This is just a fun project that I am doing for the fun of it so there have been several FAILs along the way as nothing is planned out.

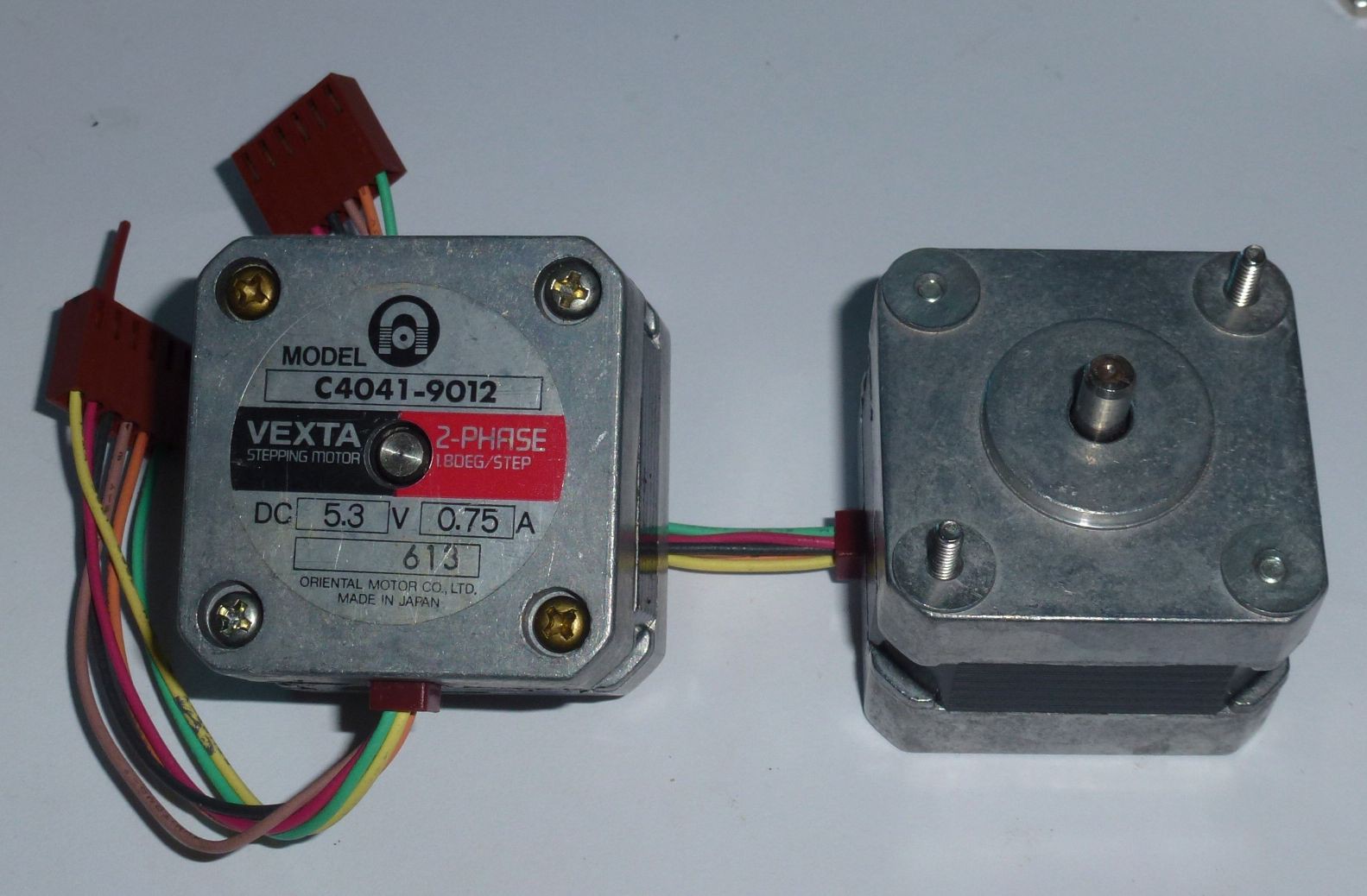

First I started by using some very small NEMA 17 steppers I had lying around -

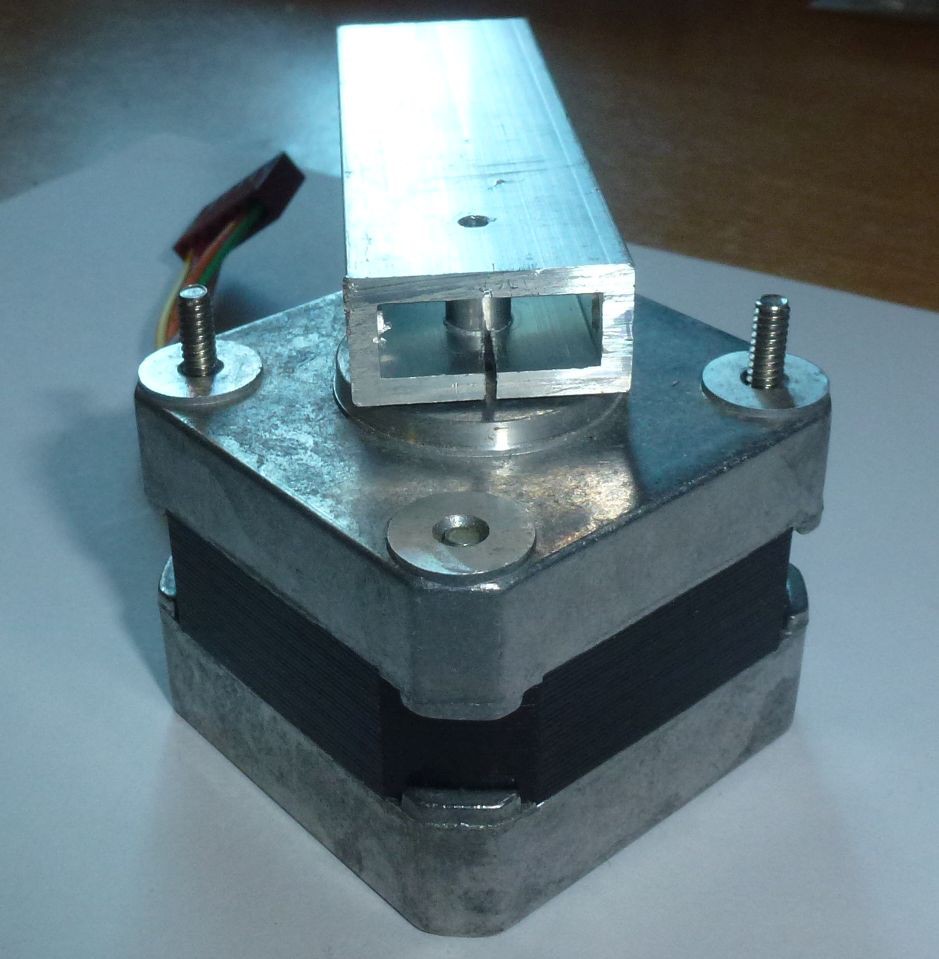

They have very short output shafts so I attaches the arms like this -

