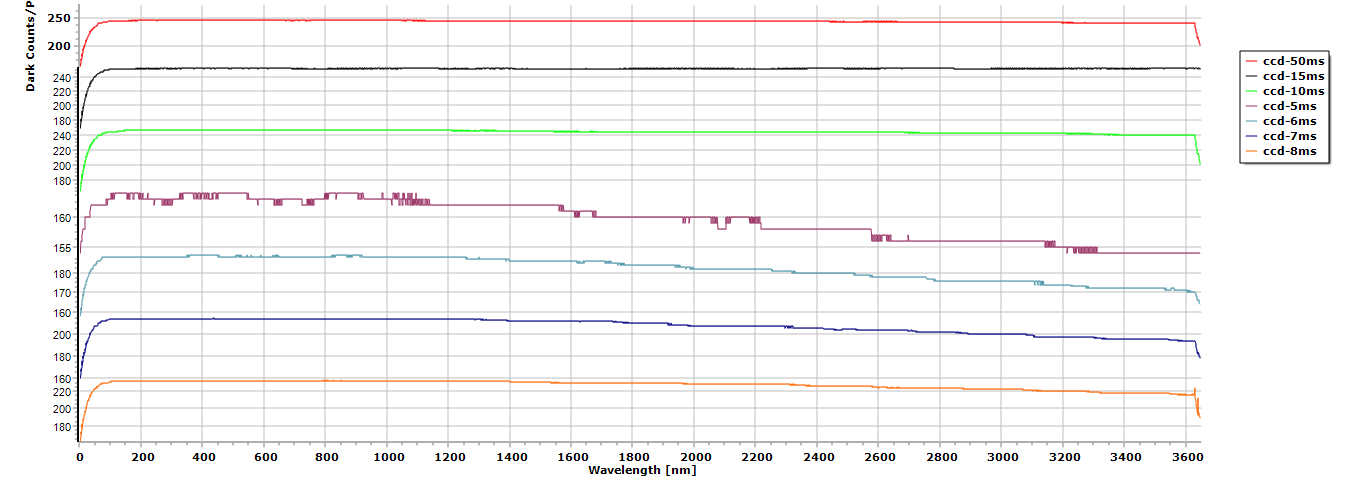

7 Dark Count scans I did to determine which integration time is the most ideal and it appears to be 50ms, 15ms and 10ms:

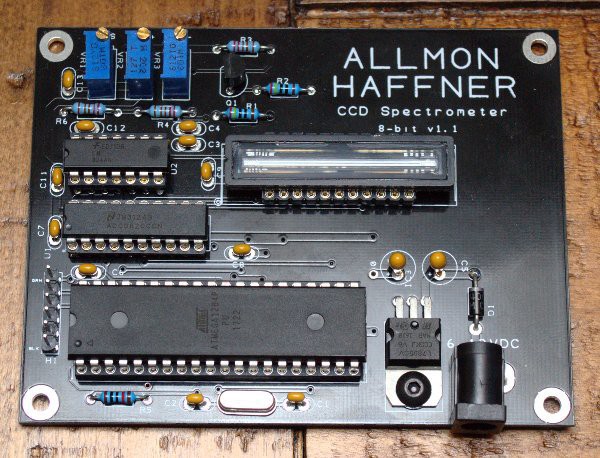

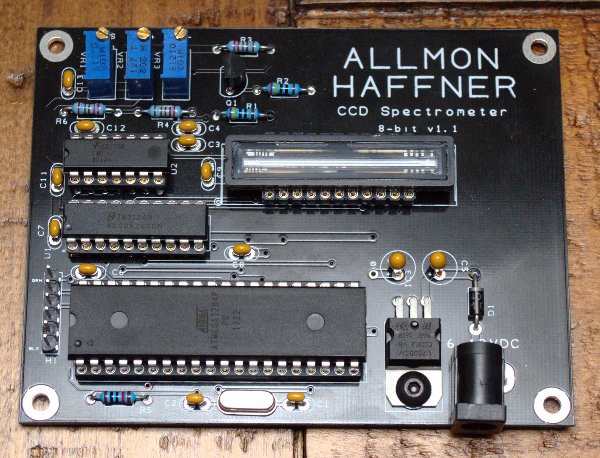

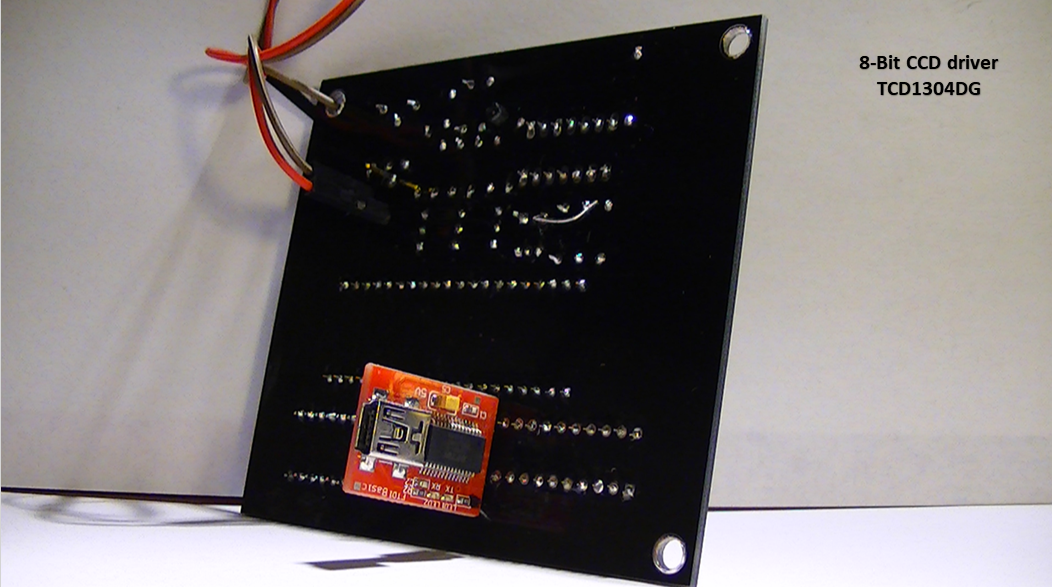

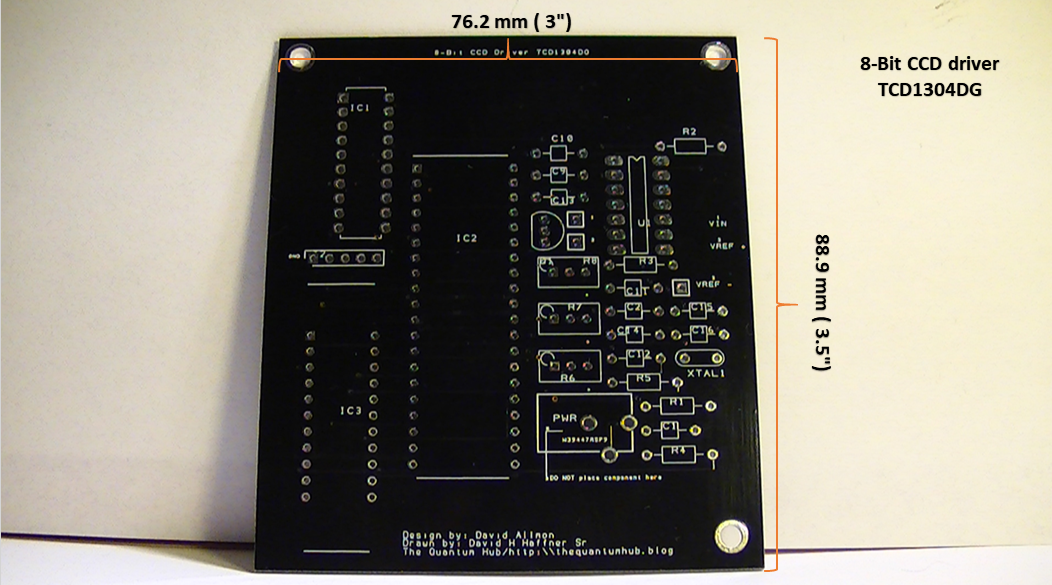

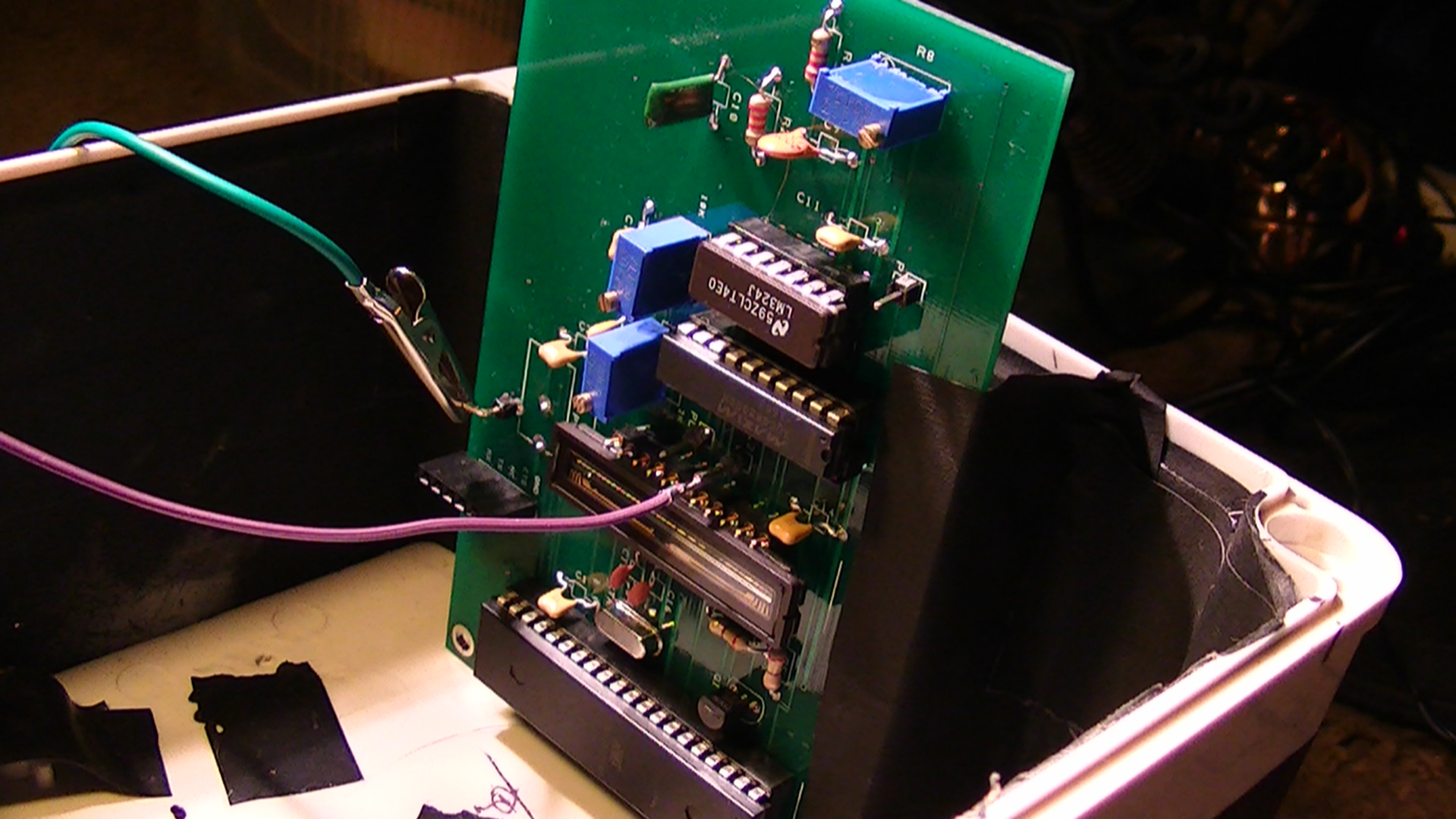

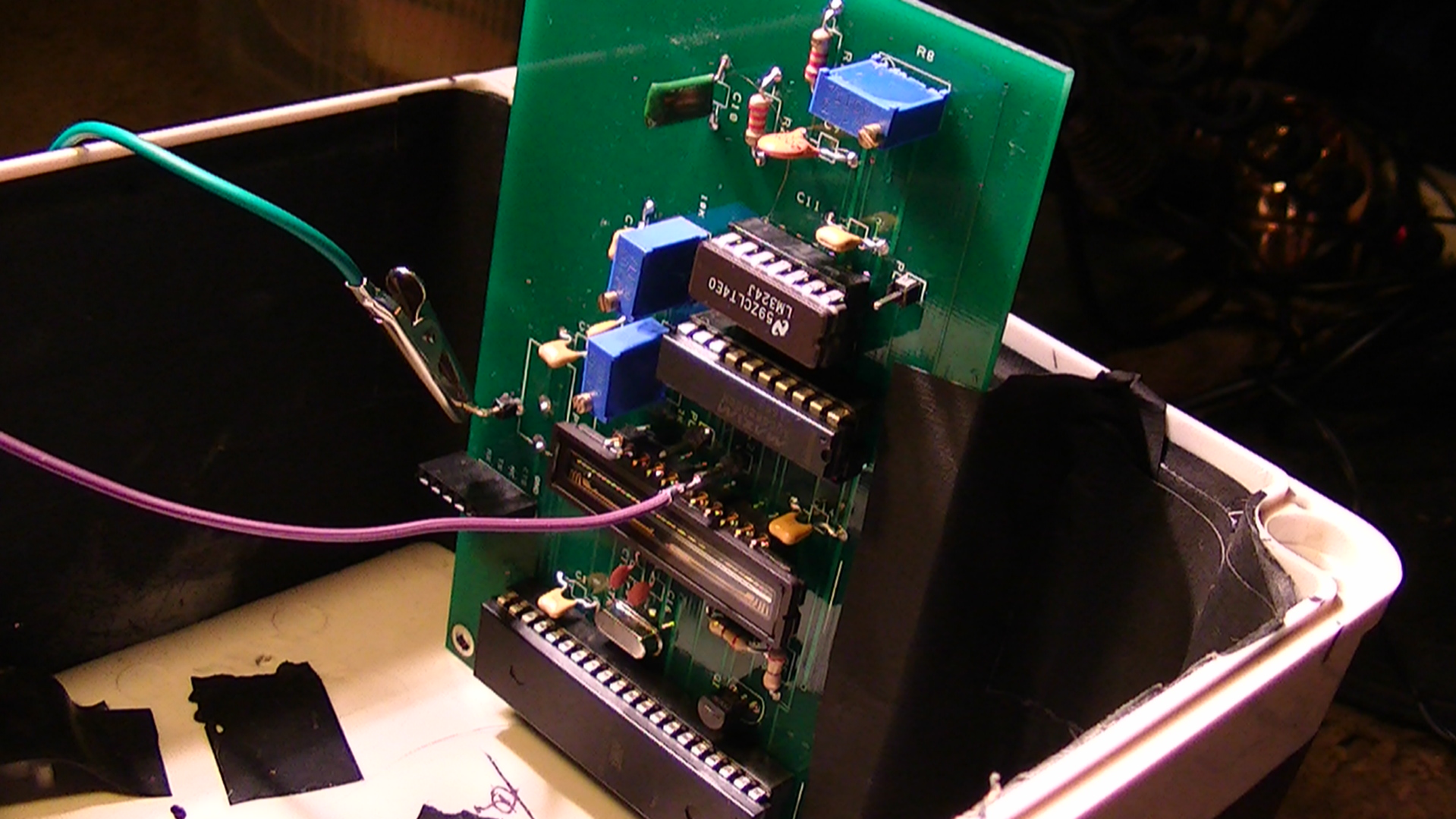

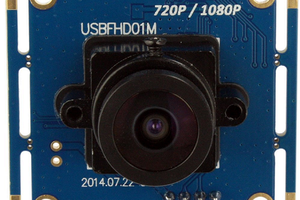

CCD detector Allmon & Haffner v1.1 is done.

