Here are some pictures of the water system:

- Deionization Filter for making the water less conductive

- Some filters in different sizes for testing

- They are used to keep the water in the reservoir clean

- Whole water system

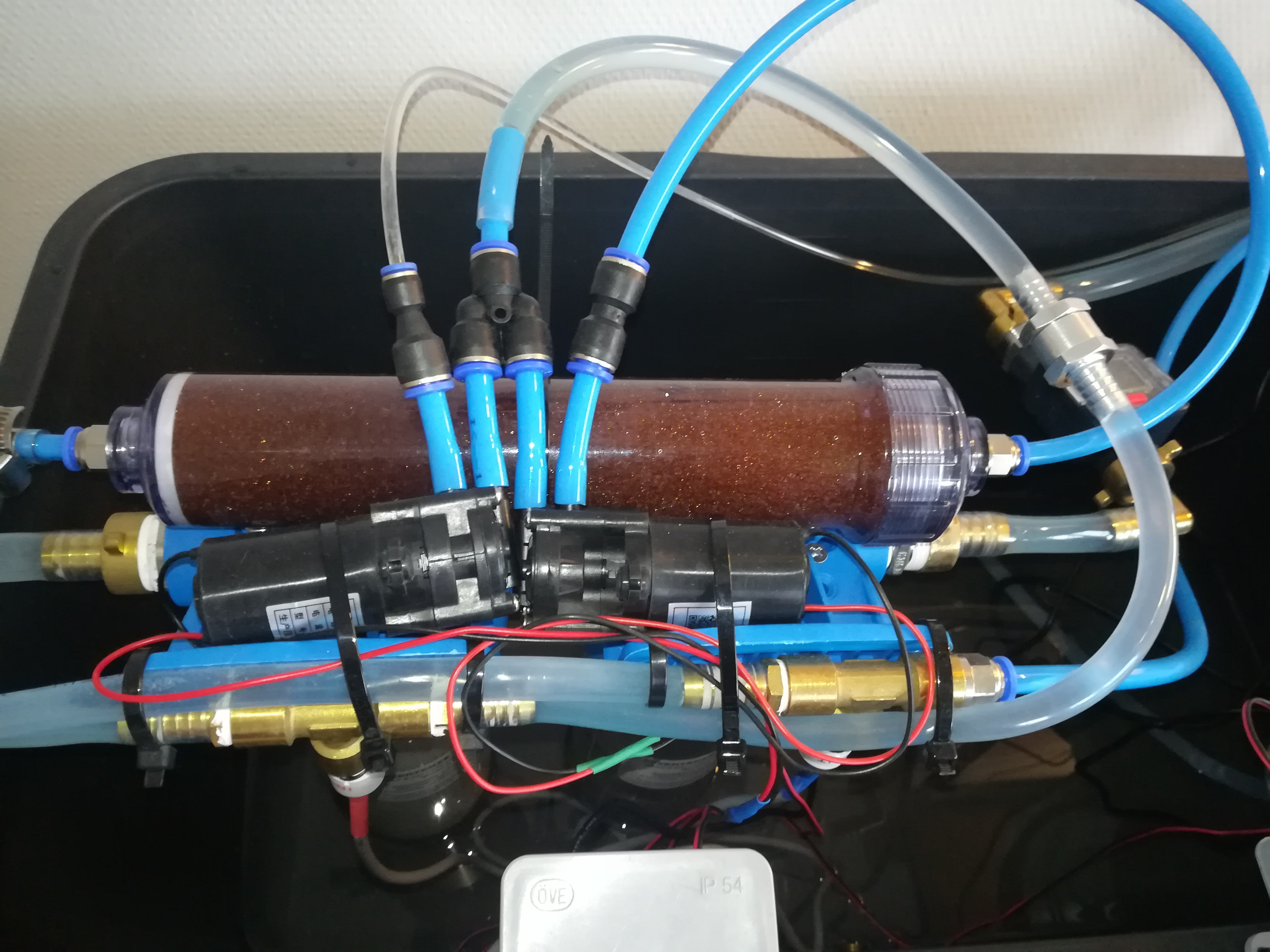

- The lower container is filled with clean deionized water and contains an aquarium pump to pump the water through a filter

- Aquarium pump

- Outlet of the DI filter (blue tube)

- The outlet of the cleaning filter and inlet of the gear pumps with a petrol filter and a weight on it

