I've made mechanical assemblies printed fully dense on the Mars 2 Pro, and shrinkage was not something I had an issue with

I've made mechanical assemblies printed fully dense on the Mars 2 Pro, and shrinkage was not something I had an issue with

![]() The radical polymerization leads to sometimes fairly significant shrinkage. (Low single percents in linear dimensions, worst case.) This can be mitigated by using bigger molecules with lower total mass contribution of the acrylic groups, or adding fillers (either discrete particles or dissolved polymer - but both can wreck your viscosity).

The radical polymerization leads to sometimes fairly significant shrinkage. (Low single percents in linear dimensions, worst case.) This can be mitigated by using bigger molecules with lower total mass contribution of the acrylic groups, or adding fillers (either discrete particles or dissolved polymer - but both can wreck your viscosity).

![]() There are other chemistries that don't suffer from that, eg. cationically polymerized epoxies. But I didn't see any such printing resin yet.

There are other chemistries that don't suffer from that, eg. cationically polymerized epoxies. But I didn't see any such printing resin yet.

Talking about fillers. Any recommendations? how about mixing resins?

Talking about fillers. Any recommendations? how about mixing resins?

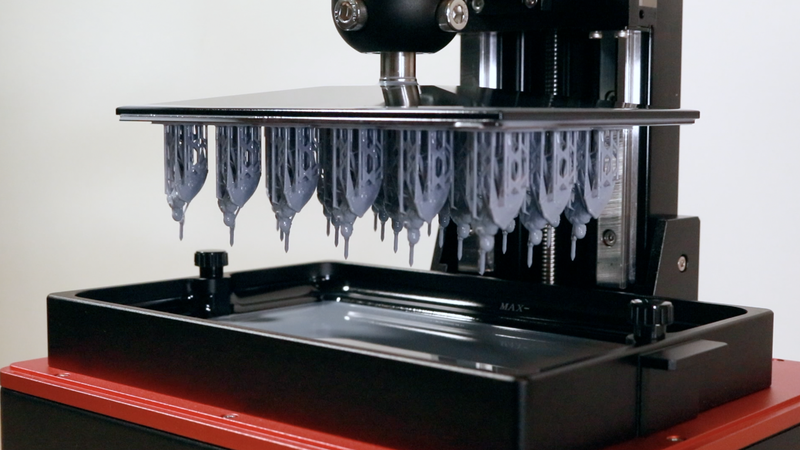

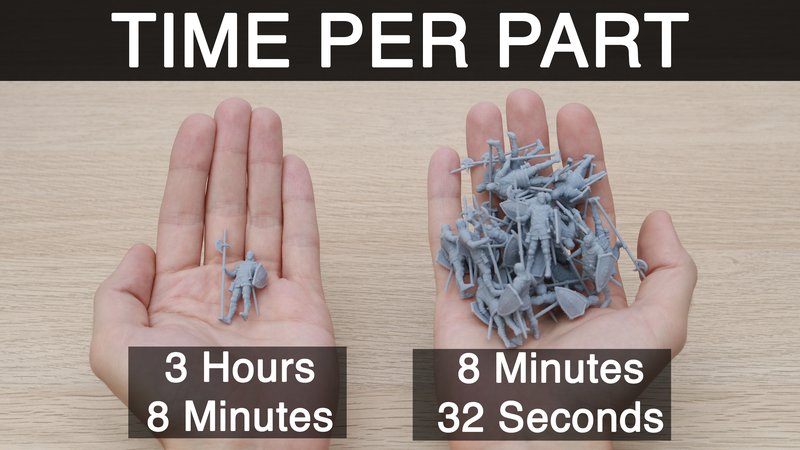

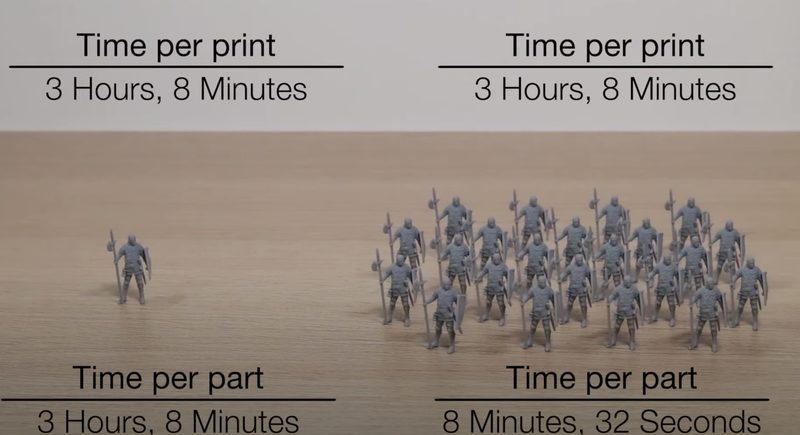

Another fun fact about resin printing (possibly my favorite fact), is the super fast print speed for printing in parallel!

Another fun fact about resin printing (possibly my favorite fact), is the super fast print speed for printing in parallel!

Because the resin is exposed one layer at a time, your build time is always a function of the tallest part

Because the resin is exposed one layer at a time, your build time is always a function of the tallest part

Are there any resins as strong as nylon?

Are there any resins as strong as nylon?

So, build time roughly equals number of layers!

So, build time roughly equals number of layers!

This means, when printing multiple parts, your cycle time drops DRAMATICALLY!

This means, when printing multiple parts, your cycle time drops DRAMATICALLY!

Wow

Wow

So, filling a print surface with parts comes with no time penalty

So, filling a print surface with parts comes with no time penalty

![]() Fillers, any way how to prevent the particulates from settling? Any way to have a high particulate loading without crippling increase in viscosity (eg. the aluminium hydroxide for fire-retardant resins)?