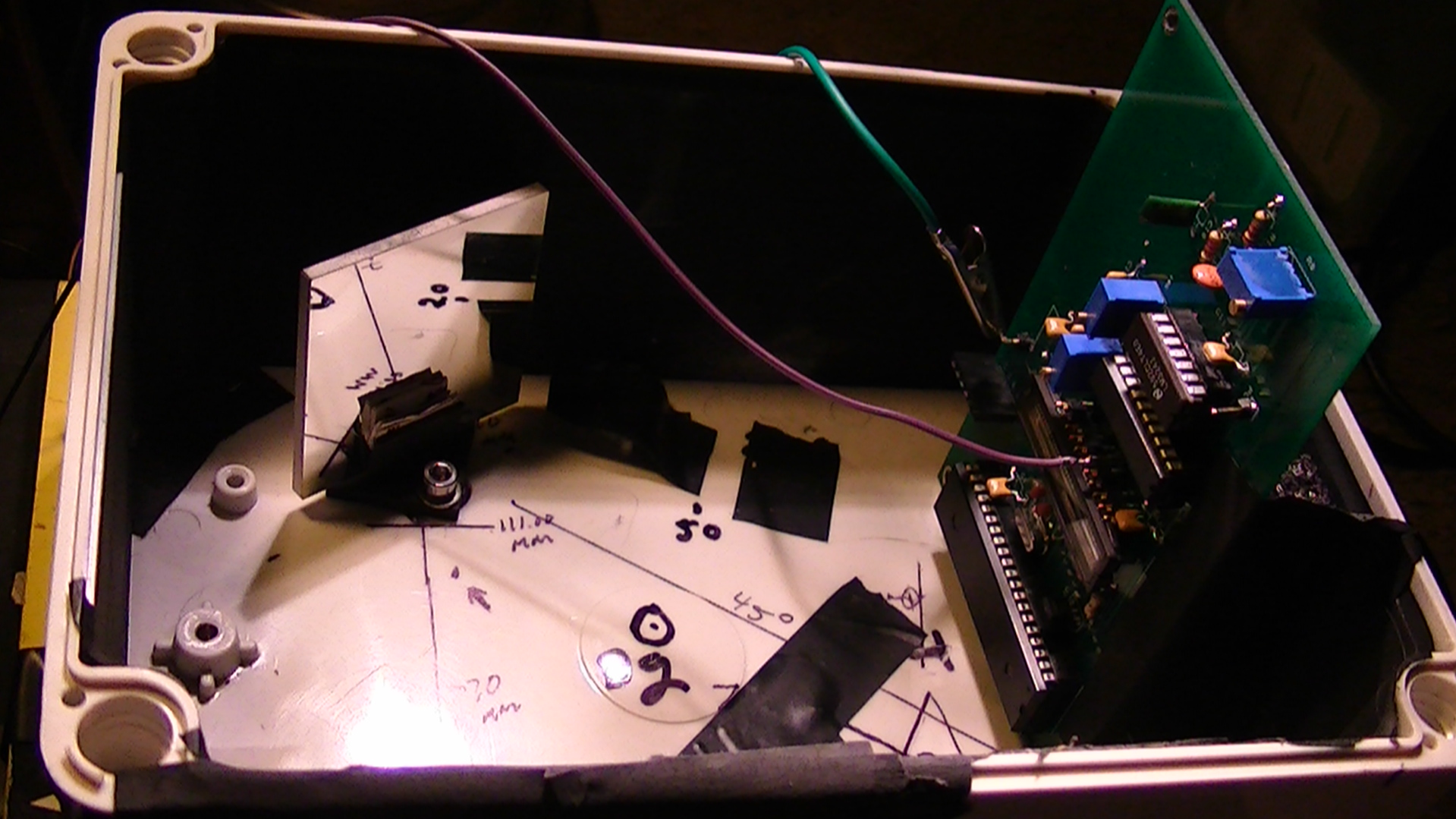

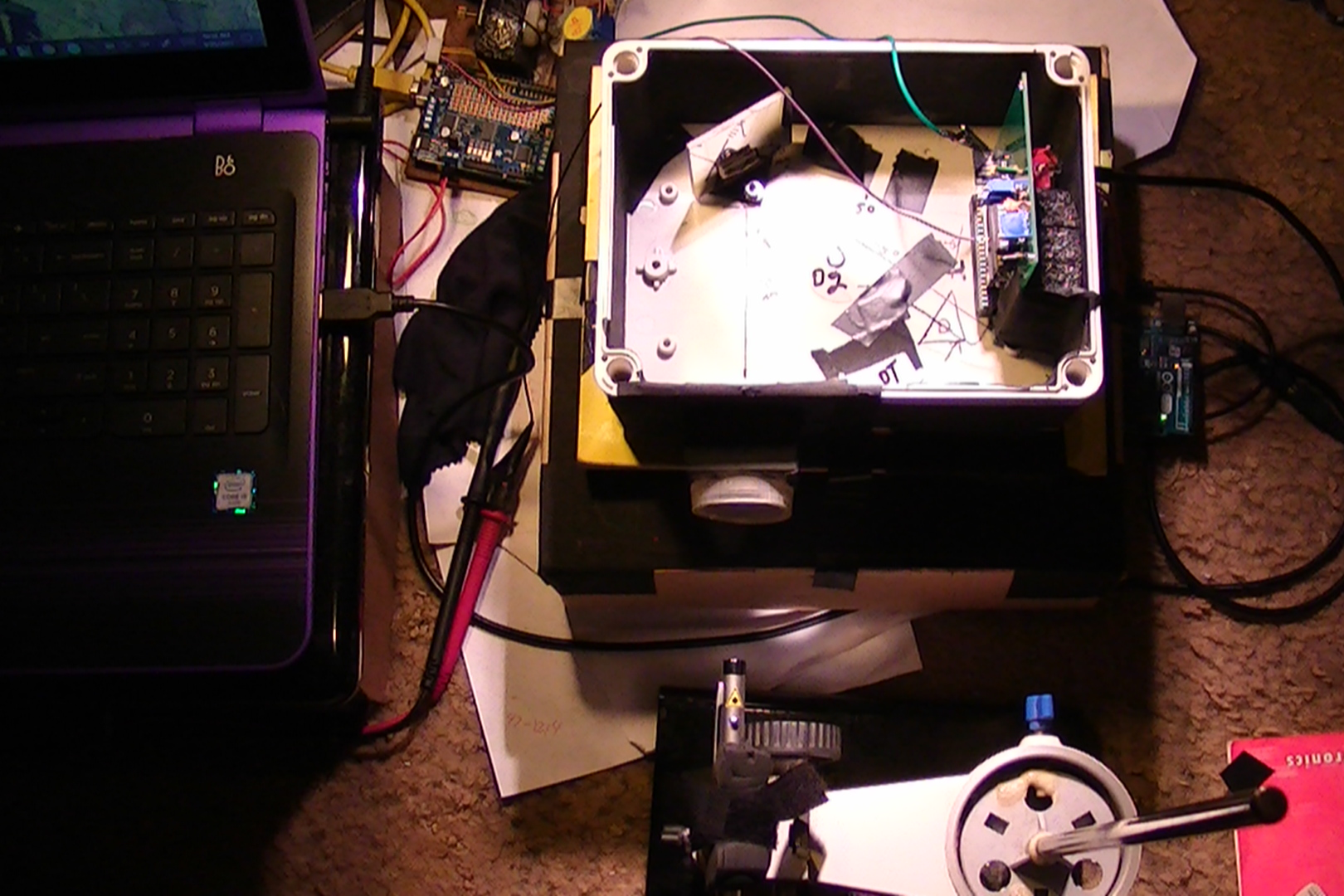

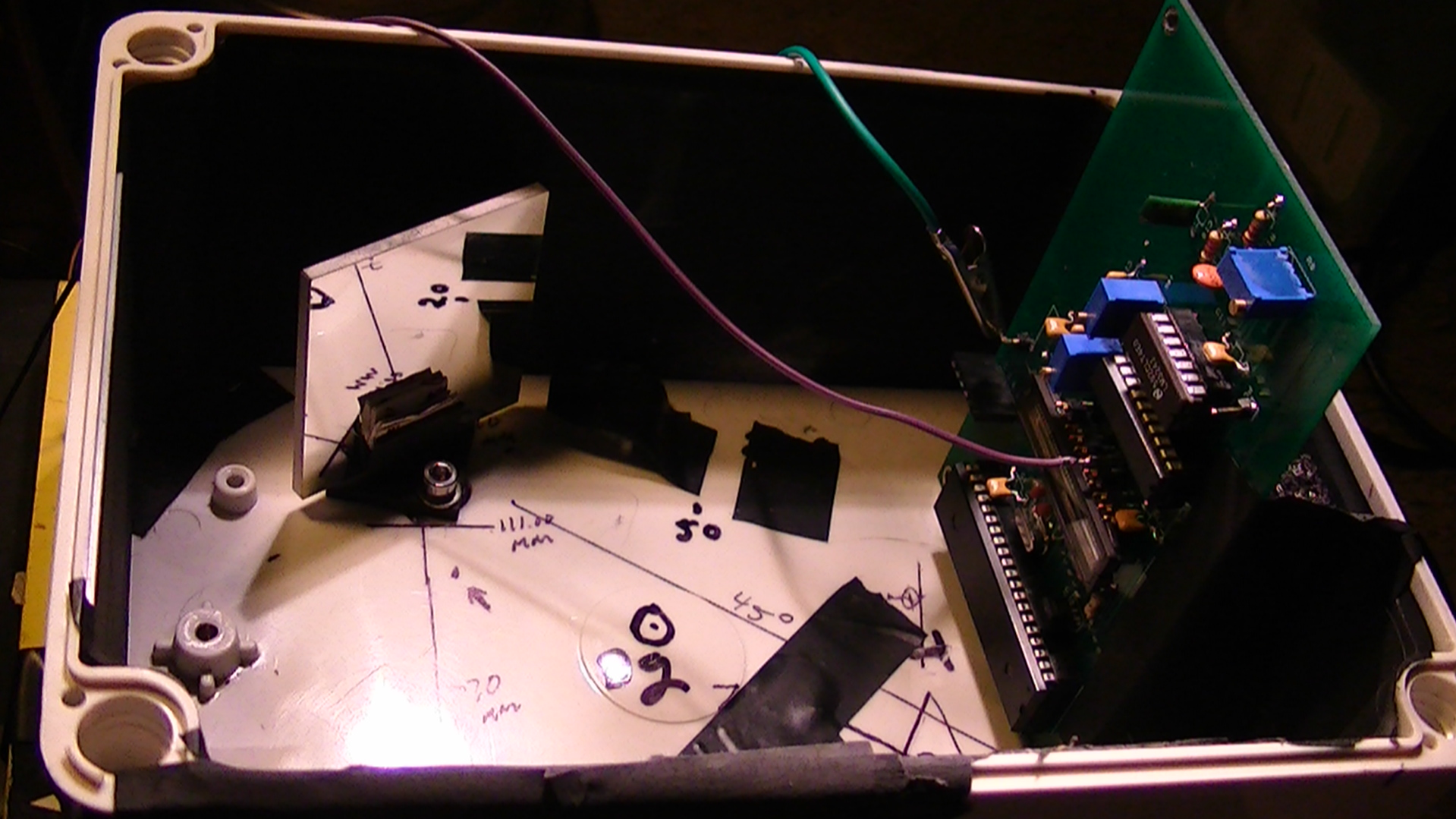

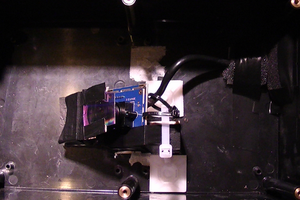

-Testing Platform

PLX-DAQ v2.11 Dual Trace Transfer to Excel

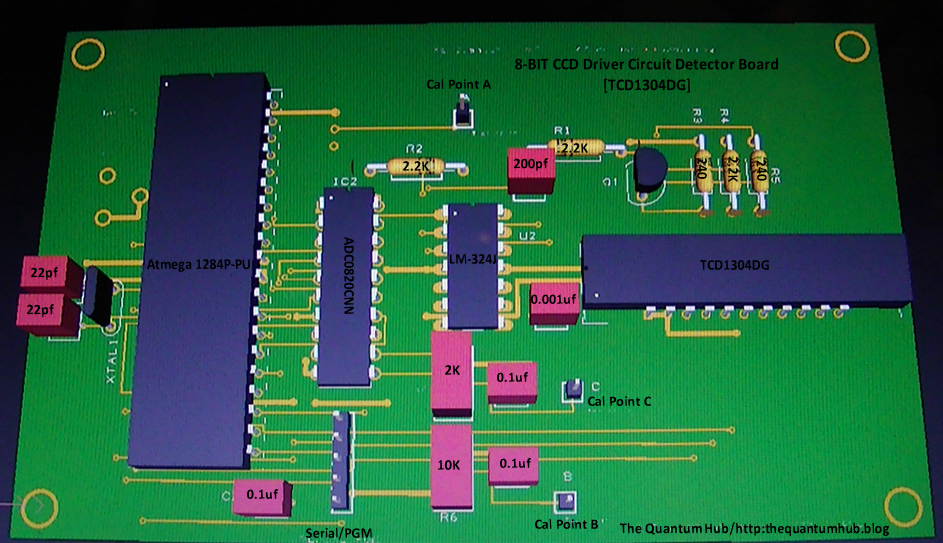

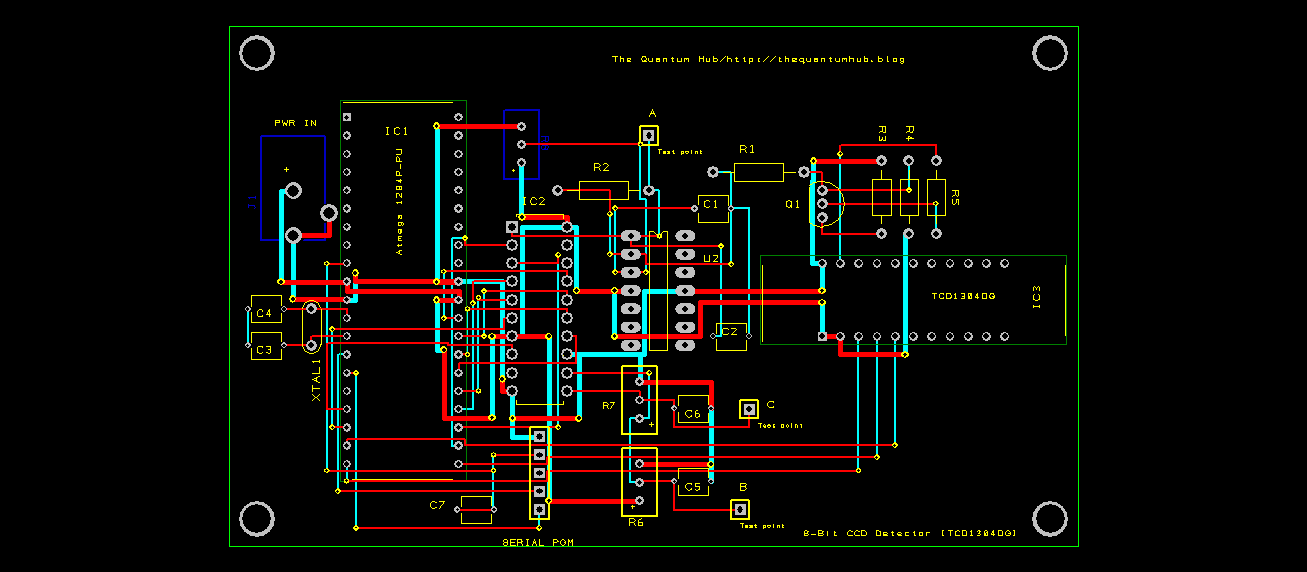

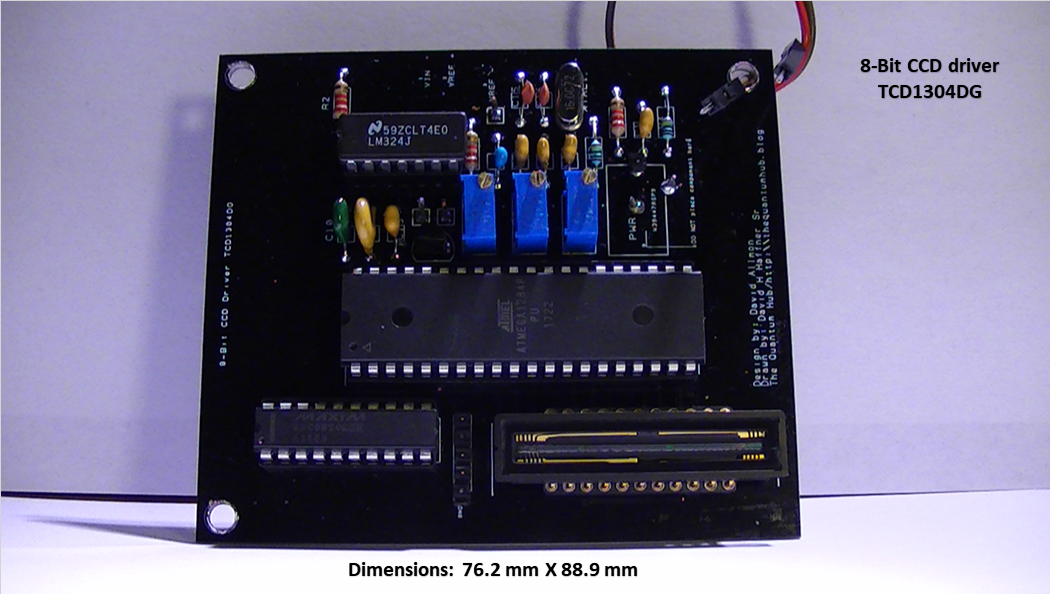