- Tube from the upper container to the lower container

- The upper container is used to store and mount the most parts and also to collect some of the dirt from cutting that settles down on the ground

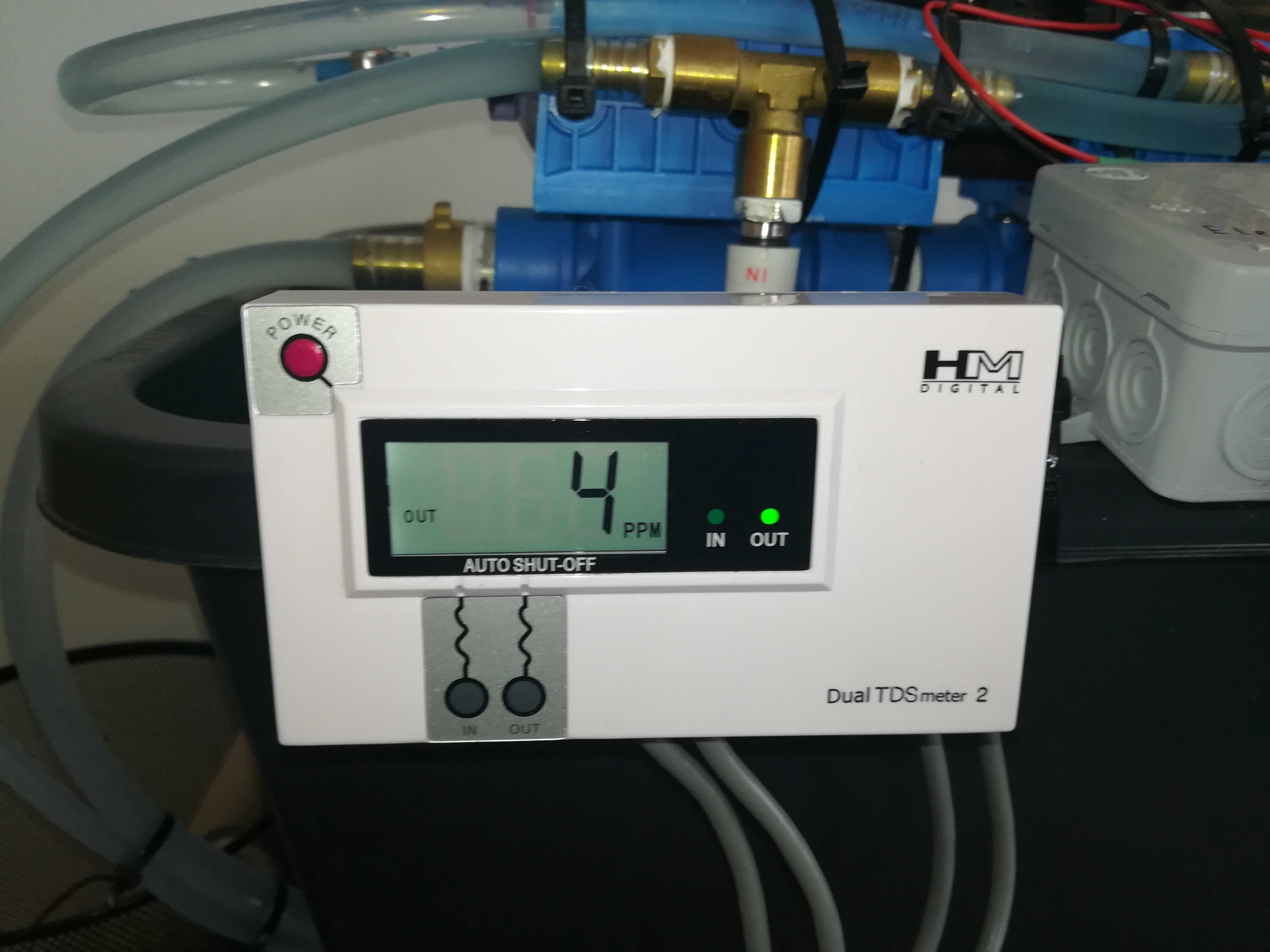

- TDS Meter to measure the conductivity on the in and outlet of the DI filter

- To check the conductivity in the system and check if the DI filter needs to be replaced