Fillers, any way how to prevent the particulates from settling? Any way to have a high particulate loading without crippling increase in viscosity (eg. the aluminium hydroxide for fire-retardant resins)?

FDM 3D printing is a volumetric equation, so printing 2x parts will take roughly 2x time

FDM 3D printing is a volumetric equation, so printing 2x parts will take roughly 2x time

Though cleaning all those little figurines....

Though cleaning all those little figurines....

Want to hear something fun?

Want to hear something fun?

Cleaning all of them took the same amount of time as cleaning one of them, @David Geller!

Cleaning all of them took the same amount of time as cleaning one of them, @David Geller!

I processed them as a batch, so they were all washed together, and cured together!

I processed them as a batch, so they were all washed together, and cured together!

So, resin printing can be ideal for printing lots of small things quickly!

So, resin printing can be ideal for printing lots of small things quickly!

@Thomas Shaddack , not exactly, just in general, taking a stock resin and modifying it with X to give you better Y and Z.

@Thomas Shaddack , not exactly, just in general, taking a stock resin and modifying it with X to give you better Y and Z.

Nice!

Nice!

Interestingly enough, I had originally intended to make 24 parts, but 2 of them failed

Interestingly enough, I had originally intended to make 24 parts, but 2 of them failed

So the cycle time (time per part) could have actually been lower!

So the cycle time (time per part) could have actually been lower!

And with some optimization of the placement of the parts, it could be driven down further than that!

And with some optimization of the placement of the parts, it could be driven down further than that!

On the right side, are you counting time to remove supports?

On the right side, are you counting time to remove supports?

@Brian McEvoy Great question "Are there any resins as strong as nylon?"

@Brian McEvoy Great question "Are there any resins as strong as nylon?"

Nylon is a thermoplastic, unlike most resins which are thermosets

Nylon is a thermoplastic, unlike most resins which are thermosets

Thermoplastics tend to be more mechanically tough, and can be deformed readily before breaking

Thermoplastics tend to be more mechanically tough, and can be deformed readily before breaking

Most thermoset resins tend to be on the brittle / stiff side, so it's hard to compare to Nylon, a material that is desirable for its ability to be deformed

Most thermoset resins tend to be on the brittle / stiff side, so it's hard to compare to Nylon, a material that is desirable for its ability to be deformed

![]() The toughness may be influenced by using a less brittle less-crosslinked resin formulation.