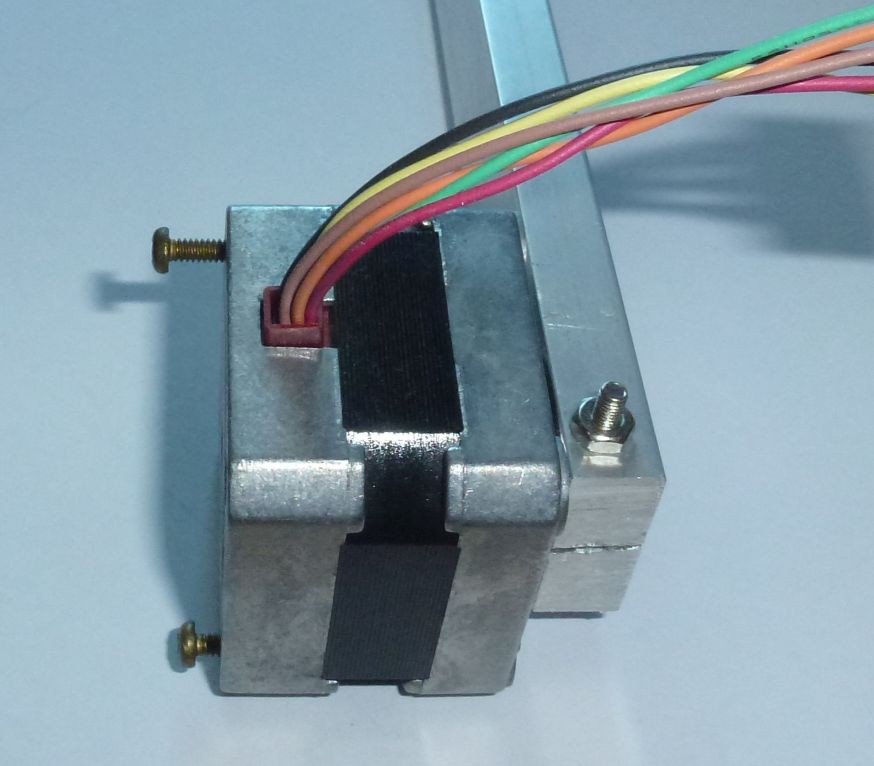

I did have screws to tension the box section to the shaft but it wasn't good enough and the fitting was sloppy because the shaft didn't go through both sides of the box section.

Plan 'B' was to use solid arms instead -

That solved the issue with the 'play' in the connection but now the motor didn't have the strength to lift the solid aluminium arm.