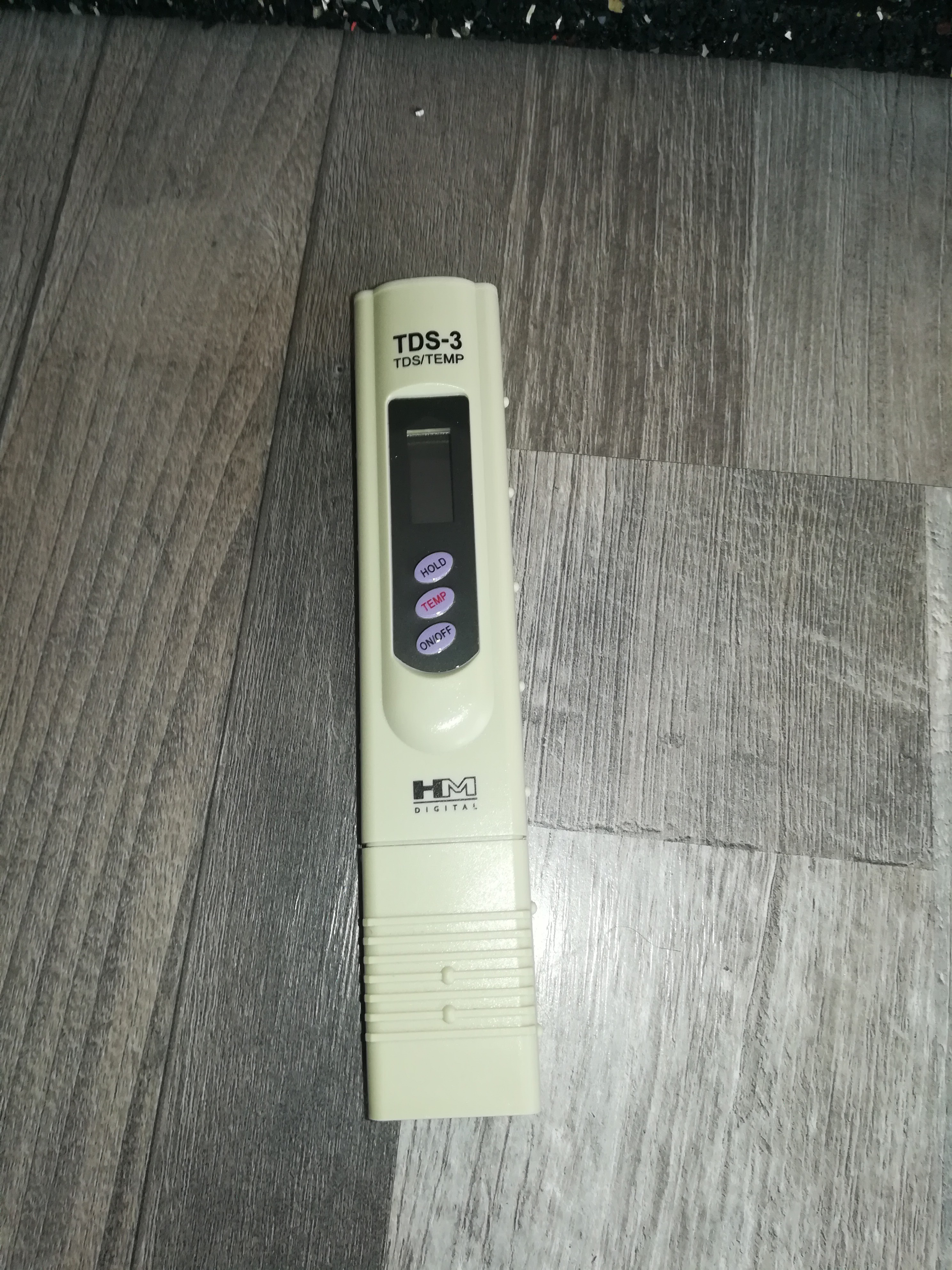

- Hand TDS Meter

- Conductivity at the EDM machine

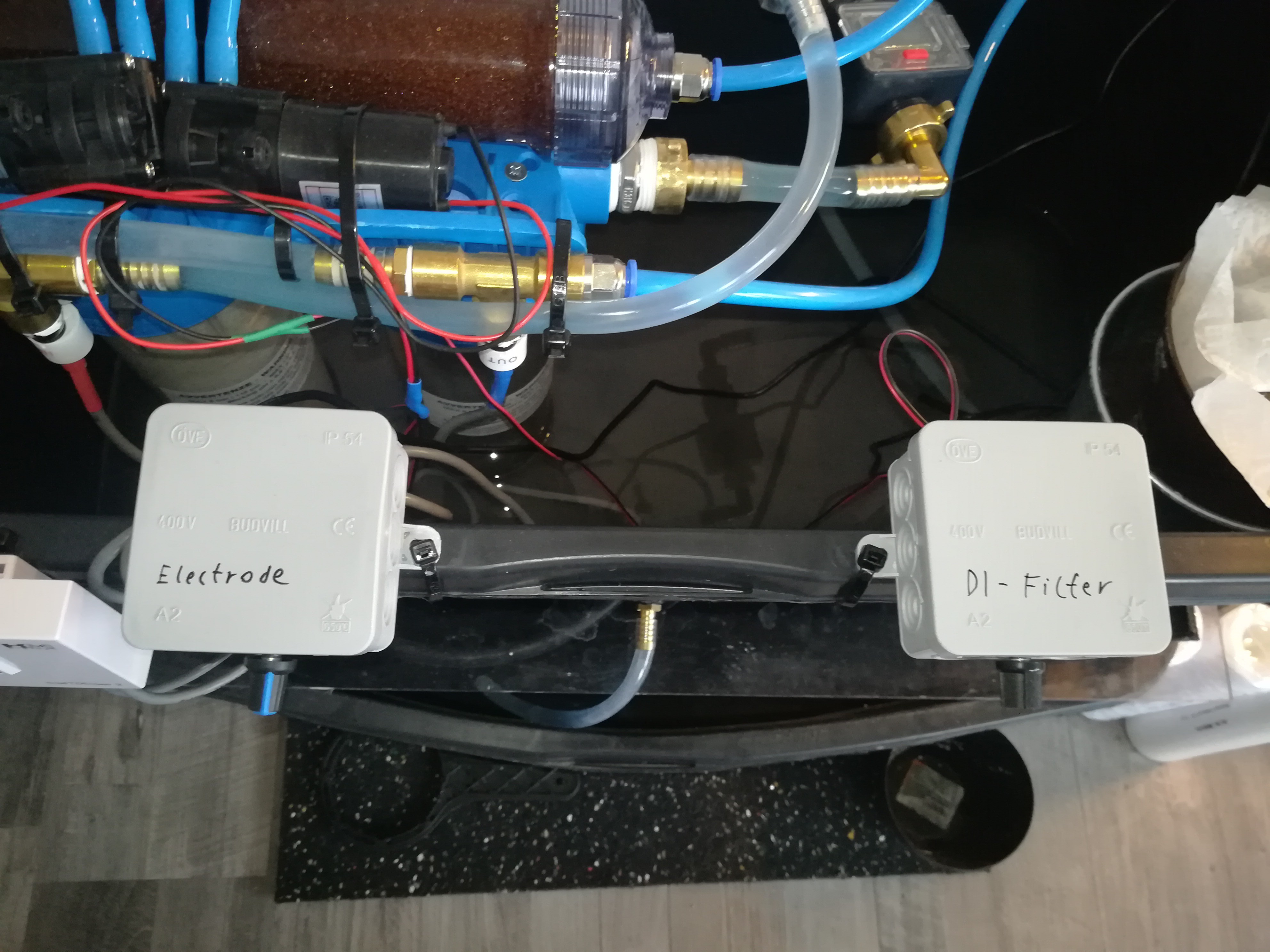

- PWM controllers for gear pumps to control flow through DI filter and to the electrode flusher

- Gear pumps with common inlet and check valve. Because for the DI filter and electrode flusher a higher pressure is needed than aquarium pumps can provide and because diaphragm pumps are too noisy, I choosed gear pumps for this.