The toughness may be influenced by using a less brittle less-crosslinked resin formulation.

@Involute, No, I didn't count the time to remove supports, but it probably added something like 20 - 30 seconds per model

@Involute, No, I didn't count the time to remove supports, but it probably added something like 20 - 30 seconds per model

The supports for that model were VERY well designed, and quick twist was all that was needed to remove them!

The supports for that model were VERY well designed, and quick twist was all that was needed to remove them!

A carefully supported model helps there

A carefully supported model helps there

It sure does, @Nicolas Tremblay!

It sure does, @Nicolas Tremblay!

![]() Here we should touch the concept of Tg, glass transition temperature. Below that, polymers are generally brittle, above that they are more tough. A piece of rubber in liquid nitrogen is an example of freezing a polymer below its Tg.

Here we should touch the concept of Tg, glass transition temperature. Below that, polymers are generally brittle, above that they are more tough. A piece of rubber in liquid nitrogen is an example of freezing a polymer below its Tg.

![]() I want to print some coins for Dungeons and Dragons. They have some fine detail. Will I get a better print with a resin printer than an ABS filament printer?

I want to print some coins for Dungeons and Dragons. They have some fine detail. Will I get a better print with a resin printer than an ABS filament printer?

![]() Definitely!

Definitely!

Hi @SimonAllen!

Hi @SimonAllen!

Any general statements about support-removal damaging/marring the surface of the model with resin vs/ FDM?

Any general statements about support-removal damaging/marring the surface of the model with resin vs/ FDM?

Absolutely, most resin printers will be capable of providing you more detail than an FDM printer, but you'll want to scroll up to read about the process involved before making a decision!

Absolutely, most resin printers will be capable of providing you more detail than an FDM printer, but you'll want to scroll up to read about the process involved before making a decision!

@Involute, another great question!

@Involute, another great question!

Support material on FDM (Stratasys / Industrial) tends to be a secondary soluble material, but most home printers will create a support structure from the same material

Support material on FDM (Stratasys / Industrial) tends to be a secondary soluble material, but most home printers will create a support structure from the same material

![]() Resin support break-off can tear a little piece from the material, making a dimple in the surface. Fortunately this can be touched up with a little drop of the resin and a bit of UV light.

Resin support break-off can tear a little piece from the material, making a dimple in the surface. Fortunately this can be touched up with a little drop of the resin and a bit of UV light.

Resin supports are actually integrated directly into the model, so removing them can leave a small divot in the model. Typically, a quick prime is all that's needed to remove those, or they can be sanded flush

Resin supports are actually integrated directly into the model, so removing them can leave a small divot in the model. Typically, a quick prime is all that's needed to remove those, or they can be sanded flush

I've found I spent less time concerned about resin support removal; it's much harder to "fix" FDM support removal!

I've found I spent less time concerned about resin support removal; it's much harder to "fix" FDM support removal!

OK! This has been a ton of fun, but we're down to the last 9 minutes!

OK! This has been a ton of fun, but we're down to the last 9 minutes!

Are there any questions that I missed? Anything that you're interested in learning about? Speak now!

Are there any questions that I missed? Anything that you're interested in learning about? Speak now!

![]() Removing supports with a scalpel is much easier when the print is still not fully cured, when it is still a bit elastic and rubbery instead of hard and britlte.

Removing supports with a scalpel is much easier when the print is still not fully cured, when it is still a bit elastic and rubbery instead of hard and britlte.

Resin printing is a VERY satisfying experience, but typically, it can be a bit messier than FDM, and the post-processing requires some discipline to keep a tidy space!

Resin printing is a VERY satisfying experience, but typically, it can be a bit messier than FDM, and the post-processing requires some discipline to keep a tidy space!

![]() What would you say is the most valuable advice you can give to someone who is already somewhat versed in resin printing (i.e. what do you know now that you wished you knew before)?

What would you say is the most valuable advice you can give to someone who is already somewhat versed in resin printing (i.e. what do you know now that you wished you knew before)?