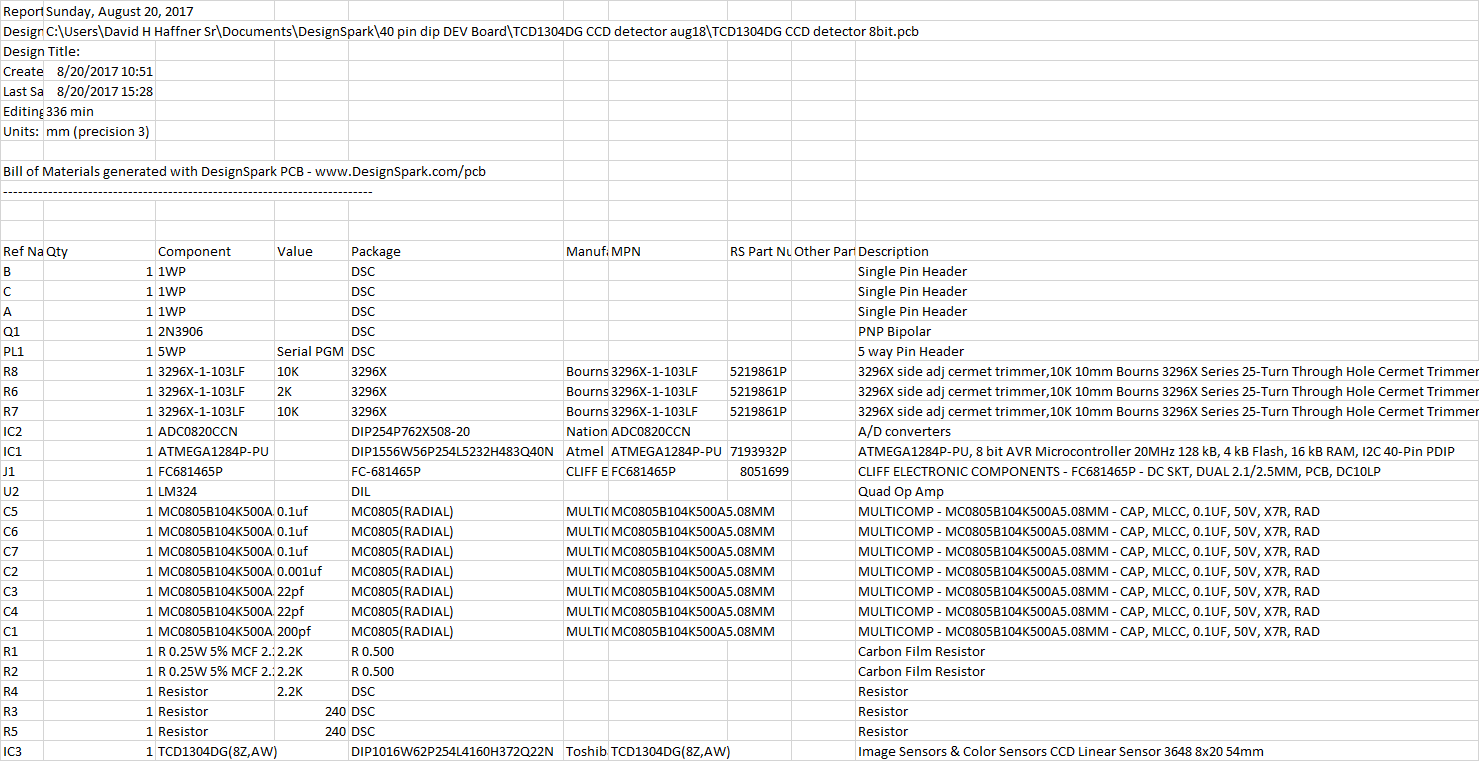

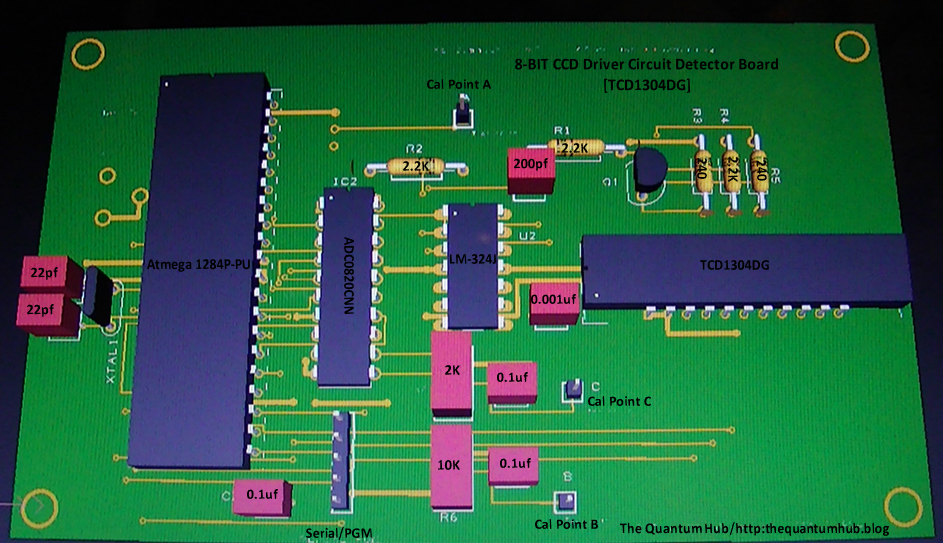

New 8-Bit TCD1304 CCD detector driver board

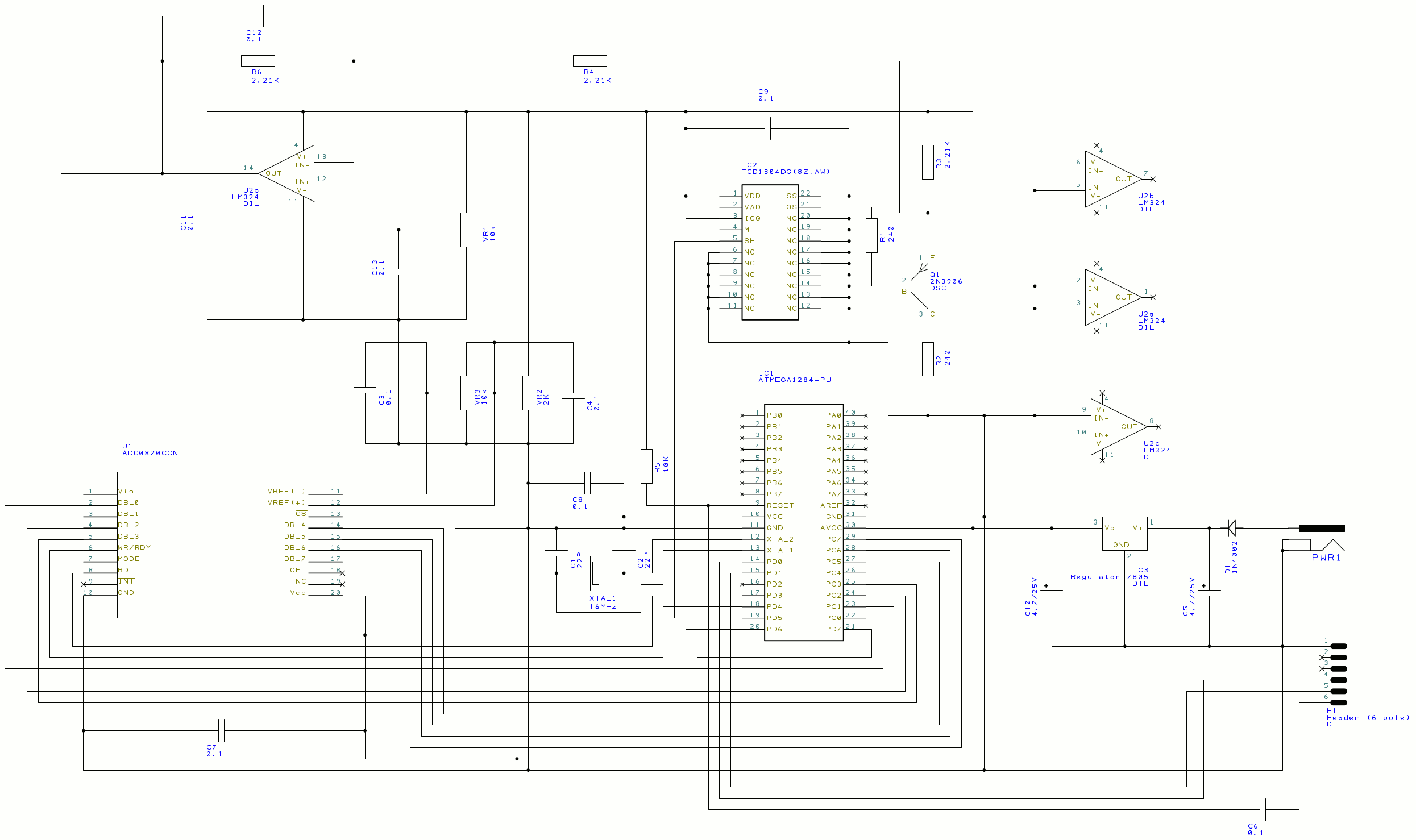

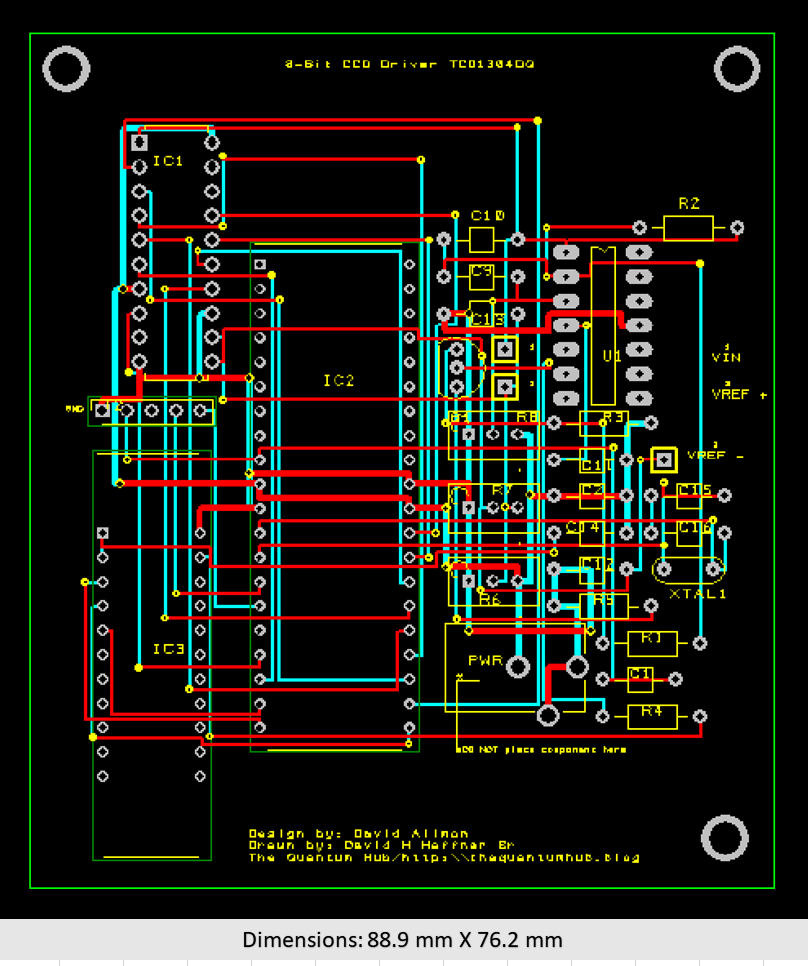

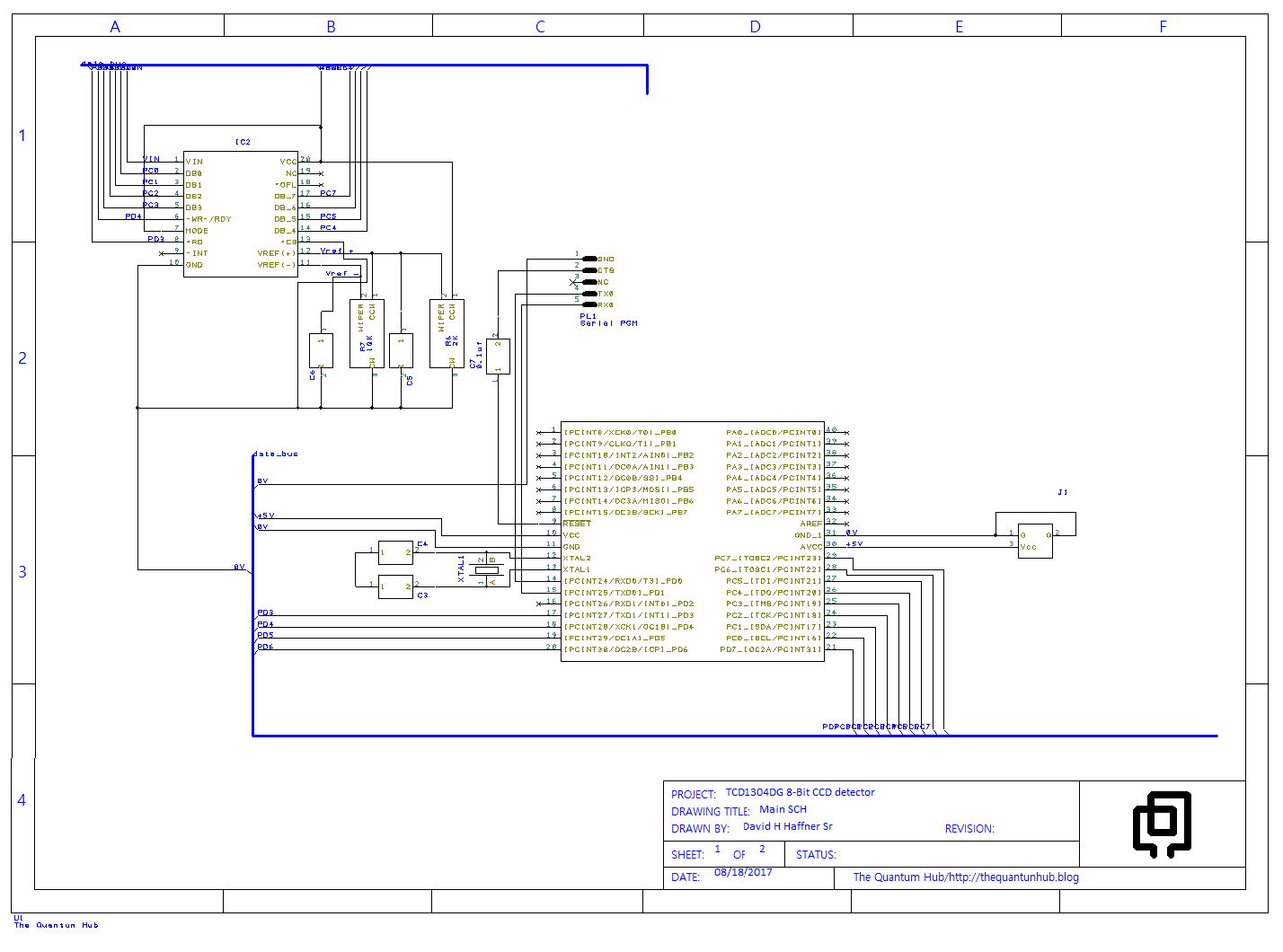

New schematic

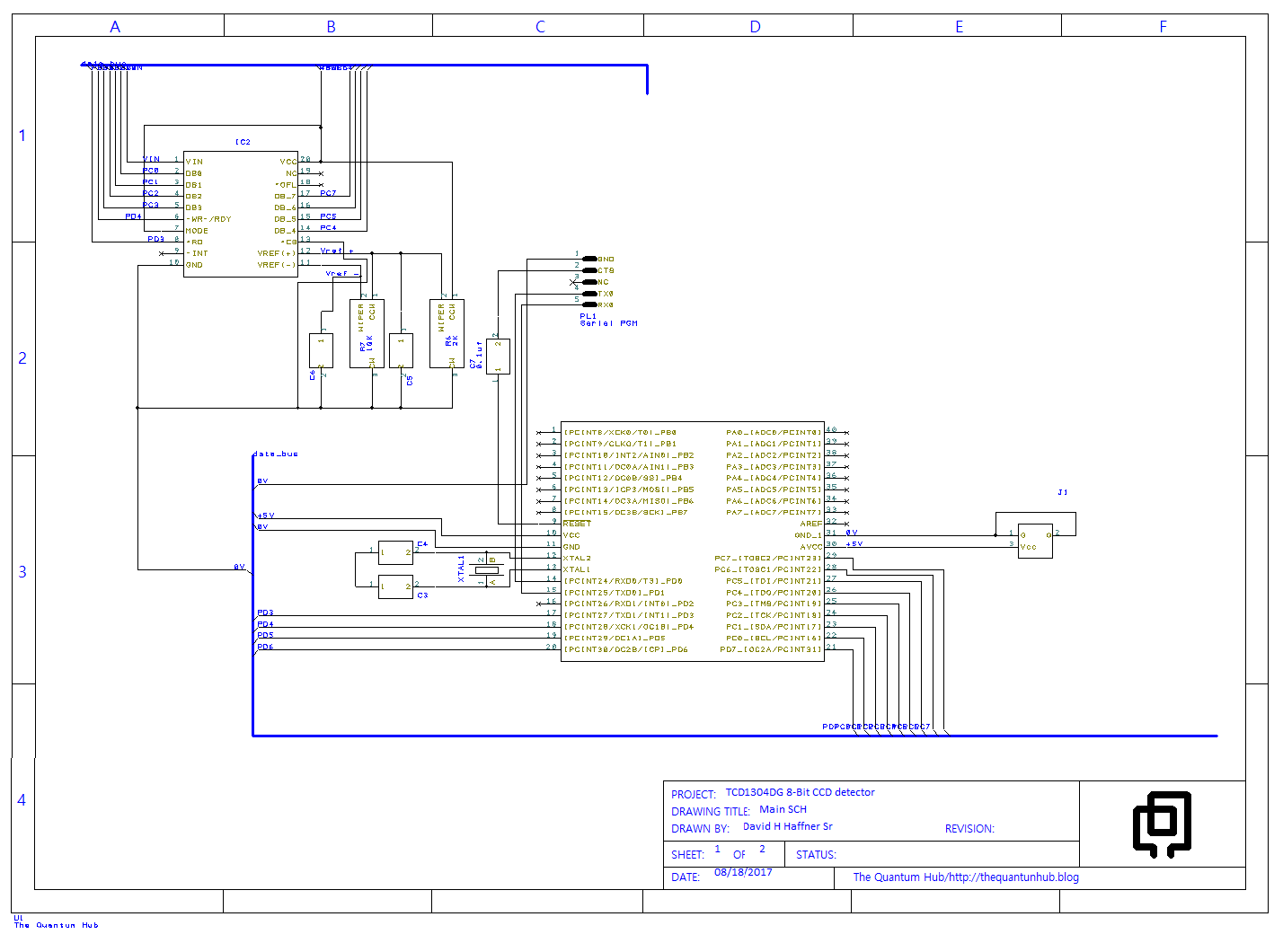

8-Bit Main SCH 1

