The idea for this project first started after seeing a demonstration of a Wimshurst machine, a type of rotary electrostatic machine known as an "influence machine". These machines use electric fields, not friction, to generate electricity. It might be easiest to think of these machines as charge copiers. Starting with whatever tiny charge imbalance there is between two conductive "sectors" when they are close together, the sectors are physically pulled apart from each other, causing the capacitance to decrease, and the voltage to increase. The higher voltage makes it possible to move the charges around, and with at least 3 sectors and by repeating the motion, there are switching operations that can be carried out that will copy the charges over and over, until the machine is operating at thousands of volts. A description of the design and operation of the Wimshurst machine can be found here: Wimshurst machine - Wikipedia, though the electrical circuit used on the latest FLAG prototypes is more similar to a machine called Wilson's Machine, or another one called Bennet's Doubler.

Virtually all the historical electrostatic influence machines were invented in the late 1800's or early 1900's, and the invention of today's common electromagnetic generator quickly made them obsolete. They were mostly made of glass, and since that time, plastic materials with superior electrical performance now existed.

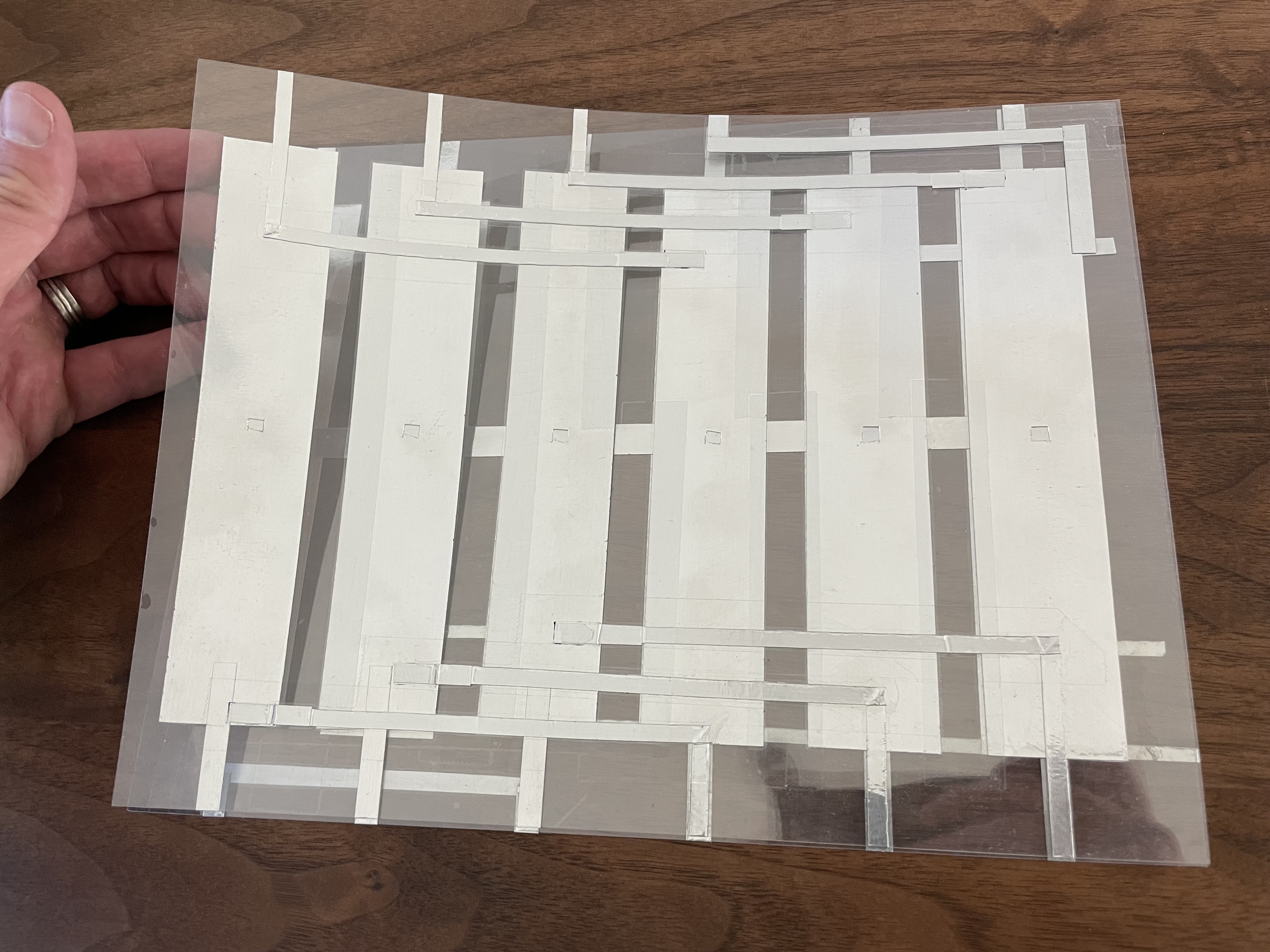

I was very interested in wind energy, and it seemed to me like it might be straightforward to make a linearized version of the Wimshurst machine into a new sort of wind generator without many parts. I imagined this a little like unwrapping the two plates of a Wimshurst machine into straight lines, and that the two layers could flutter against each other in the wind in a wave-like motion to make electricity. I proceeded to make many, many failures, from approximately the years 2000-2005 before focusing on a family generators that looked like the one shown below. These were being made using polyester transparencies, and hardware store aluminum foil tape.

It has multiple sectors, cascading switches, and grounding on the inside in the center. The sectors naturally each charge to the opposite polarity of the adjacent sector, and a rythmic wave motion would cause the machine to accumulate charge, until crackling with arcs and the smell of ozone! The machine electrically worked very well if you were to make it move by hand (and it delivered some nasty shocks), but I eventually ran into a few problems that seemed insurmountable. As a separate effort, I was trying to get the required motion from two layers of film in moving air using a shop blower at my workplace. The two layer design had a rather weak and unreliable reciprocating motion, and the surface contacts would not work reliably like this. Electrically, this design also didn't work well in humidity, and it became obvious it would never make any electricity from the wind this way. At this point I was getting married, moving houses, and starting to have kids. The generator project was packed into a box and went to sleep for a few years...

Stuart MacKenzie

Stuart MacKenzie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.