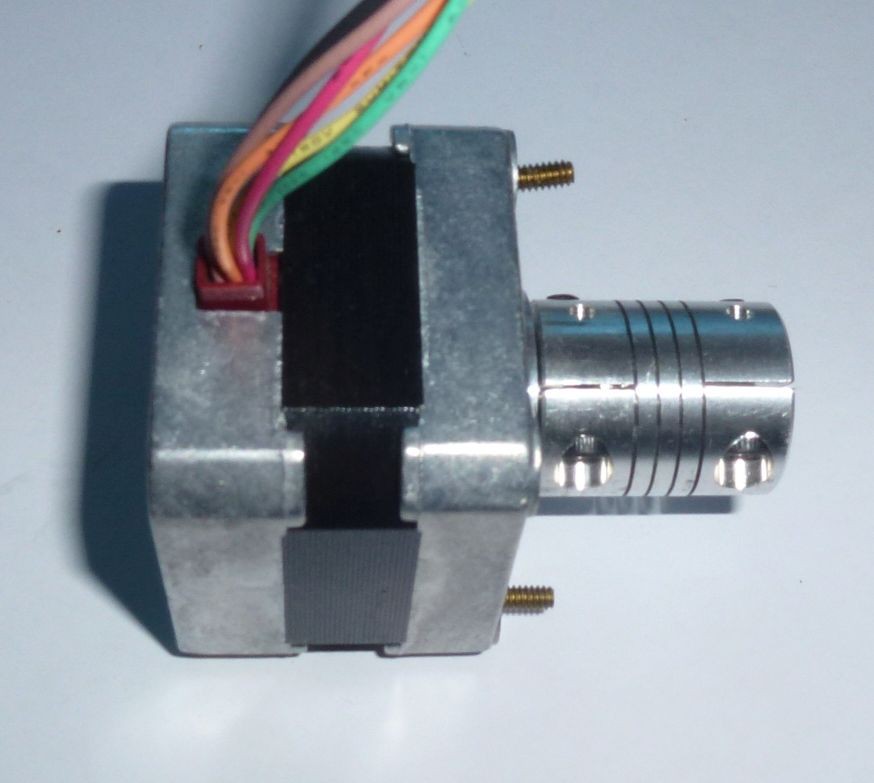

Plan 'C' was to use a coupler and separate shaft and bearings with the hollow box section, I don't have a pic of the bearing box -

This actually worked to my surprise. The coupler absorbs the force and applies gradually so that the motor overcoming the momentum. Without the coupler the stepper can't over come the momentum of the long arm.