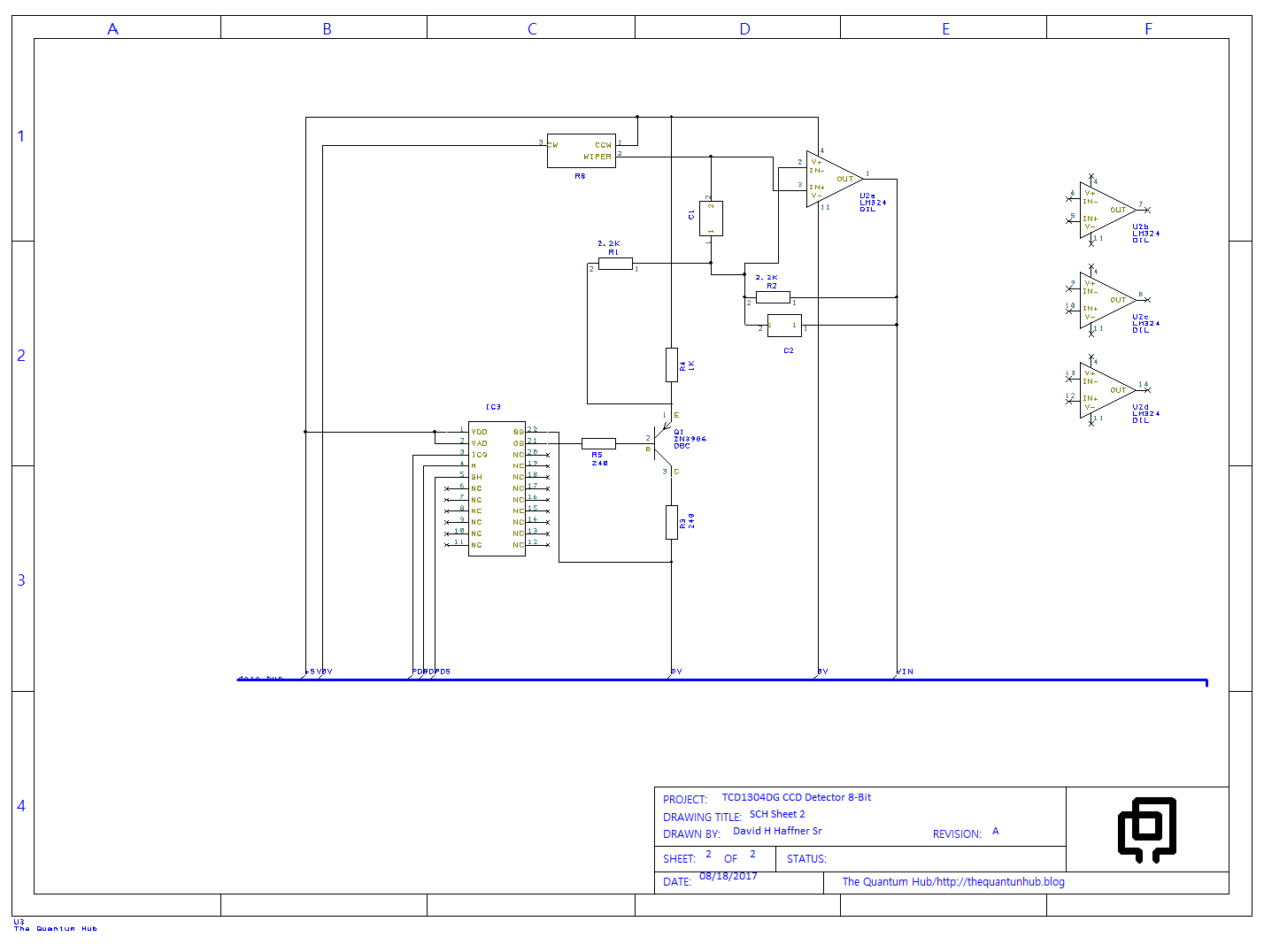

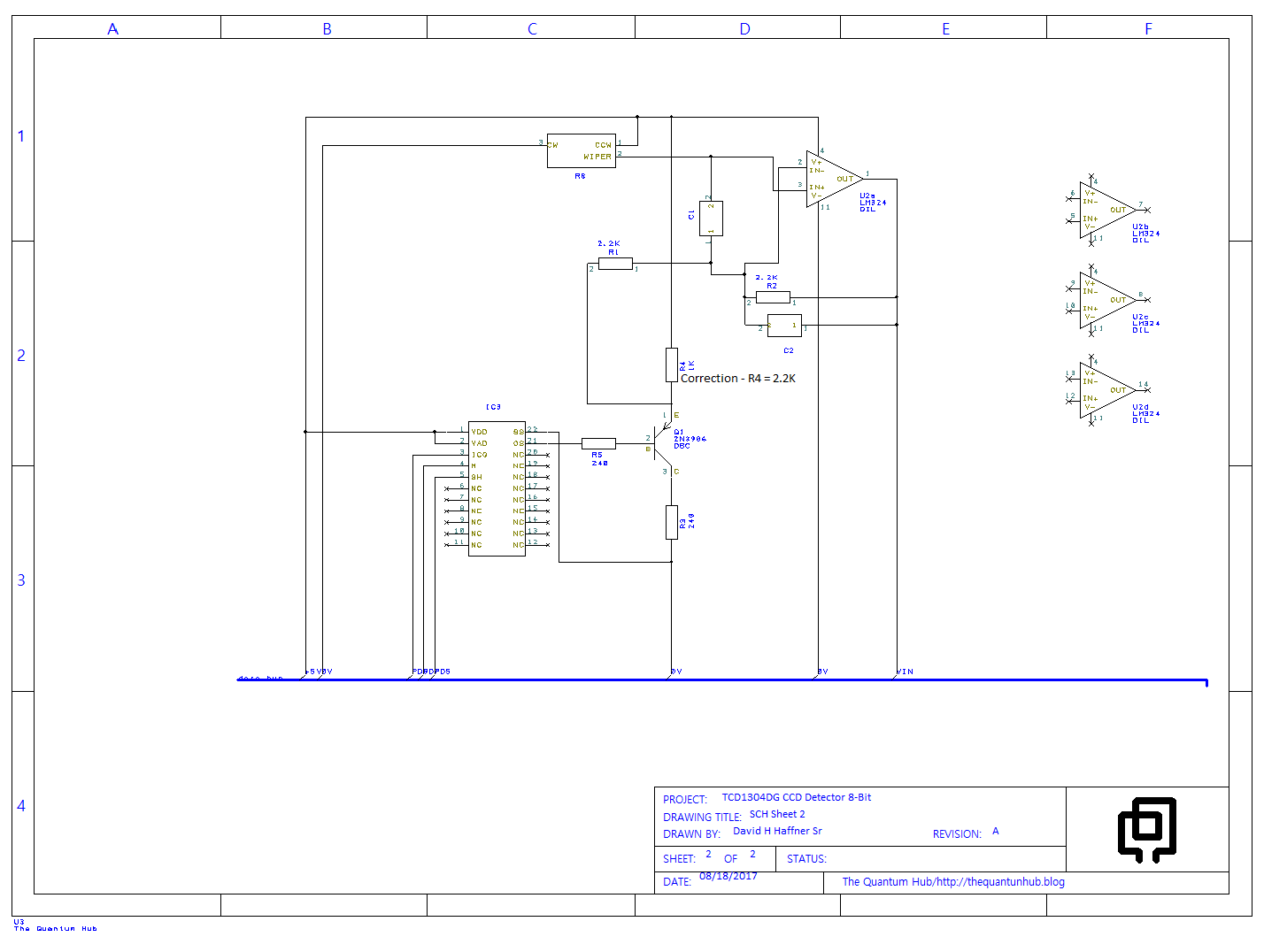

8-Bit Sheet 2

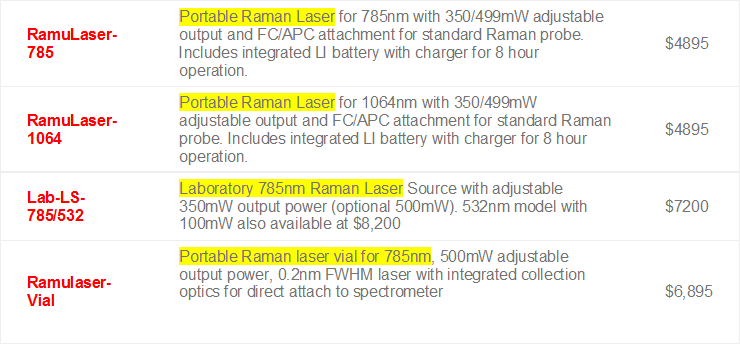

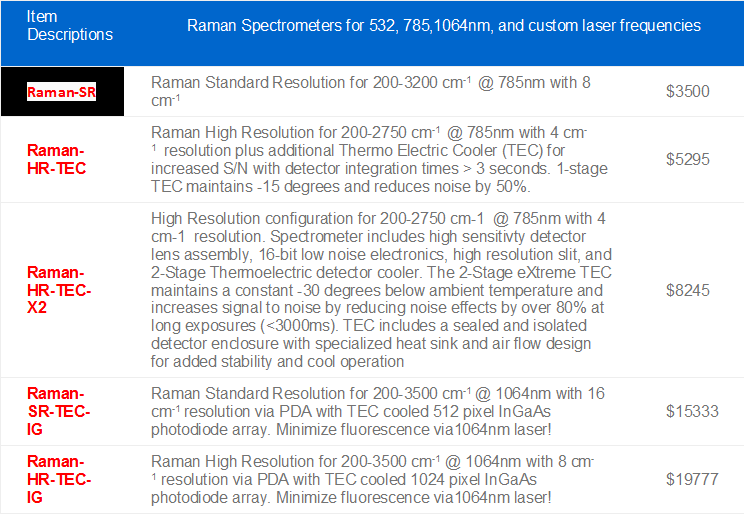

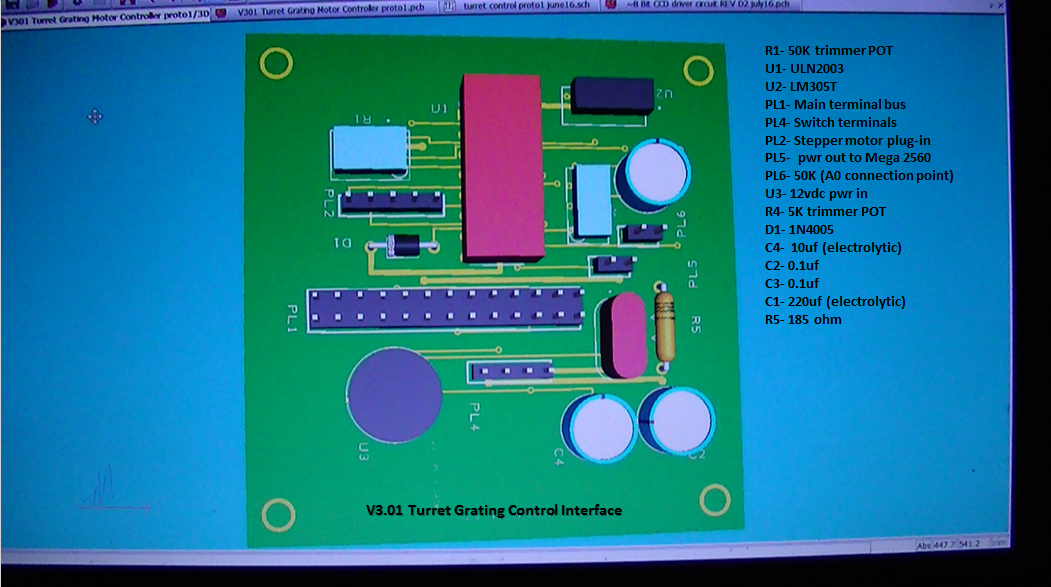

Cost analysis comparing Raman Spectrometers and Lasers from StellerNet Inc. to the DAV5 V3.01 3D printable Raman Spectrometer:

DAV5 V3.01 Raman Spectrometer uses an Aries 532nm 150mW CW/DPSS Green Laser

Cost - $ 199.99 US

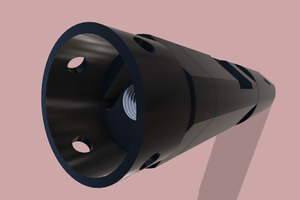

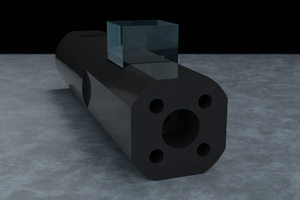

The DAV5 V3.01 3D Printable Raman Spectrometer

DAV5 V3.01 Raman Spectrometer - $ 657.35 US

David H Haffner Sr

David H Haffner Sr

-

-

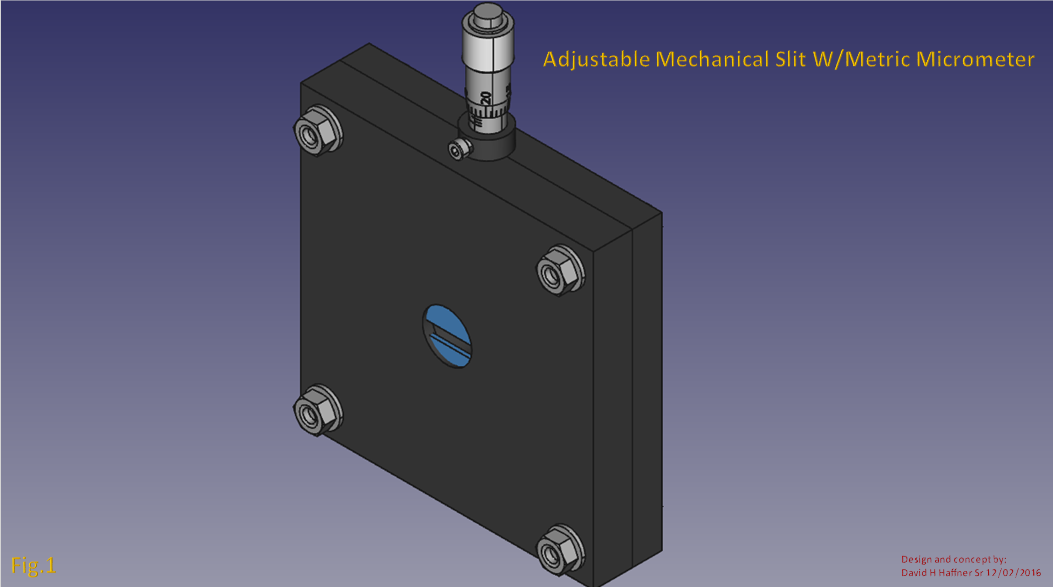

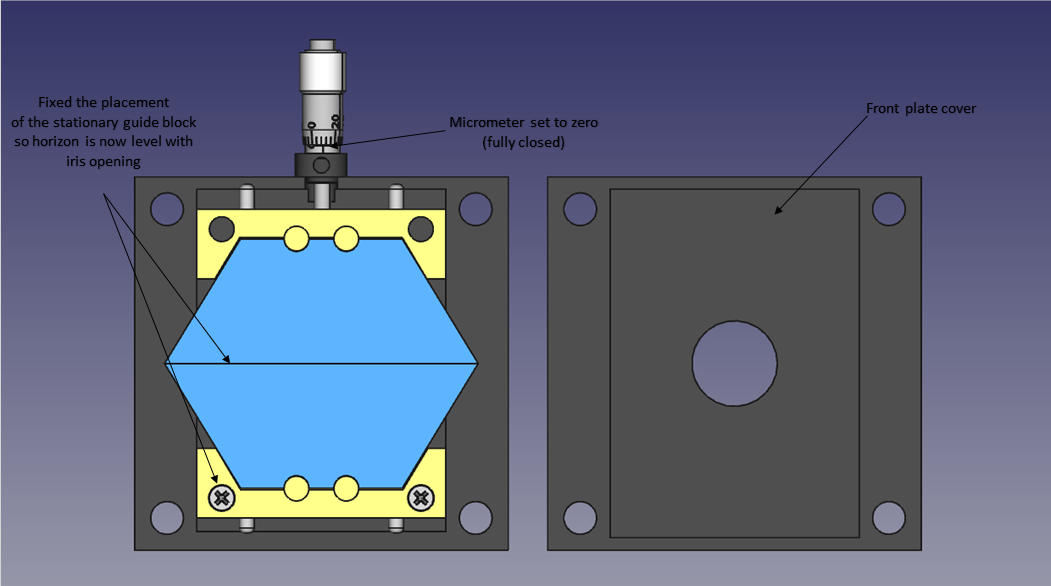

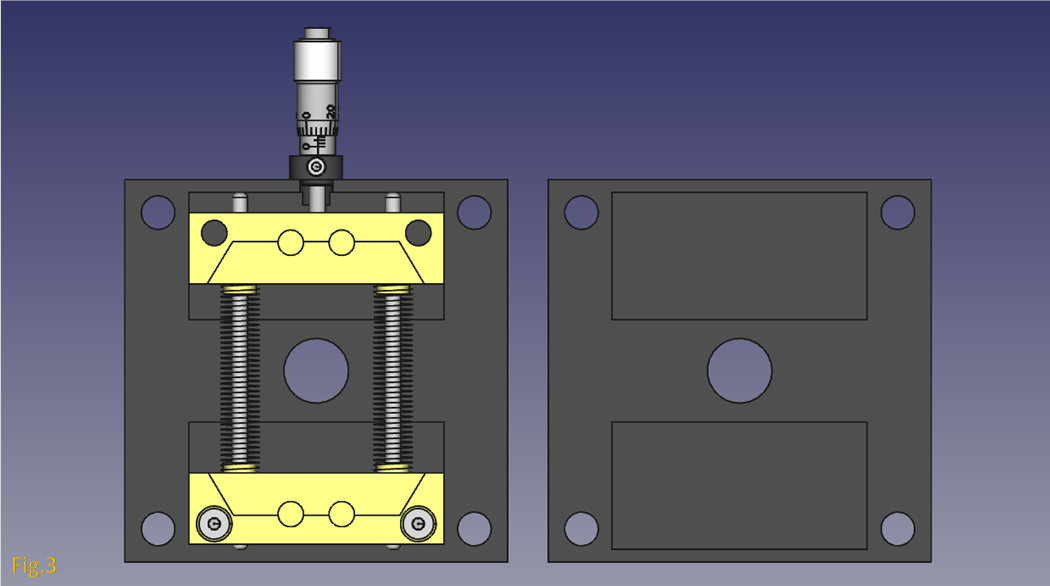

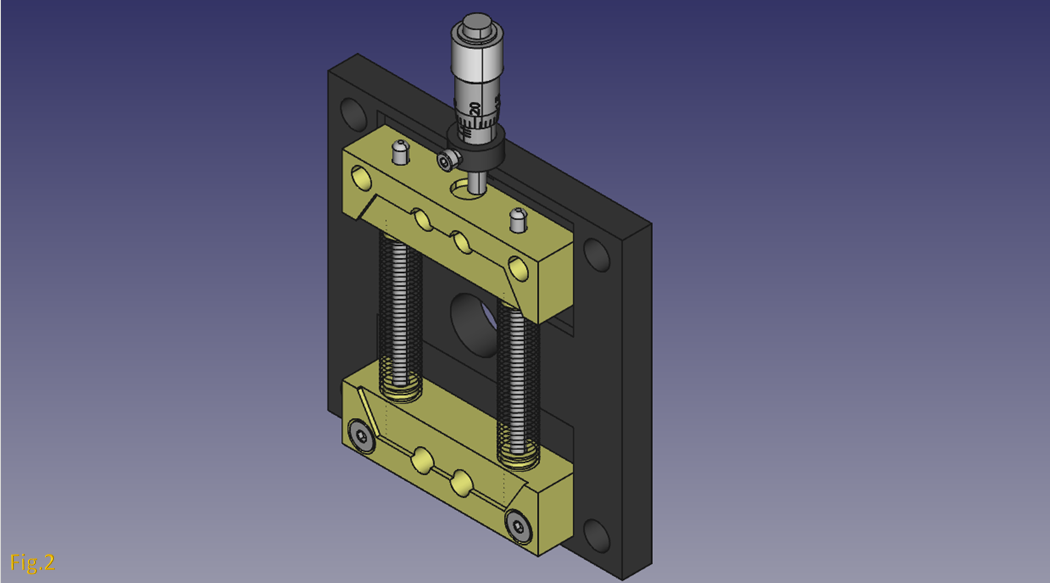