- DI filter

- TDS sensors on in and outlet of the DI filter

- Everything is mounted on top of the cleaning filters

- Cleaning filter

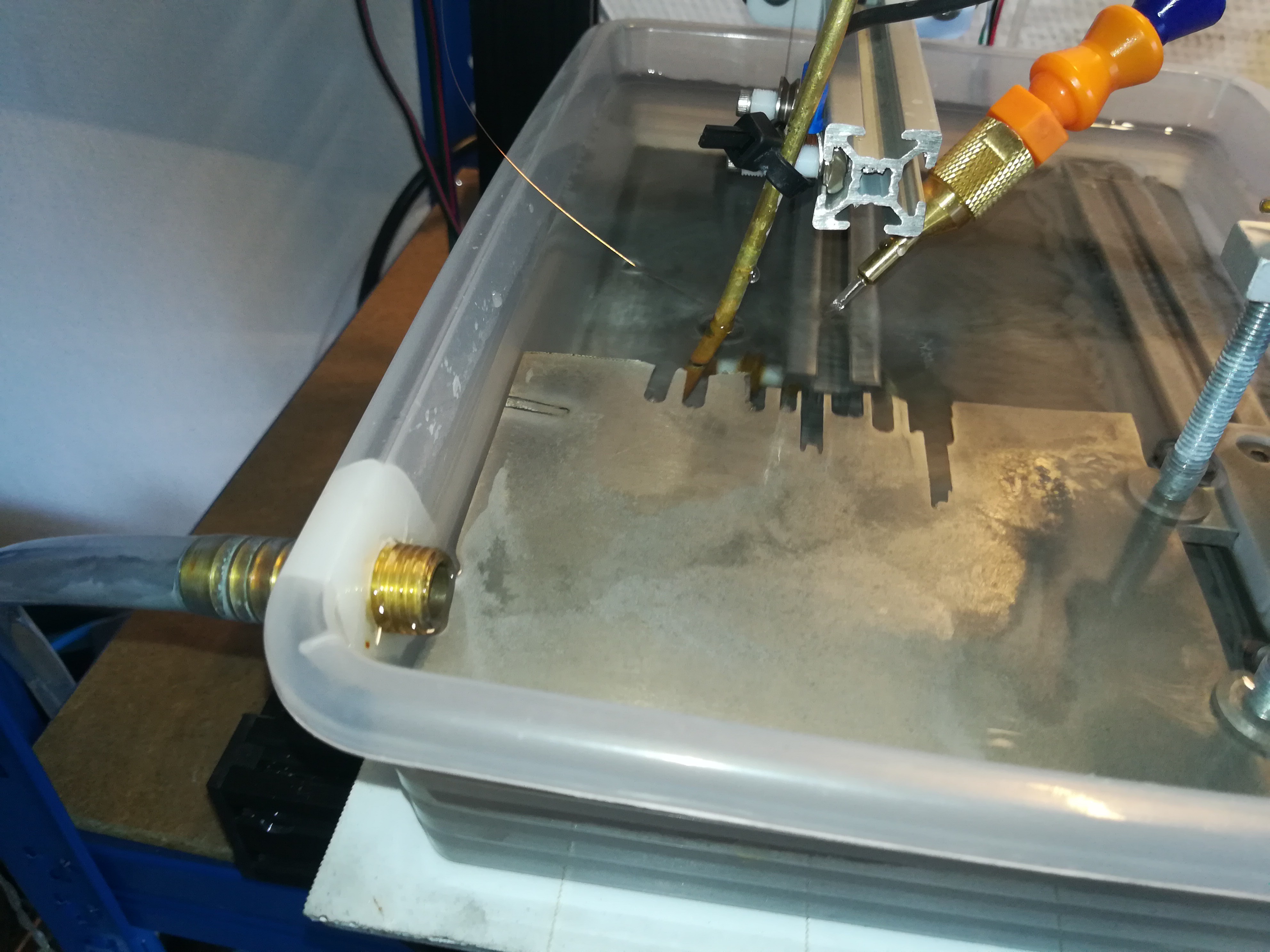

- Outlet of the EDM machine with weight

- I used paper towels to filter out most of the dirt, but while cutting they get clogged very fast.

- I think this needs an improvement, maybe some sort of continuous paper roll that slowly rolls under a waterfall into a waste bin.

