I bought the Creality Ender 5 3D printer back in march 2019. It was my first 3D printer and it was really fun to print the first couple of toys and gadgets. However it didn't take long before I realized that I wanted much more performance from a 3D printer. As an engineer, my need was mainly to make functional parts, and not toys. Therefore I started performing a series of upgrades to the printer, with two main objectives in mind: make it as reliable as possible and being able to print high performance materials that I could use for my other projects.

Just like everybody else, I started by printing PLA parts. Every part required a setup, it didn't always come out right (and sometimes it even fell off the bed mid-print) and the material was not the best for my needs.....

Here are all the upgrades that I did to the printer, in chronological order:

1) Changed the bed to glass and reinforced the bed structure

2) Replaced the stock extruder with a geared 3:1 ratio extruder, to improve filament pull

3) Added Octoprint and wifi connectivity, to make file uploads effortless

4) Changed the motherboard to a better 32-bit motherboard with quiet motor drivers, to make those motors shut-up once and for all

5) Changed some fans and fan ducts, to make it even more quiet (now I could sleep in the same room without hearing it)

6) Added BLTouch for automatic bed levelling and full bed adhesion reliability

7) Changed the stock hotend to an all-metal hotend (Micro Swiss rip-off) to print high temperature filaments

8) Converted from a bowden setup to a direct drive setup (I didn't mind if I had to slow it down and make the prints take longer, as long as quality and reliability were top notch).

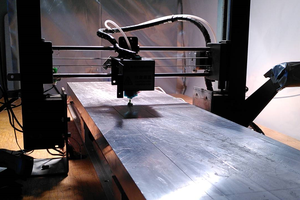

9) Used plexiglass to make a full enclosure around the printer. The heat produced by the hotend and the bed keep the inside of the printer warm enough (around 35-40 degrees) to avoid any kind of warping, even with the most complex ABS parts.

10) Added a smart filament runout sensor, to detect when the filament ends or if there is a blockage in the nozzle.

Right now I print almost exclusively ABS (which I found out to be an incredible material, especially when used in conjunction with acetone), every single print comes out perfect and I do not remember the last time that a part came off the bed or that I had a clog. In fact I even beat the quality of the really expensive Delta 3D printers in my company! The last upgrade, the full enclosure, has been completed 6 months ago and I haven't felt the need to make any other modification since then. The printer does exactly what I wanted from it when I first bought it.

In conclusion, even though it took a lot of work to make all those upgrades, I couldn't be happier with my Ender 5.

Federico Virdia

Federico Virdia

the.wretch

the.wretch

Bram Peirs @ FW2W

Bram Peirs @ FW2W

Gorky

Gorky

AVR

AVR