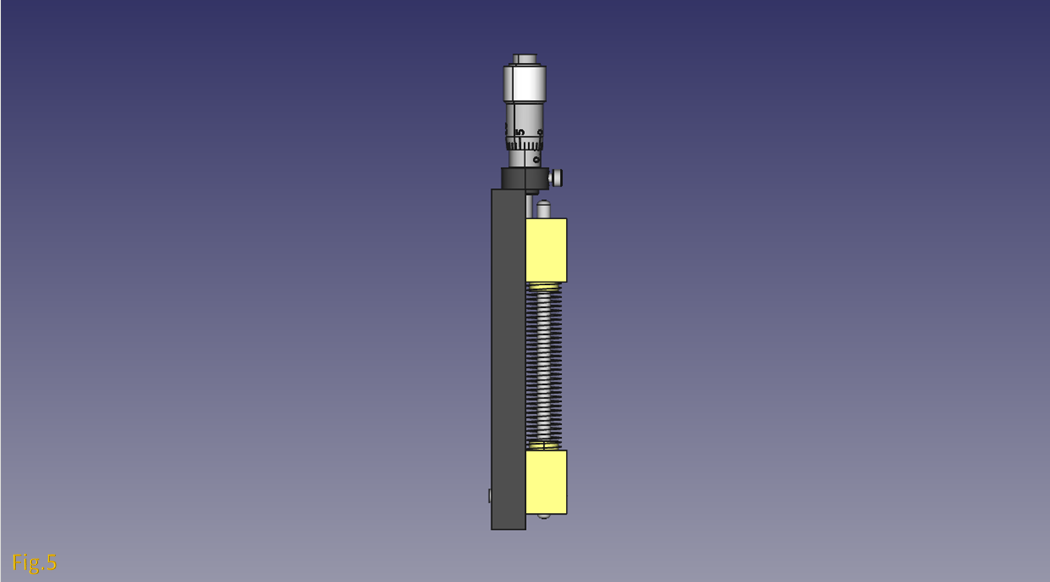

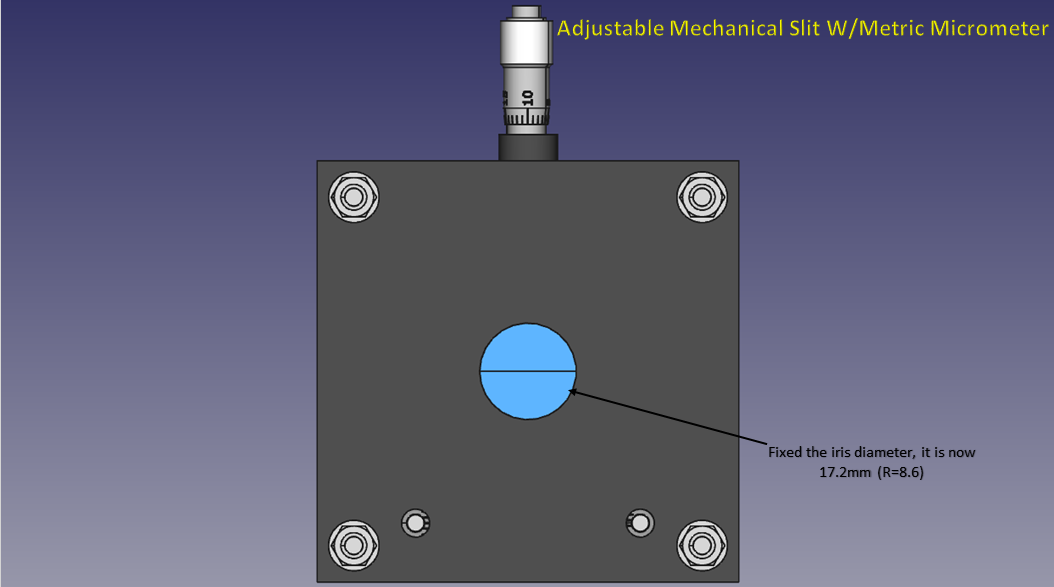

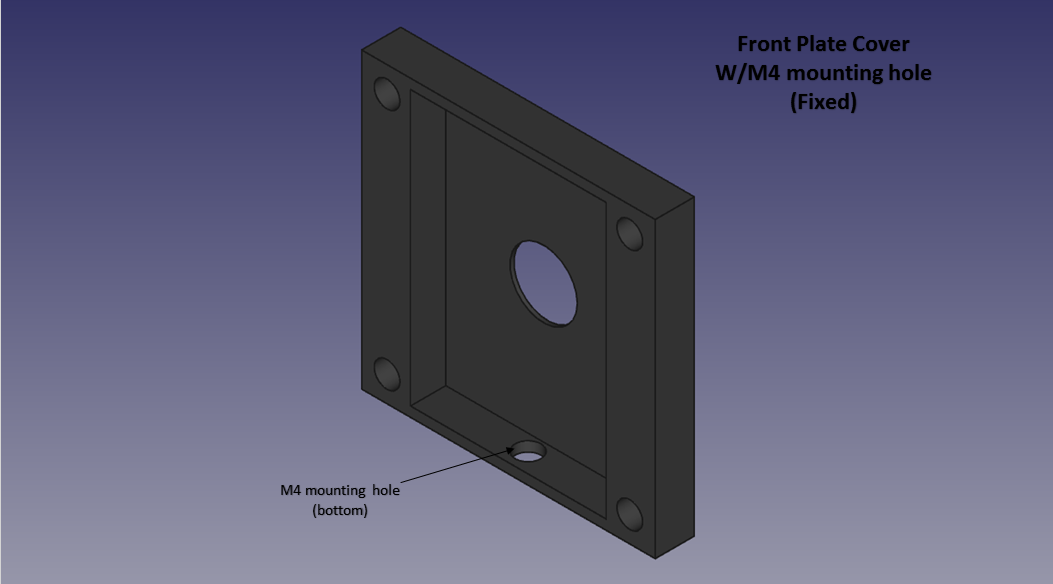

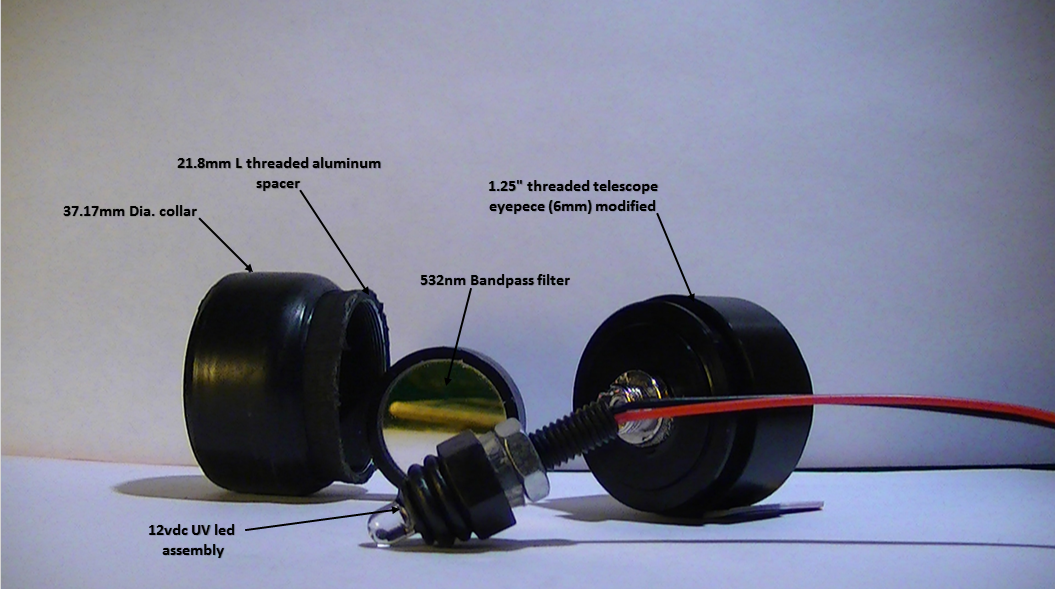

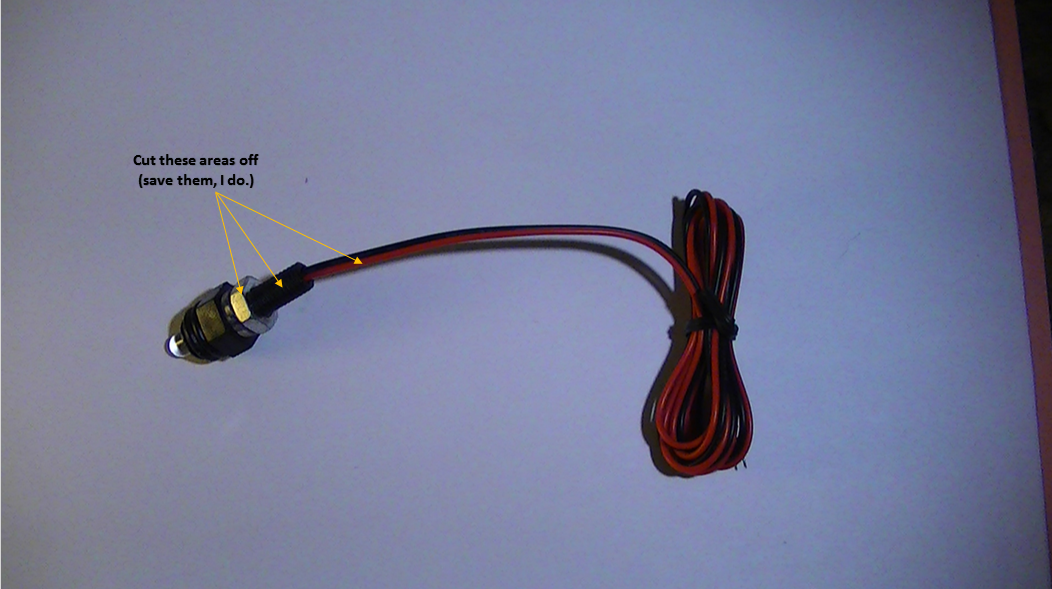

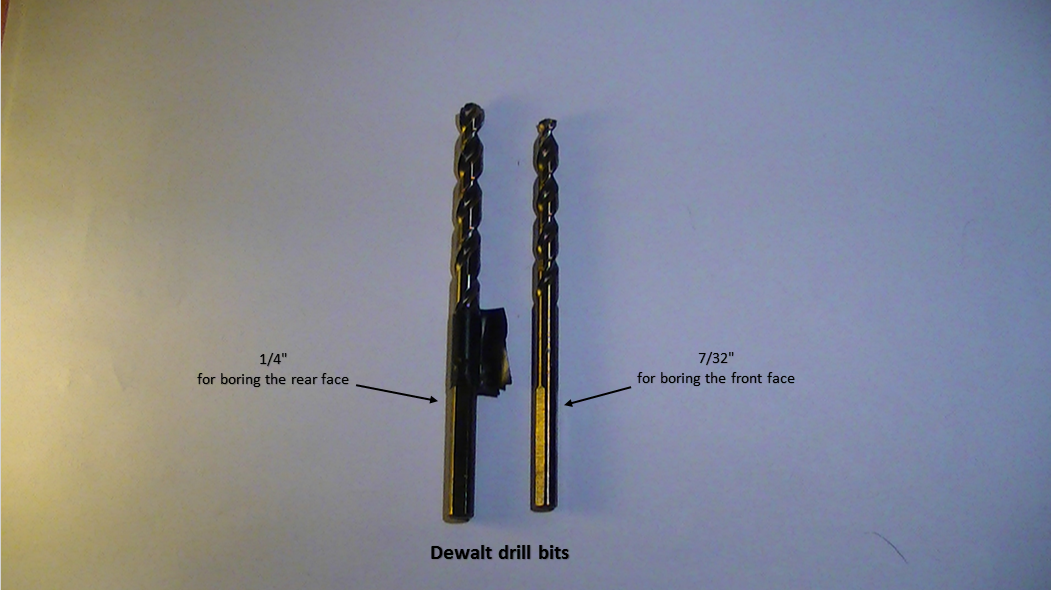

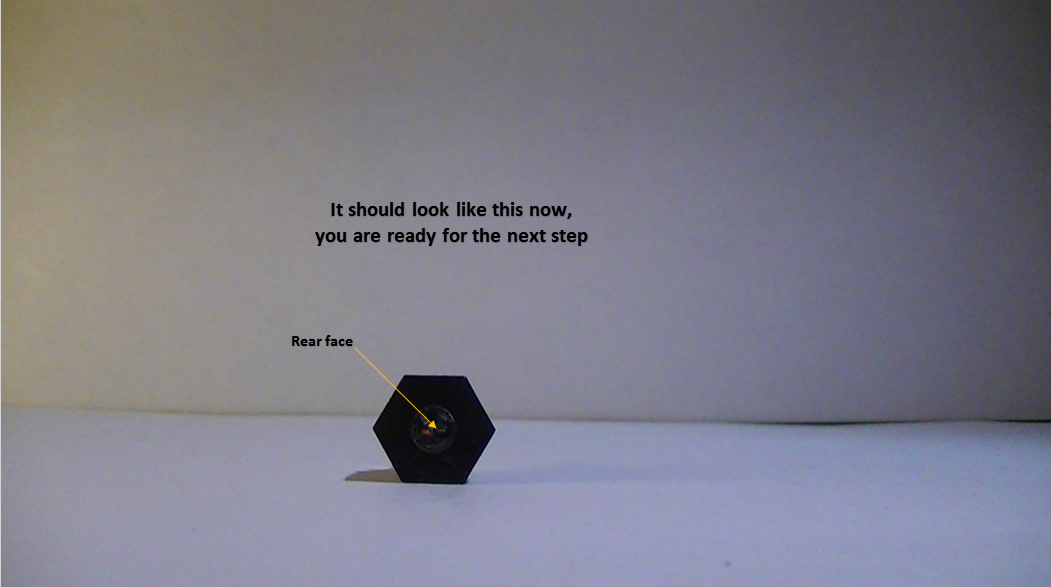

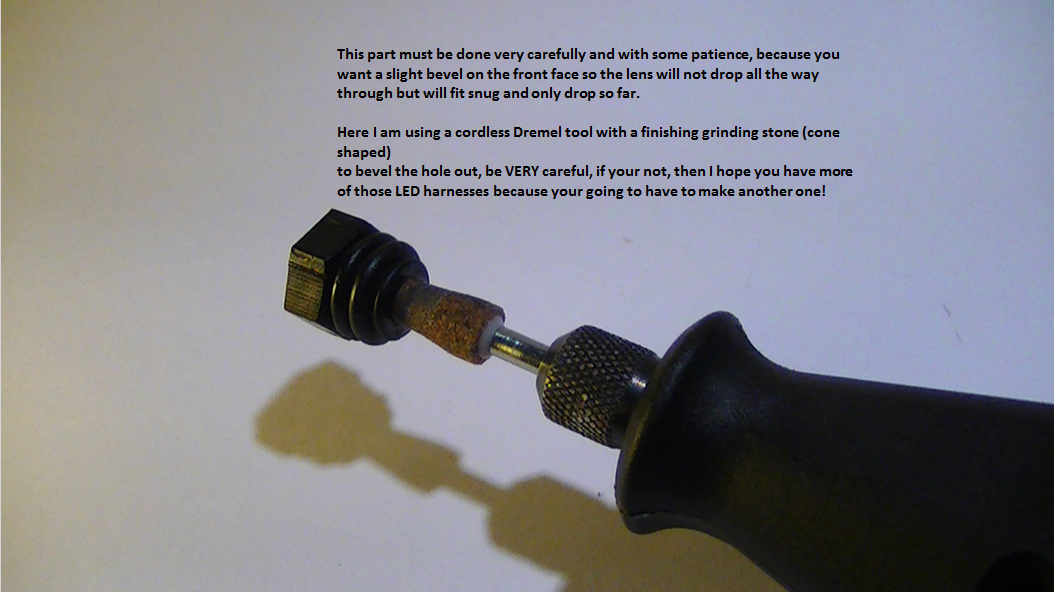

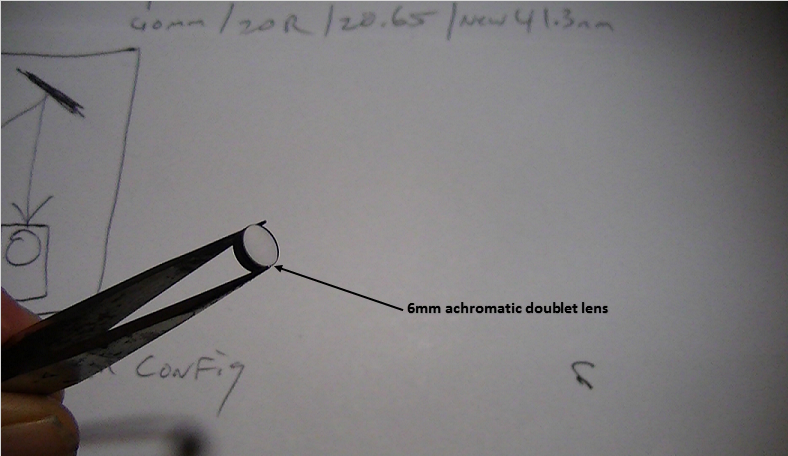

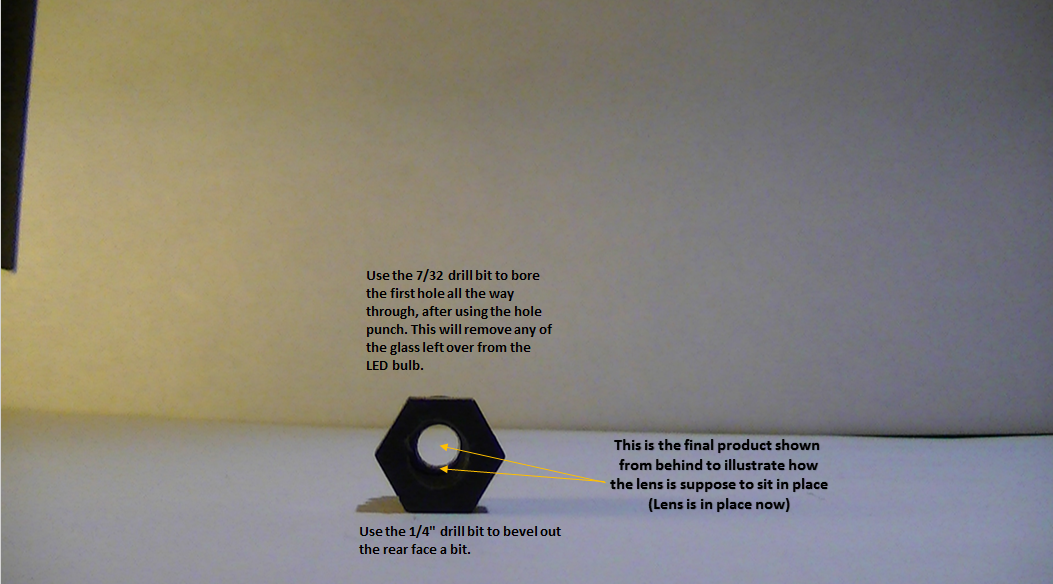

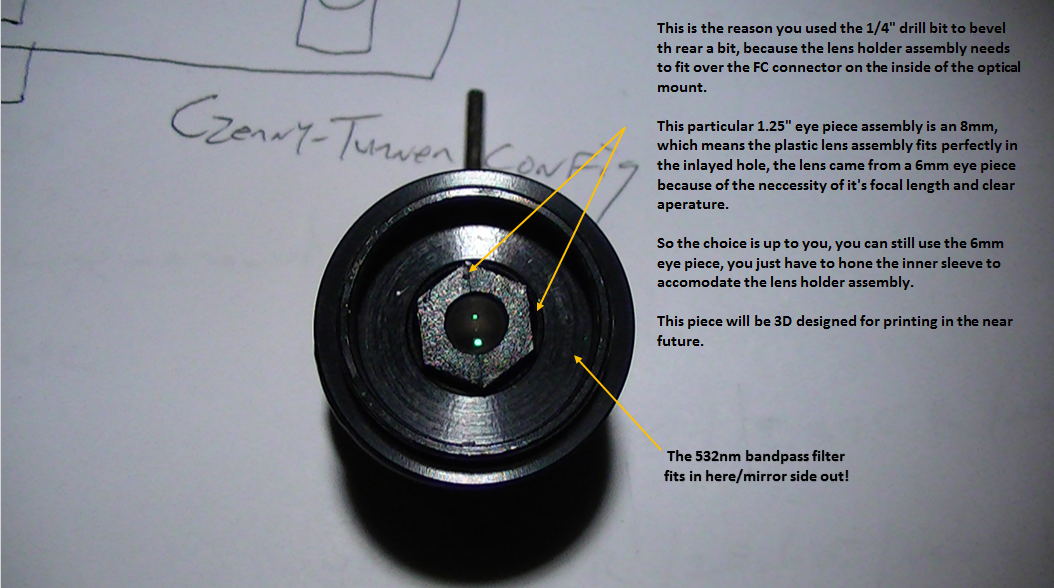

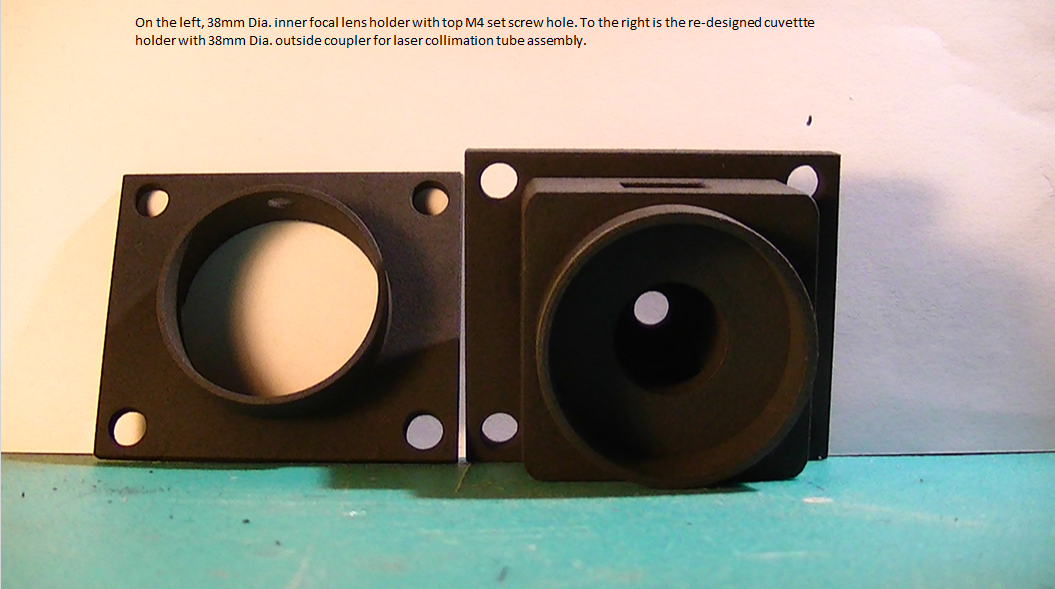