Great question, @Shayan S.!

Great question, @Shayan S.!

@Andrew Sink - just watched some of your videos. Excellent content. Very pleasing narrating style.

@Andrew Sink - just watched some of your videos. Excellent content. Very pleasing narrating style.

The MOST IMPORTANT thing is always safety, so even though it's a chore, ALWAYS wear gloves, and ALWAYS be careful

The MOST IMPORTANT thing is always safety, so even though it's a chore, ALWAYS wear gloves, and ALWAYS be careful

Barring that, don't cheap out on materials or tools

Barring that, don't cheap out on materials or tools

I've seen people go absolutely wild trying to "fix" a printer, and the problem was material that was well past its expiration date!

I've seen people go absolutely wild trying to "fix" a printer, and the problem was material that was well past its expiration date!

![]() And don't panic. Occasional contact with the raw resin won't harm you. Repeated frequent job-like contact may lead to sensitization and allergies.

And don't panic. Occasional contact with the raw resin won't harm you. Repeated frequent job-like contact may lead to sensitization and allergies.

I always wear eye protection and gloves for all my resin-related tasks. Always.

I always wear eye protection and gloves for all my resin-related tasks. Always.

OK, @Thomas Shaddack, that's actually pretty bad advice, sorry!

OK, @Thomas Shaddack, that's actually pretty bad advice, sorry!

The proper amount of skin / resin contact is 0!

The proper amount of skin / resin contact is 0!

Smart move, @David Geller!

Smart move, @David Geller!

![]() ALARA. As Low As Reasonaby Achievable.

ALARA. As Low As Reasonaby Achievable.

I got my start on YouTube making videos for college courses; my mom held the camera and told me to "SLOW DOWN", my natural speaking voice is WAY fast

I got my start on YouTube making videos for college courses; my mom held the camera and told me to "SLOW DOWN", my natural speaking voice is WAY fast

So when I make my videos, I have her in mind, so I speak slow and clear!

So when I make my videos, I have her in mind, so I speak slow and clear!

@Andrew Sink - agree about fixing vs. materials. I had bad print after bad print until I switched to a Siraya Tech resin and, since then, every single print has been spectacular. I'm on an Anycubic.

@Andrew Sink - agree about fixing vs. materials. I had bad print after bad print until I switched to a Siraya Tech resin and, since then, every single print has been spectacular. I'm on an Anycubic.

That's great!

That's great!

![]() Speak slow and clear, so people can watch you at 150% speed. :P :D

Speak slow and clear, so people can watch you at 150% speed. :P :D

![]() LOL

LOL

The Siraya Simple Clear Resin is a favorite of mine; it's about as clear as you can get, even post-curing

The Siraya Simple Clear Resin is a favorite of mine; it's about as clear as you can get, even post-curing

and it just...works?

and it just...works?

it just works.

it just works.

Most slicers have very conservative settings, so if you're having consistent part failures, check A) the model, then B) the resin

Most slicers have very conservative settings, so if you're having consistent part failures, check A) the model, then B) the resin

Tweaking settings is a fast way to get to a frustrating afternoon!

Tweaking settings is a fast way to get to a frustrating afternoon!

I can't recommend Elegoo water washable resin. It stinks.

I can't recommend Elegoo water washable resin. It stinks.

I originally liked the Water Washable resins, but I had issues with parts cracking after printing, so I've moved away from them

I originally liked the Water Washable resins, but I had issues with parts cracking after printing, so I've moved away from them

They don't seem to be as reliable long-term, and the smell does tend to be much worse

They don't seem to be as reliable long-term, and the smell does tend to be much worse

![]() Also, adjust the exposure per layer vs layer thickness. There is a tradeoff between the time and the strength achieved in-printer, and the bottom adhesion force. If the latter is higher than the strength of the part, it will tear off.

Also, adjust the exposure per layer vs layer thickness. There is a tradeoff between the time and the strength achieved in-printer, and the bottom adhesion force. If the latter is higher than the strength of the part, it will tear off.

