Okay, so I want to build a tracked robot. But to begin I need to know what length the tracks will be! I've got an idea of proportions and shape, but having the dimensions of the tracks lets me adjust wheelbase, wheel diameter accordingly. As I won't have any custom made tracks (remember, affordability is key for this project) the first thing I would do is find some. I'm thinking something along the 800mm length. I have scoured the internet searching for cheap tracks for robotics applications such as this one. Of course, there aren't any! But seriously, some online shopping sites didn't show any relevant results, and the findings I identified as useful were usually expensive products. I wanted the tracks to be rubber, but was open to finding a chained track and going with it.

As getting actual tracks ain't easy, that got me thinking. How can I make them? So I began searching on how to make rubber tracks and some special compounds were needed, etc. But then thought, is there anything similar to tracks? Yes! Toothed belts! Don't even bother to say they aren't the same, but a toothed belt is similar enough to me, I hope it works.

Disclaimer: I know nothing about tracks.

Finding some of the right dimensions wasn't easy, but I came across a specialized belt store that offered to cut a very wide belt into thinner sections. Time to pay came and, who could've thought, belts aren't cheap either! But I paid around 50 USD for two belts of 30mm width and ~1m length.

So having these, I could start the design.

The wheels

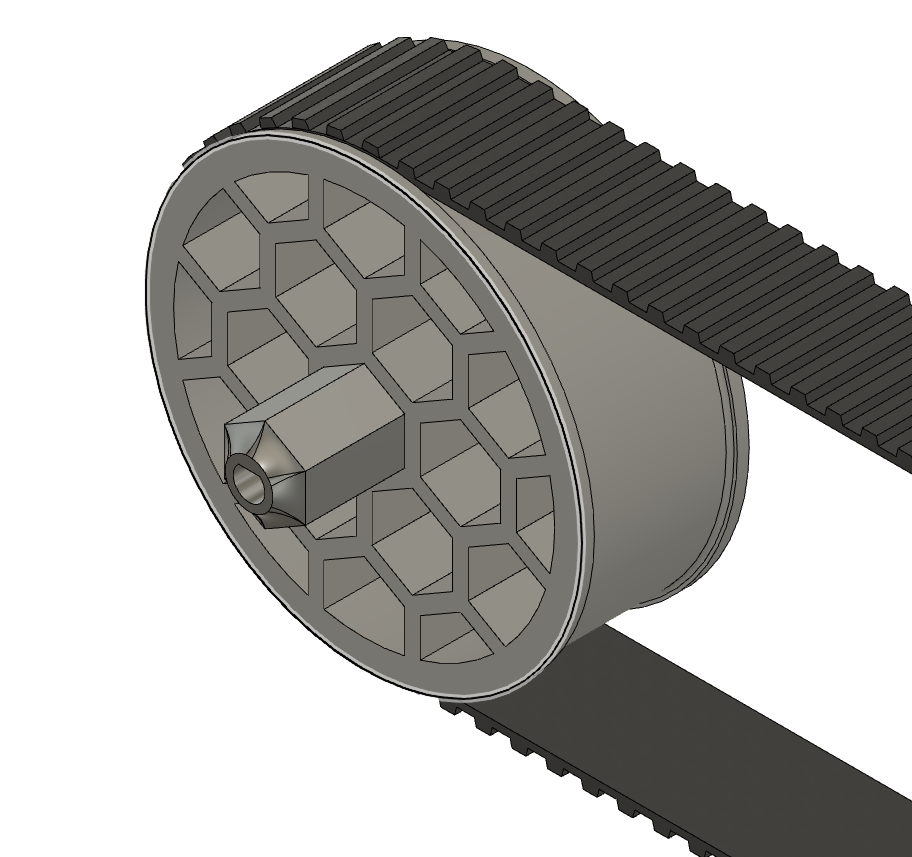

I went for two big wheels on each side. Traditionally, tracked vehicles have multiple wheels for each track, and they have different purposes. I didn't want it to look too militar-ish, and perhaps adding more wheels means adding more axles and a more complex design. As to the design of these, could've gone solid, more of a car-styled look or...who doesn't think honeycomb (or hexagon) wheels are cool?

