Tired Clock

A clock that is very tired, hands hanging down. Until someone approaches it

A clock that is very tired, hands hanging down. Until someone approaches it

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

tiredclock.scadOpenSCAD of the mechanismscad - 9.63 kB - 11/18/2021 at 11:14 |

|

.. or thereabouts. I visit the exhibition weekly, and it it "works". Sometimes the hands get stuck, but after a few cycles it is back to doing it right. I've fiddled with everything

Finally noticed that when I test the clock (standing on the table or holding it) it works fine but not when hanging on the wall. The hook is fixed to the centre hole where the axis protrude. THERE is something that moves when it is hung up, causing more friction on the axis.

Solution was to change where the clock is hung. It is now hung from the frame and seems to be working beautifully.

(Edit 3 days later: Yes, still works.)

After about 4 iterations, tweaking the 3D prints, testing each component, each subassembly when adding each component, I think I have a reliable mechanism.

I still use the shield I made. Nothing wrong with that.

The software has been tweaked I changed the stepper driving to always leave one coil on, except when the hands are hanging down. Previously I pulsed the coil for 5-7 ms and then appropiate pause for speed control. Not going powerless during movement has made it a lot smoother and hopefully not missing steps.

It has worked for 3 hours in my home - but without the clockface (that is at the exhibition). This morning I got out there and put the improved clockworks in there.

I cautiously declare it a success. [Edit after 24 hours - it still works. yeah!]

The design is OpenSCAD (uploaded). I found out that one of the gearpairs where too close (clockmakers call this "depthing") or my homemade gearteeth where too tight (the "modulus" of a gear). This made little sense, as the OpenSCAD file specified the same distance and gear size for the other pair. Possibly there is a slight scaling error in my 3D printer, or that I slightly enlarge some holes with a drill made the distances different. To get it working I made a kludge in the OpenSCAD program to force one of the gears 1mm smaller, and tweaked toothsizes to be slimmer - and it seemed to do the trick.

I have just been nudged (by overhearing a totally unrelated conversation at a electronics store) that silcon grease is usefull for plastic gears. I'll test it at home, and if usefull apply it on the exhibition clock. It must run for 2 months, and I am not sure on wear & tear on the plastic bearings and gears.

The exhibition stared and the clock worked for 5 minutes (or less).

Replaced it with a sign "Exhibit down for repairs" and tried a whole day to make it run reliably. It did so. Hung it up again, and it failed in a totally new way. It now just twitches in an unpredictable way

I've had other things on my plate last week, so it just had to be that way. This weekend I have purchased parts for 3 more clocks. Tweaked the 3D design with more clearance, thicker plates that do not warp and such like. New motors with drivers to match, not soldering a shield.

It fails the same way, meaning each component test is 100% but the total assembly doesn't work. Either something subtly jams or the "load" on the motors of an arm is too much.

Waiting for inspiration to strike....

Finally some progress after too many setbacks. It is - as I write - 19 hours until opening. But it only needs a clock face and some tidiying up Yeah....

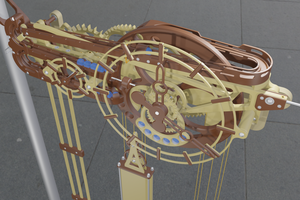

The mechanism in closeup.

This is plastic only. Steppers turn the lower two gears, and they stop at the cutsections so the hands can freely fall down.

Time is running out. Only 1 (One) Day left, and other things have to be done, too.

I reveiwed my options and time/effort, and suddnly a 3rd design struck me - with no change to the electronics and a true "flop down" of the hands.

The blue/pink gears have a section without teeth. That will allow the hands on the clock to freely rotate to vertical. The steppers then adance enough for the correct time - then keep turning until they get back to the flop-down-position.

Well, the proof of the pudding lies in the eating. The first printout looks promising. Needed a little tweak of some tolerances, and the tricky bit is fitting som limitswitches for zeroing steppers after powerup (the clock will be turned off at night in he exhibitionhall)

Sorry, I didn't use the correct colour plastic for each part :-)

Now waiting for the 2nd version to 3D print ....

Can't get the "Plan B" arrangement to work mechanically. The small 5V steppers can not turn the clockhands reliably, depsite their 1:64 gearing. They miss steps (too much load). I have to much slack in the axies for the large gears to avoid getting in each others way. Everything could be fixed, I am sure, with a few more iterations, but I'd rather have my original steppers as shown in the first log.

The next day I will make a new shield with bipolar drivers and the same DS1307 clock. The printer is busy printing new gears - just one for each hand, as the steppers have a small gear. Mechanical slack will be a lesser problem as they gear down, not up.

(printer doing a quarter gear for initial distance and gear mesh mockup)

OK, simpleminded me :-| it is quite clear. A Stepper that is designed for 2phase (or BiPolar) operation works badly when driven as 4phase/Unipolar - even if the coils are individually available. Or at least with the oversimple driver/ULN2001 I used.

