It is a truth universally acknowledged, that every single gadget in the possession of this household must be in want of a consumable item costing a good fortune. For that we probably have to thank King Camp Gillette, with his razor-razorblade business model, which is also popular with inkjet printer manufacturers. The big money is in the repeat business of supplying consumables.

And who names their child “King Camp” anyway?

But we digress. The subject of today’s diatribe is vacuum cleaners.

Mr Gillette’s insidious business practices have ostensibly infiltrated this industry too. Our Bosch vacuum cleaner used a myriad of techniques and filters to purify the air it processes, culminating in an actual HEPA filter for final cleansing. All very civilized, until you need to replace one or more of these filters. Either you cough up a fortune, or you learn that you cannot find that exact filter anywhere. You can find other Bosch filters, but not the one you need, because your machine is several years old. Gradually it becomes clear that the intent is not any more to gouge you for a small fortune, but to make you buy an entire new vacuum cleaner, for an even less small fortune.

Which I eventually did, of course. But most definitely not a Bosch, to foster the illusion that I am an independent agent with free will. The new machine is a brute – a crude Hoover canister – with a multi-layer cloth bag filter which is not only fully washable, but, more importantly, I feel confident that I and my trusty Bernina would be able to recreate a reasonable facsimile of this bag if and when the time comes.

These tribulations and attendant tirades did not go unnoticed. As a result, last Christmas Stoffel joined the household, courtesy of our generous progeny. Stoffel (the name can roughly be translated as 'Dustin') is a robotic vacuum cleaner, and he has brought us much joy with his tireless rummaging throughout the house, fossicking under the sofas, bumbling his way back to his charging station, and occasionally trying to strangle himself with a loose cellphone charger, all in a patient and good-natured way.

Stoffel improved our quality of life. We were very glad to have met him. In turn we have tried to give him a loving home, for Stoffel, it turns out, is an orphan. Nowhere can we find out who made him, which of course means we cannot find spare parts either. And so – you guessed it – we are back to the perennial filter crisis.

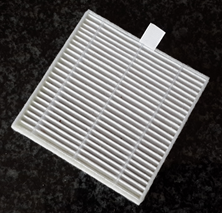

Stoffel uses a pleated paper filter measuring 80mm x 80mm (8mm thick), and nowhere on the world wide web can your humble correspondent find such an animal. In the box there was one spare filter - the first one is getting rather tired by now, despite regular cleaning using compressed air. The manual booklet also offers no clues: it simply calls Stoffel a Robovac, without any additional information regarding his origins, support infrastructure, or supply chain.

Luckily realizing in time that a replacement might be hard or impossible to find, I held off on putting the second filter into use. Instead, I printed a frame to hold down one of the currently ubiquitous disposable face masks in lieu of a filter, based on the following three premises:

- face masks are likely to remain plentiful for the foreseeable future

- face masks are supposed to stop all kinds of microscopic unpleasantness

- if humans are supposed to be able to breathe through these masks, then maybe Stoffel can too.

A test run confirmed that the mask filter indeed traps a gratifying amount of apparently superfine dust, in addition to the normal macroscopic debris which mysteriously appear throughout the house on a daily basis.

My primary concern was premise (3) though. How much does and should the filter restrict airflow? To test it I designed and printed a filter holder which attaches to a (full-sized) vacuum cleaner, to wit the Bosch bewailed above. The adaptor part, going from the square filter to a press fit onto the vacuum cleaner pipe, was printed using the ill-named ‘spiral vase’ or ‘spiralize’ mode, depending on which slicer software one uses. (Yes, there may be a slight variation in effective radius, but what the printer primarily does is to follow an essentially helical path. Like the thread on a bolt, which is also not a spiral. It’s a helix. But we digress yet again.) Although the printer nozzle is 0.4mm in diameter, I specified a 0.9mm extrusion width, and then, just for good measure, at printing time I dialed up the extrusion multiplier by another 20%, for an effective wall thickness comfortably exceeding 1mm. This results in a satisfyingly strong single-walled structure.