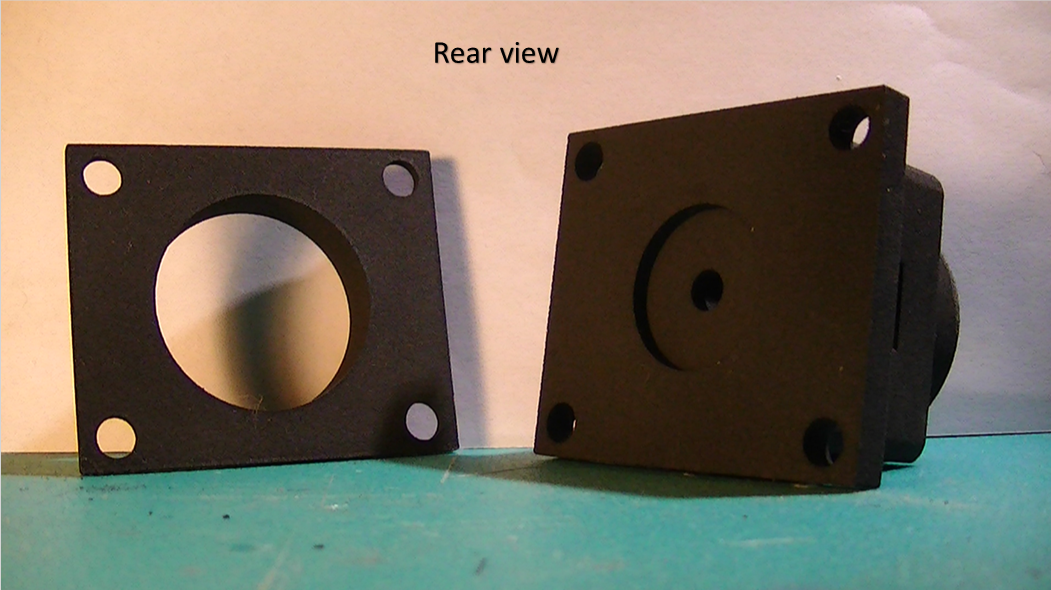

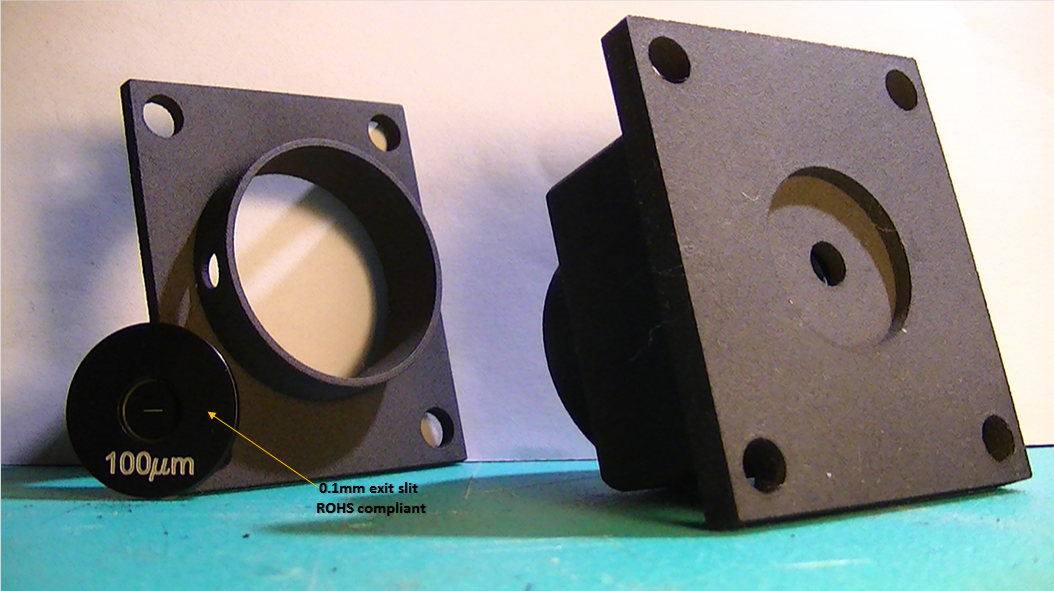

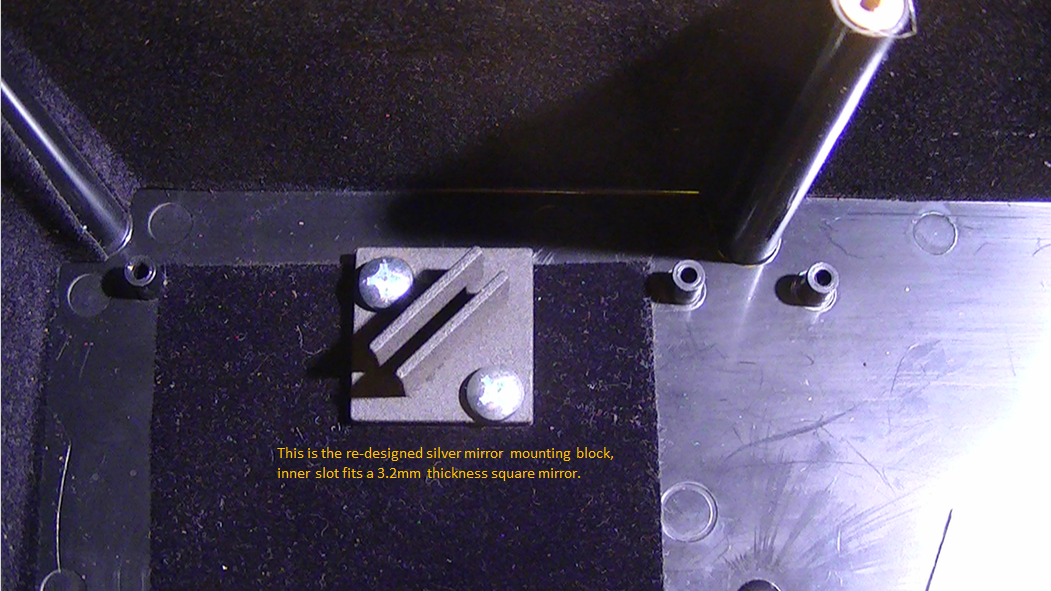

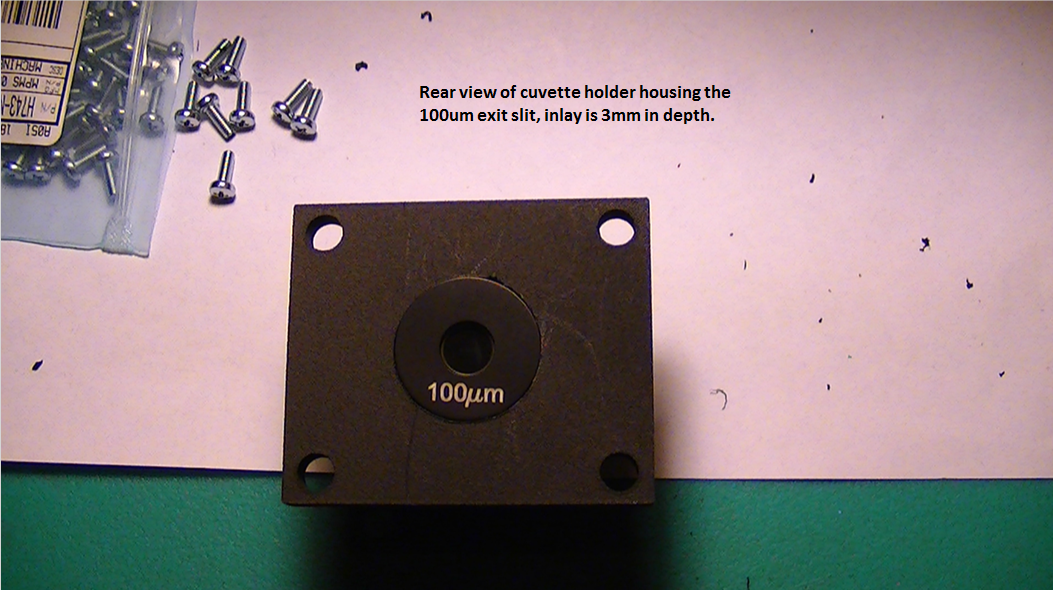

The newly re-designed parts came in so I began to prep them and wanted to include them here under build instructions;

The newly re-designed parts came in so I began to prep them and wanted to include them here under build instructions;

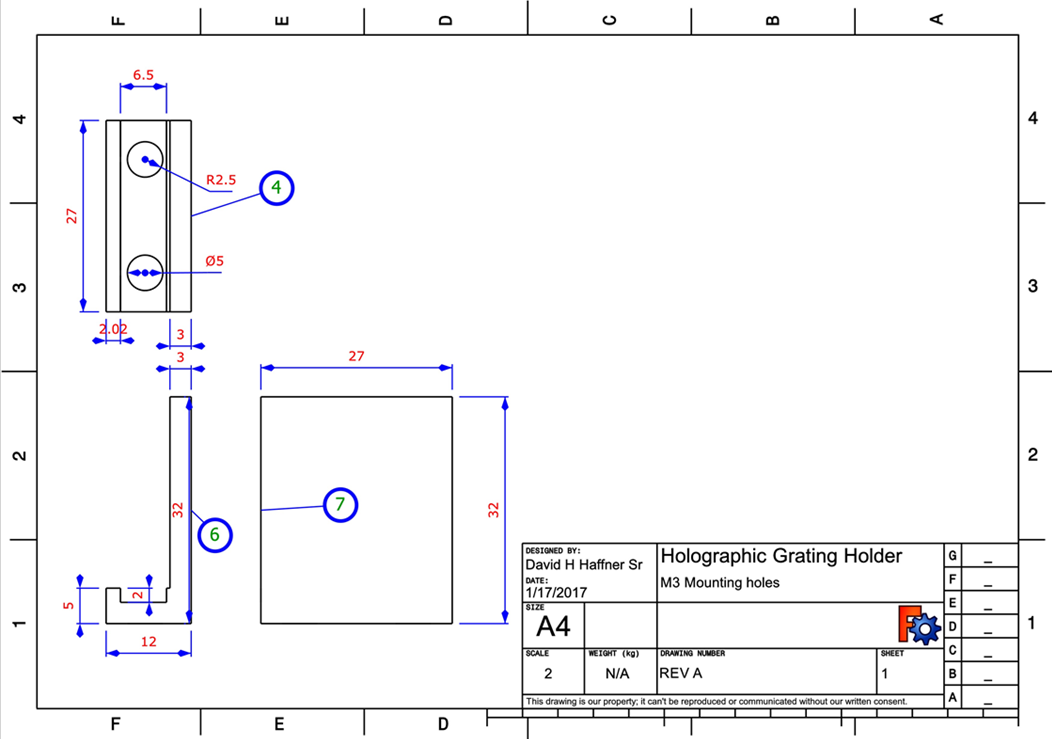

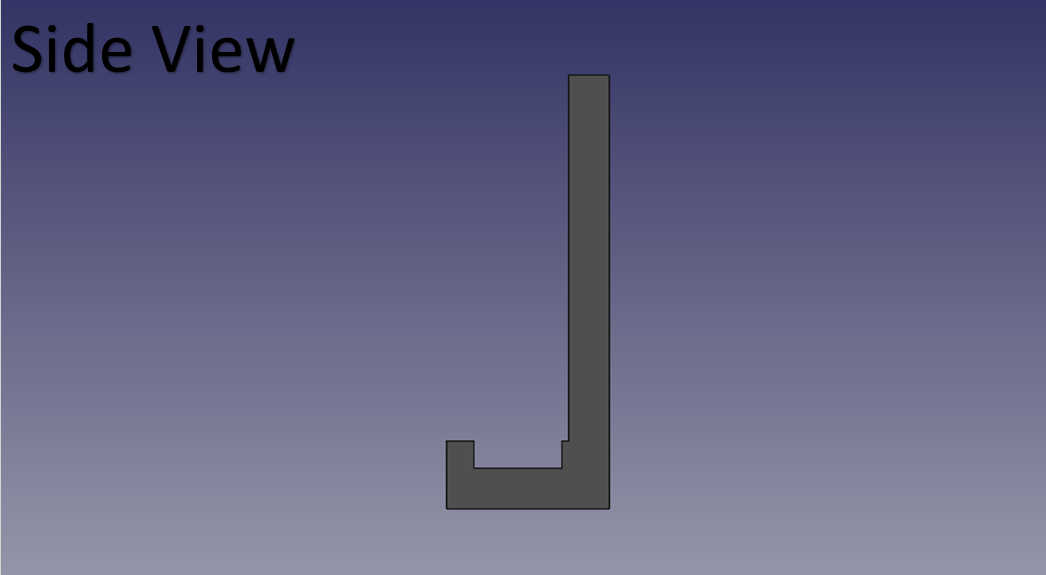