I found in the bottom of one drawer a StepperTest device, hooked up the steppers that gave me problem - and they worked beautifuly smooth and accurate. <Forehead slap!>

So what is the status, and thus the two plans? Remember, exhibition opens on Thursday.

The currently fitted steppers, turn slowly, because their 48 step/revolution is through a integrated reduction gear giving them 2000 step/rev. At the fastest I can drive them they are too slow, so I have 3D printed mechanical gearing that undoes some of the reduction bringing them back to 360 step/rev. There is slack in the gearing, and I could say "that's a feature, not a bug!", especially as the clock is supposed to be "tired" or worn out.

I will carry this to completin (it is "nearly conmplete") and this is my Plan B (from where Plan A went awry - see previous log).

This is the board, complete. Well, there are no pinheaders for he two limitswitches (for the steppers to zero on powerup) nor the distancesensor, but that just a minor detail.

The gearing. Its 122:22, so only a fraction of the large gear is needed. This way it is also easy to place the endstop switches. The two clockhands go on the small gears at the apex.

these "failed" initially. (Incidentlly, salavged from office copiers) Using them requires the right driverchip ( I have found two, together with the steppertester board) and a new 3d print gearing mount, as they are 48 step/rev - too coarse. I need to make a new shield with those drivers (and also use another of my DS1307 chips/crystals) so that I keep my Plan B version intact.

I presume that movement will be quicker/cleaner, and thus I call it Plan A. But with the deadline, work on it will wait until Plan B is "presentable".

Either still needs the software. It is sort of complete (but not tested with motors) and changing the step/rev for the handmovements and the different driver chip is just changing that function(class). It therefore is not an issue.

May the Best Plan win!

Wired up the first ULN2001 and it steps the stepper ... every 2nd step. I can hear the "pulse" on the steps where the shaft only jerks a tiny amount. If I drive pins 1 and 3 it works the the same; double steps so to speak. If I drive the other pair of pins it also works - but the other way ?! I've tried all combinations I think, and it still only does every other step or just to&fro.

Hmmm...I can not find any wiring hints. The stepper is a J262-135, "2 phase 6 wire". So I assumed to drive it like a 5 wire unipolar stepper, energizing one coil at a time. (I need not that much torque, the holding force is 1000% over the need for holding a clock hand :-) ) Yes, I know it is a 24V and I am only driving it with 12V, that shouldn't matter. I have verified coil connections with the Ohm meter

My suspicion is that the opposite pairs have to have opposite polarity; (the coils are still unipolar) that means the ULN2001 circuit is useless. I try to test that with some switches on a breadboard. I could wire it as a bipolar 4 wire and use a normal stepper driver, that would mean redoing the shield (here shown partially completed) and buying drivers

Ideas?

An early version of a program, that will drive the motors, with rudamentary animation for the while being, has been completed.

The mechanics of the gear needs revising - motor mounts and gears get in the way of each other. Just details, not a showstopper. 3D prints are cheap, fortunatly.

It started with me bouncing ideas about my other clocks with an artist that is into "confrontation with machines doing their own thing". Thus, at the next exhibition - in two weeks time - I am graciously allowed to add one exhibit.

Outwards it looks like the clock is nonfunctional, both hands hanging straight down (which is impossible on a normal clock) At random minute intervals, the clock hands slowly and erratically manage to move up to their correct position, and hold it there for a moment, shiver and then fall back down. Additionally, a distance sensor triggers the display sequence on person approaching.

Internally it is simply two steppers driving each hand, via some simple mechanics, an Arduino orchestrating this and a clockchip for timing.

The challenge is the short time, and the software to make the movements seem like the clock makes an effort to get the hands into position. Otherwise, piece of cake, right?

Time is short, but I know I have the parts lying around in my workshop. Found two stepper motors in the box with leftover/salvaged motors, fortunatly they are the bipolar type, so no complicated driver chips needed, so a pair of ULN2001 I have in plenty from other projects should do.

Arduino: check, DS1307 chip: check (but SMD?!), prototype shield for Arduino that fortunatly has a SMD area. Clock face ... hmmm ... repurpose from the Jumbleclock.

Also two 3D printed plastic far left; quick prototype/test of the gear and mount of the steppers for moving the clock hands

MISSING: A distance sensor. I think I have one somewhere, but if I do not find it soon, I'll have to buy one. Let's hope it is next-day-delivery available.

First soldered the SMD DS1307 on the prototype area and a buttoncell holder. Get the pinheaders and a few wires. I think I'll test the clockchip before the next.

Hmmm... it allows me to set the time, but doesn't keep running when unplugged. After a some software twiddling I seemed to have not "started" the clockchip correct. Now it seems to be working.

Onwards to mounting the ULN2001 and drive steppers.

Create an account to leave a comment. Already have an account? Log In.

Become a member to follow this project and never miss any updates

Michael Möller

Michael Möller

Andrew Cooney

Andrew Cooney

Cute idea, a reluctant clock. 👍 If you could somehow manage to make droopy hands that would be even more eye-catching.