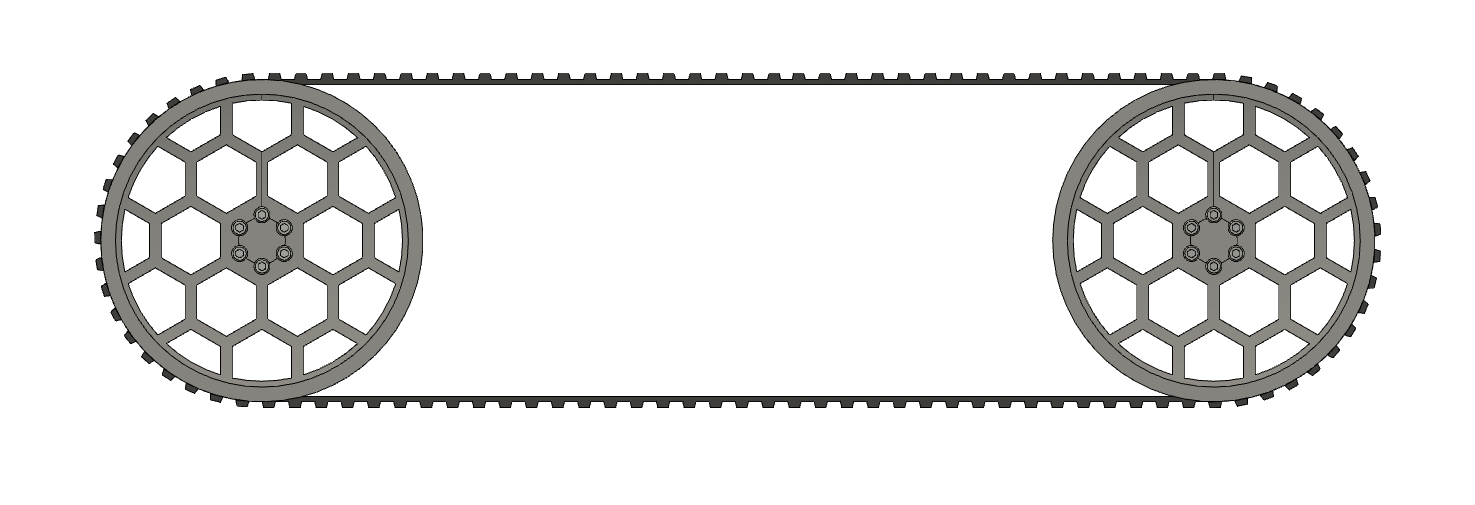

The track was modeled as a solid, to help calculations of wheel separation and obviously help design completeness.

As for the axles, I intend to use some old printer roller axles that are conveniently 8mm in diameter, which is almost perfect fit for 608zz bearings. Will have to cut them into the proper length and probably file a flat surface for spin locking with the wheels. I wanted to be able to remove the wheels without removing the axis, so came up with an interface that will be pressure inserted with the steel axis and the wheel will be removable with some screws.

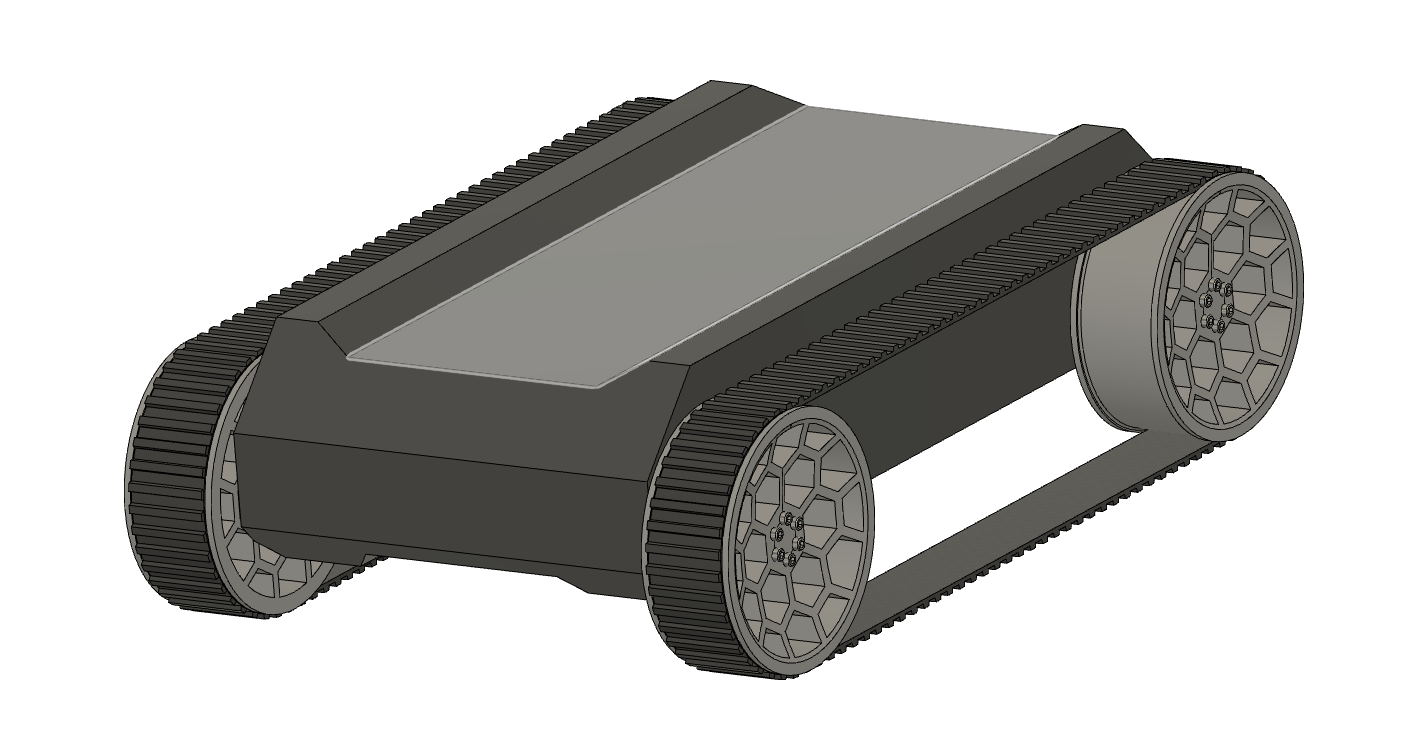

The body

Body-wise, the intention was to create something futuristic looking, or at least, modern looking. Design is going more and more into the strong lines and edges in many industries. I didn't want to disappoint.

Next, I will make a shell out of the solid body, and begin designing the interior to hold all the components. I'll probably go crazy and change some of the current design, or add more detail on the outside, we'll see.

Maximiliano Palay

Maximiliano Palay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.