I use Elegoo Standard Photopolymer as my "daily driver", it's cheap, comes in interesting and easy-to-see colors, and works well on most machines!

I use Elegoo Standard Photopolymer as my "daily driver", it's cheap, comes in interesting and easy-to-see colors, and works well on most machines!

Alright, with that last comment, my time is up!

Alright, with that last comment, my time is up!

My printer got banned to the garage because of it. Glad I got the air purifier.

My printer got banned to the garage because of it. Glad I got the air purifier.

I want to take a minute to thank @Dan Maloney and the rest of the @Hackaday team for having me this afternoon!

I want to take a minute to thank @Dan Maloney and the rest of the @Hackaday team for having me this afternoon!

We're up against our allotted hour now, so I'm going to call an "official" time on the chat. Of course the channel is always open, so feel free to keep the conversation going. But we'll just say a big thanks to Andrew for his time today, and a great Hack Chat. Great questions too from everyone -- thanks!

We're up against our allotted hour now, so I'm going to call an "official" time on the chat. Of course the channel is always open, so feel free to keep the conversation going. But we'll just say a big thanks to Andrew for his time today, and a great Hack Chat. Great questions too from everyone -- thanks!

Thank you Andrew and HAD, very informative!

Thank you Andrew and HAD, very informative!

Oops, crossed in the mail...

Oops, crossed in the mail...

I appreciate the chance to talk about resin printing, feel free to reach out on Twitter if you want to ping me with anything else! https://twitter.com/AndrewASink

I appreciate the chance to talk about resin printing, feel free to reach out on Twitter if you want to ping me with anything else! https://twitter.com/AndrewASink

Thanks @Andrew Sink and @Thomas Shaddack <

Thanks @Andrew Sink and @Thomas Shaddack <

Haha! Thanks @Dan Maloney! Have a great afternoon, everyone!

Haha! Thanks @Dan Maloney! Have a great afternoon, everyone!

![]() Thank you Andrew

Thank you Andrew

Are there any resins that would make functional gears?

Are there any resins that would make functional gears?

![]() All of them. For different mechanical requirements.

All of them. For different mechanical requirements.

Yes thank you @Thomas Shaddack!

Yes thank you @Thomas Shaddack!

![]() Thought. A resin with built-in reducing agent that would cover itself with copper when immersed in copper sulfate. (Then continue with electroplating. Voila, small metal parts!)

Thought. A resin with built-in reducing agent that would cover itself with copper when immersed in copper sulfate. (Then continue with electroplating. Voila, small metal parts!)

![]() Another thought I am nurturing. Borrow the thermolabile crosslinkers from reworkable epoxies, where they have issues with their too low thermal stability. Print a hard stiff thing. UV-cure. Bake thermally to a rubbery thing.

Another thought I am nurturing. Borrow the thermolabile crosslinkers from reworkable epoxies, where they have issues with their too low thermal stability. Print a hard stiff thing. UV-cure. Bake thermally to a rubbery thing.

Just a dip in the reducing agant before post-cure?

Just a dip in the reducing agant before post-cure?

![]() That maaaaaaaay work...

That maaaaaaaay work...

or a 50/50 solution, agent/resin to dip. And may need some oxygen protection?

or a 50/50 solution, agent/resin to dip. And may need some oxygen protection?

![]() A related thought is some reducing agent that is activated by another wavelength (molecule splitting similar to the photoinitiator, without the radical). Then we could print "two-color", with locally activating the reducing moieties, and then selectively deposit metal just by immersion. Voila, potential way of printing metamaterials for microwaves and millimeter waves.

A related thought is some reducing agent that is activated by another wavelength (molecule splitting similar to the photoinitiator, without the radical). Then we could print "two-color", with locally activating the reducing moieties, and then selectively deposit metal just by immersion. Voila, potential way of printing metamaterials for microwaves and millimeter waves.

I had the same idea a few years ago. Relatively easy on paper.

I had the same idea a few years ago. Relatively easy on paper.

Dan Maloney

Dan Maloney

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.