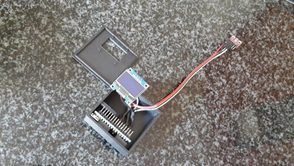

An Arduino Nano with a BMP280 pressure sensor and a 0.96” OLED display were mounted in another printed case, with power and I2C wiring as needed. Assembled it looks like this:

A USB battery bank supplies power to the barometer, and the sensor is mounted in the plenum behind the filter, where it can be used to determine the pressure drop caused by the filter. To reduce possible flow effects, the sensor is mounted approximately square to the expected air flow direction, to measure stagnation pressure. A test conducted without any filter installed confirmed that the pressure indeed remains essentially unchanged when the vacuum cleaner is switched on, with air streaming unrestrictedly into the funnel.

To simplify life, the Arduino code takes a number of ambient pressure readings on startup, averages them, and then subtracts the live reading from this startup reference, displaying the result on the OLED screen. This facilitates direct comparison between the pressure drops caused by the various filters.

Which brings us to the results: As can be seen on the image above, the original (clean) filter causes a pressure drop of 5.6 hPa with the much-maligned (now HEPA-filterless) Bosch mentioned earlier running flat-out. Out of idle curiosity I also blocked the filter end completely, registering a drop of almost 200 hPa, which the single-walled adaptor gratifyingly resisted without complaint. The vacuum cleaner, on the other hand, sounded unhappy, so I desisted after taking the reading. It needs the airflow for cooling too.

The well-used dirty original paper filter caused a pressure drop of 13 hPa; this is significant, as it means that Stoffel’s effective suction would be noticeably reduced. This is undesirable, for the air pumps in these autonomous vacuum cleaners are pretty puny at the best of times. Any additional reduction in suction should hence be avoided. While I expected a gradual degradation due to clogging, this was an unwelcome surprise, underlining the need for a plentiful source of replacements, because compressed-air cleaning clearly does not restore it to full flow. Another clue is its colour, which is an unpleasant shade of gray by now.

Then I tested the face mask filter, and found a pressure drop of 10 hPa. Not too bad – and if we could increase the surface area somewhat, it should be possible to approach that of the reference filter.

To achieve this a former was designed and printed, to force the filter into a pleated shape. The two halves are identical, for the sake of simplicity and elegance (also sometimes called laziness).

However, at this point things got complicated.

Because the original face mask filter was cut to size to fit the flat 80 mm square shape, I had to use a new mask, trying to eke out the largest surface area I could. This is when I realized (and in hindsight it should not have come as a surprise), that there is a huge variation between masks. To make a long story short - I was unable to find one behaving even remotely like the first one I tested.

Back to using the flat square configuration I then tested 5 different disposable 3-layer masks, registering pressure drops between 27 and 50 hPa – not one of them even close to the first one that I tried (and of course I do not know where that one came from - it has been that kind of year). At a local supermarket I at last found a sixth type which caused a drop of 5.2 hPa, so, for the time being, this is what Stoffel is using.

But of course there is more to a filter than just permeability: it should also actually trap dust (premise (2) mentioned above). But how much? That is hard to say. Anything is better than nothing, and Stoffel is perfectly happy to try and try again. Philosophically the main purpose of a vacuum cleaner is to clean the house, not primarily to clean the air, which is another way of saying there should be a balance between filter efficiency and suction power. There is no point in having a molecular filter without suction, while conversely one would not want to simply redistribute the dust either. For that we have a broom.

So now we need a way of testing the cleanliness of the air before and after, ideally even the distribution of particle sizes. Maybe one could use a particle concentration sensor such as the PMS5003 or PM1006, except that we live thousands of kilometres from the nearest IKEA. But, courtesy of a family member currently travelling in Europe, I now eagerly await delivery of a couple of Vindriktning air quality sensors, hoping that I will be able to figure out how to use it (and all the marvelous hacking of these devices reported on this site) to devise a test to assess filter efficiency. Some compromise is needed, and to assist that decision, more data are needed. (Yes, are, because I am in that kind of mood right now. Hopefully I shall feel better once the Vindriktnings arrive in a few weeks’ time.)

Final thoughts:

The results obtained thus far seem to indicate that one does not really breathe through many masks; instead, you breathe past the mask, over your cheeks, or worse, over your glasses, as many of us have experienced. At least the mask, if worn correctly, should intercept most bodily fluids and similar ejecta, which is its primary purpose, we are led to believe. So kindly keep on keeping on. In the meantime the search continues for the perfect mask, while I inexplicably provoke disparagement and vilification by submitting these preliminary results and musings to the world, in the hope that it may help, amuse, or inspire others, as it has me.