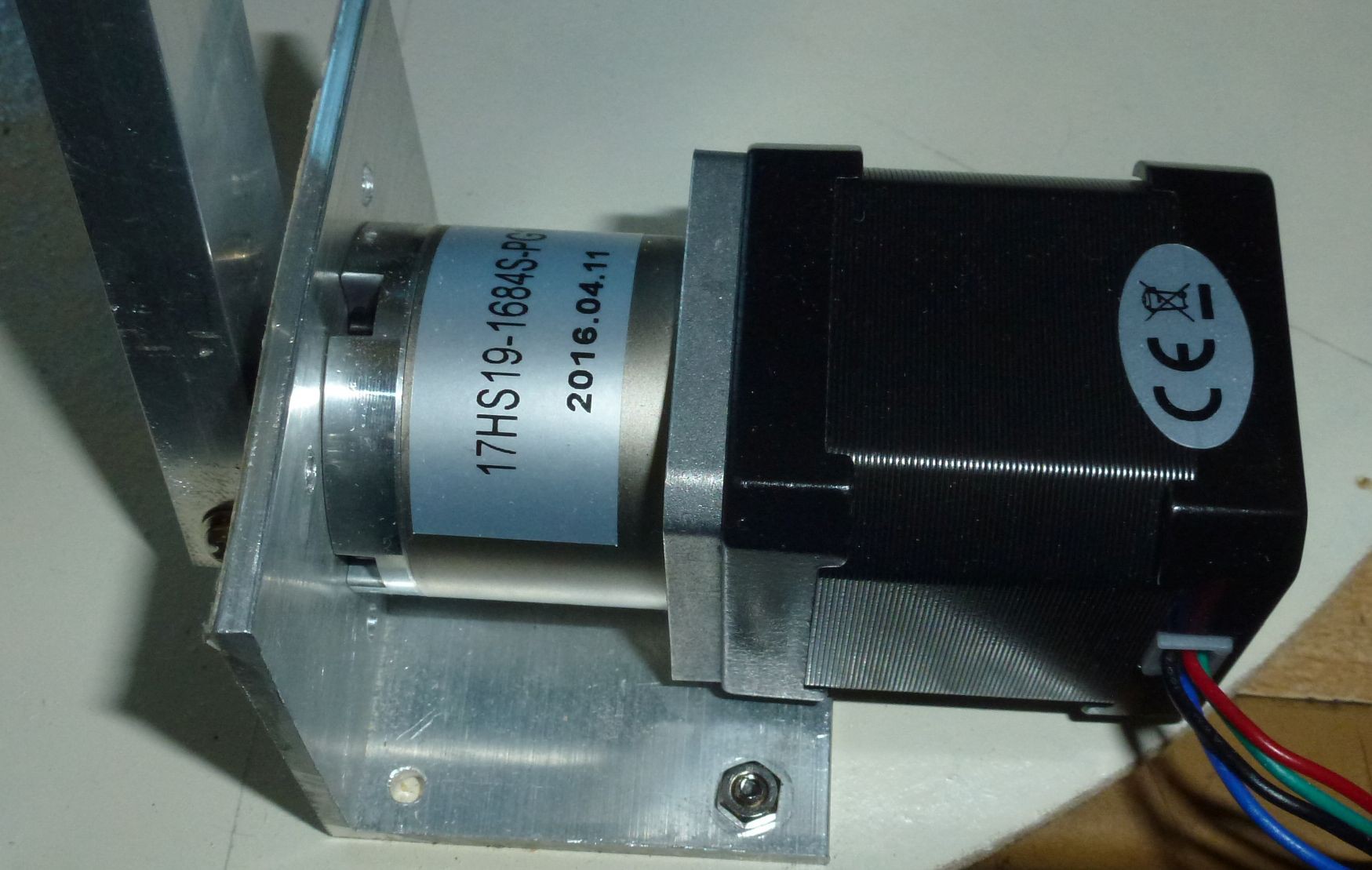

Well dammed if I am going to make 3 custom shafts on bearings so I went with these motors from ebay -

They're a NEMA 17 1.8°/step, 200 steps per revolution for the stepper, with a 14:1 planetary reduction gearbox giving me about 2,800 full steps per revolution on the final out put shaft.

I am hoping this is problem solved *but* I have noticed some play (not backlash) on the final output shaft so I may end up having add a separate shaft on berrings anyway.

Hacker404

Hacker404

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.