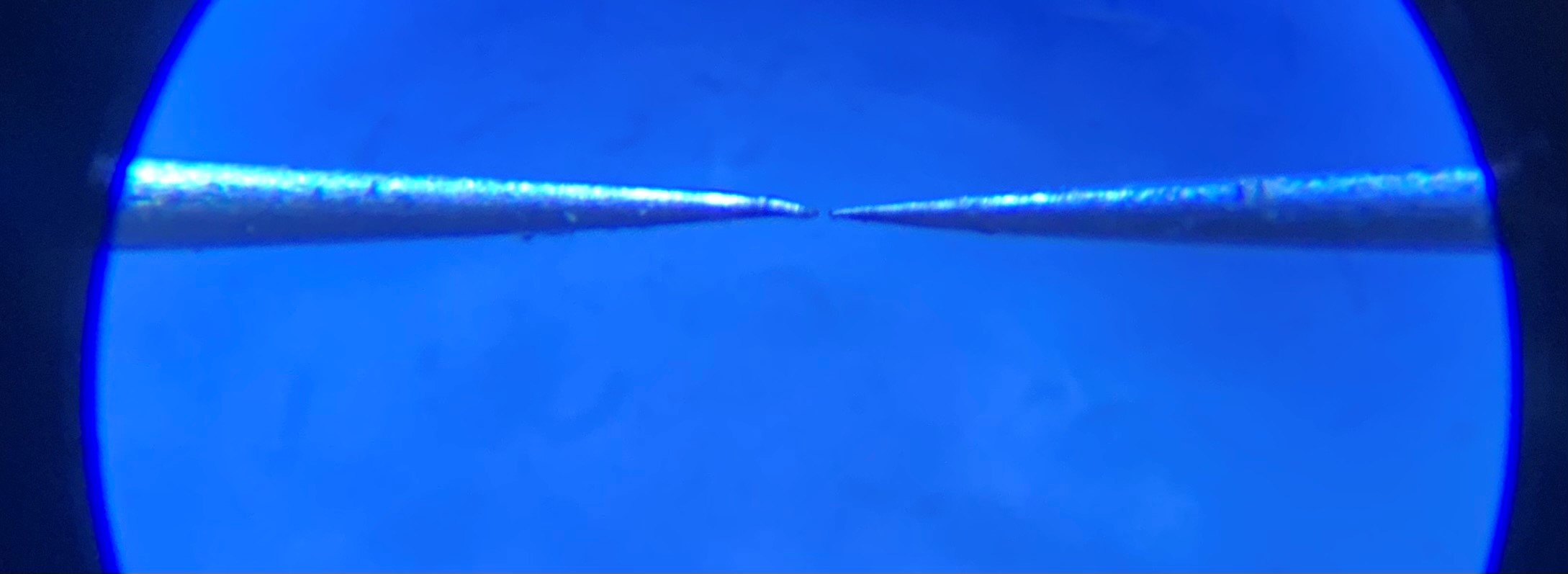

I really wanted to demonstrate the FLAG powering loads other than fluorescent light bulbs, so I set about getting it to light up LED's. LED's act a little more like a direct short across the generator output terminals, so it is necessary to put them in series with a spark gap so that there is enough load on the generator to keep it operating at high voltage. There have recently some interesting publications about using very small spark gaps to improve the performance in electrostatic harvesting systems (Plasma Switch), so I ordered some ultra-fine tip tungsten needles (0.6 µm radius tip) and machined a mount for them out of nylon. Under a microscope I carefully adjusted the gap, and I have been using this spark gap to light my LED's ever since (picture below). Prior to doing this, I have used a much more ordinary spark gap using a couple bolt heads, and it worked fine as well. In case you're wondering why one of the tungsten needles is a little bent in the below photo, I accidentally dropped it while putting this together, and had to straighten it again. When the FLAG is lighting the LED's through the needles, you can see a nice glow emanating coming from the tips.

Here is a picture of 98 ordinary LED's being lit in series (blinking at about 10 Hz, partial brightness). This was my first attempt, so I do not know the maximum number of LED's that can be lit in series with a FLAG:

Stuart MacKenzie

Stuart MacKenzie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.