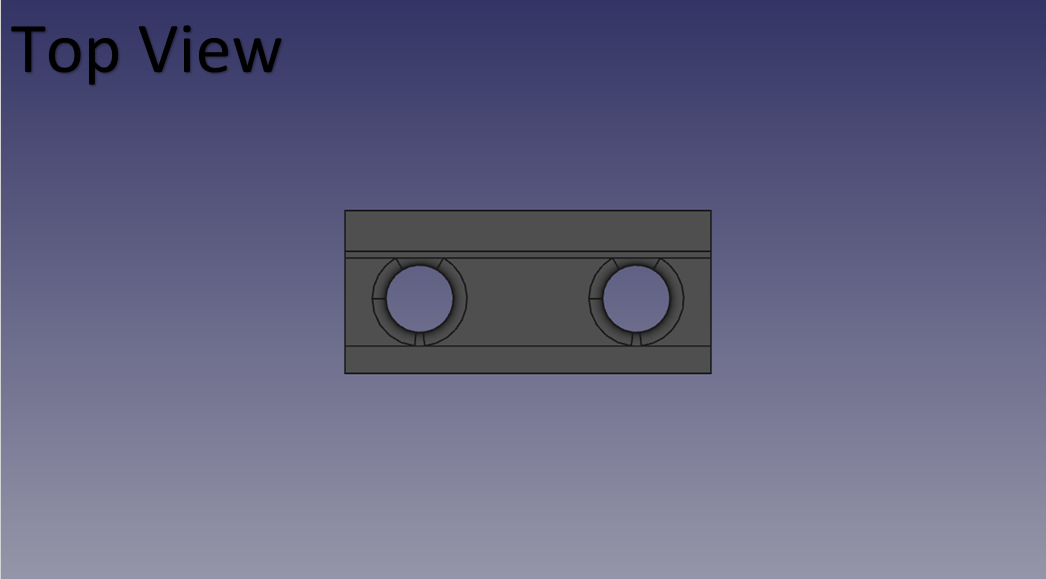

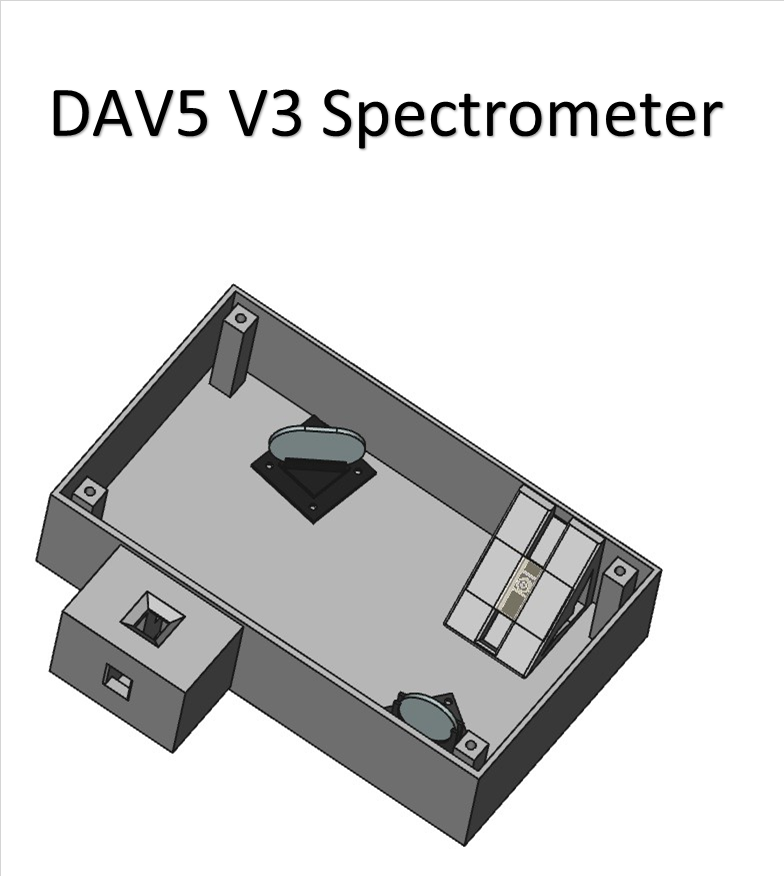

These are the first preliminary drawings and CAD blueprints depicting several aspects in the assembly design and by no means is this the final assembly steps;

These are the first preliminary drawings and CAD blueprints depicting several aspects in the assembly design and by no means is this the final assembly steps;

This is great! That too with 80% 3d printed objects!

Cool stuff sir!