- Inlet from the reservoir to the gear pumps

- The right pump goes to the DI filter

- The left pump goes to the electrode flusher

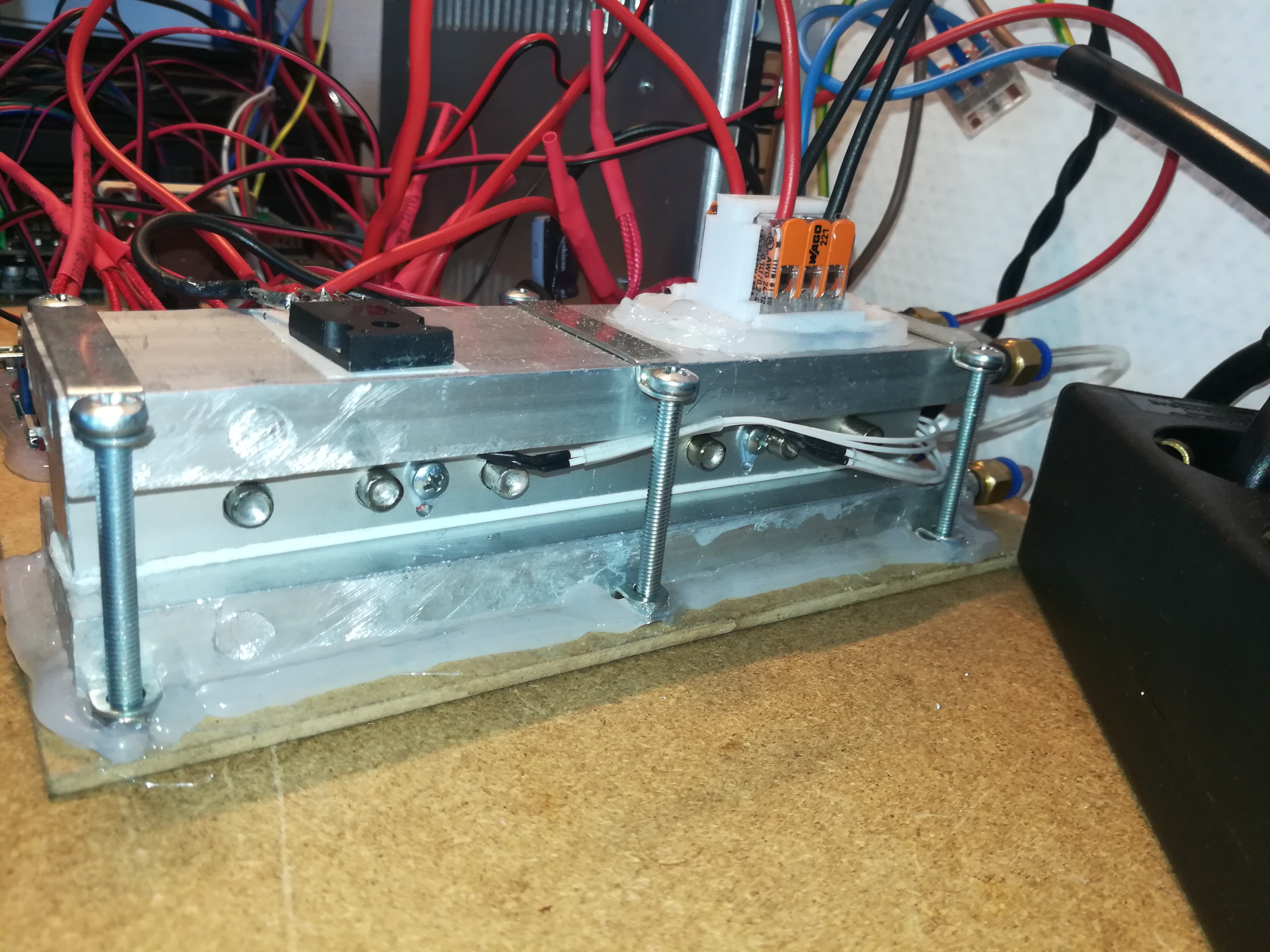

- Here you can see the cooling block for all parts that will heat up during cutting. It is placed between the gear pump and the electrode flusher

- Between two cooling elements there is an aluminum bar in which six 12V 40W heaters are placed, that are used as resistor for the arc generator circuit

- There is also a IRFP260 MOSFET placed on top of it, also from the circuit

- The temperature of the cooling block is measured with two thermistors for redundancy

- In the rare case that the cooling should fail at the time when there is a short on the workpiece what would lead to overheating of the cooling block after some time, an emergency stop would be called that would cut off the power to the arc generator circuit.

- Electrode flusher to flush out the dirt from cutting

- Outlet of the EDM machine that leads to the paper towel filter

So, that's the water system that I use for testing at the moment.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.